Professional Documents

Culture Documents

CAPA

Uploaded by

Balaji AnbazaganCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAPA

Uploaded by

Balaji AnbazaganCopyright:

Available Formats

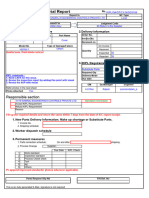

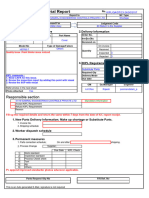

Non Conforming Material Report No.

KIPL/QA/DT/23-24/12/04015

Issue Section Date of Issue Report to NC Type

KIPL-QA 12/22/2023 N119-SAMRAJ ENGINEERING CONTROLS PRIVATE LTD Local

Report Status Issued For Judgment Code

New Report On/After Assy 60 Return to the Supplier

1.Detail of Damage and/or Failure 2.Delivery Information

Part Number r Suffix Part Name Order No.

Invoice No.

5614384122 0 Bracket

Received on

Model No Type of Damage/Failure On invoice

HD785-7 Others Received

Quantity

Quality Issue :Wrong nut welded noticed Inspected 01

Rejected 01

3. KIPL Requirement

Issues

Substitute Parts

Required Qty 01

KIPL comments : Delivery Mode Yes

1. Need CAPA for this issue. Due date

2. Revise the inspection report by adding this point with visual

3. Revise the SOP with visual

GM Dy.Manager Engineer

Refer photos in the next sheet

A.K.Rao Rajesh poomandalam_p

Photo Attached Yes

Responsible section

N119-SAMRAJ ENGINEERING CONTROLS PRIVATE LTD Mandatory Information

Accept KIPL Requirement

Refuse KIPL Requirement

Reason

Fill up the required details and return the same within 7 days from the date of N.C report receipt.

1. New Parts Delivery Information; Make up shortage or Substitute Parts.

1. Invoice No.

2. Shipping schedule

2. Worker dispatch schedule

3. Permanent measures

1. Parts correction schedule; On and after shipping.

2. Process Change Supplier;

Due Date KIPL Check

1 Work standard

2 Inspection standard

3 Process Cheek sheet

4 Tool

5 Jig

6 Others;

Pl. append improved standards/ photos wherever applicable.

Parts Request Slip No FIR Ref. No

This is an Auto generated E-Mail, signature is not required

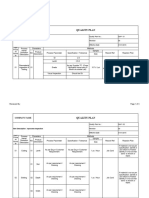

CORRECTIVE ACTION PREVENTIVE ACTION PLA

Supplier Name :SAMRAJ ENGINEERING CONTROLS P LTD,CHENNAI.

CAPA No :KIPL/QA/DT/23-24/12/04015

TEAM : Mr.RamKumar, Mr.Venkatesh, Mr.Hariprakash, Mr.Balaji, Mr.Suresh

PROBLEM :

Wrong nut welded noticed

Note: Repeated Problem : (Yes/No)

If Yes, Mention earlier NC NO

Quality Issue :Paint blister noticed

No. of times problem has been repeated.

ROOT CAUSE(S): ( 5 Why Analysis )

Dimension issue

Therefore

System

Wrong nut welded

noticed Therefore

Why?

Therefore

Why?

Dimension issue

Why?

Therefore

Process

TPG process skipped

Therefore

Why? As per plan qty wise

Nut Required

properly not

followed (like avoid Therefore

the excess nut)

Why?

Different nut type

of parts welded at

Dimension issue same welding area

Different nut type

of parts welded at

Dimension issue same welding area

Therefore

Why?

Inspection

Visual inspection only

followed at PDI Therefore

Why?

TPG gauge

inspection skipped Therefore

Why?

Sampling inspection

only followed at

fabrication

Why?

TEMPORARY CORRECTIVE ACTION :

1. 100% segregation done in RFD parts

PERMANENT CORRECTIVE ACTION :

1.One point lesson updated in gemba

2.Job card implemented to avoid nut mixup & excess nut.

3.Tick mark provided In M16*2.0 nut top side

Fill up the required details and return the same within 7 days from the date of N.C report receipt.

1.New Parts Delivery Information:Make up shortage or Substitute Parts.

Invoice Number :

Date :

2. Worker dispatch schedule

Yes No Dt:

3. Permanent Mesures ( Put tick mark wherever applicable)

S.NO Changes to be made Due Date

1 Work standard

2 Inspection standard

3 Process Cheek sheet

4 Tool

5 Jig

6 Others

Pl. append improved standards/ photos wherever applicable.

E ACTION PREVENTIVE ACTION PLAN

Customer Name : Komatsu India Private Limited

PART NUMBER:5614384122

NC DATE : 12/22/2023

Target Date : 20-1-2024

CAPA NO:

Remarks:

Therefore

Therefore

Why?

Therefore Root cause

Therefore

M16*1.5 & M16*2.0

pitch nut stored at

same location

Why?

M16 different pitch

types of nut mixup

condition

Therefore

Root cause

Therefore

Incoming inspection

skipped

Why?

Inspection skipped

Root cause

m the date of N.C report receipt.

(If yes, Pl. Inform the date )

KIPL Check Remarks

completed

completed

completed

You might also like

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- 8D Report For VDC Wrong - NNLDocument10 pages8D Report For VDC Wrong - NNLAbhinav SinghNo ratings yet

- Civil Engineering StandardDocument39 pagesCivil Engineering StandardAli Amzad BhuiyanNo ratings yet

- Oracle BI Publisher PDFDocument61 pagesOracle BI Publisher PDFSatheessh KonthalaNo ratings yet

- Ok Part NG: (Vendor Non-Conformance Report)Document2 pagesOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNo ratings yet

- Consumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Document27 pagesConsumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Kannan MurugesanNo ratings yet

- Welding Sequence-561-04-81120Document4 pagesWelding Sequence-561-04-81120Balaji AnbazaganNo ratings yet

- 2018 Nissan Qashqai 111809Document512 pages2018 Nissan Qashqai 111809hectorNo ratings yet

- Supplier 8D Report: D 1. Description of The ProblemDocument7 pagesSupplier 8D Report: D 1. Description of The ProblemDearRed FrankNo ratings yet

- Basf PolyTHFDocument12 pagesBasf PolyTHFadrianrdeitosNo ratings yet

- Transport Economics by Kenneth ButtonDocument520 pagesTransport Economics by Kenneth ButtonHadi100% (6)

- AgendaDocument24 pagesAgendaable.ankit.94No ratings yet

- 8D Problem Analysis Report: (Rotor Id Over Size)Document4 pages8D Problem Analysis Report: (Rotor Id Over Size)Kuldeep SinghNo ratings yet

- Carrier chiller-30XADocument12 pagesCarrier chiller-30XAamitbslpawar100% (1)

- Irn 20.09.2019 Fl-Smidth VoltampDocument2 pagesIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNo ratings yet

- CapaDocument10 pagesCapaBalaji AnbazaganNo ratings yet

- Capa Kipl Qa DT 23 24 9 03156Document16 pagesCapa Kipl Qa DT 23 24 9 03156Balaji AnbazaganNo ratings yet

- Capa Kipl Qa DT 23 24 9 03157Document16 pagesCapa Kipl Qa DT 23 24 9 03157Balaji AnbazaganNo ratings yet

- NCR 4e38785b PDFDocument9 pagesNCR 4e38785b PDFDeepak DasNo ratings yet

- Problem: Part Hight Out of Spec Problem PhotoDocument8 pagesProblem: Part Hight Out of Spec Problem PhotoManikandanNo ratings yet

- Double Punch 63241: Quality Problem Note (Supplier/In House/SYIPL Dock/Customer)Document1 pageDouble Punch 63241: Quality Problem Note (Supplier/In House/SYIPL Dock/Customer)ladkasaurabhNo ratings yet

- Supplier Problem Response Report Unpressed IssueDocument1 pageSupplier Problem Response Report Unpressed IssueKuldeep SinghNo ratings yet

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocument1 pageCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleNo ratings yet

- Control Plan Bracket, Front EngineDocument4 pagesControl Plan Bracket, Front EngineDevam EngineeringNo ratings yet

- TA1 - GenSet 6 (Service Report)Document6 pagesTA1 - GenSet 6 (Service Report)97faithoNo ratings yet

- Haier Job SheetDocument1 pageHaier Job Sheetgokilam sukumar100% (1)

- CAT 777D-FORM DemoDocument46 pagesCAT 777D-FORM DemomkNo ratings yet

- Mahindra Bolt Loosening Issue 3.10.2017Document24 pagesMahindra Bolt Loosening Issue 3.10.2017Sridharan VenkatNo ratings yet

- RMDR-Traction Title-Corrective Action ReportDocument2 pagesRMDR-Traction Title-Corrective Action Reportv subbiahNo ratings yet

- Nonconformance Report: Internal External SurveyDocument7 pagesNonconformance Report: Internal External Surveymuhammad imtiazNo ratings yet

- Vendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitleDocument6 pagesVendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitlenisargkedarNo ratings yet

- Online Feedback System 1769Document2 pagesOnline Feedback System 1769santosh kumarNo ratings yet

- Unscheduled EMR U.390257: Additional InformationDocument1 pageUnscheduled EMR U.390257: Additional Informationondem108No ratings yet

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- 545 7489 (Eag349) - PSWDocument2 pages545 7489 (Eag349) - PSWDurai NaiduNo ratings yet

- Non Conformance Report (NCR) : Disposition Quantity Department (Dept.) Pen Id Comments / ConfirmationDocument2 pagesNon Conformance Report (NCR) : Disposition Quantity Department (Dept.) Pen Id Comments / ConfirmationMangesh MohiteNo ratings yet

- 8D Example-NewDocument1 page8D Example-NewFR LMNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorDocument6 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorVasanth KumarNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanQuality VenusNo ratings yet

- CAPA Escort (08.08.2023)Document1 pageCAPA Escort (08.08.2023)HOD QUALITYNo ratings yet

- Nonconformance Report: Internal External SurveyDocument6 pagesNonconformance Report: Internal External Surveymuhammad imtiazNo ratings yet

- Service Report Monark: Dealer Process 9 1 1 5Document4 pagesService Report Monark: Dealer Process 9 1 1 5Resa Ken BorresNo ratings yet

- Online Feedback System 1656Document2 pagesOnline Feedback System 1656santosh kumarNo ratings yet

- MR 05 Problem SolvingDocument2 pagesMR 05 Problem SolvingManoj KaushikNo ratings yet

- Request For Deviation, Process Change or ReworkDocument5 pagesRequest For Deviation, Process Change or ReworkJayant Kumar JhaNo ratings yet

- Airport Authority, VaranashiDocument10 pagesAirport Authority, VaranashiAbhinav SinghNo ratings yet

- Online Feedback System 1665Document2 pagesOnline Feedback System 1665santosh kumarNo ratings yet

- Counteraction ReportDocument6 pagesCounteraction Reportgagandeep isherNo ratings yet

- Service Report Perbaikan X-Ray Stationary Rumah Sakit Kurnia SerangDocument2 pagesService Report Perbaikan X-Ray Stationary Rumah Sakit Kurnia SerangDiana Putri SofyanNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument2 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- 13 PSWDocument1 page13 PSWTapamNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- Online Feedback System 2011Document2 pagesOnline Feedback System 2011santosh kumarNo ratings yet

- TSI Information TSI Information TSI Information TSI InformationDocument2 pagesTSI Information TSI Information TSI Information TSI InformationLinbergNo ratings yet

- Customer Engineering ApprovalDocument28 pagesCustomer Engineering Approvalgagandeep isherNo ratings yet

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 pageChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraNo ratings yet

- 8.12.20 - Ai 0402 AcDocument1 page8.12.20 - Ai 0402 AcrijoNo ratings yet

- Online Feedback System 1921Document2 pagesOnline Feedback System 1921santosh kumarNo ratings yet

- Online Feedback System 1723Document2 pagesOnline Feedback System 1723santosh kumarNo ratings yet

- Pipe W Comp Brake (City) 13-Jan-22Document2 pagesPipe W Comp Brake (City) 13-Jan-22majidNo ratings yet

- NO Specific Activity Quality Job Type Quality SectionDocument6 pagesNO Specific Activity Quality Job Type Quality SectionRicardo MalondaNo ratings yet

- Corrective Action Form-qs-141ADocument1 pageCorrective Action Form-qs-141AGAURAV SHARMANo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Gas DryerDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Gas Dryerjp mishraNo ratings yet

- Part Submission Warrant: Part Name: Stopper Bracket Part Number 1 L0081-13 Rev.:01Document4 pagesPart Submission Warrant: Part Name: Stopper Bracket Part Number 1 L0081-13 Rev.:01karan singhNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Eo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofDocument7 pagesEo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofVince Renier RamosNo ratings yet

- Ultrasonics PDFDocument12 pagesUltrasonics PDFRahul KottayiNo ratings yet

- Welding Sequence-770Document4 pagesWelding Sequence-770Balaji AnbazaganNo ratings yet

- 17.final PaintingDocument1 page17.final PaintingBalaji AnbazaganNo ratings yet

- 16.primer ProcedureDocument2 pages16.primer ProcedureBalaji AnbazaganNo ratings yet

- 19 MaskingDocument1 page19 MaskingBalaji AnbazaganNo ratings yet

- Adelio Lattuada TL10AV & TL10Document7 pagesAdelio Lattuada TL10AV & TL10yaser radNo ratings yet

- Stock-LedMax - XLSX 0Document96 pagesStock-LedMax - XLSX 0Emidio CostaNo ratings yet

- The Objectives of Product QualityDocument8 pagesThe Objectives of Product QualityDarko SandicNo ratings yet

- Reservdelskatalog Parts Catalogue: PARK 102MDocument8 pagesReservdelskatalog Parts Catalogue: PARK 102MChristian CristofoliniNo ratings yet

- Supply Chain Manager ResumeDocument3 pagesSupply Chain Manager ResumeRaheelJairajpuriNo ratings yet

- As 2377-2002 Acoustics - Methods For The Measurement of Railbound Vehicle NoiseDocument7 pagesAs 2377-2002 Acoustics - Methods For The Measurement of Railbound Vehicle NoiseSAI Global - APACNo ratings yet

- PlywoodDocument4 pagesPlywoodaishu.fullscreenstatusNo ratings yet

- Ensuring American Leadership Av 4Document56 pagesEnsuring American Leadership Av 4Ed PraetorianNo ratings yet

- Deviation SettlementDocument29 pagesDeviation SettlementSayan AichNo ratings yet

- Ce12 Moe 2016Document20 pagesCe12 Moe 2016Dawood UllahNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- Express Gearbox FlyerDocument2 pagesExpress Gearbox FlyerFernando RomeroNo ratings yet

- Ida Aryanie BahrudinDocument44 pagesIda Aryanie BahrudinBDzikri HidayatNo ratings yet

- FR5000 Series: Test Drive and Review From Rick Burke, Federal RadioDocument6 pagesFR5000 Series: Test Drive and Review From Rick Burke, Federal RadioBoban ButrićNo ratings yet

- Ufgs 33 52 90.00 20Document22 pagesUfgs 33 52 90.00 20pradanangkpNo ratings yet

- Airgas Welding To Complete CO 24Document5 pagesAirgas Welding To Complete CO 24johndupNo ratings yet

- About Nordenaudit 2.0Document11 pagesAbout Nordenaudit 2.0Jose DenizNo ratings yet

- This Is An Atlanta Developer's $1B Vision For Redeveloping University Ridge. All 429 Pages.Document429 pagesThis Is An Atlanta Developer's $1B Vision For Redeveloping University Ridge. All 429 Pages.AnnaBrutzmanNo ratings yet

- Hyperlynx High-Speed Serial Interface Analysis: Student WorkbookDocument6 pagesHyperlynx High-Speed Serial Interface Analysis: Student WorkbookPawanNo ratings yet

- Material Master Search Help Creation Step by Step GuideDocument14 pagesMaterial Master Search Help Creation Step by Step GuideMuralikrishna PeravaliNo ratings yet

- Contactors CB-line Leaflet English Ed04!10!680876Document6 pagesContactors CB-line Leaflet English Ed04!10!680876Osun Deji LanaNo ratings yet

- HeroDocument9 pagesHeroPraroop FuloriaNo ratings yet

- CAP 3300 - Appendix B AOP Schedule of EventsDocument8 pagesCAP 3300 - Appendix B AOP Schedule of EventssaradeepsNo ratings yet

- PagesDocument97 pagesPagesEminaŠarkinovićNo ratings yet