Professional Documents

Culture Documents

Quality Assurance Plan

Uploaded by

Quality Venus0 ratings0% found this document useful (0 votes)

4 views4 pagesOriginal Title

QUALITY ASSURANCE PLAN

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views4 pagesQuality Assurance Plan

Uploaded by

Quality VenusCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 4

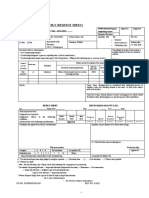

COMPANY NAME QUALITY PLAN

Quality Plan No. : QAP / 01

Item Description : Raw Material Revision 00

Effective Date 01/01/2015

Part/ Characters Methods

Process

Proce

Name/ Sample

ss

Operation NO. Product Process Parameter Specification / Tolerance Record Ref. Reaction Plan

Numb Description Size

Description

er

ID ± 2.0

Lenth ± 5.0

If material is not as per

specification, identify it

Rawmaterial As per Supplier TC (Cross

Incoming and inform to supplier. If

01 inspection & 01 Grade Verification done every 6 10 % / Lot

Inspection Report material is not ok send

Testing Month at outside Lab)

back to supplier and

reject it.

Visual Inspection Should be Ok

Reviewed By: Page 1 of 4

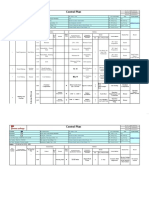

COMPANY NAME QUALITY PLAN

Quality Plan No. : QAP / 02

Item Description : Inprocess Inspection Revision 00

Effective Date 01/01/2015

Part/ Characters Methods

Process

Proce

Name/ Sample

ss

Operation NO. Product Process Parameter Specification / Tolerance Record Ref. Reaction Plan

Numb Description Size

Description

er

If material is not as per

specification, identify it

As per Drg or Customer As per Drg or Customer and inform to Partner

01 Cutting 01 Lenth 1 pc / Hour Job Card

Requirement Requirement identify if it not ok then

send to rework or

reject.

As per requirement / As per requirement /

01 Slot

Drawing Drawing

If material is not as per

specification, identify it

As per requirement / As per requirement / and inform to Partner

02 Slotting 02 Depth 1 pc / Hour Job Card

Drawing Drawing identify if it not ok then

send to rework or

reject.

As per requirement / As per requirement /

03 Width

Drawing Drawing

As per requirement / As per requirement /

01 OD

Drawing Drawing

Reviewed By: Page 2 of 4

COMPANY NAME QUALITY PLAN

Quality Plan No. : QAP / 02

Item Description : Inprocess Inspection Revision 00

Effective Date 01/01/2015

Part/ Characters Methods

Process

Proce

Name/ Sample

ss

Operation NO. Product Process Parameter Specification / Tolerance Record Ref. Reaction Plan

Numb Description Size

Description

er

As per requirement / As per requirement /

01 OD

Drawing Drawing

If material is not as per

specification, identify it

and inform to Partner

03 Threading As per requirement / As per requirement / 10% / Lot Job Card

02 ID identify if it not ok then

Drawing Drawing send to rework or

reject.

As per requirement /

03 Gauge Go No Go Gauge

Drawing

As per requirement / As per requirement / If material is not as per

01 OD

Drawing Drawing specification, identify it

and inform to Partner

04 Driling 10% / Lot Job Card

identify if it not ok then

As per requirement / As per requirement / send to rework or

02 Bore

Drawing Drawing reject.

Reviewed By: Page 3 of 4

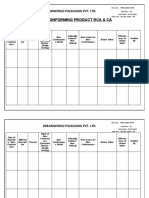

COMPANY NAME QUALITY PLAN

Quality Plan No. : QAP / 03

Item Description : Final Inspection Revision 00

Effective Date 01/01/2015

Part/ Characters Methods

Proc Process Name/ Sample

ess Operation Product

Num Description NO. Process Parameter Specification / Tolerance Record Ref. Reaction Plan

Description Size

ber

01 OD As per Requirement / Drawing

02 Thickness As per Requirement / Drawing

03 Slot As per Requirement / Drawing If finish product is not

as per specification,

Final CASTING Final Inspection identify it and inform to

01 04 Depth As per Requirement / Drawing 10% / Lot

Inspection PARTS Report Partner identify if it not

ok then send to

05 Gauge As per Requirement / Drawing rework or reject.

06 Bore As per Requirement / Drawing

07 Finshing Should be Ok

You might also like

- Pt. Prestasi Inti Rubber: Control PlanDocument1 pagePt. Prestasi Inti Rubber: Control PlanHardjonoNo ratings yet

- WoodwardDocument104 pagesWoodwardwachuwachuNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- PPAP Approval RequestDocument1 pagePPAP Approval RequestJosué PérezNo ratings yet

- Plan de Surveillance ExempleDocument2 pagesPlan de Surveillance ExempleAudrey GavaletNo ratings yet

- SMT Generic Control PlanDocument3 pagesSMT Generic Control Plantuan mai vanNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- Insp ReportDocument1 pageInsp ReportMATHEENNo ratings yet

- Control PlanDocument4 pagesControl PlanRakesh PandeyNo ratings yet

- FM - MKT - 02 Quality Control Process ChartDocument4 pagesFM - MKT - 02 Quality Control Process Chartbarja subarjaNo ratings yet

- Double Punch 63241: Quality Problem Note (Supplier/In House/SYIPL Dock/Customer)Document1 pageDouble Punch 63241: Quality Problem Note (Supplier/In House/SYIPL Dock/Customer)ladkasaurabhNo ratings yet

- Control Plan Template 2011 PDFDocument1 pageControl Plan Template 2011 PDFSenthil_KNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- Supplier Problem Response Report Unpressed IssueDocument1 pageSupplier Problem Response Report Unpressed IssueKuldeep SinghNo ratings yet

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- Inspection-Test-plan For Block WorkDocument3 pagesInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- CP St. Assy Upp 12.04.24Document92 pagesCP St. Assy Upp 12.04.24Hemant GuptaNo ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- Waiver Request Format Rev 3Document2 pagesWaiver Request Format Rev 3manjunatha gNo ratings yet

- CP-SS BLK-01Document5 pagesCP-SS BLK-01yogesh WakchaureNo ratings yet

- CP YwdDocument5 pagesCP YwdRaj BistNo ratings yet

- Material Submittal - ChecklistDocument1 pageMaterial Submittal - Checklistlinga2014No ratings yet

- Control Plan-StampingDocument2 pagesControl Plan-StampingVipin Jangra100% (1)

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaNo ratings yet

- Material Receiving Inspection ReportDocument1 pageMaterial Receiving Inspection ReportktwfaevlmhtfbdgeojNo ratings yet

- 3.itp-Installation of GRP Water TanksDocument2 pages3.itp-Installation of GRP Water Tankssarmad spectrum100% (2)

- H0294281 CP UpdatedDocument2 pagesH0294281 CP UpdatedSandeep SinghNo ratings yet

- Quality Problem Corrective Action - QPCADocument3 pagesQuality Problem Corrective Action - QPCAsateeshkoriNo ratings yet

- Control Plan: FG 260 As Per IS 210: 2009Document24 pagesControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNo ratings yet

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- Page 1 of 1: Control PlanDocument1 pagePage 1 of 1: Control PlannormalNo ratings yet

- Machining Control PlannDocument18 pagesMachining Control PlannSuraj RawatNo ratings yet

- GM Casting CPDocument3 pagesGM Casting CPSuraj RawatNo ratings yet

- 07 Control PlanDocument5 pages07 Control PlanManoharar RNo ratings yet

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- Pfmea 714-A54838-004Document4 pagesPfmea 714-A54838-004Cam-ToolsNo ratings yet

- Fmea Ecedy WASHERDocument3 pagesFmea Ecedy WASHERMuralidhara BangaloreNo ratings yet

- 4M Inspection ReportDocument4 pages4M Inspection ReportKaran Malhi100% (1)

- Non-Conforming ProductDocument5 pagesNon-Conforming ProductDipjyoti SenNo ratings yet

- Check Sheet I QCDocument4 pagesCheck Sheet I QCEri ParihahNo ratings yet

- CAPADocument1 pageCAPAQuality ManagementNo ratings yet

- CAPADocument9 pagesCAPABalaji AnbazaganNo ratings yet

- 2.5 PCPDocument6 pages2.5 PCPAndrea InfanteNo ratings yet

- QAD Procedure - Control of Inspection, Measuring & Test Equipment P2Document1 pageQAD Procedure - Control of Inspection, Measuring & Test Equipment P2sumanNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- Supplier Rating ProcedureDocument4 pagesSupplier Rating ProcedureAmine Chahi100% (1)

- Control Plan ExampleDocument1 pageControl Plan Examplelingkungan.agathaNo ratings yet

- Quality PlanDocument2 pagesQuality PlanSekar KrishNo ratings yet

- 10-Qua-15 F01 Deviation Request Format-01.12.2019Document1 page10-Qua-15 F01 Deviation Request Format-01.12.2019Rohit SoniNo ratings yet

- Control PlanDocument2 pagesControl PlanChintamani Giramkar100% (1)

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALNo ratings yet

- Inspection & Testing Plan For Installation of GRP PipesDocument3 pagesInspection & Testing Plan For Installation of GRP Pipessandeep reshmaNo ratings yet

- RMDR-Traction Title-Corrective Action ReportDocument2 pagesRMDR-Traction Title-Corrective Action Reportv subbiahNo ratings yet

- The Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsFrom EverandThe Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsNo ratings yet

- Certificate of Conformance: VenusDocument1 pageCertificate of Conformance: VenusQuality VenusNo ratings yet

- Caliper Calibration ProcedureDocument3 pagesCaliper Calibration ProcedureQuality VenusNo ratings yet

- Microscope Calibration ProcedureDocument4 pagesMicroscope Calibration ProcedureQuality VenusNo ratings yet

- Dryer Verification ProcedureDocument2 pagesDryer Verification ProcedureQuality VenusNo ratings yet

- Training Schedule 2018Document2 pagesTraining Schedule 2018Quality VenusNo ratings yet

- Shutdown-Start-Up ProcedureDocument2 pagesShutdown-Start-Up ProcedureQuality VenusNo ratings yet

- Training Evaluation FormDocument2 pagesTraining Evaluation FormQuality VenusNo ratings yet

- MAT P 014 Counterfeit Parts Avoidance ProcedureDocument5 pagesMAT P 014 Counterfeit Parts Avoidance ProcedureQuality VenusNo ratings yet

- Customer Standards Required For ReferenceDocument7 pagesCustomer Standards Required For ReferenceS. VeeravelNo ratings yet

- Safety CalenderDocument1 pageSafety CalenderQuality VenusNo ratings yet

- First & Last PieceDocument3 pagesFirst & Last PieceQuality VenusNo ratings yet

- Attribute R&RDocument3 pagesAttribute R&RQuality VenusNo ratings yet

- Attribute R&RDocument3 pagesAttribute R&RQuality VenusNo ratings yet

- Certificate of ConformanceDocument1 pageCertificate of ConformanceQuality VenusNo ratings yet

- Rmi CMRT6-10Document176 pagesRmi CMRT6-10Quality VenusNo ratings yet

- Integrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelDocument4 pagesIntegrated Cost and Risk Analysis Using Monte Carlo Simulation of A CPM ModelPavlos Vardoulakis0% (1)

- Imeko TC5 2010 009Document4 pagesImeko TC5 2010 009FSNo ratings yet

- Pacom S72724+PDR32-RMT-HYB+ManualDocument130 pagesPacom S72724+PDR32-RMT-HYB+ManualDavidChisholmNo ratings yet

- Differential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridDocument13 pagesDifferential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridANURAAGNo ratings yet

- HARMAN Infinity Processing White PaperDocument2 pagesHARMAN Infinity Processing White PaperSound Technology LtdNo ratings yet

- Company ProfileDocument6 pagesCompany ProfileFaidzil ChabibNo ratings yet

- Aluminium - Copper AlloysDocument3 pagesAluminium - Copper AlloysRex RusselNo ratings yet

- Concrete Solutions-ProgramDocument18 pagesConcrete Solutions-ProgramEfthymios TatsisNo ratings yet

- 10 - Design of Doubly Reinforced BeamsDocument13 pages10 - Design of Doubly Reinforced BeamsammarnakhiNo ratings yet

- Vmware ManualDocument512 pagesVmware ManualMohd Safian ZakariaNo ratings yet

- Computational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)Document441 pagesComputational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)EisernesHerzNo ratings yet

- Specification: CL 21 B 105 K A F N N N EDocument3 pagesSpecification: CL 21 B 105 K A F N N N EcometNo ratings yet

- Random PDFDocument15 pagesRandom PDFgreeblemeebleNo ratings yet

- Calculating The Maximum Attenuation For Optical Fiber LinksDocument5 pagesCalculating The Maximum Attenuation For Optical Fiber LinksMiguel LiceagaNo ratings yet

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Document23 pagesData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainNo ratings yet

- Rftmdc6a PDFDocument17 pagesRftmdc6a PDFShakeebNo ratings yet

- 9365Document69 pages9365Kivanc NEROGLUNo ratings yet

- Understand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaDocument168 pagesUnderstand and Troubleshoot Virtualized Domain Controller in Windows Server 8 BetaChiTownITNo ratings yet

- fr19 21Document8 pagesfr19 21ErmanNo ratings yet

- Makalah Program PDFDocument10 pagesMakalah Program PDFIvanFolkNo ratings yet

- Financial Auditor Job DescriptionDocument8 pagesFinancial Auditor Job Descriptionfinancemanagement702No ratings yet

- Abid Ali SAP Resume (Experience)Document3 pagesAbid Ali SAP Resume (Experience)Abid AliNo ratings yet

- CH 16Document20 pagesCH 16Engr. Talha Riaz PersotaNo ratings yet

- Expansion Joint PDFDocument7 pagesExpansion Joint PDFPramit RajKarnikarNo ratings yet

- 82 To 88 CompleteDocument6 pages82 To 88 CompleteUmer KhanNo ratings yet

- 20v4000enDocument266 pages20v4000enMario MartinezNo ratings yet

- 802 OM 4-InspDocument12 pages802 OM 4-InspGabriel vieiraNo ratings yet

- Structural MembersDocument37 pagesStructural Membersmario gadianoNo ratings yet

- Top 10 Masturbation Tips From WomenDocument3 pagesTop 10 Masturbation Tips From WomengmeadesNo ratings yet

- An Assignment On Double Chute Feed SystemDocument11 pagesAn Assignment On Double Chute Feed SystemShawan Roy100% (1)