Professional Documents

Culture Documents

H0294281 CP Updated

Uploaded by

Sandeep SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H0294281 CP Updated

Uploaded by

Sandeep SinghCopyright:

Available Formats

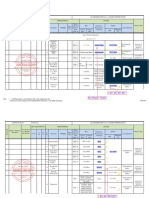

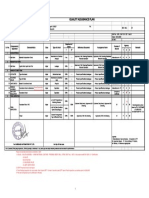

REV NO - 00

INDOPOL FOOD PROCESSING MACHINERY PVT LTD. DATED 1ST OCT 2016

DOC NO - NPDF11

Control Plan Number: Key Contact/Phone: Date (Orig.) Date (Rev.)

IFPM/KB/H0294281 Akhilesh Sharma ( 9990876405 ) 9/20/2021 1 (16/06/2022)

Part Number / Latest Change Level: Core Team: Customer Engineering Approval/Date (If Req'd.)

H0294281 / A Mr.Mohan Shyam,Amit Kumar, Sanjay Kumar ,Nitin Kumar ,Deepak

Part Name / Description: Supplier/Plant Approval/Date :- Customer Quality Approval/Date (If Req'd.)

Child Part 9/20/2021

Supplier / Plant Supplier Code Other Approval/Date (If Req'd.) Other Approval/Date (If Req'd.)

INDOPOL 646820

MACHINE,

CHARACTERISTICS METHODS

PART/ PROCESS NAME/ DEVICE, SPECIAL

PROCESS OPERATION JIG,TOOLS, CHAR. PRODUCT/PROCESS EVALUATION/ SAMPLE REACTION PLAN

NUMBER DESCRIPTION FOR MFG. NO. PRODUCT PROCESS CLASS SPECIFICATION/ MEASUREMENT SIZE FREQ. CONTROL METHOD

TOLERANCE TECHNIQUE

1.2+0.15 Incoming inspection report

Reject the material and send

1 Thickness __ MM 5 NOS. Every lot

-0.06 ( INSPF01 )

back to supplier

Raw Material Third party verification as per

2 __ SA 666 SS304L Compare mill tc 1 sheet Every lot

Grade plan

Raw material receiving &

10 None

inspection __ Free from dent Visually 100% Every lot

Incoming inspection report

3 Apperances __ Free from rust Visually 100% Every lot

( INSPF01 )

__ Free from scratches Visually 100% Every lot

FIFO to be maintained & Storage as per call the store & qa head for

4 __ Color Coding Visually 100% Every lot identification and if not able to

WI

identify the heat code and

batch code put the red paint

20 Storage None compare sheets heat and Incoming area stock board put R punch on the material

Identifying sheet

batch code with mill tc and move the material to nc

5 with Heat Code & __ As per mention in Mill TC 100% Every lot

received ( color coding for area

Batch Code

identification

6 ___ Feed 3200 Program sheet Set up approval Every lot

7 ___ Power 4000 Program sheet Set up approval Every lot

8 ___ Frequency 2000 Program sheet Set up approval Every lot

Verification with cutting

30 Laser cutting laser M/C f1

parameters SOP

9 ___ Duty 95 Program sheet Set up approval Every lot

10 ___ Gas Pressure 0.95 Program sheet Set up approval Every lot

11 ___ Nozzle Gap 0.3 Program sheet Set up approval Every lot

40 In-process inspection Manually 1 Dim. Laser Cutting As per drawing DVC/DHG First and last pc. Every lot Inprocess inspection report

---- call The in-process inspector

for 1st & last 5 pcs approval if

50 Bending ------------ 1 Dimensions Bending M/c As per Drawing DVC/HG found any descrepency follow

sop's 25 process no sop25-4

1 Dim. 368.02±1.2 MT

2 Dim. 2097.60±3 MT

3 Dim. 387.21±1.2 DVC

4 Dim. 106.46±0.8 DVC

60 In-process inspection None First and last pc. Every lot inprocess inspection report

5 Dim. 35±0.8 DHG

6 Dim. 52.60±0.8 DHG

7* Hemming Height 13.8±1 DVC

8 Apperances ___ Free from burr, dent, sharpe edge Visually

Move the NG parts into RED

70 Move to Shop Floor None 1 Material handling Visually 100% Every lot Follow handling SOP

BIN.

Prepared by:- Amit Kumar Approved by:-Akhilesh Sharma

You might also like

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- Control Plan For Zinc Flake CoatingDocument3 pagesControl Plan For Zinc Flake Coatingx y100% (1)

- Control Plan AIAGDocument1 pageControl Plan AIAGAhmad Firdaus100% (1)

- WoodwardDocument104 pagesWoodwardwachuwachuNo ratings yet

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- 195 CasingDocument14 pages195 Casingsasi10000No ratings yet

- Control PlanDocument2 pagesControl PlanChintamani Giramkar100% (1)

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALNo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Cp St. Assy Upp 12.04.24Document92 pagesCp St. Assy Upp 12.04.24Hemant GuptaNo ratings yet

- VR1241 - 8116610659 - Rev. 00 D-25.04.2023Document9 pagesVR1241 - 8116610659 - Rev. 00 D-25.04.2023Agni DuttaNo ratings yet

- IVR-8117994011-01 - Rev.00Document6 pagesIVR-8117994011-01 - Rev.00Abhay KarandeNo ratings yet

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaNo ratings yet

- Control Plan for Flywheel CastingDocument3 pagesControl Plan for Flywheel CastingSuraj RawatNo ratings yet

- 545 7489 (EAG349) - Control PlanDocument3 pages545 7489 (EAG349) - Control PlanDurai NaiduNo ratings yet

- Control Plan for Flywheel Assembly CastingDocument24 pagesControl Plan for Flywheel Assembly CastingSuraj RawatNo ratings yet

- 03. CP ProductionDocument7 pages03. CP Productionsandeep.pantNo ratings yet

- Technip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFDocument18 pagesTechnip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFAbhay KarandeNo ratings yet

- IVR 010102112023 - 32 3 Rev.0Document5 pagesIVR 010102112023 - 32 3 Rev.0harsh upadhyayNo ratings yet

- QAV-2 Step-3 Audit check sheet-PDFDocument5 pagesQAV-2 Step-3 Audit check sheet-PDFRajNo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument2 pagesTuv India Private Limited: Inspection Visit Reportdavid dagarNo ratings yet

- Quality Control Process Chart: Prototype Pre-Launch ProductionDocument2 pagesQuality Control Process Chart: Prototype Pre-Launch Productionmaria katherine pantojaNo ratings yet

- 1.PFD 561-89-86933Document8 pages1.PFD 561-89-86933Balaji AnbazaganNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- 137.process Map +flow Chart ASSY S.drawER DC97-23881Document6 pages137.process Map +flow Chart ASSY S.drawER DC97-23881Shinichi SuzukiNo ratings yet

- Plating Process Control Plan Template (2738)Document10 pagesPlating Process Control Plan Template (2738)George Hardy100% (1)

- Company Process Flow and FMEA DiagramsDocument12 pagesCompany Process Flow and FMEA DiagramsDINESH SHARMA100% (1)

- Control Plan for Flywheel Assembly ProductionDocument18 pagesControl Plan for Flywheel Assembly ProductionSuraj RawatNo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument5 pagesTuv India Private Limited: Inspection Visit ReportAkhtar aliNo ratings yet

- 9.PFD - 001733000520Document1 page9.PFD - 001733000520BHUSHANNo ratings yet

- Pentair PPAP Guideline Level 3_Rev 2021Document14 pagesPentair PPAP Guideline Level 3_Rev 2021Cuarto ChinoNo ratings yet

- Quality Control Process Chart: Prototype Pre-Launch ProductionDocument3 pagesQuality Control Process Chart: Prototype Pre-Launch Productionmaria katherine pantojaNo ratings yet

- Tata Growth Shop: Inspection Report / Check ListDocument2 pagesTata Growth Shop: Inspection Report / Check ListBhanu Pratap ChoudhuryNo ratings yet

- 447 Final Inspn Edited PDFDocument3 pages447 Final Inspn Edited PDFATHIBAN VNo ratings yet

- CP Gear Spindle MkeDocument2 pagesCP Gear Spindle Mkeamol vadnereNo ratings yet

- Itp For Installation of Ahu FahuDocument1 pageItp For Installation of Ahu FahuSamer AliNo ratings yet

- EAPL/CP/SFT 0090 CONTROL PLANDocument24 pagesEAPL/CP/SFT 0090 CONTROL PLANspdhimanNo ratings yet

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- 3.itp-Installation of GRP Water TanksDocument2 pages3.itp-Installation of GRP Water Tankssarmad spectrum100% (2)

- 12 900000 1100014154 BSC Mec Mir 000003Document2 pages12 900000 1100014154 BSC Mec Mir 000003muzumalsajjadNo ratings yet

- Itp - Water ProofingDocument1 pageItp - Water ProofingUbaidullah KhanNo ratings yet

- Petrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BDocument11 pagesPetrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BAliasgar100% (1)

- ITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFDocument3 pagesITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFGordon LongforganNo ratings yet

- Annex 2 Process Audit PDFDocument15 pagesAnnex 2 Process Audit PDFAngie GuerreroNo ratings yet

- Hydromatik potential failure mode and effect analysis (FMEA) for weld neck itemDocument2 pagesHydromatik potential failure mode and effect analysis (FMEA) for weld neck itemprasad sapareNo ratings yet

- 9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyDocument2 pages9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyANIL PLAMOOTTILNo ratings yet

- Machining Control PlanDocument1 pageMachining Control PlanGARIMA CASTINGS, JAIPURNo ratings yet

- IRS For AgitatorDocument3 pagesIRS For AgitatorMonaNo ratings yet

- Auto On Off Ball Valve Suresales - Commented - QAP - REV-01Document1 pageAuto On Off Ball Valve Suresales - Commented - QAP - REV-01Deepak UpadhyayNo ratings yet

- Control Plan- Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan- Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Use This As Reference For Painting Process It May Be Similar To YoursDocument7 pagesUse This As Reference For Painting Process It May Be Similar To Yoursabdelnasser hasanNo ratings yet

- Control Plan Template 2011 PDFDocument1 pageControl Plan Template 2011 PDFSenthil_KNo ratings yet

- Don Honorio State University welding lesson planDocument4 pagesDon Honorio State University welding lesson planCris TolentinoNo ratings yet

- The Special Steel Book - V08.00.1119 - WEBDocument52 pagesThe Special Steel Book - V08.00.1119 - WEBkevin honiballNo ratings yet

- Specification For Dual-Layer FBEDocument19 pagesSpecification For Dual-Layer FBEali saidNo ratings yet

- Alcomet FurseweldOverviewDocument7 pagesAlcomet FurseweldOverviewHemo A AlsharifNo ratings yet

- Steel Raw Material PDFDocument3 pagesSteel Raw Material PDFRudiantoNo ratings yet

- NOZZLE AND MANWAY SCHEDULEDocument1 pageNOZZLE AND MANWAY SCHEDULEdhaktodesatyajitNo ratings yet

- Taylor'S Tool Life EquationDocument15 pagesTaylor'S Tool Life EquationabrabarbaraNo ratings yet

- Mold Check ListDocument10 pagesMold Check Listapk11No ratings yet

- Index of Gold Technology journal articles 1990-2002Document7 pagesIndex of Gold Technology journal articles 1990-2002mv_jewellers0% (1)

- Chemistry Tutorvista Com Inorganic Chemistry Metallurgy HTMLDocument18 pagesChemistry Tutorvista Com Inorganic Chemistry Metallurgy HTMLSaid MajiNo ratings yet

- ??? Popular Screen Trading LLC, Screen Printing, Sharjah, ... +971 6 5618Document1 page??? Popular Screen Trading LLC, Screen Printing, Sharjah, ... +971 6 5618oasisabyssNo ratings yet

- Techniques Tips For Polishing PDFDocument6 pagesTechniques Tips For Polishing PDFrobin parmarNo ratings yet

- Balancing Wear, StrengthDocument4 pagesBalancing Wear, StrengthStephen MontelepreNo ratings yet

- Solder JointsDocument8 pagesSolder JointsJhobhel Christopher GalivoNo ratings yet

- Liquid Penetrant Test: Level IiDocument21 pagesLiquid Penetrant Test: Level IiAhmed El MorsyNo ratings yet

- Temper Etch Inspection Process for Aircraft Landing Gear PartsDocument16 pagesTemper Etch Inspection Process for Aircraft Landing Gear PartsJustformedia JustformediaNo ratings yet

- Lec4-Diffusion Bonding&Powder MetallurgyDocument18 pagesLec4-Diffusion Bonding&Powder Metallurgyguru prasadNo ratings yet

- Pre-Test Tve Carpentry 7Document3 pagesPre-Test Tve Carpentry 7Maria Theresa Dejesa100% (1)

- Nitocote EP405 Sept21Document4 pagesNitocote EP405 Sept21Fun TonNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- Astm A-269Document2 pagesAstm A-269vargaslu73No ratings yet

- Technical Datasheet Qoc With Jaws: Product InformationDocument1 pageTechnical Datasheet Qoc With Jaws: Product Informationagung wijaya100% (1)

- SysDS CONIPROOF PPC DL OS11a en 2Document2 pagesSysDS CONIPROOF PPC DL OS11a en 2remmers.romaniaNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- Syllabus - Template Cement TechnologyDocument2 pagesSyllabus - Template Cement TechnologyUrgen TamangNo ratings yet

- Only For Feasibility Purpose: Al P/N As Per Din 1451 Punched On PartDocument1 pageOnly For Feasibility Purpose: Al P/N As Per Din 1451 Punched On PartKaramjit SinghNo ratings yet

- US5457886Document9 pagesUS5457886aungkyawzoreNo ratings yet

- Aws D1.1 - Field: Welding PlanDocument6 pagesAws D1.1 - Field: Welding Planwael badawiNo ratings yet

- Ceramic Repair Paste TDSDocument3 pagesCeramic Repair Paste TDSAzril DahariNo ratings yet