Professional Documents

Culture Documents

Control Plan

Uploaded by

Chintamani GiramkarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Plan

Uploaded by

Chintamani GiramkarCopyright:

Available Formats

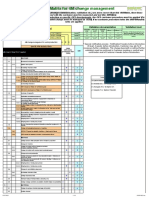

CONTROL PLAN

Prototype Pre-Launch Production Key Contact / Phone-Mr.S M Muley Date (Orig.) :- 04.10.2011 Date (Rev.)

Control Plan Number CP /ACA/02 Phone : 08605017517 , Fax :

Part Number : PLCPKCO030 CORE TEAM : SMM/AAG/VGH Customer Engineering Approval / Date(If Req'd)

Part Name : K1 K2 BAJAJ Supplier / Plant Approval / Date Customer Quality Approval / Date (If Req'd)

Customer Name : ALICON CASTALLOY LTD. Other Approval / Date (If Req'd) Other Approval / Date (If Req'd)

Characteristics Methods

Error

Part / Process Name / Machine,Device, No. Product Process Special Product/Process Evaluation Sample Control Methods

Proofing Reaction Plan Corrective Action

Process Operation Jigs,Tools for Char. Specification / Measurement Size Freq.

Number Description Mfg. Class Tolerance Techniques

- Every Lot Inform to -

Raw Material 1 GSM Strength 120 GSM Tester 05 Nos. WPI/F/QA/07

10 supplier & reject

Inspection

- lot

2 Bursting Strength 7.5 to 8.5 Bursting Tester 05 Nos. Every Lot WPI/F/QA/07 -

Start of the Inform to

- add water or starch powder

3 Glue viscosity 25 to 30 Seconds B 4 Cup 01 Nos. Shift supervisor

WPI/F/PROD/13

Start of the Wait until

- -

4 Temperature 110° to 120° Visual 01 Nos. M/C specified Temp.

20 Corrugation WPI/COR/ 01

Start of the

- 01 Nos. - -

5 Speed 10 to 45 Speed Nob M/C WPI/F/PROD/13

Start of the Stop the cutting

- Adjust cutting size

6 Cutting Size 22.5'' X 62.5'' Measuring Tape 02 Nos. lot WPI/F/PROD/13 process

Start of the Inform to

7 - Glue viscosity 35 to 40 Seconds B 4 Cup 01 Nos. WPI/F/PROD/13 add water or starch powder

Shift supervisor

30 Pasting WPI/PAS/05

Start of the add or remove ply as per

- Stop pasting

8 Ply Qty. 5 ply's Visual 01 Nos. lot WPI/F/PROD/13 req.

Inform to Check another lot & reject

40 Pressing - Every Lot

9 Bursting Strength 7.5 to 8.5 Bursting Tester 05 Nos. WPI/F/PROD/13 supervisor material if strength is low

10 Box Size - 380 X 380 X 165 mm Measuring Tape 02 Nos. Start of the WPI/F/PROD/13 Stop the rotary Adjust cutting size

50 Rotary WPI/ROT/07

11 Finishing - Cutting Sharpness Visual 02 Nos. lot WPI/F/PROD/13 process Adjust cutting sharpness

Start of the

60 Slotting WPI/SLOT/08 12 Finishing - Cutting Sharpness Visual 02 Nos. WPI/F/PROD/13 Stop the Slotting Adjust cutting sharpness

lot

Start of the

13 - Pin 12 X 25 Visual 02 Nos. WPI/F/PROD/13

lot

70 Stiching

Start of the

14 Pin Qty - 06 Nos. Visual 02 Nos. WPI/F/PROD/13

lot

Start of the

80 Bundling 15 Box Qty. - 10 Nos./Bundle Visual 02 Nos. WPI/F/PROD/13

lot

16 Box Length - 380 mm Measuring Tape 03 Nos.

17 Box Width - 380 mm Measuring Tape 03 Nos.

18 Box Height - 164 mm Measuring Tape 03 Nos.

19 Bursting Strength - 7.5 to 8.5 Bursting Tester 03 Nos.

Pre Dispatch 20 GSM -Top - 120 GSM WPI/F/QA/07 03 Nos. Every 100 % inspection to be

90 WPI/F/QA/08 Hold lot

Inspection 21 GSM liner & Flute - 120 GSM WPI/F/QA/07 03 Nos. Dispatch counduct

22 No.of Pins - 6 Nos. Visual 03 Nos.

23 No.of Ply's - 5 ply's Visual 03 Nos.

24 Pasting Bonding - Delaminate free Visual 03 Nos.

25 Type of Flute - B Flute Visual 03 Nos.

Every

100 Dispatch 26 Box Qty. - As per requirment Visual 100% WPI/F/MKT/05

Dispatch

FORM NO.:WPI/F/PD/45 REV.NO.DATE : 00/01.09.2011 PAGE : 1 of 2

NOTE:- INPSECTION SHOULD BE DONE ACCORDING TO CONTROL PLAN & RECORD ONLY ONE READING .

FORM NO.:WPI/F/PD/45 REV.NO.DATE : 00/01.09.2011 PAGE : 2 of 2

You might also like

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- QAD Procedure - Corrective Action P2Document1 pageQAD Procedure - Corrective Action P2sumanNo ratings yet

- Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)Document5 pagesManufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)khmorteza100% (1)

- F-PD-11 Tool Development Plan (Micro Plan)Document3 pagesF-PD-11 Tool Development Plan (Micro Plan)Trivesh SharmaNo ratings yet

- Process Validation RecordDocument11 pagesProcess Validation Recordthindmanmohan50% (2)

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Vendor Registration FormDocument3 pagesVendor Registration FormCorrosion FactoryNo ratings yet

- PPAP Part Submission WarrantDocument4 pagesPPAP Part Submission WarrantazadNo ratings yet

- PDF Process Audit Vda 63Document9 pagesPDF Process Audit Vda 63Shahrazed ZineNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- MSP ProceduresDocument18 pagesMSP ProcedurestarunNo ratings yet

- 16 Major Losses in ProductionDocument18 pages16 Major Losses in ProductionAgung Chilmy FirdanaNo ratings yet

- Al PSW FormatDocument2 pagesAl PSW Formatabhayjha1988No ratings yet

- Form - Nonconforming Part DispositionDocument1 pageForm - Nonconforming Part DispositionSelvaraj SimiyonNo ratings yet

- Control PlanDocument6 pagesControl PlanFahmy Khoerul HudaNo ratings yet

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDocument25 pagesPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- Sampling PlanDocument9 pagesSampling PlanBalvinder SinghNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- MRM PlanDocument2 pagesMRM Plang.kannan100% (1)

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocument3 pagesDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungNo ratings yet

- Packaging Details: Vendor Name & AddressDocument4 pagesPackaging Details: Vendor Name & AddressPk NimiwalNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Procedure Name: Amendment RecordDocument6 pagesProcedure Name: Amendment RecordsubbuNo ratings yet

- Keerthi Engineering: Initial Production Part TagDocument2 pagesKeerthi Engineering: Initial Production Part Tagkeerthi EngineeringNo ratings yet

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Document10 pagesNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreNo ratings yet

- Appendix 11 Design FMEA ChecklistDocument16 pagesAppendix 11 Design FMEA ChecklistDearRed FrankNo ratings yet

- AIAG PPAP Cover SheetDocument1 pageAIAG PPAP Cover SheetSCHOPENHAUERNo ratings yet

- Supply Packaging Approve FormDocument1 pageSupply Packaging Approve Formcong daNo ratings yet

- 4M Change ManagementDocument2 pages4M Change ManagementDamodaran RajanayagamNo ratings yet

- QS-2-010, Issue 01, Procedure For Control & Handling of Non Confirming Products, Corrections, Corrective & Preventive ActionsDocument2 pagesQS-2-010, Issue 01, Procedure For Control & Handling of Non Confirming Products, Corrections, Corrective & Preventive Actionssajid waqasNo ratings yet

- Change Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NameDocument2 pagesChange Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NamePk NimiwalNo ratings yet

- Master TimingDocument4 pagesMaster TimingPk NimiwalNo ratings yet

- NC Management Procedure..Document8 pagesNC Management Procedure..shobha shelarNo ratings yet

- Iqc Chapter 01 PDFDocument8 pagesIqc Chapter 01 PDFNaveen Kumar GunisettyNo ratings yet

- Kaga Components (M) SDN BHD: Operator Training ProceduresDocument2 pagesKaga Components (M) SDN BHD: Operator Training Proceduresrajesh sharmaNo ratings yet

- Purpose:: Procedure Manual FifoDocument3 pagesPurpose:: Procedure Manual FifoartiNo ratings yet

- Contract Review FormatDocument1 pageContract Review Formatsuresh kumarNo ratings yet

- QMS Formats PDFDocument11 pagesQMS Formats PDFBhavin SukhadiyaNo ratings yet

- Past Defect History 2021Document10 pagesPast Defect History 2021RahulNo ratings yet

- Vda FmeaDocument30 pagesVda Fmealalit GuptaNo ratings yet

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- MRM FormatDocument3 pagesMRM FormatPk NimiwalNo ratings yet

- Vda Fmea TemplateDocument54 pagesVda Fmea Templatehmp90No ratings yet

- Action Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableDocument39 pagesAction Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableSanjay KumarNo ratings yet

- Guidelines For Making PFMEA - A PDFDocument10 pagesGuidelines For Making PFMEA - A PDFKalimuthu PsNo ratings yet

- FMEA SampleDocument94 pagesFMEA SampleKaran MalhiNo ratings yet

- 23.sop - HRDDocument4 pages23.sop - HRDrishi gautamNo ratings yet

- Maruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingDocument3 pagesMaruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingAnkush Chourasia100% (1)

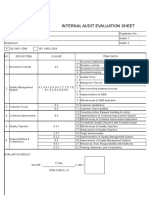

- Internal Audit Evaluation SheetDocument16 pagesInternal Audit Evaluation SheetHarnani Nanik100% (1)

- QAD Procedure - Control of Inspection, Measuring & Test Equipment P1Document1 pageQAD Procedure - Control of Inspection, Measuring & Test Equipment P1sumanNo ratings yet

- 1) PPAP YHA VIBRACOUSTIC Production)Document31 pages1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalNo ratings yet

- TVS Format APQP Timing Plan Template N10 01 July 23Document5 pagesTVS Format APQP Timing Plan Template N10 01 July 23harishtmk24No ratings yet

- In House PPM MonitoringDocument2 pagesIn House PPM MonitoringSrinath NavadaNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- H0294281 CP UpdatedDocument2 pagesH0294281 CP UpdatedSandeep SinghNo ratings yet

- Checking AidsDocument1 pageChecking AidsChintamani GiramkarNo ratings yet

- Process Capability Study 04.10.2011 Plcpkco030 Bursting Strength K1 K2 Bajaj AliconDocument1 pageProcess Capability Study 04.10.2011 Plcpkco030 Bursting Strength K1 K2 Bajaj AliconChintamani GiramkarNo ratings yet

- Procedure For EcnDocument8 pagesProcedure For EcnChintamani GiramkarNo ratings yet

- Template Equipment Register - 0Document8 pagesTemplate Equipment Register - 0Chintamani GiramkarNo ratings yet

- CST 336 Final Project Computown DocumentationDocument12 pagesCST 336 Final Project Computown Documentationapi-461214598No ratings yet

- SW Product SummaryDocument64 pagesSW Product SummaryFabio MenegatoNo ratings yet

- Heat Rate Calc in ExcelDocument13 pagesHeat Rate Calc in ExcelMukesh VadaliaNo ratings yet

- An Analysis of The Ejector-Ram-Rocket EngineDocument9 pagesAn Analysis of The Ejector-Ram-Rocket Enginefundamental_aeroNo ratings yet

- AK Carbon Steel PB 201307Document70 pagesAK Carbon Steel PB 201307SilveradoNo ratings yet

- AWV39 EAR42W: Acoustic Wall Ventilator Acoustic Window VentilatorDocument1 pageAWV39 EAR42W: Acoustic Wall Ventilator Acoustic Window Ventilatorrita_mendes_1No ratings yet

- Forklift Operator Evaluation Form: Operator Behaviors Rating Comments Pre-Use InspectionDocument2 pagesForklift Operator Evaluation Form: Operator Behaviors Rating Comments Pre-Use InspectionXionNo ratings yet

- Alloc 150 DMDocument301 pagesAlloc 150 DMSheik Mohamed ImranNo ratings yet

- Paper AeroplaneDocument19 pagesPaper Aeroplanejkb SudhakarNo ratings yet

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Document2 pagesSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaNo ratings yet

- PeopleSoft Doc UpdateDocument20 pagesPeopleSoft Doc UpdateupenderNo ratings yet

- Course Material Fees: Terms 1190 - 1193Document8 pagesCourse Material Fees: Terms 1190 - 1193Frances Ijeoma ObiakorNo ratings yet

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocument23 pagesConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNo ratings yet

- VAPORISERDocument62 pagesVAPORISERAshish ChavanNo ratings yet

- Shock AbsorberDocument0 pagesShock AbsorberSahaya GrinspanNo ratings yet

- Operate A Personal Computer PDFDocument56 pagesOperate A Personal Computer PDFBirhanu Girmay100% (8)

- McLaren Artura Order BKZQG37 Summary 2023-12-10Document6 pagesMcLaren Artura Order BKZQG37 Summary 2023-12-10Salvador BaulenasNo ratings yet

- PB Hydro en PDFDocument86 pagesPB Hydro en PDFWahyu Tirta NugrahaNo ratings yet

- 1450 01 Air Hoists and Trolleys Atlas CopcoDocument12 pages1450 01 Air Hoists and Trolleys Atlas Copcomohammed shammiNo ratings yet

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pages1.1 Control Philosophy CAS-1 NMDCkoushik42000No ratings yet

- Droop Vs Iso Control Modes For Gas TurbinesDocument3 pagesDroop Vs Iso Control Modes For Gas TurbinesArdvark100% (1)

- Overview On Sourcing: Oracle Fusion: 21D UpdatesDocument24 pagesOverview On Sourcing: Oracle Fusion: 21D UpdatesMathi VathaniNo ratings yet

- Notes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsDocument4 pagesNotes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsArif HidayatNo ratings yet

- Rankel Engine.Document16 pagesRankel Engine.Divya Prakash SrivastavaNo ratings yet

- Inspection and Quality Control in Production ManagementDocument4 pagesInspection and Quality Control in Production ManagementSameer KhanNo ratings yet

- Viewnet Diy PricelistDocument2 pagesViewnet Diy PricelistKhay SaadNo ratings yet

- Uses of The Components of Crude Oil As FuelsDocument6 pagesUses of The Components of Crude Oil As FuelsPearl LawrenceNo ratings yet

- Porting Relations 2 StrokesDocument10 pagesPorting Relations 2 Strokespistonbreaker100% (8)

- UT TransducersDocument20 pagesUT TransducersSamanyarak AnanNo ratings yet

- Carte Tehnicădetector Metale GarretDocument53 pagesCarte Tehnicădetector Metale Garretely_ely3395No ratings yet