Professional Documents

Culture Documents

Agenda Training

Uploaded by

Nirmani Hansini0 ratings0% found this document useful (0 votes)

1 views2 pagesOriginal Title

Agenda training

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pagesAgenda Training

Uploaded by

Nirmani HansiniCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

MEDICAL INSTRUMENTS, DIESELSTRASSE 1

PRODUCTION + TRADING GMBH D-84088 NEUFAHRN NB

Web: www.teco-gmbh.com TEL: #49 8773 7078010

Email: info@teco-gmbh.com FAX: #49 8773 7078029

Agenda of Coatron A training

Required material: Operation manual, Service manual, FB037, Serviceplan, green text marker, allen wrench kit 1.5 -10, screw

driver

Application Training: (first day) Service Training: (second day)

1. Optional: Hemostasis basics 1. Replacement of components:

2. First Installation and system overview a. Tube system

3. Basic Application: Service, Setup System, b. Needle + silicon tube

Setup Test, Analysis c. Wash

4. Service menu (Basics) d. Syringe

5. Theory of operation e. Valve

a. Detection principle f. Insulationsblock

b. Method clotting, chromogenic, g. Mainboard

immun,point and DFIB h. Optic

c. Mechanical clotting time i. Power supply

d. Correlation adjustment j. Replace peltier

e. Reflex testing (method and unit reflex) 2. Typical malfunctions

f. All other test protocol parameter a. Level sensor

g. How to change test protocols b. Cuvette detection

6. Calibration of test PT and FIB c. Needle clogged

7. TECAM Software d. False results (by levelsensor, optics,

a. Installation and registration cuvette, needle , valve, syringe, wash)

b. Quick tutorial to receive and print 3. Firmware Update

results 4. Hidden functions

c. Option screen a. Change test protocols

d. Create and run a worklist b. Configure as Close and Open

e. P24b option c. Reset to Default

f. Sample continuous loading d. How to use Barcode

g. Detail screen of results e. How to create Barcode

h. EDIT screen of order 5. Running QCR report (final system check + Mirror

i. Database functions print)

j. Quality control 6. Reset Service Interval

k. Compare LITE,PRO,PROLIS 7. External waste tank

l. Connecting to LIS 8. Regular maintentance, Service Plan

m. Using paient barcode (internal,external 9. Known problems from field and how to solve

scanner, LIS request) a. Cuvette don’t stop

n. Test calibration management with b. False level

different LOTs c. Robot error

o. Control 2 intruments d. Unclog needle

p. Mirror Print 10. Reporting problems to Teco

q. Translating user dialogue 11. Teco download area

End of application training End of service training

MEDICAL INSTRUMENTS, DIESELSTRASSE 1

PRODUCTION + TRADING GMBH D-84088 NEUFAHRN NB

Web: www.teco-gmbh.com TEL: #49 8773 7078010

Email: info@teco-gmbh.com FAX: #49 8773 7078029

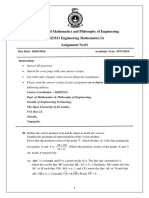

COATRON SERVICE PLAN AND REPORT

Model: Serial - No.: Firmware Rev.:

Service Interval yearly 50.000 100.000 200.000

Failure/Repair during service

Date of service Service engineer (Name, Company) Signature/Stamp

Decontamination procedure (weekly or before each service) yes

Use 30% diluted bleach and commercial disinfectant (e.g. Bacillol®AF)

Decontaminate working area, needle area, patient racks, keyboard, LCD screen, front casings, printer and waste

drawers

Every year yes

Clean and decontaminate instrument yes no

Remove syringe and clean plunger and glas with alcoholic solution yes no

Clean the fan of power supply with a small brush yes no

Every 50.000tests or 2 years yes

Additionally to yearly service

Replace needle cleaning position yes no

Perform a system check according to PA-07-10 (document FB037) yes no

Reset service interval yes no

Print a service report 2x (Keep one for yourself and fix the other on the rear casing) yes no

Every 100.000tests or 5 years yes

Additionally to 50.000 service

Replace needle yes no

Replace syringe yes no

Replace valve yes no

Replace tubing yes no

Replace insulation block yes no

Check battery on mainboard (SL 750/PT 3.6V 1.1A) and replace if below 3.3V yes no

Every 200.000tests or 10 years yes

Additionally to 100.000 service

Replace all belts (x,y,z) yes no

Replace Z-Pinion yes no

Replace Flatcable yes no

Replace Y-Pulley yes no

Clean all wheels, rollers and guide rails with alcoholic solution and apply silica oil yes no

Check Z-Bearing and replace if required yes no

Reset Service Interval yes

You might also like

- Joint Industry Standard: Solderability Tests For Printed BoardsDocument16 pagesJoint Industry Standard: Solderability Tests For Printed BoardsKishor JadhavNo ratings yet

- Short Guide EN Cobas E411 PDFDocument13 pagesShort Guide EN Cobas E411 PDFMahmoud Ahmed67% (3)

- NanoVNA User Guide English Reformat Jan 15 20Document38 pagesNanoVNA User Guide English Reformat Jan 15 20Charly GNo ratings yet

- Creo Parametric 4.0 Quick ReferenceDocument14 pagesCreo Parametric 4.0 Quick Referencemszlazak4179No ratings yet

- GE Control System - Mark VI Operation 10 DaysDocument5 pagesGE Control System - Mark VI Operation 10 DaysChidiebere Samuel OkogwuNo ratings yet

- Chip Level Laptop Repairing Institute PDFDocument10 pagesChip Level Laptop Repairing Institute PDFMagzoub NourNo ratings yet

- Answer ListDocument33 pagesAnswer ListBasovi Wahyu AdytamaNo ratings yet

- BIO - 200D Portable Ultrasound Scanner English User's ManualDocument36 pagesBIO - 200D Portable Ultrasound Scanner English User's Manualjhonsr100% (1)

- Nternet Protocol Based CCTV CameraDocument1 pageNternet Protocol Based CCTV CameraJason SalazarNo ratings yet

- Exam Iv Spring 2008: BAN 530 Ves/VpmDocument14 pagesExam Iv Spring 2008: BAN 530 Ves/VpmKasim MergaNo ratings yet

- Sony Mhc-V50, V50d Ver. 1.0Document70 pagesSony Mhc-V50, V50d Ver. 1.0ЕвгенийNo ratings yet

- 8000 Anthem U RevhDocument278 pages8000 Anthem U RevhRaymond Molleson100% (1)

- Cobas-C-311-Operator Manual-En PDFDocument132 pagesCobas-C-311-Operator Manual-En PDFnbiolab665986% (7)

- Epas PretestDocument3 pagesEpas PretestLovely Babes LagudNo ratings yet

- Oqc Check Sheet - 12Document5 pagesOqc Check Sheet - 12prabu cNo ratings yet

- DocumentationDocument4 pagesDocumentationPradeep Kumar BowmarajuNo ratings yet

- EA-10-Preinstructional Survay-ISADocument7 pagesEA-10-Preinstructional Survay-ISAKellie RamosNo ratings yet

- Cy009 Cyansmart User Manual RuDocument94 pagesCy009 Cyansmart User Manual RuТемирлан ТоктогуловNo ratings yet

- Instructions For Use Cobas b121 enDocument192 pagesInstructions For Use Cobas b121 enAnonymous AhvJI5kWAz72% (18)

- FinalexamDocument14 pagesFinalexamSureshNo ratings yet

- DocUReader 2 PRO Uputstvo enDocument66 pagesDocUReader 2 PRO Uputstvo enDarko MaksimovicNo ratings yet

- Written Test A. Matching Type: Instructions: Match The Letters in Column B With The Numbers in ColumnDocument10 pagesWritten Test A. Matching Type: Instructions: Match The Letters in Column B With The Numbers in Columnopep77No ratings yet

- Cobas C 311 Analyzer: Operator's Manual Software Version 01-04Document590 pagesCobas C 311 Analyzer: Operator's Manual Software Version 01-04khoangsachNo ratings yet

- Esco Micro Pte. Ltd. - Co. Reg No.: 198400165W - 21 Changi South Street 1, Singapore 486777Document6 pagesEsco Micro Pte. Ltd. - Co. Reg No.: 198400165W - 21 Changi South Street 1, Singapore 486777rajNo ratings yet

- Uritek-720 Plus: Operator's ManualDocument41 pagesUritek-720 Plus: Operator's ManualHoang Nhi TranNo ratings yet

- Btk004 en Elx808 Op Man Rev k1Document212 pagesBtk004 en Elx808 Op Man Rev k1ahmed.alhamooNo ratings yet

- TM001017r3IT3 MaintenanceDocument43 pagesTM001017r3IT3 MaintenanceKoli CatakiraNo ratings yet

- ACCO 30083 - Auditing in CIS Environment Multiple Choice Questions GroupDocument2 pagesACCO 30083 - Auditing in CIS Environment Multiple Choice Questions GroupaskNo ratings yet

- Final Report On Taguchi3443434434Document42 pagesFinal Report On Taguchi3443434434Nirmal KushwahaNo ratings yet

- SQC Model ExamDocument6 pagesSQC Model ExambahreabdellaNo ratings yet

- Course Outline DFC 2073 Programming FundamentalsDocument3 pagesCourse Outline DFC 2073 Programming FundamentalsFaizal Akhtar AzharNo ratings yet

- Work Instruction For Coil Taping Process of EE14 (1&4 Pin)Document6 pagesWork Instruction For Coil Taping Process of EE14 (1&4 Pin)k.mehaboob bashaNo ratings yet

- Service Manual Biobas10 V0R0 (101-203) (051-103)Document53 pagesService Manual Biobas10 V0R0 (101-203) (051-103)wilmerrrNo ratings yet

- GC Fid SopDocument6 pagesGC Fid SopHamidReza ShahbaaziNo ratings yet

- Rheodyne 2-Way SwitchDocument34 pagesRheodyne 2-Way SwitchOliver Müller100% (1)

- SRF - CER - SRV000367 - Field Overflow Error - ZWM004 Carton ID Label Report V1.1Document7 pagesSRF - CER - SRV000367 - Field Overflow Error - ZWM004 Carton ID Label Report V1.1Fahim AbrariNo ratings yet

- DWG Ti 2198 A - 008 - 01Document52 pagesDWG Ti 2198 A - 008 - 01fadilNo ratings yet

- c111 Operators Manual V 1 en IntranetDocument390 pagesc111 Operators Manual V 1 en IntranetReactivos Del Valle S.A.SNo ratings yet

- PB Preventative Maintenance 2 EN 0015Document8 pagesPB Preventative Maintenance 2 EN 0015ClaudiNo ratings yet

- Level-Radar: Non-Contact Level Gauging Using Electromagnetic WavesDocument78 pagesLevel-Radar: Non-Contact Level Gauging Using Electromagnetic WavesFrancisco Mones RuizNo ratings yet

- Daily Points To Recall (Day 8) : 1. GeneralDocument4 pagesDaily Points To Recall (Day 8) : 1. GeneralshakeelahmadjsrNo ratings yet

- Demonstration and Training TA1056 MBI Sampang Agung Brewery Extension 017900 - 1Document7 pagesDemonstration and Training TA1056 MBI Sampang Agung Brewery Extension 017900 - 1ery achjariNo ratings yet

- Project Handover Check List: Page 1 of 5Document5 pagesProject Handover Check List: Page 1 of 5Mohammed Al DissoukyNo ratings yet

- T370XW02 V0 Auo PDFDocument28 pagesT370XW02 V0 Auo PDFBeh IndraNo ratings yet

- Machine Shop1 PDFDocument68 pagesMachine Shop1 PDFAnonymous 9QQ0Rrml9vNo ratings yet

- First Periodical Test IctDocument9 pagesFirst Periodical Test IctClaire NotadoNo ratings yet

- VC Rev215 Manual enDocument560 pagesVC Rev215 Manual engoksel OnverNo ratings yet

- Basic Training ChecklistDocument2 pagesBasic Training Checklistابكر ابو ميلاد100% (1)

- CSS9 TQ PT 1st2ndDocument8 pagesCSS9 TQ PT 1st2ndJevan Hope BaltazarNo ratings yet

- FoxThermal Ft1 ManualDocument84 pagesFoxThermal Ft1 ManualJuan Carlos Del AngelNo ratings yet

- CY015 CYANElite-290 Installation Report EN RELDocument4 pagesCY015 CYANElite-290 Installation Report EN RELlemmabekeleNo ratings yet

- Daily Points To Recall (Day 6) : 1. GeneralDocument5 pagesDaily Points To Recall (Day 6) : 1. GeneralGeorge KudiaborNo ratings yet

- Displays & Touch ScreensDocument24 pagesDisplays & Touch ScreensImadMehdiNo ratings yet

- OY2TA104P0150P WenglorDocument27 pagesOY2TA104P0150P WenglorYair Rojas CarrilloNo ratings yet

- ICPE-9800 Simadzu Installation Checlist PDFDocument2 pagesICPE-9800 Simadzu Installation Checlist PDFDodi MulyadiNo ratings yet

- Panel AUO T460HW04 V3 0 (DS)Document26 pagesPanel AUO T460HW04 V3 0 (DS)Javier PellejeroNo ratings yet

- DocUReader 2 Operators ManualDocument85 pagesDocUReader 2 Operators ManualKinnari BhattNo ratings yet

- Technical Specifications of Energy Meters For Energy AuditDocument13 pagesTechnical Specifications of Energy Meters For Energy AuditBinode sarkarNo ratings yet

- (Nisp-Standard Maintenance Procedure) : (Earth Pit Maintainence) Document Code.-PPDSDocument4 pages(Nisp-Standard Maintenance Procedure) : (Earth Pit Maintainence) Document Code.-PPDSPrabagaran PrtNo ratings yet

- EMC Pro1040 Pro1050 2No363A PV701 Pro1050 40 N36201B 0B X SignedDocument10 pagesEMC Pro1040 Pro1050 2No363A PV701 Pro1050 40 N36201B 0B X SignedTayfun SezişNo ratings yet

- Penetrant Procedure-B1900 BU HousingDocument3 pagesPenetrant Procedure-B1900 BU Housingmegh prasad UpadhyayNo ratings yet

- Advanced Plasma TechnologyFrom EverandAdvanced Plasma TechnologyRiccardo d'AgostinoNo ratings yet

- DH Matugama Gov. R-11 Hematology 3 Mindray BC-30s TH-5C000453 17/02/2017 50,336 912000.00Document1 pageDH Matugama Gov. R-11 Hematology 3 Mindray BC-30s TH-5C000453 17/02/2017 50,336 912000.00Nirmani HansiniNo ratings yet

- BC2303B Assay SheetDocument4 pagesBC2303B Assay SheetNirmani HansiniNo ratings yet

- Analytical Instruments (PVT) Ltd. Doc No: AI/AS/FM/4-A: Spare Parts Requisition FormDocument1 pageAnalytical Instruments (PVT) Ltd. Doc No: AI/AS/FM/4-A: Spare Parts Requisition FormNirmani HansiniNo ratings yet

- Instrument Name Serial Number CL-900i BB1-9800635 12/28/2022 Placement Priyankara Warranty Starting Date Preferred Resource Resposible Sales PersonDocument2 pagesInstrument Name Serial Number CL-900i BB1-9800635 12/28/2022 Placement Priyankara Warranty Starting Date Preferred Resource Resposible Sales PersonNirmani HansiniNo ratings yet

- CRM of GH Kalutara - Lamp FanDocument4 pagesCRM of GH Kalutara - Lamp FanNirmani HansiniNo ratings yet

- CRM of BH Horana - Lamp FanDocument4 pagesCRM of BH Horana - Lamp FanNirmani HansiniNo ratings yet

- UntitledDocument2 pagesUntitledNirmani HansiniNo ratings yet

- Rathna Laboratory BS-240Document1 pageRathna Laboratory BS-240Nirmani HansiniNo ratings yet

- Faculty Memo-2018-FinalDocument5 pagesFaculty Memo-2018-FinalNirmani HansiniNo ratings yet

- Veenus Medi Lab Panadura - BC 10Document7 pagesVeenus Medi Lab Panadura - BC 10Nirmani HansiniNo ratings yet

- S/L AmendmentDocument44 pagesS/L AmendmentNirmani HansiniNo ratings yet

- Cey Med LaboratoryDocument1 pageCey Med LaboratoryNirmani HansiniNo ratings yet

- Ceymed Estimate InputDocument1 pageCeymed Estimate InputNirmani HansiniNo ratings yet

- BS-120 Parameter Sheet v17Document2 pagesBS-120 Parameter Sheet v17Nirmani Hansini100% (1)

- B0520 Assay Sheet (For BC-30 Vet RESEARCH USE ONLY)Document1 pageB0520 Assay Sheet (For BC-30 Vet RESEARCH USE ONLY)Halan Dyego DiasNo ratings yet

- Multi Sera Calibrator: Value Sheet of Mindray BS Measurement SystemDocument4 pagesMulti Sera Calibrator: Value Sheet of Mindray BS Measurement SystemNirmani Hansini100% (1)

- Medi Help - Horana - BS 800M - MkitDocument1 pageMedi Help - Horana - BS 800M - MkitNirmani HansiniNo ratings yet

- Centrifugation Lecture 2008 PDFDocument7 pagesCentrifugation Lecture 2008 PDFFajar Kurniawan KNNo ratings yet

- BC-20s-REAGENT RECOVERY AUTHORIZATIONDocument1 pageBC-20s-REAGENT RECOVERY AUTHORIZATIONNirmani HansiniNo ratings yet

- Communications & Information Technology: Assume The Following Scenario and Answer The Parts (B), (C) and (D)Document2 pagesCommunications & Information Technology: Assume The Following Scenario and Answer The Parts (B), (C) and (D)Nirmani HansiniNo ratings yet

- Application For MembershipDocument2 pagesApplication For MembershipsrilasithaNo ratings yet

- Richy Projects - Type 01Document22 pagesRichy Projects - Type 01Upeksha VirajiniNo ratings yet

- Faculty Memo-2018-FinalDocument5 pagesFaculty Memo-2018-FinalNirmani HansiniNo ratings yet

- Dear MHZ3531 Student PDFDocument1 pageDear MHZ3531 Student PDFnisanthaNo ratings yet

- Dear MHZ3531 Student PDFDocument1 pageDear MHZ3531 Student PDFnisanthaNo ratings yet

- Control Sestems - EC280Document7 pagesControl Sestems - EC280Nirmani HansiniNo ratings yet

- Admission To Bachelor of Technology Honours in Engineering Degree Program Under Section 2.1.3 of The Pertaining RegulationsDocument1 pageAdmission To Bachelor of Technology Honours in Engineering Degree Program Under Section 2.1.3 of The Pertaining RegulationsNirmani HansiniNo ratings yet

- 059317001Document14 pages059317001Nirmani HansiniNo ratings yet

- Tma 01 MHZ3531 2017-2018.Document3 pagesTma 01 MHZ3531 2017-2018.Nirmani HansiniNo ratings yet

- Case Exploded ViewDocument1 pageCase Exploded ViewNirmani HansiniNo ratings yet

- ENGLISH - Oral Communication - Short Original Script - ORIGINALDocument3 pagesENGLISH - Oral Communication - Short Original Script - ORIGINALIan BoneoNo ratings yet

- Motherboard: by John AnthonyDocument3 pagesMotherboard: by John Anthonyraghu_534No ratings yet

- TwinCAT TimersDocument6 pagesTwinCAT TimersveithungengNo ratings yet

- FMZ Z058 Bizon Rekord - Instrukcja Obslugi I Napraw PLDocument103 pagesFMZ Z058 Bizon Rekord - Instrukcja Obslugi I Napraw PLJakub GráčikNo ratings yet

- Shading A Sphere: Read The Description!How To Draw A Realistic Sphere With ..Document1 pageShading A Sphere: Read The Description!How To Draw A Realistic Sphere With ..Omar AntarNo ratings yet

- The Impact of Ict On SocietyDocument5 pagesThe Impact of Ict On SocietyMariel Marfa UnatoNo ratings yet

- Python QuizDocument99 pagesPython QuizPravin PoudelNo ratings yet

- Fundamentals of Computing Assignment QuestionDocument11 pagesFundamentals of Computing Assignment QuestionMandip MandalNo ratings yet

- Network Attack Detection and Visual Payload LabeliDocument12 pagesNetwork Attack Detection and Visual Payload LabeliBeria SimNo ratings yet

- Vanessa Morgan Da Silva - CV - ENDocument2 pagesVanessa Morgan Da Silva - CV - ENDiogo DomicianoNo ratings yet

- Gen008 Sas 2Document4 pagesGen008 Sas 2Christian Dave Santocildes YanilaNo ratings yet

- Cisco 3850 Switches StackingDocument14 pagesCisco 3850 Switches StackingMinalSalviNo ratings yet

- Literature Review of JewelleryDocument8 pagesLiterature Review of Jewelleryfvjawjkt100% (1)

- S 4 - Cryptography and Encryption AlgorithmsDocument28 pagesS 4 - Cryptography and Encryption AlgorithmsPPNo ratings yet

- Getting - ORA-27106 - System Pages Not Available To Allocate Memory - While Starting Oracle Database. - Red Hat Customer PortalDocument3 pagesGetting - ORA-27106 - System Pages Not Available To Allocate Memory - While Starting Oracle Database. - Red Hat Customer Portalnguyenhaitoan2008No ratings yet

- Gujarat Technological University: G. H. Patel College of Engineering and Technology, Vallabh VidyanagarDocument22 pagesGujarat Technological University: G. H. Patel College of Engineering and Technology, Vallabh VidyanagarniteshNo ratings yet

- Cube-To-Sphere Projections For Procedural Texturing and BeyondDocument22 pagesCube-To-Sphere Projections For Procedural Texturing and Beyondqrwyy8763876No ratings yet

- 3M SoundPro User Manual (053-576 Rev L)Document240 pages3M SoundPro User Manual (053-576 Rev L)laboratorioneuquenNo ratings yet

- 2488H V6 - 0000hangel - Vindel202311300004 - ENDocument5 pages2488H V6 - 0000hangel - Vindel202311300004 - ENangel.vinacNo ratings yet

- V3 Service ManualDocument50 pagesV3 Service ManualpiotreNo ratings yet

- Test Bank For Organizational Communication Approaches and Processes 7th EditionDocument34 pagesTest Bank For Organizational Communication Approaches and Processes 7th Editiontoadletgeand1j4dNo ratings yet

- Spring Security: Basic Steps & ConfigurationDocument14 pagesSpring Security: Basic Steps & ConfigurationPRABHU SORTURNo ratings yet

- 8 GraphsFundamentalsDocument28 pages8 GraphsFundamentalsguptharishNo ratings yet

- Introduction of AppleDocument3 pagesIntroduction of AppleSachin SinghNo ratings yet

- Assassin's Creed IV - Black Flag CheatsDocument10 pagesAssassin's Creed IV - Black Flag CheatsLuis LealNo ratings yet

- TH L32C20RDocument100 pagesTH L32C20Rdeep gillNo ratings yet

- 5.3.7 Lab - Introduction To Wireshark - Es XLDocument13 pages5.3.7 Lab - Introduction To Wireshark - Es XLJeelon MTNo ratings yet

- COM 121 Topic 1Document10 pagesCOM 121 Topic 1Bakari HamisiNo ratings yet