Professional Documents

Culture Documents

SLIMDIP L Mitsubishi

Uploaded by

Hanh TranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SLIMDIP L Mitsubishi

Uploaded by

Hanh TranCopyright:

Available Formats

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

OUTLINE MAIN FUNCTION AND RATINGS

RC-IGBT inverter bridge for three phase DC-to-AC power

conversion

Built-in bootstrap diodes with current limiting resistor

Open emitter type

APPLICATION

AC 100~240V (DC voltage:400V or below) three phase

low power motor inverter drive

TERMINAL LINE UP

Terminal Part number Suffix

Normal terminal SLIMDIP-L 500

Normal terminal type Short terminal SLIMDIP-L 505

INTEGRATED DRIVE, PROTECTION AND SYSTEM CONTROL FUNCTIONS

● For P-side : Drive circuit, High voltage high-speed level shifting, Control supply under-voltage protection (UV)

● For N-side : Drive circuit, Control supply under-voltage protection (UV), Short circuit protection (SC),

Over temperature protection (OT)

● Fault signaling : Corresponding to SC fault (N-side IGBT), UV fault (N-side supply) and OT fault

● Temperature monitoring : Outputting LVIC temperature by analog signal

● Input interface : Schmitt-triggered 3V, 5V input compatible, high active logic.

● UL Recognized : UL1557 File E323585

INTERNAL CIRCUIT

VUFS(2) RC-IGBT1 P(27)

VUFB(3)

Bootstrap Diode RC-IGBT

with current limiting VVFS(4)

resistor VVFB(5) U(26)

RC-IGBT2

VWFS(6)

VWFB(7)

HVIC

UP(8) V(25)

VP(9) RC-IGBT3

WP(10)

VP1(11)

W(24)

RC-IGBT4

VNC(12)

UN(13)

NU(23)

VN(14)

RC-IGBT5

WN(15)

VN1(16)

NV(22)

LVIC

FO(17) RC-IGBT6

CIN(18)

VNC(19) NW(21)

VOT(20)

Publication Date : January 2019

1

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

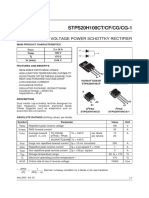

MAXIMUM RATINGS (Tj = 25°C, unless otherwise noted)

INVERTER PART

Symbol Parameter Condition Ratings Unit

VCC Supply voltage Applied between P-NU,NV,NW 450 V

VCC(surge) Supply voltage (surge) Applied between P-NU,NV,NW 500 V

VCES Collector-emitter voltage 600 V

±IC Each IGBT collector current TC= 25°C (Note 1) 15 A

±ICP Each IGBT collector current (peak) TC= 25°C, less than 1ms 30 A

Tj Junction temperature (Note 2) -30~+150 °C

Note1: Pulse width and period are limited due to junction temperature.

CONTROL (PROTECTION) PART

Symbol Parameter Condition Ratings Unit

VD Control supply voltage Applied between VP1-VNC, VN1-VNC 20 V

VDB Control supply voltage Applied between VUFB-VUFS, VVFB-VVFS,VWFB-VWFS 20 V

VIN Input voltage Applied between UP, VP, WP, UN, VN, WN-VNC -0.5~VD+0.5 V

VFO Fault output supply voltage Applied between FO-VNC -0.5~VD+0.5 V

IFO Fault output current Sink current at FO terminal 1 mA

VSC Current sensing input voltage Applied between CIN-VNC -0.5~VD+0.5 V

TOTAL SYSTEM

Symbol Parameter Condition Ratings Unit

Self protection supply voltage limit VD = 13.5~16.5V, Inverter Part

VCC(PROT) 400 V

(Short circuit protection capability) Tj = 125°C, non-repetitive, less than 2μs

TC Module case operation temperature Measurement point of Tc is described in Fig.1 (Note2) -30~+115 °C

Tstg Storage temperature -40~+125 °C

60Hz, Sinusoidal, AC 1min, between connected all pins

Viso Isolation voltage 2000 Vrms

and heat sink plate

Note2 TC MEASUREMENT POINT

Fig. 1

Control terminals

Heat sink

RC-IGBT 9.6mm

chip position

Power terminals

Tc point

THERMAL RESISTANCE

Limits

Symbol Parameter Condition Unit

Min. Typ. Max.

Junction to case thermal

Rth(j-c)Q Inverter RC-IGBT part (per 1/6 module) - - 4.0 K/W

resistance (Note 3)

Note 3: Grease with good thermal conductivity and long-term endurance should be applied evenly with about +100μm~+200μm on the contacting surface of

DIPIPM and heat sink. The contacting thermal resistance between DIPIPM case and heat sink Rth(c-f) is determined by the thickness and the thermal

conductivity of the applied grease. For reference, Rth(c-f) is about 0.4K/W (per 1/6 module, grease thickness: 20μm, thermal conductivity: 1.0W/m•K).

Publication Date : January 2019

2

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

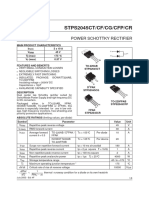

ELECTRICAL CHARACTERISTICS (Tj = 25°C, unless otherwise noted)

INVERTER PART

Limits

Symbol Parameter Condition Unit

Min. Typ. Max.

Collector-emitter saturation IC= 15A, Tj= 25°C - 1.60 1.95

VCE(sat) VD=VDB = 15V, VIN= 5V V

voltage IC= 15A, Tj= 125°C - 1.80 2.15

VEC FWDi forward voltage VIN= 0V, -IC= 15A - 1.40 1.90 V

ton 0.65 1.05 1.45 μs

tC(on) VCC= 300V, VD= VDB= 15V - 0.40 0.65 μs

toff Switching times IC= 15A, Tj= 125°C, VIN= 0↔5V - 1.15 1.60 μs

tC(off) Inductive Load (upper-lower arm) - 0.15 0.30 μs

trr - 0.30 - μs

Collector-emitter cut-off Tj= 25°C - - 1

ICES VCE=VCES mA

current Tj= 125°C - - 10

CONTROL (PROTECTION) PART

Limits

Symbol Parameter Condition Unit

Min. Typ. Max.

VD=15V, VIN=0V - - 3.10

ID Total of VP1-VNC, VN1-VNC VD=15V, VIN=3.3V - - 4.20

Circuit current VD=15V, VIN=5V - - 3.10 mA

Each part of VUFB-VUFS, VD=VDB=15V, VIN=0V - - 0.10

IDB

VVFB-VVFS, VWFB-VWFS VD=VDB=15V, VIN=5V - - 0.10

VSC(ref) Short circuit trip level VD = 15V (Note 4) 0.455 0.480 0.505 V

UVDBt P-side Control supply Trip level 7.0 10.0 12.0 V

UVDBr under-voltage protection(UV) Reset level 7.0 10.0 12.0 V

Tj ≤125°C

UVDt N-side Control supply Trip level 10.3 - 12.5 V

UVDr under-voltage protection(UV) Reset level 10.8 - 13.0 V

LVIC Temperature=95C 2.76 2.89 3.03 V

VOT Temperature Output Pull down R=5.1kΩ (Note 5)

LVIC Temperature=25C 0.86 1.16 1.39 V

OTt Over temperature protection VD = 15V Trip level 115 130 145 °C

OTrh (Note6) Detect LVIC temperature Hysteresis of trip-reset - 10 - °C

VFOH VSC = 0V, FO terminal pulled up to 5V by 10kΩ 4.9 - - V

Fault output voltage

VFOL VSC = 1V, IFO = 1mA - - 0.95 V

tFO Fault output pulse width (Note 7) 20 - - μs

IIN Input current VIN = 5V 0.70 1.00 1.50 mA

Vth(on) ON threshold voltage - 1.70 2.35

Vth(off) OFF threshold voltage 0.70 1.30 -

Applied between UP, VP, WP, UN, VN, WN-VNC V

ON/OFF threshold

Vth(hys) 0.25 0.40 -

hysteresis voltage

VF Bootstrap Di forward voltage IF=10mA including voltage drop by limiting resistor (Note 8) 1.1 1.7 2.3 V

R Built-in limiting resistance Included in bootstrap Di 80 100 120 Ω

Note 4 : SC protection works only for N-side IGBT. Please select the external shunt resistance such that the SC trip-level is less than 1.7 times of the current rating.

5 : Temperature of LVIC vs. VOT output characteristics is described in Fig.3.

6 : When the LVIC temperature exceeds OT trip temperature level(OTt), OT protection works and Fo outputs. In that case if the heat sink dropped off or fixed

loosely, don't reuse that DIPIPM. (There is a possibility that junction temperature of power chips exceeded maximum Tj(150C).

7 : Fault signal Fo outputs when SC, UV or OT protection works. Fo pulse width is different for each protection modes. At SC failure, Fo pulse width is a fixed

width (=minimum 20μs), but at UV or OT failure, Fo outputs continuously until recovering from UV or OT state. (But minimum Fo pulse width is 20μs.)

8 : The characteristics of bootstrap Di is described in Fig.2.

Fig. 2 Characteristics of Bootstrap Di VF-IF curve (@Ta=25C) Including Voltage Drop by Limiting Resistor (Right chart is enlarged chart.)

Publication Date : January 2019

3

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

Fig. 3 Temperature of LVIC vs. VOT Output Characteristics

4.0 max

3.8 typ

3.6 min

3.4

3.2

3.03

3.0

VOT Output [V]

2.89

2.8 2.76

2.6

2.4

2.2

2.0

1.8

1.6

60 70 80 90 95 100 110 120 130

LVIC Temperature [℃]

Fig. 4 Pattern Wiring Around the Analog Voltage Output Circuit [VOT terminal]

Inside LVIC

of DIPIPM

Temperature VOT

signal MCU

Ref

VNC

5.1kΩ

(1) VOT outputs the analog signal that is amplified signal of temperature detecting element on LVIC by inverting amplifier.

(2) It is recommended to insert 5kΩ (5.1kΩ is recommended) pull down resistor for getting linear output characteristics at low temperature below room

temperature. When the pull down resistor is inserted between VOT and VNC(control GND), the extra circuit current, which is calculated approximately by VOT

output voltage divided by pull down resistance, flows as LVIC circuit current continuously. In the case of using VOT for detecting high temperature over room

temperature only, it is unnecessary to insert the pull down resistor.

(3) In the case of using VOT with low voltage controller like 3.3V MCU, VOT output might exceed control supply voltage 3.3V when temperature rises excessively.

If system uses low voltage controller, it is recommended to insert a clamp Di between control supply of the controller and VOT output for preventing over

voltage destruction.

(4) In the case of not using VOT, leave VOT output NC (No Connection).

Refer the application note for SLIMDIP series about the usage of VOT.

Publication Date : January 2019

4

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

MECHANICAL CHARACTERISTICS AND RATINGS

Limits

Parameter Condition Unit

Min. Typ. Max.

Mounting torque Mounting screw : M3 (Note 9) Recommended 0.69N·m 0.59 0.69 0.78 N·m

Control terminal: Load 5N

Terminal pulling strength JEITA-ED-4701 10 - - s

Power terminal: Load 10N

Control terminal: Load 2.5N

Terminal bending strength Power terminal: Load 5N JEITA-ED-4701 2 - - times

90deg. bend

Weight - 5.5 - g

Heat radiation part flatness (Note 10) -30 - 80 μm

Note 9: Plain washers (ISO 7089~7094) are recommended.

Note 10: Measurement positions of heat radiation part flatness are as below

0.5mm

-+

Measurement position

14.9mm

Heat sink side

+

-

Heat sink side

RECOMMENDED OPERATION CONDITIONS

Limits

Symbol Parameter Condition Unit

Min. Typ. Max.

VCC Supply voltage Applied between P-NU, NV, NW 0 300 400 V

VD Control supply voltage Applied between VP1-VNC, VN1-VNC 13.5 15.0 16.5 V

VDB Control supply voltage Applied between VUFB-VUFS, VVFB-VVFS,VWFB-VWFS 13.0 15.0 18.5 V

∆VD, ∆VDB Control supply variation -1 - +1 V/μs

tdead Arm shoot-through blocking time For each input signal, TC100C 1.0 - - μs

fPWM PWM input frequency TC ≤ 100°C, Tj ≤ 125°C - - 20 kHz

VCC = 300V, VD=VDB=15V, P.F = 0.8, fPWM= 5kHz - - 7.0

IO Allowable r.m.s. current Sinusoidal PWM Arms

TC ≤ 100°C, Tj ≤ 125°C (Note11) fPWM= 15kHz - - 4.0

PWIN(on) 0.7 - -

Minimum input pulse width (Note 12) μs

PWIN(off) 0.7 - -

VNC VNC variation Between VNC-NU, NV, NW (including surge) -5.0 - +5.0 V

Tj Junction temperature -20 - +125 °C

Note 11: Allowable r.m.s. current depends on the actual application conditions.

12: DIPIPM might not make response if the input signal pulse width is less than PWIN(on), PWIN(off).

Publication Date : January 2019

5

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

Fig. 5 Timing Charts of The DIPIPM Protective Functions

[A] Short-Circuit Protection (N-side only with the external shunt resistor and RC filter)

a1. Normal operation: IGBT ON and outputs current.

a2. Short circuit current detection (SC trigger)

(It is recommended to set RC time constant 1.5~2.0μs so that IGBT shut down within 2.0μs when SC.)

a3. All N-side IGBT's gates are hard interrupted.

a4. All N-side IGBTs turn OFF.

a5. FO outputs for tFo=minimum 20μs.

a6. Input = “L”: IGBT OFF

a7. Fo finishes output, but IGBTs don't turn on until inputting next ON signal (LH).

(IGBT of each phase can return to normal state by inputting ON signal to each phase.)

a8. Normal operation: IGBT ON and outputs current.

Lower-side control

input a6

SET RESET

Protection circuit state

a3

Internal IGBT gate

a4

SC trip current level

a8

Output current Ic a1 a7

a2

SC reference voltage

Sense voltage of

the shunt resistor

Delay by RC filtering

Error output Fo a5

[B] Under-Voltage Protection (N-side, UVD)

b1. Control supply voltage V D exceeds under voltage reset level (UVDr), but IGBT turns ON by next ON signal (LH).

(IGBT of each phase can return to normal state by inputting ON signal to each phase.)

b2. Normal operation: IGBT ON and outputs current.

b3. VD level drops to under voltage trip level. (UVDt).

b4. All N-side IGBTs turn OFF in spite of control input condition.

b5. Fo outputs for tFo=minimum 20μs, but output is extended during VD keeps below UVDr.

b6. VD level reaches UVDr.

b7. Normal operation: IGBT ON and outputs current.

Control input

Protection circuit state RESET SET RESET

UVDr

Control supply voltage VD b1 b6

UVDt b3

b2 b4 b7

Output current Ic

Error output Fo b5

Publication Date : January 2019

6

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

[C] Under-Voltage Protection (P-side, UVDB)

c1. Control supply voltage VDB rises. After the voltage reaches under voltage reset level UVDBr, IGBT turns on by next ON signal (LH).

c2. Normal operation: IGBT ON and outputs current.

c3. VDB level drops to under voltage trip level (UVDBt).

c4. IGBT of the corresponding phase only turns OFF in spite of control input signal level, but there is no FO signal output.

c5. VDB level reaches UVDBr.

c6. Normal operation: IGBT ON and outputs current.

Control input

RESET SET RESET

Protection circuit state

UVDBr

c3

Control supply voltage VDB c1 UVDBt c5

c2 c4 c6

Output current Ic

Error output Fo Keep High-level (no fault output)

[D] Over Temperature Protection (N-side, Detecting LVIC temperature)

d1. Normal operation: IGBT ON and outputs current.

d2. LVIC temperature exceeds over temperature trip level(OTt).

d3. All N-side IGBTs turn OFF in spite of control input condition.

d4. Fo outputs for tFo=minimum 20μs, but output is extended during LVIC temperature keeps over OTt.

d5. LVIC temperature drops to over temperature reset level.

d6. Normal operation: IGBT turns on by next ON signal (LH).

(IGBT of each phase can return to normal state by inputting ON signal to each phase.)

Control input

Protection circuit state SET RESET

d2

OTt

d5

Temperature of LVIC

OTt - OTrh

d1 d3 d6

Output current Ic

d4

Error output Fo

Publication Date : January 2019

7

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

Fig. 6 Example of Application Circuit

P(27)

C1 D1 C2 VUFS(2) RC-IGBT

+ VUFB(3)

C1 D1 C2 VVFS(4) U(26)

+ VVFB(5)

In the case of being affected

by noise, it is recommended to C1 D1 C2 VWFS(6)

insert RC filter. VWFB(7)

+ HVIC

UP(8) V(25)

M

VP(9)

WP(10)

VP1(11)

W(24)

C2

+

VNC(12)

MCU

C3

UN(13)

VN(14)

NU(23)

WN(15)

5V

VN1(16)

C2

Fo(17)

LVIC

NV(22)

15V VD

CIN(18)

+

C1 D1 R1 C4 VNC(19)

Long wiring might cause

NW(21)

VOT(20) short circuit failure

5.1kΩ Long wiring might cause SC level C

fluctuation and malfunction

D

Long GND wiring might generate B Shunt

noise to input signal and cause resistor

IGBT malfunction A N1

Control GND wiring Power GND wiring

(1) If control GND is connected with power GND by common broad pattern, it may cause malfunction by power GND fluctuation.

It is recommended to connect control GND and power GND at only a point N1 (near the terminal of shunt resistor).

(2) It is recommended to insert a Zener diode D1(24V/1W) between each pair of control supply terminals to prevent surge destruction.

(3) To prevent surge destruction, the wiring between the smoothing capacitor and the P, N1 terminals should be as short as possible.

Generally a 0.1-0.22μF snubber capacitor C3 between the P-N1 terminals is recommended.

(4) R1, C4 of RC filter for preventing protection circuit malfunction is recommended to select tight tolerance, temp-compensated type.

The time constant R1C4 should be set so that SC current is shut down within 2μs. (1.5μs~2μs is general value.) SC interrupting time might

vary with the wiring pattern, so the enough evaluation on the real system is necessary.

(5) To prevent malfunction, the wiring of A, B, C should be as short as possible.

(6) The point D at which the wiring to CIN filter is divided should be near the terminal of shunt resistor. NU, NV, NW terminals should be

connected at near NU, NV, NW terminals.

(7) All capacitors should be mounted as close to the terminals as possible. (C1: good temperature, frequency characteristic electrolytic type and

C2:0.01μ-2μF, good temperature, frequency and DC bias characteristic ceramic type are recommended.)

(8) Input drive is High-active type. There is a minimum 3.3kΩ pull-down resistor in the input circuit of IC. To prevent malfunction, the wiring of

each input should be as short as possible. When using RC coupling circuit, make sure the input signal level meet the turn-on and turn-off

threshold voltage.

(9) Thanks to built-in HVIC, direct coupling to MCU without any optocoupler or transformer isolation is possible.

(10) Fo output is open drain type. It should be pulled up to MCU or control power supply (e.g. 5V,15V) by a resistor that makes IFo up to 1mA. (IFO

is estimated roughly by the formula of control power supply voltage divided by pull-up resistance. In the case of pulled up to 5V, 10kΩ (5kΩ

or more) is recommended.)

(11) Two VNC terminals are connected inside DIPIPM, please connect either one to the 15V power supply GND outside and leave another one

open.

(12) If high frequency noise superimposed to the control supply line, IC malfunction might happen and cause DIPIPM erroneous operation. To

avoid such problem, line ripple voltage should meet dV/dt ≤+/-1V/μs, Vripple≤2Vp-p.

Publication Date : January 2019

8

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

Fig. 7 MCU I/O Interface Circuit

5V line

Note: The RC coupling (parts shown in the dotted line) at

each input depends on user’s PWM control strategy

10kΩ DIPIPM and the wiring impedance of the printed circuit board.

The DIPIPM signal input section integrates a

UP,VP,WP,UN,VN,WN 3.3kΩ(min) pull-down resistor. Therefore, when using

MCU an external filtering resistor, please pay attention to

the signal voltage drop at input terminal.

3.3kΩ(min)

Fo

VNC(Logic)

Fig. 8 Pattern Wiring Around the Shunt Resistor

NU, NV, NW should be connected

each other at near terminals.

DIPIPM DIPIPM

Wiring Inductance should be less than 10nH. Each wiring Inductance should be less than 10nH.

Inductance of a copper pattern with Inductance of a copper pattern with

length=17mm, width=3mm is about 10nH. length=17mm, width=3mm is about 10nH.

NU N1 NU N1

NV

NV

NW

VNC Shunt VNC NW

resistor GND wiring from VNC should GND wiring from VNC should

Shunt

be connected close to the resistors be connected close to the

terminal of shunt resistor. terminal of shunt resistor.

Low inductance shunt resistor like surface mounted (SMD) type is recommended.

Fig. 9 External SC Protection Circuit with Using Three Shunt Resistors

DIPIPM

Drive circuit

P

P-side

U

V External protection circuit

W

N-side Comparator

(Open collector output type)

Rf

C B

NW - 5V

Cf

NV Vref +

NU

Drive circuit

-

Protection circuit D OR output

Vref +

VNC CIN

-

Shunt

A resistors Vref +

N1

(1) It is necessary to set the time constant RfCf of external comparator input so that IGBT stop within 2μs when short circuit occurs.

SC interrupting time might vary with the wiring pattern, comparator speed and so on.

(2) The threshold voltage Vref should be set up the same rating of short circuit trip level (Vsc(ref) typ. 0.48V).

(3) Select the external shunt resistance so that SC trip-level is less than specified maximum value.

(4) To avoid malfunction, the wiring A, B, C should be as short as possible.

(5) The point D at which the wiring to comparator is divided should be near the terminal of shunt resistor.

(6) OR output high level should be over 0.505V (=maximum Vsc(ref)).

(7) GND of Comparator, Vref circuit and Cf should be not connected to noisy power GND but to control GND wiring.

Publication Date : January 2019

9

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

Fig. 10 Package Outlines [Dimension: mm]

[ SLIMDIP-L Suffix:500 : Normal Terminal Type ]

[ SLIMDIP-L Suffix:505 : Short Terminal Type ]

Note: Connect only one VNC terminal (No.12 or 19) to the system GND and leave another one open.

Publication Date : January 2019

10

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

Revision Record

Rev. Date Page Revised contents

1 19/04/2016 - New

2 03/04/2017 10 Revise detail B part of package outline

1 Short terminal type is added to terminal line up.

3 05/04/2018 5 JEITA-ED-4701 was EIAJ-ED-4701

10 Add ‘Short terminal type’

4 22/01/2019 1 Outline note was ‘Long terminal type’.

Publication Date : January 2019

11

< DIPIPM >

SLIMDIP-L

TRANSFER MOLDING TYPE

INSULATED TYPE

Keep safety first in your circuit designs!

Mitsubishi Electric Corporation puts the maximum effort into making semiconductor products better and more

reliable, but there is always the possibility that trouble may occur with them. Trouble with semiconductors

may lead to personal injury, fire or property damage. Remember to give due consideration to safety when

making your circuit designs, with appropriate measures such as (i) placement of substitutive, auxiliary

circuits, (ii) use of non-flammable material or (iii) prevention against any malfunction or mishap.

Notes regarding these materials

•These materials are intended as a reference to assist our customers in the selection of the Mitsubishi

semiconductor product best suited to the customer’s application; they do not convey any license under any

intellectual property rights, or any other rights, belonging to Mitsubishi Electric Corporation or a third party.

•Mitsubishi Electric Corporation assumes no responsibility for any damage, or infringement of any

third-party’s rights, originating in the use of any product data, diagrams, charts, programs, algorithms, or

circuit application examples contained in these materials.

•All information contained in these materials, including product data, diagrams, charts, programs and

algorithms represents information on products at the time of publication of these materials, and are subject

to change by Mitsubishi Electric Corporation without notice due to product improvements or other reasons. It

is therefore recommended that customers contact Mitsubishi Electric Corporation or an authorized

Mitsubishi Semiconductor product distributor for the latest product information before purchasing a product

listed herein.

The information described here may contain technical inaccuracies or typographical errors. Mitsubishi

Electric Corporation assumes no responsibility for any damage, liability, or other loss rising from these

inaccuracies or errors.

Please also pay attention to information published by Mitsubishi Electric Corporation by various means,

including the Mitsubishi Semiconductor home page (http://www.MitsubishiElectric.com/semiconductors/).

•When using any or all of the information contained in these materials, including product data, diagrams,

charts, programs, and algorithms, please be sure to evaluate all information as a total system before making

a final decision on the applicability of the information and products. Mitsubishi Electric Corporation assumes

no responsibility for any damage, liability or other loss resulting from the information contained herein.

•Mitsubishi Electric Corporation semiconductors are not designed or manufactured for use in a device or

system that is used under circumstances in which human life is potentially at stake. Please contact

Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor when

considering the use of a product contained herein for any specific purposes, such as apparatus or systems

for transportation, vehicular, medical, aerospace, nuclear, or undersea repeater use.

•The prior written approval of Mitsubishi Electric Corporation is necessary to reprint or reproduce in whole or

in part these materials.

•If these products or technologies are subject to the Japanese export control restrictions, they must be

exported under a license from the Japanese government and cannot be imported into a country other than

the approved destination.

Any diversion or re-export contrary to the export control laws and regulations of Japan and/or the country of

destination is prohibited.

•Please contact Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor

for further details on these materials or the products contained therein.

© 2019 MITSUBISHI ELECTRIC CORPORATION. ALL RIGHTS RESERVED.

SLIMDIP, DIPIPM and CSTBT are trademarks of MITSUBISHI ELECTRIC CORPORATION.

Publication Date : January 2019

12

You might also like

- AntimatterDocument24 pagesAntimatterBoner DarelNo ratings yet

- Control IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ADocument17 pagesControl IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ASledge HammerNo ratings yet

- Hermann Bondi - Relativity and Common Sense - A New Approach To Einstein - (December 1980)Document210 pagesHermann Bondi - Relativity and Common Sense - A New Approach To Einstein - (December 1980)Erickson SantosNo ratings yet

- 15A Universal 1/2 Wave Self Excited AVRDocument2 pages15A Universal 1/2 Wave Self Excited AVRHerbertNo ratings yet

- Vibration AnalysisDocument12 pagesVibration AnalysistheealokNo ratings yet

- Measuring Altitude with AltimetryDocument13 pagesMeasuring Altitude with AltimetryMustaphaNo ratings yet

- Caterpillar Systems Operation Testing and Adjusting Digital Voltage RegulatorDocument8 pagesCaterpillar Systems Operation Testing and Adjusting Digital Voltage RegulatorEdward100% (45)

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RDocument3 pagesSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinNo ratings yet

- pss20s92f6 AgDocument12 pagespss20s92f6 AgMohammad UsmanNo ratings yet

- Nfva34065l32 D-2317928Document15 pagesNfva34065l32 D-2317928achil de troyNo ratings yet

- Iramx16up60b 2Document18 pagesIramx16up60b 2Odair SilvaNo ratings yet

- PDF Irams10up60b IRFDocument19 pagesPDF Irams10up60b IRFAndy LNo ratings yet

- pss05s72ft eDocument12 pagespss05s72ft eJackson Dias RochaNo ratings yet

- IRAMS10UP60A Integrated Power Module for Appliance Motor DriveDocument18 pagesIRAMS10UP60A Integrated Power Module for Appliance Motor DriveAnselmo LimaNo ratings yet

- TC7W14FU DatasheetDocument7 pagesTC7W14FU DatasheetmangstromNo ratings yet

- TC7W14 CMOS Schmitt InverterDocument7 pagesTC7W14 CMOS Schmitt InverterFrancisco Espin RomeroNo ratings yet

- MITSUBISHI MODULEDocument9 pagesMITSUBISHI MODULEMadai Sanchez TopeteNo ratings yet

- FSBS15CH60F: Motion SPM 3 SeriesDocument15 pagesFSBS15CH60F: Motion SPM 3 SeriesGilvana Cristina FerreiraNo ratings yet

- Quadoperational Am Pli Fi Ers: Uni Soni C Technologi Es Co., LTDDocument5 pagesQuadoperational Am Pli Fi Ers: Uni Soni C Technologi Es Co., LTDsgblake06No ratings yet

- Quadoperational Am Pli Fi Ers: Uni Soni C Technologi Es Co., LTDDocument5 pagesQuadoperational Am Pli Fi Ers: Uni Soni C Technologi Es Co., LTDOscar GuevaraNo ratings yet

- Fna 41560 B 2Document16 pagesFna 41560 B 2JundiyahNo ratings yet

- Ka 34063a (Cuk)Document6 pagesKa 34063a (Cuk)sujitNo ratings yet

- Unisonic Technologies Co.,: Quad Operational AmplifiersDocument6 pagesUnisonic Technologies Co.,: Quad Operational AmplifierssebastianNo ratings yet

- FNC42060F / FNC42060F2: Motion SPM 45 SeriesDocument17 pagesFNC42060F / FNC42060F2: Motion SPM 45 SeriesSergio ReyesNo ratings yet

- UC3848Document12 pagesUC3848isaiasvaNo ratings yet

- IRAMS10UP60B: Series 10A, 600VDocument17 pagesIRAMS10UP60B: Series 10A, 600VAngel VelasquezNo ratings yet

- FSAM75SM60A Motion SPM 2 Series: Features General DescriptionDocument16 pagesFSAM75SM60A Motion SPM 2 Series: Features General Descriptionมนต์ชัย บุญธนลาภNo ratings yet

- Infineon IR2153 DataSheet v01 00 enDocument9 pagesInfineon IR2153 DataSheet v01 00 enApexAudio BpnNo ratings yet

- Infineon IR2153 DataSheet v01 00 enDocument9 pagesInfineon IR2153 DataSheet v01 00 enApexAudio BpnNo ratings yet

- 3842a DatasheetDocument8 pages3842a DatasheetVịnh DemoNo ratings yet

- High Voltage Ignition Coil Driver Power I.C.: VB921ZVFI VB921ZVSPDocument7 pagesHigh Voltage Ignition Coil Driver Power I.C.: VB921ZVFI VB921ZVSPNgoc AnNo ratings yet

- Unisonic Technologies Co., LTD: General Purpose, Low Voltage, Rail-To-Rail Output Operational AmplifiersDocument12 pagesUnisonic Technologies Co., LTD: General Purpose, Low Voltage, Rail-To-Rail Output Operational AmplifiersJonathan NuñezNo ratings yet

- LOW POWER QUAD OP AMPSDocument11 pagesLOW POWER QUAD OP AMPSАлександрNo ratings yet

- Ir2175 (S) & (PBF) : Linear Current Sensing IcDocument7 pagesIr2175 (S) & (PBF) : Linear Current Sensing IcDavid CoronadoNo ratings yet

- Ka5S-Series: KA5S0765C/KA5S0965/KA5S12656/KA5S1265 Fairchild Power Switch (FPS)Document16 pagesKa5S-Series: KA5S0765C/KA5S0965/KA5S12656/KA5S1265 Fairchild Power Switch (FPS)Arte Y MecatrónicaNo ratings yet

- STPS20H 100CTDocument7 pagesSTPS20H 100CTManuel G Medina LopezNo ratings yet

- Schott yDocument8 pagesSchott yDinalba(Formación) El Espíritu Santo ObraNo ratings yet

- FSBB20CH60F 83493Document15 pagesFSBB20CH60F 83493Hla Swe OoNo ratings yet

- Self-Oscillating Half-Bridge Driver: Ir2153 (D) (S) & (PBF)Document9 pagesSelf-Oscillating Half-Bridge Driver: Ir2153 (D) (S) & (PBF)Javier ParedesNo ratings yet

- BD8160AEFV DatasheetDocument21 pagesBD8160AEFV Datasheetjose peresNo ratings yet

- STPS2045CTCFCGCFPCRDocument8 pagesSTPS2045CTCFCGCFPCROmaraye JoshuaNo ratings yet

- Multifunction Very Low Drop Voltage Regulator: DescriptionDocument10 pagesMultifunction Very Low Drop Voltage Regulator: DescriptionErasmo FrancoNo ratings yet

- SK6406 PDFDocument6 pagesSK6406 PDFjddgNo ratings yet

- 3 Phase Hall Motor Driver Ic: FeaturesDocument12 pages3 Phase Hall Motor Driver Ic: FeaturesSoro FoxNo ratings yet

- TPD4122K ToshibaSemiconductorDocument25 pagesTPD4122K ToshibaSemiconductorHeru susantoNo ratings yet

- IR2133/IR2135 (J S IR2233 IR2235 J S: Product Summary FeaturesDocument27 pagesIR2133/IR2135 (J S IR2233 IR2235 J S: Product Summary FeaturesAshish RanaNo ratings yet

- TDA7265 UnisonicTechnologiesDocument8 pagesTDA7265 UnisonicTechnologiesEduardo FahidNo ratings yet

- Sllimm - 2 Series IPM, 3-Phase Inverter, 25 A, 600 V Short-Circuit Rugged IGBTDocument24 pagesSllimm - 2 Series IPM, 3-Phase Inverter, 25 A, 600 V Short-Circuit Rugged IGBTЛеонид ДорфманNo ratings yet

- PWM Controller IC For AC/DC Converter: DatasheetDocument35 pagesPWM Controller IC For AC/DC Converter: DatasheetRaka Satria PradanaNo ratings yet

- Regulador 4949ed PDFDocument11 pagesRegulador 4949ed PDFluizNo ratings yet

- Igbt Irams10up60a IrDocument17 pagesIgbt Irams10up60a IrMarco Antonio VilelaNo ratings yet

- YG4558/E/L: Dual Operational AmplifierDocument7 pagesYG4558/E/L: Dual Operational AmplifierJoel Rondinel PachecoNo ratings yet

- Unisonic Technologies Co., LTD: Low Voltage Audio Power AmplifierDocument5 pagesUnisonic Technologies Co., LTD: Low Voltage Audio Power Amplifieressen999No ratings yet

- IR2127(S) / IR21271(S) / IR2128(S) Current Sensing Driver Data SheetDocument16 pagesIR2127(S) / IR21271(S) / IR2128(S) Current Sensing Driver Data SheetxexericaNo ratings yet

- Integrados KaDocument20 pagesIntegrados KaJosé Carlos de Barros MelloNo ratings yet

- Components Used:: Experiment No: OBJECTIVE:-Analysis of NMOS Inverter Using STEP Input Software Required:-PspiceDocument5 pagesComponents Used:: Experiment No: OBJECTIVE:-Analysis of NMOS Inverter Using STEP Input Software Required:-PspiceAnonymous eWMnRr70qNo ratings yet

- Ir21531D (S) & (PBF) : Self-Oscillating Half-Bridge DriverDocument9 pagesIr21531D (S) & (PBF) : Self-Oscillating Half-Bridge DriverErasmo Franco SNo ratings yet

- FSBB20CH60: Smart Power ModuleDocument16 pagesFSBB20CH60: Smart Power ModuleDhaka AsasaNo ratings yet

- Boost (Step-Up) WLED Driver With OVP: General DescriptionDocument8 pagesBoost (Step-Up) WLED Driver With OVP: General DescriptiondneprashNo ratings yet

- Iris 4015Document6 pagesIris 4015vetchboyNo ratings yet

- Preliminary Data Sheet for IR2151 Half-Bridge Driver ICDocument6 pagesPreliminary Data Sheet for IR2151 Half-Bridge Driver ICJean AlvesNo ratings yet

- Power Converters Lab ManualDocument89 pagesPower Converters Lab ManualHari PrasadNo ratings yet

- LM393Document4 pagesLM393maher mlbaseNo ratings yet

- Dual Bridge Driver IC Technical SpecificationDocument10 pagesDual Bridge Driver IC Technical SpecificationAndi HarsonoNo ratings yet

- Ir2133 PDFDocument13 pagesIr2133 PDFViola Safa Nur AnnisaNo ratings yet

- FNA41060 / FNA41060B2: Motion SPM 45 SeriesDocument16 pagesFNA41060 / FNA41060B2: Motion SPM 45 SeriesAmjad ShehadaNo ratings yet

- Metal-Oxide Varistors (Movs) Radial Leaded-Standard D SeriesDocument30 pagesMetal-Oxide Varistors (Movs) Radial Leaded-Standard D SeriesoguiaNo ratings yet

- Tps 2051Document25 pagesTps 2051Hanh TranNo ratings yet

- Silicon Zener Diodes DatasheetDocument2 pagesSilicon Zener Diodes DatasheetHernando Ochoa RamirezNo ratings yet

- Kfr-72Lw/88Fzbpc Maintenance Manual: Hisense Kelon Air-Conditionning Co.,LtdDocument37 pagesKfr-72Lw/88Fzbpc Maintenance Manual: Hisense Kelon Air-Conditionning Co.,LtdHanh TranNo ratings yet

- GRT200Document46 pagesGRT200Hanh Tran100% (1)

- Vol3 23Document2 pagesVol3 23Momtaz MoniNo ratings yet

- Instructions For Use: ContactorDocument38 pagesInstructions For Use: ContactorHanh TranNo ratings yet

- RED670I11r01 - Technical Reference Manual PDFDocument1,014 pagesRED670I11r01 - Technical Reference Manual PDFHanh TranNo ratings yet

- RE 615 Tech 756887 ENm PDFDocument1,224 pagesRE 615 Tech 756887 ENm PDFKiran KarthikNo ratings yet

- Compact Vault Trident-INDICATIVODocument18 pagesCompact Vault Trident-INDICATIVOAdrián Darío Nieves LeyvaNo ratings yet

- Packing List for Simco Spinning & Textiles LtdDocument1 pagePacking List for Simco Spinning & Textiles LtdRivan rNo ratings yet

- Taller de Calor EstDocument2 pagesTaller de Calor EstDiegoMuñozNo ratings yet

- Unit 3 - Thermal Engineering and Gas Dynamics - WWW - Rgpvnotes.inDocument9 pagesUnit 3 - Thermal Engineering and Gas Dynamics - WWW - Rgpvnotes.inFno FnoNo ratings yet

- 519 - Transmission Line Theory by VishnuDocument24 pages519 - Transmission Line Theory by VishnuSairam SairamNo ratings yet

- Power Quality Analysis PDFDocument16 pagesPower Quality Analysis PDFNurul HidayahNo ratings yet

- Customer: Rohit Ferro Tech Ltd. Consultant: Development Consultant Pvt. Ltd.. Project: PC0391/92Document7 pagesCustomer: Rohit Ferro Tech Ltd. Consultant: Development Consultant Pvt. Ltd.. Project: PC0391/92Jatindra AndiaNo ratings yet

- Displacement Ventilation Is An Air Distribution Technology That Introduces Cool Air Into A Zone at Low VelocityDocument24 pagesDisplacement Ventilation Is An Air Distribution Technology That Introduces Cool Air Into A Zone at Low VelocityBilal AhmedNo ratings yet

- English 11test Unit 9 10 11Document2 pagesEnglish 11test Unit 9 10 11Suri V TranNo ratings yet

- NDA Physics MCQs For PracticeDocument10 pagesNDA Physics MCQs For Practicekumar HarshNo ratings yet

- Practice Mock Test-2024 - T02 (Code-A) - QuestionDocument15 pagesPractice Mock Test-2024 - T02 (Code-A) - Questionudhav malpaniNo ratings yet

- Application Note Isolation Technique For Signal ConditioningDocument7 pagesApplication Note Isolation Technique For Signal ConditioningEdsonNo ratings yet

- HighVolt Capacitive Impulse Voltage Dividers 3-61-EnDocument4 pagesHighVolt Capacitive Impulse Voltage Dividers 3-61-EnRenato Almache FloresNo ratings yet

- NB - 250-450445 - AS-F1-B-E-BAQE Secondry PumpDocument8 pagesNB - 250-450445 - AS-F1-B-E-BAQE Secondry PumprohitshetyeNo ratings yet

- Short Circuit Detector AcceptabilityDocument15 pagesShort Circuit Detector AcceptabilityRomilyn PiocNo ratings yet

- Performance Analysis of Three Phase Full Bridge Converter Controlled DC MotorDocument45 pagesPerformance Analysis of Three Phase Full Bridge Converter Controlled DC Motoranon_451051243No ratings yet

- Physical Quantities and UnitsCmbDocument22 pagesPhysical Quantities and UnitsCmbManula MuthunayakeNo ratings yet

- Magnetism Section SummaryDocument1 pageMagnetism Section Summaryapi-261954479No ratings yet

- Parallel Operation of DC Generators Homework ProblemsDocument2 pagesParallel Operation of DC Generators Homework ProblemsRyan De GuzmanNo ratings yet

- PitotDocument120 pagesPitotIqnasius MandagiNo ratings yet

- Gauss' Law & Electric PotentialDocument21 pagesGauss' Law & Electric PotentialEliot TrubelNo ratings yet

- Analyze Pipeline Flows & SystemsDocument43 pagesAnalyze Pipeline Flows & SystemsnazreenNo ratings yet

- Physics GR 11 and GR 12 Energy ReviewDocument19 pagesPhysics GR 11 and GR 12 Energy ReviewAN - 12BM 795510 Harold M Brathwaite SSNo ratings yet

- SMT1 Nature of Force KeyDocument2 pagesSMT1 Nature of Force KeyRoan Tapia AntiquenoNo ratings yet