Professional Documents

Culture Documents

7-22196-XX-001 - 1 - C - 00cse

Uploaded by

julio0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

7-22196-XX-001_ 1_C_00CSE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 page7-22196-XX-001 - 1 - C - 00cse

Uploaded by

julioCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

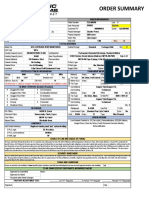

INLET FILTER HOUSE PERFORMANCE DATA SHEET

INLET FILTER HOUSE PERFORMANCE DATA SHEET

DESCRIPTION US units SI units Electrical: Voltage / Load

480 VAC/ 3phase/ 60 Hz/ 80 FLA (Feed for Pneumafil transformer, uncontrolled power

Total Air Flow (@ISO-59) 890,000 cfm 420.03 m3/s Power (Supply) supply, & compressor, not including pumps)

120 VAC / 1Phase / 60 Hz/ 25 FLA (480V to 120 V conversion by Pneumafil

Number of Elements 552 pairs 552 pairs Power & Controls supplied transformer)

Flow per Filter 1612 cfm 2741 m3/hr Alarm 48 VDC/24VDC

Pressure Drop: Pumps (Cooler) (2x7.5 hp) 480 VAC/ 3phase/ 60 Hz/ (22 FLA)

- Hoods, bird screens, eliminators 0.11 in. w.c. 3 mm w.c. Rating NEMA 4

- Pulse Filter 0.89 in. w.c. 23 mm w.c. Material of Construction

- Evaporative Cooler Media 0.36 in. w.c. 9 mm w.c. Hoods Galvaneal

- Eliminators 0.04 in. w.c. 1 mm w.c. Bird Screen Galvanized (1/2" x 1/2" mesh)

- Plenum 0.11 in. w.c. 3 mm w.c. Filter Module Painted Carbon Steel

- Exit 0.22 in. w.c. 6 mm w.c. Clean Air Plenum Painted Carbon Steel

- Inlet duct and silencer 1.80 in. w.c. 46 mm w.c. Platforms (Internal/Ext) Hot dipped Galvanized

Ladders/Handrail Hot dipped Galvanized

- Total Theoretical Pressure Drop 3.53 in. w.c. 90 mm w.c. Structural Steel Hot dipped Galvanized

- Total Guaranteed Pressure Drop 3.60 in. w.c. 91 mm w.c. Cooler Service Area Painted Carbon Steel

Design Data: Cooler Module 304L Stainless steel

- Hood Entrance Velocity 600 fpm 3.05 m/s Cooler piping External - 304L stainless steel; Internal - CPVC Sch. 80

- Filter Face Velocity 550 fpm 2.79 m/s Duct liner Galvanized

- Filter Media Velocity 3.2 fpm 16.25 mm/s Silencer baffles 304 stainless steel

- Max. system pressure drop for 16,000 hours of life of filter elements* 4 in. w.c. 102 mm w.c. Surface Finish

- Evap. Cooler Media Face Velocity 646 fpm 3.28 m/s Carbon Steel Surfaces (except hoods)

Evaporative Cooler Specifications Surface Prep (Internal/External) SSPC SP-10 1-3 mils blast profile

- Saturation Efficiency (Min.) 85%

- Mist Eliminator or Efficiency @ 50 micron particle size & larger 99.90% Prime Coat (Internal/External) Inorganic Zinc Primer, 2-4 mils DFT

- Cycles of Concentration 2

Intermediate / Final (Unlined duct,

- Evaporation Rate 19.2 gpm 72 L/min internal ONLY) Two coats, 2-pack Epoxy, 4-6 mils DFT

- Blowdown Rate 19.2 gpm 72 L/min

- Make up water rate 38.3 gpm 145 L/min

- Customer drain system to be able to handle 400 gpm @ 0 psig

Other

Water Pressure Required 40-90 psi Stainless Steel Surfaces No additional finish

Compressed Air Requirements: Galvanized Surfaces No additional finish

Compressed Air Pressure 100 psig 6.8 atm Filter Media/Type:

Compressed Air Flow 69.0 scfm 117 s m3/hr Pulse Filters cellulose/ synthetic blend

Pulse Air Cycle 20 min 20 min Evaporative Cooler Media Cellulose

Design Criteria: Droplet Eliminator PVC

- NaCl concentration downstream of filter media (ppm by weight) <0.01 Temperature Design Data

- Initial atmospheric dust spot efficiency per ASHRAE 52.1-1992 60% Entering D.B.T. (deg F) 105

New & Clean Filter Media Efficiency @ 5 micron particle size & larger 99.90% Entering R.H. (%) 60%

- New & Clean Filter Media Efficiency @ 2 micron particle size & larger 99.00% Leaving D.B.T. (deg F) 93.52

- Leaving R.H. (%) 92%

Guaranteed Filter Dynamic Insertion Loss @ Octave Band Guaranteed Evaporative Cooler Dynamic Insertion Loss @

31.5 Hz 0 31.5 Hz 0

63 Hz 2 63 Hz 2

125 Hz 4 125 Hz 2

250 Hz 10 250 Hz 1

500 Hz 15 500 Hz 1

1000 Hz 16 1000 Hz 2

2000 Hz 26 2000 Hz 3

4000 Hz 27 4000 Hz 6

8000 Hz 27 8000 Hz 13

Evaporative Cooler Pump Sound Level (A-weighted) requirements

- 3 feet from pump <90 dbA

- 3 feet from filter <80 dBA

Rev Comments Checked DATE Dwg: 7-22196-XX-1 Sht 1 of 3

A Released RBH 1/10/2007 Customer Siemens Power Generation, Inc.

B NO CHANGES TO THIS SHEET RBH 1/26/2007 Project Termozulia II

C NO CHANGES TO THIS SHEET RBH 4/10/2007

You might also like

- RV Generator Set Quiet Gasoline Series RV QG 4000: Specification SheetDocument4 pagesRV Generator Set Quiet Gasoline Series RV QG 4000: Specification Sheetيرشد ممتازNo ratings yet

- Understanding The Nature of ReligionDocument41 pagesUnderstanding The Nature of Religioneden l. abadNo ratings yet

- Design of A Tuned Intake Manifold - H. W. Engelman (ASME Paper 73-WA/DGP-2)Document9 pagesDesign of A Tuned Intake Manifold - H. W. Engelman (ASME Paper 73-WA/DGP-2)david_luzNo ratings yet

- 1992SGSDesignersGuidetoPowerProductsApplicationManual2Ed 1182713547Document1,298 pages1992SGSDesignersGuidetoPowerProductsApplicationManual2Ed 1182713547analog changeNo ratings yet

- Trane Chiller Data Sheet RTHDDocument1 pageTrane Chiller Data Sheet RTHDivyspellNo ratings yet

- Metal Enameling: Arts & CommunicationDocument15 pagesMetal Enameling: Arts & CommunicationAnjali DavidNo ratings yet

- Shock Classification and PathophysiologyDocument40 pagesShock Classification and PathophysiologyErick Anca100% (2)

- Fire and Blast in The Future OffshoreDocument45 pagesFire and Blast in The Future OffshoredrgNo ratings yet

- Thermatrac Air-To-Water Heat Pump Water HeaterDocument15 pagesThermatrac Air-To-Water Heat Pump Water Heatercodefinder100% (1)

- Asta09lccsm PDFDocument19 pagesAsta09lccsm PDFlinmar7071No ratings yet

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Steel Plant Facilities and Process FlowDocument35 pagesSteel Plant Facilities and Process Flowtehseen banuNo ratings yet

- Kellogs Linares Air Handler SpecsDocument14 pagesKellogs Linares Air Handler SpecsAlejandro DuranNo ratings yet

- Units @norm. @max. Zinc Concentrate Process DataDocument1 pageUnits @norm. @max. Zinc Concentrate Process DataCristhian Niño MartinezNo ratings yet

- 38lha 40lha h15 1pd Rev2Document28 pages38lha 40lha h15 1pd Rev2nhatNo ratings yet

- Climaveneta Air Handler Unit - SPDocument7 pagesClimaveneta Air Handler Unit - SPJavier VespaNo ratings yet

- UCCA - UCCA-1 - Consolidated Customer PackageDocument23 pagesUCCA - UCCA-1 - Consolidated Customer PackageVincent Aarón RodríguezNo ratings yet

- Air Cooled Screw Chiller R134aDocument12 pagesAir Cooled Screw Chiller R134aalkaf08No ratings yet

- UCCA - UCCA-2 - Consolidated Customer PackageDocument25 pagesUCCA - UCCA-2 - Consolidated Customer PackageAnderson AlvaradoNo ratings yet

- Saiver SDF BrochureDocument10 pagesSaiver SDF Brochureahmed selimNo ratings yet

- DEWA Specification 01 NPD26XL R LDocument2 pagesDEWA Specification 01 NPD26XL R Lwael72No ratings yet

- GR&BS Fahu EuDocument3 pagesGR&BS Fahu EuMohammad IsmailNo ratings yet

- TX Thermal Dispersion Switch Data SheetDocument5 pagesTX Thermal Dispersion Switch Data SheetROGELIO QUIJANONo ratings yet

- Gradall XL3200Document4 pagesGradall XL3200ediNo ratings yet

- Båtservice Mandal Iran: Air Treatment Unit AccommodationDocument6 pagesBåtservice Mandal Iran: Air Treatment Unit AccommodationhamzehNo ratings yet

- Gas Shutoff Valves: FeaturesDocument136 pagesGas Shutoff Valves: FeaturesJuan BejaranoNo ratings yet

- Specification - Dryer - MDA 1250Document1 pageSpecification - Dryer - MDA 1250jiangshencaoNo ratings yet

- CLCP Customer PackageDocument9 pagesCLCP Customer PackageAlejandroNo ratings yet

- High-Power 12-Inch Midbass DriverDocument2 pagesHigh-Power 12-Inch Midbass DriverDiego PauloNo ratings yet

- Dossier Teca A BDocument20 pagesDossier Teca A Bpeter2002No ratings yet

- Wall Mounted: Split Type Room Air Conditioner TypeDocument18 pagesWall Mounted: Split Type Room Air Conditioner TypeDavid Lemos Sanchez100% (1)

- PRODUCT SHEET - MasterLiquid PL240 FluxDocument2 pagesPRODUCT SHEET - MasterLiquid PL240 FluxPutri AdnyaswariNo ratings yet

- Ciare Hw202 enDocument1 pageCiare Hw202 enAntonelloNo ratings yet

- SHPDDocument32 pagesSHPDManuel Alvarez MNo ratings yet

- Ciare hw202 SpecDocument1 pageCiare hw202 SpecGiorgio De VecchiNo ratings yet

- RF-SJ104L3H-063N04D: CondenserDocument2 pagesRF-SJ104L3H-063N04D: CondenserAndreeaNo ratings yet

- Flier Standard CassetteDocument4 pagesFlier Standard Cassetteeng.abdullrahmanNo ratings yet

- Marketing Brochure Slim Cassette enDocument2 pagesMarketing Brochure Slim Cassette enramsi17No ratings yet

- C Series Spec Sheet Rev HDocument2 pagesC Series Spec Sheet Rev HiyergvNo ratings yet

- CirculationDocument56 pagesCirculationLuis Nahuelhuaique LemusNo ratings yet

- Filter Specifications and DimensionsDocument2 pagesFilter Specifications and DimensionsHanzil HakeemNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- 40-003 Modulating TSSDocument2 pages40-003 Modulating TSSmsajanjNo ratings yet

- Tech.-Data Sheet - UMA-01 - Neolpharma - Esclusas Solidos - CDMX PDFDocument1 pageTech.-Data Sheet - UMA-01 - Neolpharma - Esclusas Solidos - CDMX PDFFrancisco Javier Ramirez MartinezNo ratings yet

- Dividido Trane 30 TonsDocument23 pagesDividido Trane 30 TonsairemexNo ratings yet

- 518 HV SL VFD (ATEX) - Equipment Data Sheet (Rev 06)Document2 pages518 HV SL VFD (ATEX) - Equipment Data Sheet (Rev 06)Gerard HoffardNo ratings yet

- Item No.: Version: 50 HZDocument5 pagesItem No.: Version: 50 HZKamal AliyevNo ratings yet

- Asco Series 210 Gas Shutoff No CatalogDocument2 pagesAsco Series 210 Gas Shutoff No CatalogManuel ParraNo ratings yet

- DSP Split Unit Technical ManualDocument31 pagesDSP Split Unit Technical Manualfarshan296015100% (1)

- RR23243 Salonta GC 2 5mm 35dB FrigotehnicaDocument3 pagesRR23243 Salonta GC 2 5mm 35dB Frigotehnicaandrei.ursuNo ratings yet

- Tomahawk 1538Document1 pageTomahawk 1538Alvaro VillarroelNo ratings yet

- Rotameter Overview PDFDocument8 pagesRotameter Overview PDFSteve Goke AyeniNo ratings yet

- SizingDocument3 pagesSizingheinfongNo ratings yet

- 2023-000092CMP - TechnicalDocument12 pages2023-000092CMP - Technicalinfo.infinitytechnicalNo ratings yet

- Evacuated Tube Collector SpecificationDocument5 pagesEvacuated Tube Collector SpecificationJaswinder SinghNo ratings yet

- Pi 1669PDocument3 pagesPi 1669PmustafaNo ratings yet

- Unit ParametersDocument16 pagesUnit ParametersTrever TomesNo ratings yet

- Catalogue Carrier 39CNEDocument32 pagesCatalogue Carrier 39CNEZahin BasriNo ratings yet

- مواصفات الكابلاتDocument17 pagesمواصفات الكابلاتAdel FawziNo ratings yet

- Asco Series 042 Gas Shutoff CatalogDocument4 pagesAsco Series 042 Gas Shutoff CatalogRoqueNetNo ratings yet

- HF 570 / HF 575 / HF 578 Series: Tank Mounted Return Line FiltersDocument36 pagesHF 570 / HF 575 / HF 578 Series: Tank Mounted Return Line FilterssitnikovsNo ratings yet

- DVM S Eco air conditioner specification summaryDocument3 pagesDVM S Eco air conditioner specification summaryFabian GuapisacaNo ratings yet

- Waterless Eagle Spec SheetDocument1 pageWaterless Eagle Spec SheetMariano PonsNo ratings yet

- Ficha Tecnica Am060hxmdbcDocument3 pagesFicha Tecnica Am060hxmdbcFabian GuapisacaNo ratings yet

- VLM Aire de Planta e InstrumentosDocument1 pageVLM Aire de Planta e InstrumentosJorge RodríguezNo ratings yet

- Science 8-02.02 - Sensitivity in Living OrganismsDocument9 pagesScience 8-02.02 - Sensitivity in Living OrganismsAnoushia AhmerNo ratings yet

- The Picture of Dorian GrayDocument137 pagesThe Picture of Dorian GrayАнгелаС.No ratings yet

- 5020-Article Text-10917-1-10-20220808Document9 pages5020-Article Text-10917-1-10-20220808indah rumah4No ratings yet

- MX 201110 enDocument1,203 pagesMX 201110 envajrahastaNo ratings yet

- Burford-Exam 3 Spring 2018Document6 pagesBurford-Exam 3 Spring 2018api-430812455No ratings yet

- Diagrama 4 AMBIENT AIR TEMPER..Document1 pageDiagrama 4 AMBIENT AIR TEMPER..Gustavo PérezNo ratings yet

- Sample Article Used by MeDocument14 pagesSample Article Used by MeMagnum OpusNo ratings yet

- Management Foreign BodyDocument6 pagesManagement Foreign BodyRahmatia SyukrinaNo ratings yet

- Sliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallDocument4 pagesSliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallAbdul Aziz Julkarnain ZulkifliNo ratings yet

- Differences in Left Ventricular and Left Atrial FuDocument10 pagesDifferences in Left Ventricular and Left Atrial FueugeniaNo ratings yet

- Conduction Calorimetric Investigation of The Effect of Retarders On The Hydration of Portland CementDocument15 pagesConduction Calorimetric Investigation of The Effect of Retarders On The Hydration of Portland CementAlfredo Landaverde GarcíaNo ratings yet

- Erasmus Rotterdam University MCDocument24 pagesErasmus Rotterdam University MCAndreea CroitoruNo ratings yet

- Memorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North CarolinaDocument7 pagesMemorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North Carolinaestela maria dulaganNo ratings yet

- Category D Fluid ServiceDocument2 pagesCategory D Fluid Serviceaslam.ambNo ratings yet

- When Ceramic Sociology Meets Material SCDocument10 pagesWhen Ceramic Sociology Meets Material SCJosé Renato TeixeiraNo ratings yet

- Interpuls Novinki 2014Document64 pagesInterpuls Novinki 2014BaklanovaSVNo ratings yet

- Mañanita Songs Mañanita SongsDocument2 pagesMañanita Songs Mañanita SongsSanchez Bayan100% (1)

- Deskripsi (Caffein)Document4 pagesDeskripsi (Caffein)jibefahlaNo ratings yet

- Musical Siren Project Report Under 40 CharactersDocument10 pagesMusical Siren Project Report Under 40 Charactersvinod kapateNo ratings yet

- Cadence Monte Carlo Simulation TutorialDocument51 pagesCadence Monte Carlo Simulation Tutorialkuomatt100% (1)

- Postmodern EthicsDocument1 pagePostmodern Ethicsgeorge elerickNo ratings yet

- Electronic V-MAC IV Vehicle Mgmt. and Control With Co-Pilot Display Operator ManualDocument133 pagesElectronic V-MAC IV Vehicle Mgmt. and Control With Co-Pilot Display Operator Manualsanach0412No ratings yet