Professional Documents

Culture Documents

CBLM John

Uploaded by

John Buenaagua0 ratings0% found this document useful (0 votes)

6 views5 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views5 pagesCBLM John

Uploaded by

John BuenaaguaCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

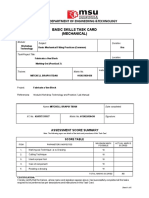

COMPETENCY-BASED LEARNING MATERIALS

SECTOR: METALS AND ENGINEERING

QUALIFICATION: MACHINING NC II

UNIT OF COMPETENCY: TURN WORKPIECE (Intermediate)

MODULE TITLE: TURNING WORKPIECE

PREPARED BY: JOHN D. BUENAAGUA (Instructor I)

List of Competencies

No. Unit of Competency Module Title Code

1. Introduction to Turn and Introduction to Turning and MEE722303

Set the Workpiece Setting the Workpiece

2. Perform Lathe Machine Turn Perform Lathe Machine MEE722303

Operation Turning Operation

Unit of Competency: TURN WORKPIECE (Intermediate)

Module Title: TURNING WORKPIECE

MODULE DESCRIPTION: This module provides a solid foundation in turning

workpiece operations and prepares learners for further skill development in the field of

machining and manufacturing.

NOMINAL DURATION: 80 Hrs.

CERTIFICATION LEVEL: NC II

Soon After completion of this module students/trainees must be able to:

LO 1. Introduction to Turn and Set the Workpiece

ASSESSMENT CRITERIA:

Demonstrates knowledge of lathe machine components and their

functions.

Understands the principles of turning operations, including facing,

turning, boring, and chamfering.

Interprets engineering drawings and work instructions accurately.

Recognizes and applies safety practices related to lathe machine

operations.

CONTENTS:

Workpiece mounting techniques

Selection and installation of cutting tools

Adjusting machine settings for optimal performance

Overview of turning processes and applications

CONDITIONS: The student/trainees must provide the following learning

material.

Workpiece

Drawing plan

Surface gauge

Dial indicator on a magnetic stand

Lathe machine with complete

3 and 4jaw chuck

Lathe center

Drill chuck

Lathe dog

Follower rest

Measuring Tools:

Vernier Caliper

Micrometer

Steel RuleDial Indicator

Surface gauge

Personal Protection Equipment

Safety Shoes

Face shield/Safety goggles

You might also like

- MachinistDocument28 pagesMachinistabyzenNo ratings yet

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- Andromeda Council About The 4th DimensionDocument11 pagesAndromeda Council About The 4th DimensionWonderlust100% (1)

- Workshop & Machineshop Practice Lab Manual: (18MEL38A/48A)Document101 pagesWorkshop & Machineshop Practice Lab Manual: (18MEL38A/48A)MAN MOHAN VATSNo ratings yet

- Apprentice Machinist Curriculum StandardDocument114 pagesApprentice Machinist Curriculum Standardabyzen100% (1)

- Fitter: Syllabus of Semester System For The Trade ofDocument24 pagesFitter: Syllabus of Semester System For The Trade ofkumarNo ratings yet

- The Manning EquationDocument10 pagesThe Manning EquationFederico LeonNo ratings yet

- Metrology ICS Lab Manual A.y-2018-19Document93 pagesMetrology ICS Lab Manual A.y-2018-19chandrarao chNo ratings yet

- Public OpinionDocument7 pagesPublic OpinionSona Grewal100% (1)

- Sand Compaction MethodDocument124 pagesSand Compaction Methodisaych33ze100% (1)

- Metal Cutting and Production LAB Manual-New (ME452)Document58 pagesMetal Cutting and Production LAB Manual-New (ME452)Ravichandran GNo ratings yet

- 01 - PV - RESCO 1d Workshop - S1 PDFDocument61 pages01 - PV - RESCO 1d Workshop - S1 PDFDeasy KurniawatiNo ratings yet

- SMAW Welding GuideDocument3 pagesSMAW Welding GuideOdlnayer Allebram100% (2)

- Gartner CRM Handbook FinalDocument0 pagesGartner CRM Handbook FinalghanshyamdassNo ratings yet

- CTS Technician Mechatronics CTS NSQF-5Document77 pagesCTS Technician Mechatronics CTS NSQF-5Mohammad AbdullahNo ratings yet

- MC MIN-Q0423 Mine-WelderDocument14 pagesMC MIN-Q0423 Mine-Welderdwarka prasadNo ratings yet

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument7 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaNur Aiman NorahimNo ratings yet

- Date: ............................................................(Assistant’s SignatureDocument8 pagesDate: ............................................................(Assistant’s SignatureThaneswaran BaluNo ratings yet

- CNC Lathe Machine Technician and ProgrammerDocument16 pagesCNC Lathe Machine Technician and ProgrammermanjuNo ratings yet

- Manufacturing Technology Lab IDocument41 pagesManufacturing Technology Lab ISudhir KumarNo ratings yet

- Metrology-and-Measurement-Laboratory-Manual ReferenceDocument32 pagesMetrology-and-Measurement-Laboratory-Manual Referencechandrarao chNo ratings yet

- EN21472848_Lathe MachineDocument22 pagesEN21472848_Lathe Machinedissanayakerahul14No ratings yet

- Vee Block - Practical 2Document5 pagesVee Block - Practical 2Mitchell TidanNo ratings yet

- Production Technology (CD)Document7 pagesProduction Technology (CD)ParasNo ratings yet

- Design of Machine ElementDocument11 pagesDesign of Machine ElementAjay Kumar Reddy K100% (1)

- MTT 243 CNC Turning Lab IDocument9 pagesMTT 243 CNC Turning Lab Iwongkw5557No ratings yet

- 3320602Document9 pages3320602Ravi Teja TNo ratings yet

- Mechanical Technician Basic Training-EHAB ABOWARDA-olDocument2 pagesMechanical Technician Basic Training-EHAB ABOWARDA-olehabwardaNo ratings yet

- CMM 2Document22 pagesCMM 2Mr CupuNo ratings yet

- MC CSCQ0202 v2.0 Asst MMAWDocument20 pagesMC CSCQ0202 v2.0 Asst MMAWARUNKUMAR PMCNo ratings yet

- Machining Science: Jigs & FixturesDocument29 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Vee Block - LAB 1Document6 pagesVee Block - LAB 1Mitchell TidanNo ratings yet

- AAiT Machine Elements Design CourseDocument2 pagesAAiT Machine Elements Design CourseWolelaw FikaduNo ratings yet

- Annexure 1 Shaikh EENDocument3 pagesAnnexure 1 Shaikh EENtejasgaminghubNo ratings yet

- R16 B.Tech Mechanical EnggDocument34 pagesR16 B.Tech Mechanical EnggmechhodNo ratings yet

- MACHINING WORKSHOP REPORT 2Document17 pagesMACHINING WORKSHOP REPORT 2Harith DanialNo ratings yet

- Machine Tools LabDocument85 pagesMachine Tools Labmohammad sammeerNo ratings yet

- MC512 Mechanical Drawing IIDocument2 pagesMC512 Mechanical Drawing IIEduardo RNo ratings yet

- Amp MicroprojectDocument16 pagesAmp MicroprojectishantNo ratings yet

- RTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TDocument27 pagesRTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TxaloliNo ratings yet

- PDFDocument13 pagesPDFShlok PatelNo ratings yet

- Sem1WorkShop PDFDocument8 pagesSem1WorkShop PDFGuddu RajputNo ratings yet

- MechatronicsDocument36 pagesMechatronicsThusith WijayawardenaNo ratings yet

- Index: 3351903 Manufacturing Engineering-IiiDocument14 pagesIndex: 3351903 Manufacturing Engineering-Iiimer sanjayNo ratings yet

- Fabricator CurriculumDocument20 pagesFabricator CurriculumRodzNo ratings yet

- MCNC 75C CNC Lathes & Horizontal Machining Centers Programming & Operation, 4th Rotary Axis, Fixture Design 4 1/2 Unit(s)Document4 pagesMCNC 75C CNC Lathes & Horizontal Machining Centers Programming & Operation, 4th Rotary Axis, Fixture Design 4 1/2 Unit(s)taher ncirNo ratings yet

- Revised MN 201 Manufacturing Processes Lab Manual-1 PDFDocument45 pagesRevised MN 201 Manufacturing Processes Lab Manual-1 PDFHemanth GedelaNo ratings yet

- Amitwa ReportDocument29 pagesAmitwa ReportshankarNo ratings yet

- Mce 211 Course Compact 2018 2019 SessionDocument9 pagesMce 211 Course Compact 2018 2019 SessionKEHINDE BABALOLANo ratings yet

- GTU DE Sem 5 Report SampleDocument36 pagesGTU DE Sem 5 Report Samplerupamsoni11No ratings yet

- Super Mill ManualDocument77 pagesSuper Mill Manualshantanu kadamNo ratings yet

- 6.3 Program Diploma in Mechanical Engineering (DKM) : 6.3.1 Programme Overview SynopsisDocument53 pages6.3 Program Diploma in Mechanical Engineering (DKM) : 6.3.1 Programme Overview SynopsisRevathi Rethnam0% (1)

- Machining Science: Jigs & FixturesDocument29 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Lecture 2 (Fitting Shop Tools)Document4 pagesLecture 2 (Fitting Shop Tools)Mahtab IlyasNo ratings yet

- Manufacturing Processes II Year B.E. (Mechanical EnggDocument2 pagesManufacturing Processes II Year B.E. (Mechanical EnggRohan NewaskarNo ratings yet

- PDFDocument5 pagesPDFNamdev dhanawdeNo ratings yet

- Mechanical Engineering Technology Program Overview (39Document8 pagesMechanical Engineering Technology Program Overview (39A SNo ratings yet

- PDFDocument11 pagesPDFjaniirNo ratings yet

- PEC-IVDocument6 pagesPEC-IV3111hruthvikNo ratings yet

- Djj10022 - Mechanical Workshop Practice 1 Workshop Report (Machining)Document12 pagesDjj10022 - Mechanical Workshop Practice 1 Workshop Report (Machining)Aiman AzaharNo ratings yet

- Cad Cam Lab R17a0388 - MallarDocument87 pagesCad Cam Lab R17a0388 - MallardeepakNo ratings yet

- CMU Workshop Processes GuideDocument8 pagesCMU Workshop Processes GuideGavaine MattisonNo ratings yet

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- CNC TrainingDocument19 pagesCNC TrainingMahipal Singh RanawatNo ratings yet

- Bài Tập Phần Project ManagementDocument11 pagesBài Tập Phần Project ManagementhunfgNo ratings yet

- Reprocessing Guide: Shaver Handpiece TrayDocument198 pagesReprocessing Guide: Shaver Handpiece TrayAnne Stephany ZambranoNo ratings yet

- Addressable Fire Detection and Control Miniplex TranspondersDocument8 pagesAddressable Fire Detection and Control Miniplex TranspondersAfdhal SyahrullahNo ratings yet

- Business Judgment Rule and Directors' Duty to Inform in Smith v Van GorkomDocument1 pageBusiness Judgment Rule and Directors' Duty to Inform in Smith v Van GorkomDorothy ParkerNo ratings yet

- Power System Analysis and Design, SI EditionDocument5 pagesPower System Analysis and Design, SI EditionAkimeNo ratings yet

- MKTG 2126 - Assignment 3Document2 pagesMKTG 2126 - Assignment 3omar mcintoshNo ratings yet

- SMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014Document15 pagesSMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014vivek kumarNo ratings yet

- Malabsorption and Elimination DisordersDocument120 pagesMalabsorption and Elimination DisordersBeBs jai SelasorNo ratings yet

- Rustom Shams PDFDocument48 pagesRustom Shams PDFmtaha85No ratings yet

- Material Safety Data Sheet Surfacecool© Roof CoatingDocument3 pagesMaterial Safety Data Sheet Surfacecool© Roof CoatingPremfeb27No ratings yet

- 02 1 Cohen Sutherland PDFDocument3 pages02 1 Cohen Sutherland PDFSarra AnitaNo ratings yet

- MMME 21 1st Long Exam Lecture NotesDocument74 pagesMMME 21 1st Long Exam Lecture NotesGraver lumiousNo ratings yet

- Cebuano LanguageDocument15 pagesCebuano LanguageIsla PageNo ratings yet

- The Beggar's Opera by Gay, John, 1685-1732Document50 pagesThe Beggar's Opera by Gay, John, 1685-1732Gutenberg.orgNo ratings yet

- Mla 8 Mla Citation PageDocument4 pagesMla 8 Mla Citation Pageapi-458274061No ratings yet

- M.Sc. Agriculture (Agronomy)Document23 pagesM.Sc. Agriculture (Agronomy)Abhishek MauryaNo ratings yet

- Introduction To Drug DiscoveryDocument45 pagesIntroduction To Drug Discoveryachsanuddin100% (5)

- Lecture01 PushkarDocument27 pagesLecture01 PushkarabcdNo ratings yet

- Olt CliDocument2 pagesOlt CliMohammad SaeedNo ratings yet

- Sem Iii Sybcom Finacc Mang AccDocument6 pagesSem Iii Sybcom Finacc Mang AccKishori KumariNo ratings yet

- Setup LogDocument77 pagesSetup Loganon-261766No ratings yet

- Deutsche BankDocument4 pagesDeutsche BankMukesh KumarNo ratings yet

- PathFit 1 (Lessons)Document10 pagesPathFit 1 (Lessons)Patawaran, Myka R.No ratings yet

- Retrenchment StrategiesDocument3 pagesRetrenchment StrategiesSABRI AKBAL MOHAMED HASSAN100% (3)