Professional Documents

Culture Documents

Materials Required For Stressing Prestressed Girders or Slabs

Uploaded by

hariom singh chaudharyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials Required For Stressing Prestressed Girders or Slabs

Uploaded by

hariom singh chaudharyCopyright:

Available Formats

MATERIALS REQUIRED FOR STRESSING - PRESTRESSED GIRDERS or SLABS

I. Materials required before Stressing activity:

Description Quantity Application Specific brand/

company

1 Stressing Jacks 2 Nos. per Duct (if both ends stressing)

2 Wedges Depends on Nos. of Strands

3 Master Wedges Depends on Nos. of Strands Will be in Jacks

4 Wax For applying on Wedges.

5 Bearing Plates

a) End plates 2 Nos. per Duct. (will be permanenetly embedded in

Girder/ Slab)

b) Collar Plates 2 Nos. per Duct. (temporary to be placed between Locking

plate and End Bearing plate)

c) Locking Plates 2 Nos. per Duct. (temporary to be placed inside Stressing

Jacks)

6 Power Pack/ Pump 2 Nos. per Duct (if both ends stressing) to supply power to Jacks

7 Chain Pulley arrangement 2 Nos. per Duct. to hold Jacks in place.

8 3-Phase power supply 1 No. Generator

9 GI Pipe 2 Nos. per Duct. L=0.8 to 1.0m (each) to fix Wedges in Bearing plates.

Dia. of GI pipe will be more than the dia. of

Strands.

Eg.: For Strand of 12.7mm dia. = GI pipe Dia. =

20mm.

10 Measuring scales - Steel 2 Nos. per Duct, 30cm each to measure elongation of cables.

11 Scaffolding for Jacks 2 Nos. per Duct. to hold Chain Pulley and Jacks in place.

12 Calculation Sheet

13 Jack RAM Area Vendor's supply.

14 Calibration certificate Jack and Dial Gauge of Power Pack Vendor's supply.

15 Petrol 2 Litres to clean Wedges and Bearing plates.

16 Vice to clean Wedges and Bearing plates.

17 Spanner Size :- 18-19; 19-20; (Each) to tighten the pipe connection between

Jack and Power Pack.

18 Marker 2 Nos. to measure Slips in Strands

19 Hydraulic Oil 60/80 grade; 10 Litres In case of Emergency

Material_Reqd_4_Stressing file:///conversion/tmp/activity_task_scratch/676401665.xlsx

You might also like

- Mfg. Of: LT Panel, APFC, AMF, PCC, MCC, Street Light Panel, High Mast Panel, Automation PanelDocument5 pagesMfg. Of: LT Panel, APFC, AMF, PCC, MCC, Street Light Panel, High Mast Panel, Automation PanelRajesh PatelNo ratings yet

- An RambTel Monopole Presentation 280111Document29 pagesAn RambTel Monopole Presentation 280111Timmy SurarsoNo ratings yet

- Observed Construction Productivity Norms: Crude & Hydrotreating ComplexDocument2 pagesObserved Construction Productivity Norms: Crude & Hydrotreating Complexprasobh911No ratings yet

- 2-Basic Engineering Calculations - (AMOCO) Drilling Fluids ManDocument48 pages2-Basic Engineering Calculations - (AMOCO) Drilling Fluids ManEmad JamshidiNo ratings yet

- Cs of Clarification System With Filtration System at Feni River ...Document24 pagesCs of Clarification System With Filtration System at Feni River ...Tusher SahaNo ratings yet

- 132KV Plant BoQ-R1Document36 pages132KV Plant BoQ-R1Vamsi ManojNo ratings yet

- P394 WindActions PDFDocument32 pagesP394 WindActions PDFzhiyiseowNo ratings yet

- Electrical Distribution in Papermills: Monographs on Paper and Board MakingFrom EverandElectrical Distribution in Papermills: Monographs on Paper and Board MakingRating: 2 out of 5 stars2/5 (1)

- Environment PlanDocument13 pagesEnvironment Planhariom singh chaudhary100% (1)

- Deed of Assignment CorporateDocument4 pagesDeed of Assignment CorporateEric JayNo ratings yet

- Ele. Supply Boq For Taqa NeyveliDocument1 pageEle. Supply Boq For Taqa NeyvelitechbhaskarNo ratings yet

- TB8102 Rupture Disc SizingDocument9 pagesTB8102 Rupture Disc SizingtuimeqNo ratings yet

- J0231 HV TR - FINAL变压器1Document23 pagesJ0231 HV TR - FINAL变压器1SerhiiNo ratings yet

- Office Storage GuideDocument7 pagesOffice Storage Guidebob bobNo ratings yet

- K. Ramachandra Rao Transmission & Projects Pvt. LTD.: Details of Vehicles and Tools & PlantsDocument3 pagesK. Ramachandra Rao Transmission & Projects Pvt. LTD.: Details of Vehicles and Tools & PlantsDilip KumarNo ratings yet

- Potter Signal 5401206 - VSRSDocument3 pagesPotter Signal 5401206 - VSRSJulio Cabrera RuizNo ratings yet

- Individual Cassette BOQDocument5 pagesIndividual Cassette BOQabdul.qhaviNo ratings yet

- 견적서 수정본-1Document21 pages견적서 수정본-1darkkaizer23No ratings yet

- ALL TRADES Tools and Equp InfoDocument148 pagesALL TRADES Tools and Equp Infooutreach constructionsNo ratings yet

- Guaranteed Technical Particulars For Disc Insulators Units:: Page 1 of 3Document7 pagesGuaranteed Technical Particulars For Disc Insulators Units:: Page 1 of 3Saptarshi ChatterjeeNo ratings yet

- Doreen, Synchronization Panel and ATS 19 - 12 - 22-1Document3 pagesDoreen, Synchronization Panel and ATS 19 - 12 - 22-1sabujNo ratings yet

- Cahtodic Protection SystemDocument31 pagesCahtodic Protection SystemPhan Cao An TruongNo ratings yet

- RTTS Model 2 Circulating Valves: SectionDocument18 pagesRTTS Model 2 Circulating Valves: SectionMohamed ShafieNo ratings yet

- Cost Estimate: 3000/4000 K CRIDocument6 pagesCost Estimate: 3000/4000 K CRIMi YaNo ratings yet

- 4NF20L STMicroelectronics PDFDocument12 pages4NF20L STMicroelectronics PDFTiago eletrônicaNo ratings yet

- (10.08 KW On-Grid) ProposalDocument12 pages(10.08 KW On-Grid) ProposalSyed Muhammad BadarNo ratings yet

- Infenion MosfetDocument15 pagesInfenion MosfetkhumarpraveenNo ratings yet

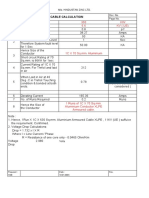

- Cable CalculationDocument1 pageCable CalculationAbhishek SinhaNo ratings yet

- Itx Max: Home Broadcast Tube Am Transmitter KitDocument8 pagesItx Max: Home Broadcast Tube Am Transmitter KitA Daniel LazarescuNo ratings yet

- Unit 5Document7 pagesUnit 5ATHARV SEVATKARNo ratings yet

- Beam Power TubeDocument8 pagesBeam Power TubePalmNo ratings yet

- Summary of Calculation: Pt. Kartini UtamaDocument3 pagesSummary of Calculation: Pt. Kartini UtamaDianWidodoNo ratings yet

- BailDocument2 pagesBailPrabhat Kumar SonyNo ratings yet

- Infineon IPN80R2K0P7 DS v02 - 01 EN 1137753Document14 pagesInfineon IPN80R2K0P7 DS v02 - 01 EN 1137753oral grootNo ratings yet

- General Electrical Notes:: LegendsDocument1 pageGeneral Electrical Notes:: LegendsemchoongNo ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- Price Bid For Lattice StructureDocument16 pagesPrice Bid For Lattice Structuresouvikbesu89No ratings yet

- Mel346 16Document33 pagesMel346 16ch301202jdocsNo ratings yet

- 2 Ends PP FDY-210317Document18 pages2 Ends PP FDY-210317Audop CompanyNo ratings yet

- BGCL - Vol II of IIDocument22 pagesBGCL - Vol II of IISuresh ChaudharyNo ratings yet

- STGF 10 NC 60 KDDocument30 pagesSTGF 10 NC 60 KDFonos ServisNo ratings yet

- Solstice Legacy DocumentationDocument6 pagesSolstice Legacy DocumentationRicardo MartNo ratings yet

- Wsp32ga - 400 P 131152 e 00Document4 pagesWsp32ga - 400 P 131152 e 00Eng-Mohammed SalemNo ratings yet

- Upper Phawa - Pending WorksDocument2 pagesUpper Phawa - Pending WorksAbhideep AdhikariNo ratings yet

- Mosfet: Powermanagement&MultimarketDocument17 pagesMosfet: Powermanagement&MultimarketAnjum MahmoodNo ratings yet

- Proportional Pressure Relief Valve Screw-In Cartridge - Direct Operated - Q 8 L/min - P 400 Bar - P 315 BarDocument2 pagesProportional Pressure Relief Valve Screw-In Cartridge - Direct Operated - Q 8 L/min - P 400 Bar - P 315 BarDavidson GattoniNo ratings yet

- Obsolete Product (S) - Obsolete Product (S) : N-Channel 60 V, 1.8, 0.35 A, Sot23-3L, To-92 Stripfet™ Power MosfetDocument14 pagesObsolete Product (S) - Obsolete Product (S) : N-Channel 60 V, 1.8, 0.35 A, Sot23-3L, To-92 Stripfet™ Power MosfetCarlo MeloniNo ratings yet

- Apl Flow HBPL-17 OrificeDocument1 pageApl Flow HBPL-17 OrificeflowdewiceNo ratings yet

- STB33N60DM2 STMicroelectronicsDocument20 pagesSTB33N60DM2 STMicroelectronicsMateus BelettiNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument7 pagesPDF Created With Pdffactory Pro Trial Versionwaveengg.coNo ratings yet

- Stn3Nf06L: N-Channel 60 V, 0.07 Ω Typ., 4 A Stripfet™ Ii Power Mosfet In A Sot-223 PackageDocument12 pagesStn3Nf06L: N-Channel 60 V, 0.07 Ω Typ., 4 A Stripfet™ Ii Power Mosfet In A Sot-223 Packageramesh sahukhalNo ratings yet

- Tender Specifications and GTP-SP 854Document19 pagesTender Specifications and GTP-SP 854aumgmoe chanNo ratings yet

- Makita 488DDocument64 pagesMakita 488DStéphane MedardNo ratings yet

- Mass Fusion Splicer: Designed To Keep You GoingDocument8 pagesMass Fusion Splicer: Designed To Keep You GoingFernando CalderonNo ratings yet

- IPD60R360P7 InfineonDocument14 pagesIPD60R360P7 InfineonJimmy Varela TraderNo ratings yet

- Lampiran IK Ropa Maumere LanjutanDocument2 pagesLampiran IK Ropa Maumere Lanjutanfarizal ibnuNo ratings yet

- Observed Construction Productivity Norms: Crude & Hydrotreating ComplexDocument1 pageObserved Construction Productivity Norms: Crude & Hydrotreating Complexprasobh911No ratings yet

- TS Transformers Product CatalogueDocument17 pagesTS Transformers Product CatalogueShawkat HossainNo ratings yet

- IMG - 0195 PSME Code 2008 184Document1 pageIMG - 0195 PSME Code 2008 184rii amosNo ratings yet

- PNP Silicon Surface Mount Transistor With Monolithic Bias Resistor NetworkDocument10 pagesPNP Silicon Surface Mount Transistor With Monolithic Bias Resistor Networkyesid velasco ninaNo ratings yet

- Sl. No. Items Unit Tender Specification Tenderer ComplianceDocument2 pagesSl. No. Items Unit Tender Specification Tenderer ComplianceRushikiesh JoshNo ratings yet

- Divine Fuzz Building Instructions V1.0Document7 pagesDivine Fuzz Building Instructions V1.0ultratumbaNo ratings yet

- Francis Critical Spare ListDocument2 pagesFrancis Critical Spare Listalok yadavNo ratings yet

- MXR Envelope Filter Kit Building ManualDocument10 pagesMXR Envelope Filter Kit Building ManualRama MamethNo ratings yet

- Ratnesh Kumar CV May 2023Document4 pagesRatnesh Kumar CV May 2023hariom singh chaudharyNo ratings yet

- RMC Plant 33+200 Plant No 23 Apr 2022Document10 pagesRMC Plant 33+200 Plant No 23 Apr 2022hariom singh chaudharyNo ratings yet

- Concrete Core TestDocument1 pageConcrete Core Testhariom singh chaudharyNo ratings yet

- 0276 RMM1Document1 page0276 RMM1hariom singh chaudharyNo ratings yet

- Sand GradationDocument6 pagesSand Gradationhariom singh chaudharyNo ratings yet

- Acceptance Criteria For Cube Test Result As Per IS 456 2000 AmndDocument2 pagesAcceptance Criteria For Cube Test Result As Per IS 456 2000 Amndhariom singh chaudharyNo ratings yet

- ControlDocument3 pagesControlhariom singh chaudharyNo ratings yet

- Traffic Management PlanDocument6 pagesTraffic Management Planhariom singh chaudharyNo ratings yet

- Traffic Management Plan JaipurDocument8 pagesTraffic Management Plan Jaipurhariom singh chaudharyNo ratings yet

- Form Three Physics Handbook-1Document94 pagesForm Three Physics Handbook-1Kisaka G100% (1)

- BSCSE at UIUDocument110 pagesBSCSE at UIUshamir mahmudNo ratings yet

- Reference Template For Feasibility Study of PLTS (English)Document4 pagesReference Template For Feasibility Study of PLTS (English)Herikson TambunanNo ratings yet

- Ts Us Global Products Accesories Supplies New Docs Accessories Supplies Catalog916cma - PDFDocument308 pagesTs Us Global Products Accesories Supplies New Docs Accessories Supplies Catalog916cma - PDFSRMPR CRMNo ratings yet

- Rebar Coupler: Barlock S/CA-Series CouplersDocument1 pageRebar Coupler: Barlock S/CA-Series CouplersHamza AldaeefNo ratings yet

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationDocument27 pagesAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfNo ratings yet

- TSB 120Document7 pagesTSB 120patelpiyushbNo ratings yet

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDocument1 pageMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNo ratings yet

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDocument27 pagesSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunNo ratings yet

- Rating SheetDocument3 pagesRating SheetShirwin OliverioNo ratings yet

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamNo ratings yet

- 1 PBDocument14 pages1 PBSaepul HayatNo ratings yet

- Blade Torrent 110 FPV BNF Basic Sales TrainingDocument4 pagesBlade Torrent 110 FPV BNF Basic Sales TrainingMarcio PisiNo ratings yet

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiNo ratings yet

- Microsoft Word - Claimants Referral (Correct Dates)Document15 pagesMicrosoft Word - Claimants Referral (Correct Dates)Michael FourieNo ratings yet

- SCDT0315 PDFDocument80 pagesSCDT0315 PDFGCMediaNo ratings yet

- Apm p5 Course NotesDocument267 pagesApm p5 Course NotesMusumbulwe Sue MambweNo ratings yet

- 48 Volt Battery ChargerDocument5 pages48 Volt Battery ChargerpradeeepgargNo ratings yet

- MSDS - Tuff-Krete HD - Part DDocument6 pagesMSDS - Tuff-Krete HD - Part DAl GuinitaranNo ratings yet

- Brochure Ref 670Document4 pagesBrochure Ref 670veerabossNo ratings yet

- L1 L2 Highway and Railroad EngineeringDocument7 pagesL1 L2 Highway and Railroad Engineeringeutikol69No ratings yet

- Week 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student HandoutDocument3 pagesWeek 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student Handoutdwkwhdq dwdNo ratings yet

- Lab 6 PicoblazeDocument6 pagesLab 6 PicoblazeMadalin NeaguNo ratings yet

- IPO Ordinance 2005Document13 pagesIPO Ordinance 2005Altaf SheikhNo ratings yet

- PFI High Flow Series Single Cartridge Filter Housing For CleaningDocument2 pagesPFI High Flow Series Single Cartridge Filter Housing For Cleaningbennypartono407No ratings yet

- Elastic Modulus SFRCDocument9 pagesElastic Modulus SFRCRatul ChopraNo ratings yet