Professional Documents

Culture Documents

Batch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022

Uploaded by

gauravOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022

Uploaded by

gauravCopyright:

Available Formats

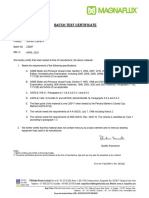

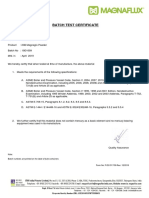

BATCH TEST CERTIFICATE

Date : 22/07/2022

Product : SKL – SP1

Batch No : 22G27

Mfd. in : JULY 2022

We hereby certify that when tested at time of manufacture, the above material:

1. Meets the requirements of the following specifications:

A. ASME Boiler and Pressure Vessel Code, 2004, 2007, 2010, 2013, 2015, 2017,2019 and 2021 Edition,

Section V, Nondestructive Examination, including 2005, 2006, 2008, 2009b, and 2011a Addenda, Article

6 Paragraph T-641 and Article 24 as applicable.

B. ASME Boiler and Pressure Vessel Code, 1995, 1998 and 2001 Edition, Section V Nondestructive

Examination, including 1999, 2000, 2002 and 2003 Addenda, Article 6 Paragraph T-640 and

Article 24 as applicable.

C. ASME Boiler and Pressure Vessel Code, 1986, 1989 and 1992 Edition, Section V , Nondestructive

Examination, Article 6 including 1992 Addenda, Paragraph T-625, 1993 Addenda Paragraph T-640

and Article 24 as applicable.

D. ASTM E-165-92, ASTME-165-94, ASTM E-165-95, ASTM E-165-02,ASTM E-165-09, ASTM E-165/E-

165M-12, ASTM-165/E-165M-18, Paragraph 7.1,

E. ASTM E 1417, Paragraph 5.1.

2. Meets the requirements of NUCLEAR POWER CORPORATION OF INDIA for materials for Dye penetrant

Inspection process.

The following test results were obtained:

1. Sulphur : <25 ppm

2. Total Chlorine + Fluorine : <25 ppm

3. Cleaner residue (see note 2) : NA g/100g

Penetrant Tests:

Flash Point (PMCC) : >93 ºC

Viscosity, ( cs. Nominal) : 3.14 cST @100º F

Water Tolerance NA

Removability, : PASS .

3. We further certify that this material does not contain mercury as a basic element and no mercury bearing

equipment was used in its manufacture.

Quality Assurance

Notes:

1. Batch numbers are printed on the base of aerosol cans and bulk containers

2. The above certification gives the results obtained at the time of manufacture. Age and use may alter the properties of any material

Form No: F/QC/008/13 Rev: 05/2022

You might also like

- 18M02Document1 page18M02Shahnawaz PathanNo ratings yet

- Batch Test Certificate: Notes: 1. Batch Numbers Are Printed On The Base of Aerosol Cans and Bulk Containers 2Document1 pageBatch Test Certificate: Notes: 1. Batch Numbers Are Printed On The Base of Aerosol Cans and Bulk Containers 2அன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022gauravNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificatevinothNo ratings yet

- SP 10 2309021Document1 pageSP 10 2309021Omkar PrindavankarNo ratings yet

- SD 30 2402064Document1 pageSD 30 2402064Omkar PrindavankarNo ratings yet

- SC-20 2308061Document1 pageSC-20 2308061Omkar PrindavankarNo ratings yet

- Batch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019Document2 pagesBatch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019அன்புடன் அஸ்வின்No ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022gauravNo ratings yet

- Batch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018Document2 pagesBatch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018sanjayprakash1979No ratings yet

- Batch Test Certificate: Less Than 0.0025 Less Than 0.0025Document3 pagesBatch Test Certificate: Less Than 0.0025 Less Than 0.0025venkiNo ratings yet

- 08E17KDocument2 pages08E17KRonny AndalasNo ratings yet

- PT Test CertificateDocument2 pagesPT Test Certificateஅன்புடன் அஸ்வின்No ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- Spotcheck Penetrant SKD-S2: CertificationDocument4 pagesSpotcheck Penetrant SKD-S2: CertificationIvan Morales AguilarNo ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Spotcheck, SKC-S: CertificationDocument3 pagesSpotcheck, SKC-S: Certificationnasser saldaña quinteroNo ratings yet

- 19C01K SKC-SDocument3 pages19C01K SKC-ScamodiNo ratings yet

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificateStructures ProductionNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificatevenkiNo ratings yet

- Certificado Liquidos PenetrantesDocument4 pagesCertificado Liquidos PenetrantesJaneth AguilarNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test Certificatenayan vyasNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: CertificationcamodiNo ratings yet

- Revelador 19C18K - SKD-S2Document4 pagesRevelador 19C18K - SKD-S2Ivan Morales AguilarNo ratings yet

- Batch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019Document3 pagesBatch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019அன்புடன் அஸ்வின்No ratings yet

- Certification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Document3 pagesCertification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Pilar MedranoNo ratings yet

- Batch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023Document3 pagesBatch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023venkiNo ratings yet

- Certificado Liquidos PenetrantesDocument3 pagesCertificado Liquidos PenetrantesEnrique AntonioNo ratings yet

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- Spotcheck Penetrant, SKL-SP2: CertificationDocument3 pagesSpotcheck Penetrant, SKL-SP2: CertificationCarlos Eduardo Alvarez SantiagoNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: Certificationjcarlos7411No ratings yet

- Batch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Document2 pagesBatch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Structures ProductionNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- 18a18k Zyglo ZP 9fDocument3 pages18a18k Zyglo ZP 9fJhon Eder OrozcoNo ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- P-005 Liquid Penetant Testing ProcedureDocument13 pagesP-005 Liquid Penetant Testing ProcedureSaheb YadavNo ratings yet

- Batch Test Certificate: Batch Numbers Are Printed On The Label of Bulk ContainersDocument2 pagesBatch Test Certificate: Batch Numbers Are Printed On The Label of Bulk Containersஅன்புடன் அஸ்வின்No ratings yet

- BS 476 Part 6 - Test Report - KCL-unlockedDocument6 pagesBS 476 Part 6 - Test Report - KCL-unlockedArmağan DemirelNo ratings yet

- ASTM D2272-09 - Oxidation StabilityDocument19 pagesASTM D2272-09 - Oxidation StabilityDr. Minhaj Uddin MonirNo ratings yet

- Def Stan 80-34 Issue 1995Document17 pagesDef Stan 80-34 Issue 1995Said AdingniNo ratings yet

- Gambian Petroleum Products StandardsDocument33 pagesGambian Petroleum Products StandardsSerge KohemunNo ratings yet

- Batch Test Certificate: Batch Numbers Are Printed On The Base of Bulk ContainersDocument1 pageBatch Test Certificate: Batch Numbers Are Printed On The Base of Bulk Containersஅன்புடன் அஸ்வின்No ratings yet

- Def Stan 91-71-2001 OX-165Document20 pagesDef Stan 91-71-2001 OX-165Rain HeinNo ratings yet

- 11k19k Skl-sp2 CertificadoDocument2 pages11k19k Skl-sp2 CertificadoEduardo Isla Millar100% (1)

- 1492-400-05-1120-DUBL-CHEK DP-50 (Aerosol)Document1 page1492-400-05-1120-DUBL-CHEK DP-50 (Aerosol)Izuddin AzmiNo ratings yet

- Engine Oil Volatility Noack Evaporation MethodDocument5 pagesEngine Oil Volatility Noack Evaporation MethodAvinash Gamit100% (1)

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Document4 pagesPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificateBhavin SukhadiyaNo ratings yet

- Astm D - 127Document2 pagesAstm D - 127wjawichNo ratings yet

- 22B21 2Document1 page22B21 2vinothNo ratings yet

- Oxidation Stability of Lubricating Greases by The Oxygen Pressure Vessel MethodDocument5 pagesOxidation Stability of Lubricating Greases by The Oxygen Pressure Vessel MethodROHITNo ratings yet

- Adco - Dodsal - Welspun: Inspection ReportDocument6 pagesAdco - Dodsal - Welspun: Inspection ReportejazalmNo ratings yet

- Date: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17KDocument2 pagesDate: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17Kisraelita77671No ratings yet

- Revised PM Is 12786 August 2020Document8 pagesRevised PM Is 12786 August 2020Mahesh YadavNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Calificacion de Soldadores BARLUM PDFDocument6 pagesCalificacion de Soldadores BARLUM PDFAnonymous Rn3IlRsKVNo ratings yet

- Steps in The Design of Pressure VesselsDocument2 pagesSteps in The Design of Pressure VesselsKirubelNo ratings yet

- Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocument12 pagesWelding of CrMo Steels For Power Generation and Petrochemical ApplicationsDries Vandezande100% (1)

- ASM Metals HandBook Volume 4 - Heat TreatingDocument15 pagesASM Metals HandBook Volume 4 - Heat TreatingK.s. Raghavendra KumarNo ratings yet

- B2020-TDC-DEF-005 Dished End Forming R0Document2 pagesB2020-TDC-DEF-005 Dished End Forming R0Ramalingam PrabhakaranNo ratings yet

- Appendix G. Fire Protection Guidelines For New Projects: Chevron Corporation G-1 January 1997Document68 pagesAppendix G. Fire Protection Guidelines For New Projects: Chevron Corporation G-1 January 1997milecsaNo ratings yet

- Articoli API 610 9 EditDocument26 pagesArticoli API 610 9 EditmariasofiarossiNo ratings yet

- Asme B31.3Document64 pagesAsme B31.3LambertWayne50% (2)

- IntegriWISE Eflyer 2-10Document2 pagesIntegriWISE Eflyer 2-10Benjamin PrattNo ratings yet

- Design Operations-And-maintenance-friendly Pressure Vessels-Part 2Document5 pagesDesign Operations-And-maintenance-friendly Pressure Vessels-Part 2chemsac2100% (1)

- Netting Analysis of Composite Pressure VesselsDocument3 pagesNetting Analysis of Composite Pressure VesselsPratyu Ch100% (1)

- Pentair-CH31153 Data Sheet PDFDocument4 pagesPentair-CH31153 Data Sheet PDFCalidadUMVNo ratings yet

- Data Sheet For Cooling TowerDocument22 pagesData Sheet For Cooling TowerJetul PatelNo ratings yet

- PSV CatalogDocument60 pagesPSV Catalogbuler empatsatuduaNo ratings yet

- AS1548-PT49ON August2009bDocument3 pagesAS1548-PT49ON August2009bsalamrefighNo ratings yet

- API 653 Above Ground Storage Tank InspectionDocument5 pagesAPI 653 Above Ground Storage Tank InspectionalgoreNo ratings yet

- Nioec SP-50-05Document47 pagesNioec SP-50-05er534ytNo ratings yet

- Fired and Unfired Pressure VesselsDocument33 pagesFired and Unfired Pressure VesselsAd Man GeTigNo ratings yet

- Fatigue Analysis ThesisDocument17 pagesFatigue Analysis ThesisIdris SiddiquiNo ratings yet

- Hydrogen Codes and Standards Workshop: Naser ChowdhuryDocument24 pagesHydrogen Codes and Standards Workshop: Naser ChowdhuryDiana DhominicNo ratings yet

- Dot 192 Full StandardDocument133 pagesDot 192 Full StandardWilmer EgeaNo ratings yet

- VBATDocument23 pagesVBATIsaias NigthNo ratings yet

- Previews Comp Guide To BPVC 3ED Vol 1 Pre PDFDocument72 pagesPreviews Comp Guide To BPVC 3ED Vol 1 Pre PDFOscar Franco MNo ratings yet

- 8495 Simple+Stresses Thin+WalledDocument18 pages8495 Simple+Stresses Thin+WalledLencie Dela CruzNo ratings yet

- Stress Analysis of Pressure Vessel Nozzle Using Fea IJERTCONV6IS16004Document6 pagesStress Analysis of Pressure Vessel Nozzle Using Fea IJERTCONV6IS16004Kingston RivingtonNo ratings yet

- (Gulf) Piping Stress Handbook - Part.1 (V.helguero - 2nd - 1986)Document207 pages(Gulf) Piping Stress Handbook - Part.1 (V.helguero - 2nd - 1986)bakkali_bilalNo ratings yet

- Strength of Materials: Al Anbar University College of EngineeringDocument16 pagesStrength of Materials: Al Anbar University College of Engineeringريام الموسويNo ratings yet

- Kapsam Dişi: No Description Type Medium QuantityDocument3 pagesKapsam Dişi: No Description Type Medium QuantityAnonymous lFvgGOGcuNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument5 pagesEquivalents of Carbon Steel QualitiesAung Naing Latt AungNo ratings yet

- Combination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofDocument8 pagesCombination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofWormInchNo ratings yet