Professional Documents

Culture Documents

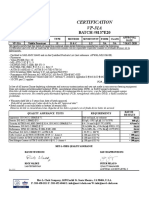

Spotcheck Developer SKD-S2: Certification

Uploaded by

nasser saldaña quintero0 ratings0% found this document useful (0 votes)

29 views3 pagesCertificado de calidad Tintas

Original Title

19D27K_SKD-S2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCertificado de calidad Tintas

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views3 pagesSpotcheck Developer SKD-S2: Certification

Uploaded by

nasser saldaña quinteroCertificado de calidad Tintas

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Spotcheck Dev

Certification

Spotcheck Developer SKD-S2

Date: 04/30/2019

Purchase Order:

Batch #: 19D27K

It is hereby certified that when tested at the time of manufacture, the above listed material and batch

number meets the requirements of and has been tested for Sulfur and Halogens according to:

• ASME Boiler and Pressure Vessel Code, 2004, 2007, 2010 2013, 2015 and 2017 Edition, Section V ,

Nondestructive Examination, including 2005, 2006, 2008,2009b, and 2011a Addenda,

Article 6 Paragraph T-641 and Article 24 as applicable.

• ASME Boiler and Pressure Vessel Code, 1995, 1998 and 2001 Edition, Section V Nondestructive

Examination, including 1999, 2000, 2002 and 2003 Addenda, Article 6 Paragraph T-640 and Article

24 as applicable.

• ASME Boiler and Pressure Vessel Code, 1986, 1989 and 1992 Edition, Section V , Nondestructive

Examination, Article 6 including 1992 Addenda, Paragraph T-625, 1993 Addenda Paragraph T-640

and Article 24 as applicable.

• ASTM E-165-92, ASTM E-165-94, ASTM E-165-95, ASTM E-165-02,ASTM E-165-09,

ASTM E-165/E-165M-12, Paragraph 7.1.

• MIL-STD-271F(SH) June 27, 1986, Paragraphs 5.3 and 5.3.1, including Notice 1 Paragraph 5.6.1

June 21, 1993.

• NAVSEA T9074-AS-GIB-010/271( April 30, 1997 including Notice 1, September 11, 2014 Rev. 1)

Paragraph 5.3.1 and 5.6.2

• NAVSEA 250-1500-1 (Rev. 10 June 1979, Rev. 11 May 1983, Rev. 12 December 1987 including ACN

2 November 15, 1990, Rev. 13 October 1993 including ACN 4 June 30, 1995, Rev. 16 May 9, 2003

Including ACN 5, Rev. 17, Sept. 2007 including ACN 6, and Rev. 18 August 2013) Paragraphs 12.5.1.1

and 12.5.1.1.1

• MIL-STD-2132D, February 11, 2003, Paragraphs 7.1, 7.1.2 and 7.1.3, Appendix C, Paragraph 40.

The following test results were obtained:

105 0.0105 wt., % of residue. CL+F___________ppm__________

Sulfur__________ppm__________ 125.540 0.0126 wt., % of residue

NA

Cleaner residue (see note 3)_________________ NA

g/100g _________________ g/100ml

It is further certified that this material does not contain mercury as a basic element and that no mercury

bearing equipment has been used in its manufacture.

Notes:

1. Our batch number appears on the bottom of all aerosol cans and on the label of all bulk containers.

2. Most specifications require test results to be stated in percent but some require parts per million (ppm). To convert “percent” figures to “parts per million” move the

decimal four places to the right.

3. The above certification gives the results obtained at the time of manufacture. Age and use may alter the properties of any material.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

FORM NO F-1569 R-11/17 magnaflux.com

Certification

Spotcheck Developer SKD-S2

Date: 04/30/2019

Purchase Order:

Batch #: 19D27K

It is hereby certified that the above listed inspection material and batch number meets the

requirements of AMS 2644F and is approved by the U.S. Air Force and listed on QPL-AMS-2644.

When tested according to paragraph 4.3.2, Sampling Plan A, the following test results were obtained:

• 4.2.2.1 Penetrant Tests:

Flash Point (PMCC), 3.3.3

NA ºF

Viscosity, 3.3.4 (cs. Nominal)

Fluorescent Brightness, 3.3.8.3.2 (FP-4PE Standard) NA cs@100 º F

NA %

Water Tolerance (Method A only), 3.3.8.5

NA %

Removability, 3.3.8.6 NA

• 4.2.2.1 Emulsifier Tests:

Flash Point (PMCC), 3.3.3

NA ºF

Viscosity, 3.3.4 ( cs. Nominal)

Water Content (Method D Only), 3.3.9.6 NA cs@100 º F

NA %

• 4.2.2.3 Developer Tests:

Developer Fluorescence, 3.3.10.2 PASS

Developer Removability, 3.3.10.4 PASS

Redispersibility, 3.3.10.5 PASS

• 3.3.11.4 Remover Tests:

Penetrant Removal, 4.4.11.2 NA

It is further certified that this material meets the requirements of ASTM E 1417, Paragraph 5.1.

Batch Numbers appear on labels of bulk containers and on bottoms of aerosol cans.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

FORM NO F-1579E R-2/16 magnaflux.com

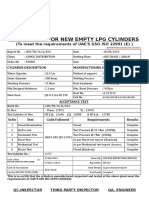

Certification

SKD-S2

Date: 04/30/2019

Purchase Order:

Batch #: 19D27K

We hereby certify that the Penetrate inspection material

Type SKD-S2 , Batch No. 19D27K

Manufactured in April, 2019 furnished on the above order number

meets the requirements of EN ISO 3452-2, with the following results.

Individual Property Section Requirement Result

Appearance 6.1 White PASS

Sensitivity (30μm panel) 6.2 Sensitivity Level (1(<75%) or 2 (≥75%)) 2

Penetrant: SKL-SP2

Density 6.3 .707-.824@ 20°C (68°F) 0.786

Residue on evaporation/solid 6.13 13.83 - 16.94 g* 15.42

content

Flashpoint 6.5 NA NA**

Corrosive Properties (Mg) 6.11 No evidence of staining, pitting or PASS

corrosion

Developer Performance 6.15 Fine, even, non-reflective and non- PASS

fluorescent coating, shall increase

visibility of the penetrant indications

Re-dispensability 6.16 Readily dispersed when stirred or PASS

agitated. Aerosol shall be suspended

after 30sec shaking

*Residue on evaporation/solid content is done from the bulk material and not the aerosol cans. Value

obtained is more accurate on bulk material.

**Flashpoint not required per ISO3452-2:2013 6.5.1 flashpoint measurement only required for

material with nominal flash of 20°C and 110°C. Flashpoint is below 20°C

***Testing in accordance with 5.4.3 Table 4 as applicable

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

Form No. 3452SKD-S2 R-02/16 magnaflux.com

You might also like

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- Revelador 19C18K - SKD-S2Document4 pagesRevelador 19C18K - SKD-S2Ivan Morales AguilarNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- Spotcheck Penetrant SKD-S2: CertificationDocument4 pagesSpotcheck Penetrant SKD-S2: CertificationIvan Morales AguilarNo ratings yet

- SKL-WP2 Certification for Batch 19D07KDocument3 pagesSKL-WP2 Certification for Batch 19D07KcamodiNo ratings yet

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- Certificado Liquidos PenetrantesDocument4 pagesCertificado Liquidos PenetrantesJaneth AguilarNo ratings yet

- 19C01K SKC-SDocument3 pages19C01K SKC-ScamodiNo ratings yet

- Spotcheck, SKC-S: CertificationDocument3 pagesSpotcheck, SKC-S: Certificationnasser saldaña quinteroNo ratings yet

- Spotcheck Penetrant, SKL-SP2: CertificationDocument3 pagesSpotcheck Penetrant, SKL-SP2: CertificationCarlos Eduardo Alvarez SantiagoNo ratings yet

- Certificado Liquidos PenetrantesDocument3 pagesCertificado Liquidos PenetrantesEnrique AntonioNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: Certificationjcarlos7411No ratings yet

- #14M10K Removedor SKC-S PDFDocument2 pages#14M10K Removedor SKC-S PDFPilar Medrano MenaNo ratings yet

- Water Suspendible ZP-5B: CertificationDocument2 pagesWater Suspendible ZP-5B: Certificationisraelita77671No ratings yet

- 18a18k Zyglo ZP 9fDocument3 pages18a18k Zyglo ZP 9fJhon Eder OrozcoNo ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022gauravNo ratings yet

- Certification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Document3 pagesCertification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Pilar MedranoNo ratings yet

- PT Test CertificateDocument2 pagesPT Test Certificateஅன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019Document2 pagesBatch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019அன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022gauravNo ratings yet

- Batch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018Document2 pagesBatch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018sanjayprakash1979No ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Batch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Document2 pagesBatch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Structures ProductionNo ratings yet

- 11k19k Skl-sp2 CertificadoDocument2 pages11k19k Skl-sp2 CertificadoEduardo Isla Millar100% (1)

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- 08E17KDocument2 pages08E17KRonny AndalasNo ratings yet

- Batch Test Certificate: Less Than 0.0025 Less Than 0.0025Document3 pagesBatch Test Certificate: Less Than 0.0025 Less Than 0.0025venkiNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Batch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023Document3 pagesBatch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023venkiNo ratings yet

- Batch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022Document1 pageBatch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022gauravNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationInspectorNo ratings yet

- SKC-S Cleaner Inspection CertificateDocument3 pagesSKC-S Cleaner Inspection CertificateAbee CungNo ratings yet

- 22B21 2Document1 page22B21 2vinothNo ratings yet

- Batch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019Document3 pagesBatch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019அன்புடன் அஸ்வின்No ratings yet

- Mercon V SpecificationDocument22 pagesMercon V Specificationocto widodoNo ratings yet

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalDocument17 pagesKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadNo ratings yet

- Inspection Certificate AnalysisDocument2 pagesInspection Certificate AnalysisInspectorNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationvenkiNo ratings yet

- Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialDocument3 pagesInspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above Materialmaheshmalaichamy007No ratings yet

- Tinte Penetrante 1124467Document1 pageTinte Penetrante 1124467Diego SilvaNo ratings yet

- 0850 02Document5 pages0850 02janiNo ratings yet

- Surface Vehicle Recommended Practice: Wheel and Wheel Trim Weathering Testing For Paint CoatingsDocument4 pagesSurface Vehicle Recommended Practice: Wheel and Wheel Trim Weathering Testing For Paint CoatingsAdriana SukmanaputraNo ratings yet

- Pruevas No DestructivasDocument2 pagesPruevas No DestructivasCeo EcNo ratings yet

- Date: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17KDocument2 pagesDate: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17Kisraelita77671No ratings yet

- Red Penetrant - MR62 - 2209040Document1 pageRed Penetrant - MR62 - 2209040Karthi KeyanNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificatevinothNo ratings yet

- 7HF Prepared Bath: CertificationDocument1 page7HF Prepared Bath: CertificationEric Figueroa UribeNo ratings yet

- NDT-SA-SATORP-PT-60 Rev 01-Date-15-AUG-2023Document14 pagesNDT-SA-SATORP-PT-60 Rev 01-Date-15-AUG-2023Md Abu Hanif RajuNo ratings yet

- Coal Tar PDFDocument4 pagesCoal Tar PDFMohammadreza AsheghNo ratings yet

- Monark Product Support Center Service ReportDocument7 pagesMonark Product Support Center Service Reportjamel SibugNo ratings yet

- NC257 SN100C: Lead-Free Solder Paste FeaturesDocument3 pagesNC257 SN100C: Lead-Free Solder Paste Featureshuynh thi y viNo ratings yet

- Def Stan 80-34 Issue 1995Document17 pagesDef Stan 80-34 Issue 1995Said AdingniNo ratings yet

- Hydraulic Oil HLP 68Document2 pagesHydraulic Oil HLP 68javierNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- Test: Test Methods: Color:: Guenther - Roth@imat-Uve - deDocument3 pagesTest: Test Methods: Color:: Guenther - Roth@imat-Uve - deDaniela CamachoNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- PCWI Compact DC High Voltage Holiday Detector Instruction ManualDocument18 pagesPCWI Compact DC High Voltage Holiday Detector Instruction Manualnasser saldaña quinteroNo ratings yet

- Spotcheck, SKC-S: CertificationDocument3 pagesSpotcheck, SKC-S: Certificationnasser saldaña quinteroNo ratings yet

- Manual Stooper BagDocument2 pagesManual Stooper Bagnasser saldaña quinteroNo ratings yet

- SplitSleeve Install PDFDocument44 pagesSplitSleeve Install PDFgeorgeNo ratings yet

- SplitSleeve Install PDFDocument44 pagesSplitSleeve Install PDFgeorgeNo ratings yet

- W Shape Property TableDocument5 pagesW Shape Property TableAlejandro OspinaNo ratings yet

- Domestic Water Heating: Engineering Utilities 2 (Basic Mechanical Engineering) ME 223Document11 pagesDomestic Water Heating: Engineering Utilities 2 (Basic Mechanical Engineering) ME 223Marifher Kate Dela CruzNo ratings yet

- Public Version of HPC PCSR3 Sub-Chapter 5.4 - Components and Systems Sizing PDFDocument96 pagesPublic Version of HPC PCSR3 Sub-Chapter 5.4 - Components and Systems Sizing PDFParaschiv AlexandruNo ratings yet

- Wingd X DF Power Plant SolutionDocument16 pagesWingd X DF Power Plant Solutionthomas pierreNo ratings yet

- Piping and Instrumentation Diagram (Pnid)Document19 pagesPiping and Instrumentation Diagram (Pnid)ridzuanzabah0% (1)

- Design and Fabrication Stirling EngineDocument54 pagesDesign and Fabrication Stirling Engineermias100% (1)

- Research On Key Technology of Wire-Bending and Equipment DevelopmentDocument7 pagesResearch On Key Technology of Wire-Bending and Equipment DevelopmentSamedNo ratings yet

- Diagnosis Dt466 & 530 eDocument3 pagesDiagnosis Dt466 & 530 eCesar Bayes Ramos100% (1)

- Packer Dual Weatherford AROWDRILLDocument9 pagesPacker Dual Weatherford AROWDRILLRodolfo RiderNo ratings yet

- ITWDocument12 pagesITWDivya BaluchamyNo ratings yet

- Es10 22MM PDS22D Operation Manual PDFDocument37 pagesEs10 22MM PDS22D Operation Manual PDFניקולאי איןNo ratings yet

- (P) Work, Power & Energy ExerciseDocument35 pages(P) Work, Power & Energy ExerciseSocial Credits Positive Million AspirantNo ratings yet

- Seismic Isolation of Djamaa El Djazir Mosque in AlgiersDocument11 pagesSeismic Isolation of Djamaa El Djazir Mosque in AlgiersFranco SerafiniNo ratings yet

- CondenserDocument44 pagesCondenserNeil John CatapangNo ratings yet

- Design and Analysis of Forged Thermostatic Expansion Valve by Using FEADocument5 pagesDesign and Analysis of Forged Thermostatic Expansion Valve by Using FEARajat JunejaNo ratings yet

- ICE Assignment 4Document3 pagesICE Assignment 4Abhimanyu Ohlyan33% (3)

- Power and Efficiency in AC Machines: Electrical Power (In or Out) Mechanical Power (In or Out) LossesDocument15 pagesPower and Efficiency in AC Machines: Electrical Power (In or Out) Mechanical Power (In or Out) LossesMohd Taufik SumariNo ratings yet

- SPC - 899 Panigale - EN - MY15 PDFDocument158 pagesSPC - 899 Panigale - EN - MY15 PDFCristian BurbanoNo ratings yet

- Compresor PN30D 3Document20 pagesCompresor PN30D 3NJunior LeónNo ratings yet

- Catalogo Ores Ajax BoilerDocument2 pagesCatalogo Ores Ajax BoilerKaren Julieth Cardenas AriasNo ratings yet

- TG PresentationDocument22 pagesTG Presentationetong saturninaNo ratings yet

- Analysis of Silo Supporting Ring Beams Resting On Discrete Supports - O Zeybek, Et Al, 2019Document12 pagesAnalysis of Silo Supporting Ring Beams Resting On Discrete Supports - O Zeybek, Et Al, 2019Benjamin IndrawanNo ratings yet

- Engine Sensors and SystemsDocument14 pagesEngine Sensors and Systemsalex generalNo ratings yet

- ESP Design - Step 4 Total Dynamic HeadDocument6 pagesESP Design - Step 4 Total Dynamic HeadazareiforoushNo ratings yet

- Natural Gas Engineering Hand Book (2005) Ch.4Document14 pagesNatural Gas Engineering Hand Book (2005) Ch.4Abdelrahman Saeed0% (1)

- LABORATORY PRACTICAL V SYNCHRONOUS GENERATORDocument5 pagesLABORATORY PRACTICAL V SYNCHRONOUS GENERATORNuwan BandaraNo ratings yet

- 107 Weldox 700 Uk Data SheetDocument2 pages107 Weldox 700 Uk Data SheetAnurag JainNo ratings yet

- ManifoldDocument10 pagesManifoldjosé_filipe_35No ratings yet

- PC 12Document8 pagesPC 12Gopinath Srinivasan100% (1)

- BUTTING Pipeline Systems For The Pneumatic ConveyingDocument16 pagesBUTTING Pipeline Systems For The Pneumatic ConveyingAleksandar KosticNo ratings yet