Professional Documents

Culture Documents

Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above Material

Uploaded by

maheshmalaichamy007Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above Material

Uploaded by

maheshmalaichamy007Copyright:

Available Formats

Inspection Certificate

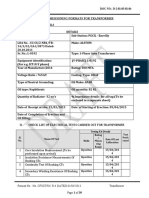

SUBJECT: Spotcheck SKC-S Cleaner/Remover Abnahmeprufzeugnis DIN EN 10204 3.1

Certificat De reception

BATCH No: 200303 Certificado di collaudo

Keuringsrapport

MANUFACTURE DATE:18-23/03/2020

B.B.E.: MAR 2023

We hereby certify that when tested at the time of manufacture, the above material:

1. Meets the requirements of and has been tested for sulfur and halogens according to:

a) ASME Boiler and Pressure Vessel Code, 2019 Edition, Section V, Non-destructive Examination.

b) Anion analysis by ASTM D129 decomposition followed by Ion Chromatography method Annex A4.

c) ASTM E-165/E-165M-18, Paragraph 7.1.

d) MIL-STD-2132D, 11 February 2003, Paragraph 7.1, 7.1.2, 7.1.3 and Appendix C, Paragraph 40.

Test results obtained were as follows:

Sulfur: wt % of residue. Chlorine + Fluorine: wt % of residue.

Cleaner residue (see note 3) 0.001/100g 0.0008 g/100ml

2. Meets the requirements of EN ISO 3452-1, EN ISO 3452-2, AMS 2644G and ASTM E 1417/E 1417M-16 Paragraph

5.1 & 6.5.1.

4.2.2.1 Penetrant Tests

Flashpoint (PMCC) (3.3.3) : N/A

Viscosity (3.3.4) : N/A

Fluorescent Brightness (3.3.8.3.2) : N/A

Water tolerance Method A, B, C, D only (3.3.8.5) : N/A

Penetrant Removability (3.3.8.6) : N/A

Water Content (3.3.8.7) : N/A

4.2.2.2 Emulsifier Tests

Flashpoint (PMCC) (3.3.3) : N/A

Viscosity (3.3.4) : N/A

Water Content Method D only (3.3.9.6) : N/A

4.2.2.3 Developer Tests

Developer Fluorescence (3.3.10.2) : N/A

Developer Removability (3.3.10.4) : N/A

Redispersibility (3.3.10.5) : N/A

3.3.11.4 Solvent Remover Tests

Penetrant Removal (4.4.11.2) : Conforms

3. We further certify that the material does not contain mercury as a basic element and no mercury bearing equipment was

used in its manufacture.

Certification is issued under the auspices of the Quality Assurance Manager.

(Authorised Employee)

For and on behalf of MAGNAFLUX DIV OF ITW LTD

Notes:

1. Our batch number appears on the label of bulk containers. Aerosols have batch numbers printed on bottom of the container. Bulk materials have a minimum shelf life of 5 years from

date of manufacture. Aerosols have a minimum shelf life of 3 years from date of manufacture.

2. Most specifications require test results stated in percent, but some require parts per million (ppm). To convert "percent" figures to "parts per million" move the decimal four places to

the right.

3. MIL-STD-271, MIL-STD-2132 and ASME Sec V, all require that materials be subject to a procedure to evaporate off volatile solvents before analysis for Sulfur and Halogens. According

to these specifications, only those residues higher than 0.005 g/100ml shall be analysed for Sulfur and Halogens. Lower residues shall be reported.

4. The above certification gives the results obtained at the time of manufacture. Age and use may alter the properties of any material.

Magnaflux (A Division of ITW Ltd),

FORMAT:MX 101.137 SK MC-02 Rev 17 Faraday Road, South Dorcan Industrial Estate,

Swindon, Wiltshire, SN3 5HE, UK

Tel: +44 (0)1793 524566 Fax: +44 (0)1793 490459

Email: sales.eu@magnaflux.com www.eu.magnaflux.com

Inspection Certificate

SUBJECT: Spotcheck SKC-S Cleaner/Remover Abnahmeprufzeugnis DIN EN 10204 3.1

Certificat De reception

BATCH No: 200303 Certificado di collaudo

Keuringsrapport

MANUFACTURE DATE:18-23/03/2020

B.B.E.: MAR 2023

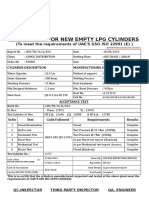

Specification: EN ISO 3452-2

When tested at the time of manufacture the following results were obtained:

Ermittlungen

nach

Einzeleigenschaft/ EN ISO Anforderungen / Ergebnis /

Characteristic 3452-2 Quality requirement Batch testing

Abschnitt

Appearance 6.1 Equal to Std Pass

Sensitivity 6.2 Equal to Std Pass

Density 6.3 0.684 – 0.756 g/cm3 0.694 g/cm3

Flashpoint 6.5 N/A Aerosol -40°C

Corrosive Properties 6.11 No Corrosion on Magnesium Alloy Pass

Sulphur Content 6.12 < 200 ppm <200 ppm

Halogen Content 6.12 < 200 ppm <200 ppm

Residue on evaporation 6.13 < 5 mg per 100 ml 1.0 mg per 100 ml

VorstehendeAngabensind die ErgebnisseunsererQualitätsprüfung. Sie entbinden den Käufernicht von einerEingangsprüfung

und habennicht die Bedeutung, die Eignung des ProduktesfüreinenkonkretenEinsatzzweckzuzusichern.

The above information is derived from our quality checks. It does not relieve the purchaser from examining the product upon

delivery and gives no assurance of the product for any particular purpose.

Certification is issued under the auspices of the Quality Assurance Manager.

(Authorised Employee)

For and on behalf of MAGNAFLUX (A DIVISION OF ITW LTD)

Magnaflux (A Division of ITW Ltd),

FORMAT:MX 101.137 SK MC-02 Rev 17 Faraday Road, South Dorcan Industrial Estate,

Swindon, Wiltshire, SN3 5HE, UK

Tel: +44 (0)1793 524566 Fax: +44 (0)1793 490459

Email: sales.eu@magnaflux.com www.eu.magnaflux.com

Inspection Certificate

SUBJECT: Spotcheck SKC-S Cleaner/Remover Abnahmeprufzeugnis DIN EN 10204 3.1

Certificat De reception

BATCH No: 200303 Certificado di collaudo

Keuringsrapport

MANUFACTURE DATE:18-23/03/2020

B.B.E.: MAR 2023

VENDOR’S REPORT – TEST RESULTS

Please forward in duplicate to:

Reports, Materials Control Laboratory

Pratt & Whitney

(Plant to which material is shipped)

This is to certify that Paragraph Numbers(s) 1 & 5 apply to the shipment below:

1. Applicable to all raw material, to parts, made from raw material furnished or purchased by vendor, or to

assemblies of which some or all components are made from raw material furnished or purchased by vendor.)

Material, parts, or components of assemblies have been inspected and accepted to the specifications involved,

and results of tests required by Pratt & Whitney Aircraft are shown herein.

2. (Applicable to parts or assembly components made from raw material furnished by Pratt & Whitney Aircraft

and not chemically or metallurgically treated by vendor so as to change surface or internal condition

significantly.) Parts or assemblies have been machined or formed from material furnished by Pratt & Whitney

Aircraft, to make these parts or components of assemblies.

3. (Applicable to parts or assembly components made from raw material furnished by Pratt & Whitney Aircraft

and chemically or metallurgically treated by vendor so as to change surface or internal condition significantly.)

Parts of components of assemblies have been made from raw material furnished by Pratt & Whitey Aircraft to

make these parts or components of assemblies. Parts, components of assemblies have been inspected and

accepted to the specifications involved, and results of tests required by Pratt & Whitney Aircraft are as show

herein.

4. (Applicable to repaired or reworked raw material, parts or assemblies.) The raw materials, parts or assemblies

have been reworked or repaired in accordance with Pratt & Whitney Aircraft Instructions, and are the same

material, parts or assemblies returned for such reworking or repair, except for replacement of assembly

components, in which case paragraphs 1 and 5 are also applicable.

5. (Applicable to all assemblies, and to parts when specifically authorized by purchaser.) Results of all

chemical and physical tests not shown below, as well as all other evidence which shows acceptability of raw

materials and assembly components, are on file and available for inspection at any reasonable time.

PART OR ASS’Y NO. (Size if no Part No.) CHG. LTR. SUF. NO. SPECIFICATIONS, AS ORDERED

PMC 4366J 1 PWA 300 Rev. BP

QUANTITY DATE SHIPPED LOCATION OF PWA PLANT TO SHIPPED TO PACK SLIP NO. P.O. NO.

HEAT, LOT, CODE OR BATCH NO. RAW MATERIAL VENDOR TYPE-COMPOUND OR CASTING PWA HEAT CODES (if required)

200303 SKC-S

If materials, parts or assemblies do not entirely conform to specification requirements, the deviation and authority for furnishing such materials are indicated

below:

RESULTS OF TESTS (Use reverse side if necessary)

This is to certify that the shipment of materials has been representatively sampled

and analysed according to the Quality Control Program of Magnaflux and that this

material meets the specifications set forth by Pratt and Whitney per PMC 4366

Rev J. Used as a pre-cleaner, post-cleaner and penetrant remover for local

applications. It is approved for use on steels, stainless steel, nickel-based alloys,

cobalt-base alloys, aluminium, magnesium, titanium and titanium alloys.

Magnaflux certifies that SKC-S does NOT contain Polychlorinated Biphenyls (PCB’S)

Magnaflux (A Division of ITW Ltd),

FORMAT:MX 101.137 SK MC-02 Rev 17 Faraday Road, South Dorcan Industrial Estate,

Swindon, Wiltshire, SN3 5HE, UK

Tel: +44 (0)1793 524566 Fax: +44 (0)1793 490459

Email: sales.eu@magnaflux.com www.eu.magnaflux.com

You might also like

- Dust Explosion Prevention and Protection: A Practical GuideFrom EverandDust Explosion Prevention and Protection: A Practical GuideNo ratings yet

- Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialDocument3 pagesInspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialAbee CungNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Batch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018Document2 pagesBatch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018sanjayprakash1979No ratings yet

- PT Test CertificateDocument2 pagesPT Test Certificateஅன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019Document2 pagesBatch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019அன்புடன் அஸ்வின்No ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022gauravNo ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022gauravNo ratings yet

- Spotcheck Penetrant SKD-S2: CertificationDocument4 pagesSpotcheck Penetrant SKD-S2: CertificationIvan Morales AguilarNo ratings yet

- 19C01K SKC-SDocument3 pages19C01K SKC-ScamodiNo ratings yet

- Spotcheck, SKC-S: CertificationDocument3 pagesSpotcheck, SKC-S: Certificationnasser saldaña quinteroNo ratings yet

- Batch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Document2 pagesBatch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Structures ProductionNo ratings yet

- Certificado Liquidos PenetrantesDocument4 pagesCertificado Liquidos PenetrantesJaneth AguilarNo ratings yet

- Mercon V SpecificationDocument22 pagesMercon V Specificationocto widodoNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- 22B21 2Document1 page22B21 2vinothNo ratings yet

- PO SR - No.8, HEL REPORT 120004Document4 pagesPO SR - No.8, HEL REPORT 120004Agni DuttaNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: CertificationcamodiNo ratings yet

- Revelador 19C18K - SKD-S2Document4 pagesRevelador 19C18K - SKD-S2Ivan Morales AguilarNo ratings yet

- Batch Test Certificate: Less Than 0.0025 Less Than 0.0025Document3 pagesBatch Test Certificate: Less Than 0.0025 Less Than 0.0025venkiNo ratings yet

- (1502-B) OLD Labelec ER195 Rod To Cable Clamp (50 To 95mm2)Document17 pages(1502-B) OLD Labelec ER195 Rod To Cable Clamp (50 To 95mm2)annamalaiNo ratings yet

- #14M10K Removedor SKC-S PDFDocument2 pages#14M10K Removedor SKC-S PDFPilar Medrano MenaNo ratings yet

- M 10 15080 Odour Control Version 2.0Document3 pagesM 10 15080 Odour Control Version 2.0Fasil ENo ratings yet

- Mechanical Test Report (51252731-Ea)Document14 pagesMechanical Test Report (51252731-Ea)Nguyen ngoc thongNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Batch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022Document1 pageBatch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022gauravNo ratings yet

- Lobatse Water Supply Master Plan - Work Package 1: Daily Field Joint Internal Lining ReportDocument2 pagesLobatse Water Supply Master Plan - Work Package 1: Daily Field Joint Internal Lining ReportvipanNo ratings yet

- Spotcheck Penetrant, SKL-SP2: CertificationDocument3 pagesSpotcheck Penetrant, SKL-SP2: CertificationCarlos Eduardo Alvarez SantiagoNo ratings yet

- NO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last CalibrationDocument39 pagesNO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last Calibrationmayur dhandeNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Certification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Document3 pagesCertification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Pilar MedranoNo ratings yet

- Spotcheck SKD S2 Developer AerosolDocument2 pagesSpotcheck SKD S2 Developer AerosolInspectorNo ratings yet

- Water Suspendible ZP-5B: CertificationDocument2 pagesWater Suspendible ZP-5B: Certificationisraelita77671No ratings yet

- Approval of MPI ProcedureDocument17 pagesApproval of MPI ProcedureimranNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: Certificationjcarlos7411No ratings yet

- HIC Test ChecklistDocument3 pagesHIC Test ChecklistVicky Kumar100% (2)

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- 7HFDocument2 pages7HFrtsdsdgNo ratings yet

- WSS M5G58 A2Document5 pagesWSS M5G58 A2Muthu GaneshNo ratings yet

- BS6920 Test Report: Sunbury Technology CentreDocument6 pagesBS6920 Test Report: Sunbury Technology CentreMohammed JavidNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument6 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- Certificado Liquidos PenetrantesDocument3 pagesCertificado Liquidos PenetrantesEnrique AntonioNo ratings yet

- TP.30.001 - Fragmentatie Getemperd - Nl.enDocument8 pagesTP.30.001 - Fragmentatie Getemperd - Nl.enHafsa BoudguigNo ratings yet

- 03OHH SengYewDocument3 pages03OHH SengYewAbhie AlbukhariNo ratings yet

- UT-Flaw1 Detection Procedure R1 - 2Document25 pagesUT-Flaw1 Detection Procedure R1 - 2George OgbecheNo ratings yet

- Def Stan 80-34 Issue 1995Document17 pagesDef Stan 80-34 Issue 1995Said AdingniNo ratings yet

- DN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowerDocument23 pagesDN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowermaheshNo ratings yet

- Fire Test - Thomas Bell Wright 12mmDocument9 pagesFire Test - Thomas Bell Wright 12mmblackcapperNo ratings yet

- HC Condensate Temporary Spool 2B Pump BladderDocument16 pagesHC Condensate Temporary Spool 2B Pump Bladderw_ibisonogNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- E4-51R-022440 Ext.04 PDFDocument88 pagesE4-51R-022440 Ext.04 PDFEduardo LozanoNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Liquid Penetrant Testing PDFDocument20 pagesLiquid Penetrant Testing PDFgueridiNo ratings yet

- Special Inspections ManualDocument50 pagesSpecial Inspections Manualmaheshmalaichamy007No ratings yet

- Fastners MTCDocument18 pagesFastners MTCmaheshmalaichamy007No ratings yet

- S1 Structural Steel and Bolting Special Inspector: Required Examinations Exam IDDocument14 pagesS1 Structural Steel and Bolting Special Inspector: Required Examinations Exam IDmaheshmalaichamy007No ratings yet

- 5 6154413776952099627Document5 pages5 6154413776952099627VenkateshMedidiNo ratings yet

- Ml12146a182 PDFDocument66 pagesMl12146a182 PDFAlex AjuNo ratings yet

- Ml12146a182 PDFDocument66 pagesMl12146a182 PDFAlex AjuNo ratings yet

- Galvanized Steel Grade Data SheetsDocument3 pagesGalvanized Steel Grade Data Sheetsأيمن أبو عيدNo ratings yet

- 800 1500lb GateValveDocument1 page800 1500lb GateValvePham AnhNo ratings yet

- 098 2017 en GL WireFluxCombinations WEBDocument24 pages098 2017 en GL WireFluxCombinations WEBlazaroccsNo ratings yet

- Art & Craft Activity (Week 2)Document2 pagesArt & Craft Activity (Week 2)maheshmalaichamy007No ratings yet

- Structural Steels: High-Quality Steels For Construction ApplicationsDocument3 pagesStructural Steels: High-Quality Steels For Construction Applicationsmaheshmalaichamy007No ratings yet

- Jsa Jis G 3302Document47 pagesJsa Jis G 3302maheshmalaichamy007No ratings yet

- GI Catalogue PDFDocument28 pagesGI Catalogue PDFVanesh KumarNo ratings yet

- Cast and Wrought Galvanic Zinc Anodes: Standard Specification ForDocument3 pagesCast and Wrought Galvanic Zinc Anodes: Standard Specification Formaheshmalaichamy007No ratings yet

- Party Fast MoveDocument2 pagesParty Fast Movemaheshmalaichamy007No ratings yet

- (Kindly Solve It at Home) : Olive International School, Al Thumama GRADE 2 SESSION 2020 - 21 Math Worksheet - Block 8Document3 pages(Kindly Solve It at Home) : Olive International School, Al Thumama GRADE 2 SESSION 2020 - 21 Math Worksheet - Block 8maheshmalaichamy007No ratings yet

- Olive International School, Al Thumama GRADE 2 SESSION 2020 - 21 Math Worksheet - Block 6 - Answer KeyDocument5 pagesOlive International School, Al Thumama GRADE 2 SESSION 2020 - 21 Math Worksheet - Block 6 - Answer Keymaheshmalaichamy007No ratings yet

- EVS BLock 2 WorksheetDocument3 pagesEVS BLock 2 Worksheetmaheshmalaichamy007No ratings yet

- Steel Hardness Reference Table 2Document2 pagesSteel Hardness Reference Table 2dilipNo ratings yet

- EVS Worksheet Block - 1Document3 pagesEVS Worksheet Block - 1maheshmalaichamy007No ratings yet

- EVS Block 1 PDFDocument6 pagesEVS Block 1 PDFmaheshmalaichamy007No ratings yet

- Olive International School, Al Thumama Grade 2 Session 2020 - 2021 EVS Worksheet - Block 8 - Answer KeyDocument1 pageOlive International School, Al Thumama Grade 2 Session 2020 - 2021 EVS Worksheet - Block 8 - Answer Keymaheshmalaichamy007No ratings yet

- EVS BLock 2 WorksheetDocument3 pagesEVS BLock 2 Worksheetmaheshmalaichamy007No ratings yet

- English Worksheet - Block 3Document3 pagesEnglish Worksheet - Block 3maheshmalaichamy007No ratings yet

- Party Fast MoveDocument2 pagesParty Fast Movemaheshmalaichamy007No ratings yet

- Olive International School, Al Thumama GRADE 2 SESSION 2020 - 21 Math Worksheet - Block 6 - Answer KeyDocument5 pagesOlive International School, Al Thumama GRADE 2 SESSION 2020 - 21 Math Worksheet - Block 6 - Answer Keymaheshmalaichamy007No ratings yet

- EVS Block 2 Practice Questions and Additional NotesDocument2 pagesEVS Block 2 Practice Questions and Additional Notesmaheshmalaichamy007No ratings yet

- As 3006-1982 Adequate Electrical Installations in Domestic PremisesDocument8 pagesAs 3006-1982 Adequate Electrical Installations in Domestic PremisesSAI Global - APACNo ratings yet

- Senr5030 3412eDocument2 pagesSenr5030 3412eait mimouneNo ratings yet

- Karcher HD 7Document2 pagesKarcher HD 7Alfhian Jeffri ChinNo ratings yet

- AS ING Rev0 PDFDocument38 pagesAS ING Rev0 PDFNguyen Quyet ThangNo ratings yet

- Ishwor ChaudharyDocument29 pagesIshwor Chaudharybinud das100% (2)

- Abrams 1919 Design of Concrete MixturesDocument28 pagesAbrams 1919 Design of Concrete MixturesjoaorioNo ratings yet

- Blade-Resolved CFD Simulations of A Periodic Array of NREL 5 MW Rotors With and Without TowersDocument17 pagesBlade-Resolved CFD Simulations of A Periodic Array of NREL 5 MW Rotors With and Without Towersmirage_et_rafale9572No ratings yet

- Derived To Base Class PDFDocument25 pagesDerived To Base Class PDFanand_duraiswamyNo ratings yet

- Entrepreneurship 1st Quarter SessionsDocument20 pagesEntrepreneurship 1st Quarter SessionsAndreiNicolaiPacheco100% (11)

- Course Specifications: University: Cairo Faculty: Engineering Department: Aerospace EngineeringDocument3 pagesCourse Specifications: University: Cairo Faculty: Engineering Department: Aerospace EngineeringscribNo ratings yet

- (J) Bimbingan Kelompok Teknik Sosiodrama Untuk Meningkatkan Interaksi Sosial Dengan Teman SebayaDocument14 pages(J) Bimbingan Kelompok Teknik Sosiodrama Untuk Meningkatkan Interaksi Sosial Dengan Teman SebayaBhima Agung NugrahaNo ratings yet

- 6 - Design of Solar Charge ControllerDocument6 pages6 - Design of Solar Charge ControllerNyanphyo AungNo ratings yet

- Internal Communication PlanDocument11 pagesInternal Communication Planjmcgrath208100% (1)

- SRV OldDocument24 pagesSRV OldAlvin PeraltaNo ratings yet

- Unit2.SP - Mill.setting and ImbibitionDocument15 pagesUnit2.SP - Mill.setting and ImbibitionHari kantNo ratings yet

- 06-810 Ul-Fm Ig100Document154 pages06-810 Ul-Fm Ig100Rizki Fadillah100% (1)

- Oracle EBS R12.2.6 Application Tier Cloning With Step by StepDocument10 pagesOracle EBS R12.2.6 Application Tier Cloning With Step by Stepdoyenblog100% (1)

- Injectomat AgiliaDocument2 pagesInjectomat Agiliasergio ribeiroNo ratings yet

- SR868C6 Controller Manual PDFDocument16 pagesSR868C6 Controller Manual PDFUltisolar0% (1)

- Wellbore CleanDocument84 pagesWellbore Cleanveljkosx100% (1)

- Industrial Control 11)Document33 pagesIndustrial Control 11)Arindam LayekNo ratings yet

- F 4400 Manual 02 16Document45 pagesF 4400 Manual 02 16Sodhi S SohalNo ratings yet

- AAC-004 Technical LogDocument12 pagesAAC-004 Technical LogMohammed HamidNo ratings yet

- MT1 SeriesDocument8 pagesMT1 Seriesrapidistu90No ratings yet

- Ducati Diavel ABS WiringDocument1 pageDucati Diavel ABS WiringKhoảng LặngNo ratings yet

- Lesson Plan DWP - Meeting 1Document4 pagesLesson Plan DWP - Meeting 1anonymous xxxNo ratings yet

- Airborne TrailblazerDocument244 pagesAirborne Trailblazerapi-3819355No ratings yet

- VoxStudio ManualDocument59 pagesVoxStudio ManualhmeyoyanNo ratings yet

- Especificações SS CHS6 5Document2 pagesEspecificações SS CHS6 5kirlaniano@gmail.comNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Fighting Westway: Environmental Law, Citizen Activism, and the Regulatory War That Transformed New York CityFrom EverandFighting Westway: Environmental Law, Citizen Activism, and the Regulatory War That Transformed New York CityNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet