Professional Documents

Culture Documents

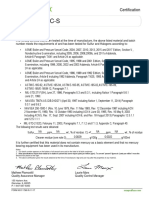

Spotcheck Penetrant SKD-S2: Certification

Uploaded by

Ivan Morales Aguilar0 ratings0% found this document useful (0 votes)

24 views4 pagesOriginal Title

REVELADOR 19C18K_SKD-S2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views4 pagesSpotcheck Penetrant SKD-S2: Certification

Uploaded by

Ivan Morales AguilarCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

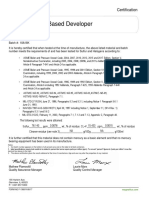

Spotcheck Dev

Certification

Spotcheck Penetrant SKD-S2

Date: 04/05/2019 Purchase

Order:

Batch #: 19C18K

It is hereby certified that when tested at the time of manufacture, the above listed material and batch number

meets the requirements of and has been tested for Sulfur and Halogens according to:

• ASME Boiler and Pressure Vessel Code, 2004, 2007, 2010 2013, 2015 and 2017 Edition, Section V ,

Nondestructive Examination, including 2005, 2006, 2008,2009b, and 2011a Addenda, Article 6

Paragraph T-641 and Article 24 as applicable.

• ASME Boiler and Pressure Vessel Code, 1995, 1998 and 2001 Edition, Section V Nondestructive

Examination, including 1999, 2000, 2002 and 2003 Addenda, Article 6 Paragraph T-640 and Article 24 as

applicable.

• ASME Boiler and Pressure Vessel Code, 1986, 1989 and 1992 Edition, Section V , Nondestructive

Examination, Article 6 including 1992 Addenda, Paragraph T-625, 1993 Addenda Paragraph T-640 and

Article 24 as applicable.

• ASTM E-165-92, ASTM E-165-94, ASTM E-165-95, ASTM E-165-02,ASTM E-165-09,

ASTM E-165/E-165M-12, Paragraph 7.1.

• MIL-STD-271F(SH) June 27, 1986, Paragraphs 5.3 and 5.3.1, including Notice 1 Paragraph 5.6.1

June 21, 1993.

• NAVSEA T9074-AS-GIB-010/271( April 30, 1997 including Notice 1, September 11, 2014 Rev. 1)

Paragraph 5.3.1 and 5.6.2

• NAVSEA 250-1500-1 (Rev. 10 June 1979, Rev. 11 May 1983, Rev. 12 December 1987 including ACN 2

November 15, 1990, Rev. 13 October 1993 including ACN 4 June 30, 1995, Rev. 16 May 9, 2003 Including ACN

5, Rev. 17, Sept. 2007 including ACN 6, and Rev. 18 August 2013) Paragraphs 12.5.1.1 and 12.5.1.1.1

• MIL-STD-2132D, February 11, 2003, Paragraphs 7.1, 7.1.2 and 7.1.3, Appendix C, Paragraph 40.

The following test results were obtained:

Sulfur 97 _ppm 0.009_7 _ wt., % of residue. CL+F 126.4_57 ppm 0.01_26 wt., % of residue

Cleaner residue (see note 3) g/100g g/100ml

NA NA

It is further certified that this material does not contain mercury as a basic element and that no mercury bearing

equipment has been used in its manufacture.

Notes:

1. Our batch number appears on the bottom of all aerosol cans and on the label of all bulk containers.

2. Most specifications require test results to be stated in percent but some require parts per million (ppm). To convert “percent” figures to “parts per million” move the decimal

four places to the right.

3. The above certification gives the results obtained at the time of manufacture. Age and use may alter the properties of any material.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave. FORM NO F-1569 R-

Glenview, IL 60025 11/17

P: 1-847-657-5300

magnaflux.com

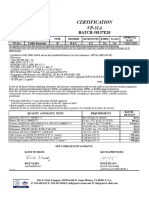

Certification

Spotcheck Penetrant SKD-S2

Date: 04/05/2019 Purchase

Order:

Batch #: 19C18K

It is hereby certified that the above listed inspection material and batch number meets the requirements of

AMS 2644F and is approved by the U.S. Air Force and listed on QPL-AMS-2644.

When tested according to paragraph 4.3.2, Sampling Plan A, the following test results were obtained:

• 4.2.2.1 Penetrant Tests:

Flash Point (PMCC), 3.3.3

Viscosity, 3.3.4 (cs. Nominal) NA ºF

Fluorescent Brightness, 3.3.8.3.2 (FP-4PE Standard) Water NA cs@100 º F

Tolerance (Method A only), 3.3.8.5 Removability, NA %

3.3.8.6 NA %

NA

• 4.2.2.1 Emulsifier Tests:

Flash Point (PMCC), 3.3.3

Viscosity, 3.3.4 ( cs. Nominal) NA ºF

Water Content (Method D Only), 3.3.9.6 NA cs@100 º F

NA %

• 4.2.2.3 Developer Tests:

Developer Fluorescence, 3.3.10.2 PASS

Developer Removability, 3.3.10.4 PASS

Redispersibility, 3.3.10.5 PASS

• 3.3.11.4 Remover Tests:

Penetrant Removal, 4.4.11.2 NA

It is further certified that this material meets the requirements of ASTM E 1417, Paragraph 5.1. Batch

Numbers appear on labels of bulk containers and on bottoms of aerosol cans.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

FORM NO F-1579E R-2/16

magnaflux.com

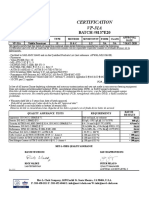

SKD-S2

Date: 04/05/2019 Purchase

Order:

Batch #: 19C18K

We hereby certify that the Penetrate inspection material

Type , Batch No. 19C18K

SKD-S2

Manufactured in March, 2019 furnished on the above order number

meets the requirements of EN ISO 3452-2, with the following results.

Individual Property Section Requirement Result

Appearance 6.1 White PASS

Sensitivity (30μm panel) 6.2 Sensitivity Level (1(<75%) or 2 2

(≥75%)) Penetrant: SKL-SP2

Density 6.3 .707-.824@ 20°C (68°F) 0.784

Residue on 6.13 13.83 - 16.94 g* 15.22

evaporation/solid content

Flashpoint 6.5 NA NA**

Corrosive Properties (Mg) 6.11 No evidence of staining, pitting PASS

or corrosion

Developer Performance 6.15 Fine, even, non-reflective and PASS

non- fluorescent coating, shall

increase visibility of the penetrant

indications

Re-dispensability 6.16 Readily dispersed when stirred or PASS

agitated. Aerosol shall be

suspended after 30sec shaking

*Residue on evaporation/solid content is done from the bulk material and not the aerosol cans. Value obtained is

more accurate on bulk material.

**Flashpoint not required per ISO3452-2:2013 6.5.1 flashpoint measurement only required for material

with nominal flash of 20°C and 110°C. Flashpoint is below 20°C

***Testing in accordance with 5.4.3 Table 4 as applicable

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

Form No. 3452SKD-S2 R-02/16

magnaflux.com

You might also like

- TTT DiagramDocument6 pagesTTT DiagramDeepa PujariNo ratings yet

- 13 PT ProcedureDocument14 pages13 PT ProcedureThân KhaNo ratings yet

- 88 D 340 nh3 Storage Tank Sept 10 2014 2Document9 pages88 D 340 nh3 Storage Tank Sept 10 2014 2mohamed abd eldayemNo ratings yet

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Vapor Pressure of A Pure LiquidDocument6 pagesVapor Pressure of A Pure LiquidAndres Zuma PhillipsNo ratings yet

- Lesson 3: The First Law of Thermodynamics: Module 1: Energy Chapter 1: FuelsDocument4 pagesLesson 3: The First Law of Thermodynamics: Module 1: Energy Chapter 1: Fuelscory kurdapyaNo ratings yet

- AC7102.1D Nadcap Audit Criteria For BrazingDocument11 pagesAC7102.1D Nadcap Audit Criteria For BrazingrsjfidderNo ratings yet

- Cblm-Smaw-Nc IiDocument80 pagesCblm-Smaw-Nc IiERIC NARAGANo ratings yet

- DHU-NOCL - JOB EXECUTION PLAN - SupersededDocument37 pagesDHU-NOCL - JOB EXECUTION PLAN - SupersededTaofiqNo ratings yet

- Water Potential Questions KeyDocument1 pageWater Potential Questions KeyHemanth Kumar RamachandranNo ratings yet

- Viscosity - Ratio of SlurriesDocument16 pagesViscosity - Ratio of Slurriesnazmul hasanNo ratings yet

- Larox ScheiblerDocument16 pagesLarox ScheiblerCarlos de la TorreNo ratings yet

- Discovering and Developing Molecules With Optimal Drug-Like Properties (20 PDFDocument510 pagesDiscovering and Developing Molecules With Optimal Drug-Like Properties (20 PDFPaqui Miranda GualdaNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- Mecanica de Suelos Tomo 1 (Juarez Badillo)Document627 pagesMecanica de Suelos Tomo 1 (Juarez Badillo)Jorge Mgalmich100% (5)

- Mecanica de Suelos Tomo 1 (Juarez Badillo)Document627 pagesMecanica de Suelos Tomo 1 (Juarez Badillo)Jorge Mgalmich100% (5)

- Revelador 19C18K - SKD-S2Document4 pagesRevelador 19C18K - SKD-S2Ivan Morales AguilarNo ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- 19C01K SKC-SDocument3 pages19C01K SKC-ScamodiNo ratings yet

- Spotcheck, SKC-S: CertificationDocument3 pagesSpotcheck, SKC-S: Certificationnasser saldaña quinteroNo ratings yet

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: CertificationcamodiNo ratings yet

- Certificado Liquidos PenetrantesDocument4 pagesCertificado Liquidos PenetrantesJaneth AguilarNo ratings yet

- Spotcheck Penetrant, SKL-SP2: CertificationDocument3 pagesSpotcheck Penetrant, SKL-SP2: CertificationCarlos Eduardo Alvarez SantiagoNo ratings yet

- #14M10K Removedor SKC-S PDFDocument2 pages#14M10K Removedor SKC-S PDFPilar Medrano MenaNo ratings yet

- Certificado Liquidos PenetrantesDocument3 pagesCertificado Liquidos PenetrantesEnrique AntonioNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: Certificationjcarlos7411No ratings yet

- Water Suspendible ZP-5B: CertificationDocument2 pagesWater Suspendible ZP-5B: Certificationisraelita77671No ratings yet

- 18a18k Zyglo ZP 9fDocument3 pages18a18k Zyglo ZP 9fJhon Eder OrozcoNo ratings yet

- Certification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Document3 pagesCertification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Pilar MedranoNo ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022gauravNo ratings yet

- PT Test CertificateDocument2 pagesPT Test Certificateஅன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019Document2 pagesBatch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019அன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018Document2 pagesBatch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018sanjayprakash1979No ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022gauravNo ratings yet

- 08E17KDocument2 pages08E17KRonny AndalasNo ratings yet

- Batch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Document2 pagesBatch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Structures ProductionNo ratings yet

- 11k19k Skl-sp2 CertificadoDocument2 pages11k19k Skl-sp2 CertificadoEduardo Isla Millar100% (1)

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Batch Test Certificate: Less Than 0.0025 Less Than 0.0025Document3 pagesBatch Test Certificate: Less Than 0.0025 Less Than 0.0025venkiNo ratings yet

- Batch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023Document3 pagesBatch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023venkiNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- Batch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019Document3 pagesBatch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019அன்புடன் அஸ்வின்No ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- 22B21 2Document1 page22B21 2vinothNo ratings yet

- Batch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022Document1 pageBatch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022gauravNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationInspectorNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationvenkiNo ratings yet

- Date: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17KDocument2 pagesDate: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17Kisraelita77671No ratings yet

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalDocument17 pagesKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadNo ratings yet

- 7HF Prepared Bath: CertificationDocument1 page7HF Prepared Bath: CertificationEric Figueroa UribeNo ratings yet

- Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialDocument3 pagesInspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialAbee CungNo ratings yet

- 7HF Prepared Bath: CertificationDocument1 page7HF Prepared Bath: CertificationSantiago Hernadez RodriguezNo ratings yet

- Pruevas No DestructivasDocument2 pagesPruevas No DestructivasCeo EcNo ratings yet

- Mercon V SpecificationDocument22 pagesMercon V Specificationocto widodoNo ratings yet

- Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialDocument3 pagesInspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above Materialmaheshmalaichamy007No ratings yet

- 18M02Document1 page18M02Shahnawaz PathanNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificatevinothNo ratings yet

- Certification VP-31A: Batch # 8137E20Document1 pageCertification VP-31A: Batch # 8137E20César Antonio Vázquez MoralesNo ratings yet

- IS 903 Product ManualDocument7 pagesIS 903 Product Manualpratik panchalNo ratings yet

- Tinte Penetrante 1124467Document1 pageTinte Penetrante 1124467Diego SilvaNo ratings yet

- TM-10-6630-238-13-and-P Koehler Cloud and Pour Point Chamber Model K46000Document32 pagesTM-10-6630-238-13-and-P Koehler Cloud and Pour Point Chamber Model K46000maruf amaludinNo ratings yet

- 0850 02Document5 pages0850 02janiNo ratings yet

- NDT-SA-SATORP-PT-60 Rev 01-Date-15-AUG-2023Document14 pagesNDT-SA-SATORP-PT-60 Rev 01-Date-15-AUG-2023Md Abu Hanif RajuNo ratings yet

- Applied TextilesDocument3 pagesApplied TextilesMAU J. G. M.No ratings yet

- Certificate of CertificationDocument2 pagesCertificate of CertificationMuhammad Bilal KhattakNo ratings yet

- Srihari Katari 11 Jan 2022Document50 pagesSrihari Katari 11 Jan 2022Abhishek DevarajNo ratings yet

- An Overview of Surface Rehabilitation Techniques For Asphalt PavementsDocument38 pagesAn Overview of Surface Rehabilitation Techniques For Asphalt PavementsIvan Morales AguilarNo ratings yet

- Limpiador 18M14KDocument3 pagesLimpiador 18M14KIvan Morales AguilarNo ratings yet

- Limpiador 18M14KDocument3 pagesLimpiador 18M14KIvan Morales AguilarNo ratings yet

- G.-Especificaciones de Ligante SuperpaveDocument29 pagesG.-Especificaciones de Ligante SuperpaveTania Elen DiazNo ratings yet

- Repetitive Static Plate Load Tests of Soils and Flexible Pavement Components, For Use in Evaluation and Design of Airport and Highway PavementsDocument3 pagesRepetitive Static Plate Load Tests of Soils and Flexible Pavement Components, For Use in Evaluation and Design of Airport and Highway PavementsIvan Morales AguilarNo ratings yet

- PHT Summary Report V2Document158 pagesPHT Summary Report V2Ivan Morales AguilarNo ratings yet

- NMX C 475 Onncce 2013Document5 pagesNMX C 475 Onncce 2013Ivan Morales AguilarNo ratings yet

- Manual V2Document73 pagesManual V2Ivan Morales AguilarNo ratings yet

- NMX C 468 Onncce 2013Document9 pagesNMX C 468 Onncce 2013Ivan Morales AguilarNo ratings yet

- NMX C 467 Onncce 2013Document8 pagesNMX C 467 Onncce 2013Ivan Morales AguilarNo ratings yet

- D2435 OnedimconsolidDocument10 pagesD2435 OnedimconsolidHilana OliveiraNo ratings yet

- Asme Sec V B Se 165 Examen Con Liquidos Penetrantes PDFDocument25 pagesAsme Sec V B Se 165 Examen Con Liquidos Penetrantes PDFA.A100% (1)

- ME6404 Thermal EngineeringDocument18 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- 6.lesson Plan KD 3.2Document15 pages6.lesson Plan KD 3.2septiriyanNo ratings yet

- IS-EN CoolFit 4.0 v1Document58 pagesIS-EN CoolFit 4.0 v1carloscareca1No ratings yet

- Biology 11th Edition Raven Test BankDocument24 pagesBiology 11th Edition Raven Test BankAngelaLewisyqza100% (23)

- EC2 - General Rules PDFDocument141 pagesEC2 - General Rules PDFglmuralidharNo ratings yet

- Accepted Manuscript: Computers & EducationDocument32 pagesAccepted Manuscript: Computers & EducationAlpyh ZahrohNo ratings yet

- Physics 27 - Electrical Quantities 1 - SupplementDocument32 pagesPhysics 27 - Electrical Quantities 1 - SupplementRumaisa RahmanNo ratings yet

- Materials Engineer Examination No.6Document4 pagesMaterials Engineer Examination No.6Carren MarquezNo ratings yet

- Substitution Elimination (Alkilhalides) Bab 5 FessendenDocument113 pagesSubstitution Elimination (Alkilhalides) Bab 5 Fessendenahmad jamalNo ratings yet

- Chemical Reactions: Intended Learning OutcomesDocument17 pagesChemical Reactions: Intended Learning OutcomesAlias SalvadorNo ratings yet

- Material Equivalent 16-6-05Document7 pagesMaterial Equivalent 16-6-05Aan SharmaNo ratings yet

- Microbiology Lab (Midterms) : November 2015 Dr. Mark CalbanDocument3 pagesMicrobiology Lab (Midterms) : November 2015 Dr. Mark Calbanrichmarkconag1No ratings yet

- Paracetamol (7457)Document11 pagesParacetamol (7457)Prakashkumar PatelNo ratings yet

- 02a LASERs Session 2 (ND YAG Laser, He-Ne Laser and Semiconductor Laser)Document7 pages02a LASERs Session 2 (ND YAG Laser, He-Ne Laser and Semiconductor Laser)Bibaswan ChakmaNo ratings yet

- Fluid Mechanics Ii (Meng 3306) : Worksheet 1 Chapter1. Potential Flow TheoryDocument4 pagesFluid Mechanics Ii (Meng 3306) : Worksheet 1 Chapter1. Potential Flow TheoryAddisu DagneNo ratings yet

- Epoxy Hardeners, Water-Reducible: ProductsDocument1 pageEpoxy Hardeners, Water-Reducible: ProductsDhruv SevakNo ratings yet

- Specification For Electric-Resistance-Welded Steel Pipe: (Identical With ASTM Specification A 135-96)Document9 pagesSpecification For Electric-Resistance-Welded Steel Pipe: (Identical With ASTM Specification A 135-96)mileNo ratings yet

- Paths To Low-Cost Hydrogen Energy at A Scale For TDocument22 pagesPaths To Low-Cost Hydrogen Energy at A Scale For Trgh19No ratings yet

- JEE Main 2018 Question Paper Set ADocument40 pagesJEE Main 2018 Question Paper Set AAnsh Pratap SinghNo ratings yet

- Computer Physics Communications: Vei Wang, Nan Xu, Jin-Cheng Liu, Gang Tang, Wen-Tong GengDocument19 pagesComputer Physics Communications: Vei Wang, Nan Xu, Jin-Cheng Liu, Gang Tang, Wen-Tong Genglixiang RaoNo ratings yet