Professional Documents

Culture Documents

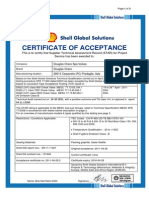

Certification VP-31A: Batch # 8137E20

Uploaded by

César Antonio Vázquez MoralesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certification VP-31A: Batch # 8137E20

Uploaded by

César Antonio Vázquez MoralesCopyright:

Available Formats

CERTIFICATION

VP-31A

BATCH #8137E20

APPROVAL

PRODUCT DESCRIPTION TYPE METHOD SENSITIVITY FORM CLASS

DATE

VP-31A Visible Penetrant II B&C L2* NA NA 7-MAY-2020

We hereby certify that this batch of inspection material when tested following manufacture meets the following:

Certificamos que este lote de material de inspeccíon cumple con los siguientes requisitos cuando es probado despues de la

fabricación:

- Certified to SAE AMS 2644G and on the Qualified Products List (test reference: AFWAL/MLS 86-88).

- Flowserve

- Velan PS-008, Rev. 10

- MIL-STD-2132 ¶ 7.1.3

- ISO/FDIS 3452-2:2006, EN 571-3

- NAVSEA 250-1500-1 ¶ 12.5.1.1.1, Rev 17

- ASTM E-165/E165-12, ASTM E-1417/E1417M-16

- RCC-M edition 2000, Section V-F, sub-section F6423 ¶ 3

- Framatome ANP Seimens AG; NFQS DC 103 Rev B 2004 ¶ MC 4200

- ASME Boiler & Pressure Vessel Code 2017, Section V, Article 6, appendix II-¶-641& II-¶-642

- 10 CFR part 21 applies

PO# ____________________

Is free of all known Ozone depleting substances and mercury contamination and was not made in any mercury bearing equipment.

Does not contain polychlorinated biphenyl (PCB), nonylphenol ethoxylates (NPE), or RoHS banned substances.

Esta libre de todas sustancias degradantes del ozono, de contaminación de mercurio, y no fue fabricado usando equipo

conteniendo mercurio. No contiene polychlorinated biphenyl (PCB), nonylphenol ethoxylates (NPE), o RoHS sustancias

prohibidas.

• Warranty shelf life is 5 years from date of batch approval.

Vida útil de garantia son 5 años desde la fecha del "approval date".

• Batch number is on bulk labels or bottom of aerosol cans.

Numeros de lote se encuentran en las etiquetas de los botes a granel o en el fondo de los botes de aerosol.

BATCH

QUALITY ASSURANCE TESTS REQUIREMENTS

RESULTS

Appearance: ISO 3452-2:2006(E) ¶ 7.1 Dark red liquid, no sediment. PASS

Density: ISO 3452-2:2006(E) ¶7.3 853 g/L - 870.7 g/L @ 21.1˚C(70˚F) 860 g/L

Viscosity: ASTM D-445, AMS-2644G ¶ 3.3.4, ISO 3452-2:2006(E) ¶ 7.4 4.4 - 5.4 mm2/s @ 37.7˚C (100˚F) 4.9 mm2/s

Performance: ISO 3452-2:2006(E) ¶ 7.2 *L2=(100% 50µ, >75% 30µ)@ 70˚F(21.1˚C) PASS

Performance: NFQS DC 1003 Rev B 2004, ¶ MC 4200. *L2=(100% 50µ, >75% 30µ)@ 122˚F(50˚C) PASS

Flash Point: ISO 3452-2:2006(E) ¶7.5: ASTM D-93 > 93.3˚C (> 200 ˚F) > 200°F

Sulfur Content: per ASTM E-165/E165M-18 ¶ 9.1.2 - Annex 4 ≤ 200 ppm (0.02 %) < 200 ppm

Chloride Content: ASTM E-165/E165M-18 ¶ 9.1.2 - Annex 4 ≤ 200 ppm (0.02 %) < 200 ppm

Total Halogen Content: ASTM E-165/E165M-18 ¶ 9.1.2 - Annex 4 ≤ 200 ppm (0.02 %) < 200 ppm

MET-L-CHEK QUALITY ASSURANCE

BATCH TESTED BY: BATCH APPROVED BY:

RICK VALDEZ PETER PELAYO

LAB TECHNICIAN QUALITY MANAGER

Rev. 10/19 ASNT/NAS 410 NDT LEVEL 3

Met-L-Chek Company, 1639 Euclid St. Santa Monica, CA 90404, U.S.A.

P: 310-450-1111 F: 310-452-4046 E: info@met-l-chek.com W: info@met-l-chek.com

You might also like

- Tinte Penetrante 1124467Document1 pageTinte Penetrante 1124467Diego SilvaNo ratings yet

- Cert. 16430 MPI-1400BDocument1 pageCert. 16430 MPI-1400BCristian Muñoz INGYENDNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Hepco Motion - Clean RoomDocument2 pagesHepco Motion - Clean RoomjoechengshNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- Spotcheck Penetrant SKD-S2: CertificationDocument4 pagesSpotcheck Penetrant SKD-S2: CertificationIvan Morales AguilarNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Kok04200 Material TracabilityDocument41 pagesKok04200 Material Tracabilityqamar qateebNo ratings yet

- Revelador 19C18K - SKD-S2Document4 pagesRevelador 19C18K - SKD-S2Ivan Morales AguilarNo ratings yet

- Material Test Report: ISO EN 10204 2004-3.1Document4 pagesMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- NC257 SN100C: Lead-Free Solder Paste FeaturesDocument3 pagesNC257 SN100C: Lead-Free Solder Paste Featureshuynh thi y viNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Technical Characteristics: Tutela Transmission ZC 75 Synth Product Code: 1475Document1 pageTechnical Characteristics: Tutela Transmission ZC 75 Synth Product Code: 1475carlosNo ratings yet

- 4 - Serial 89985-120-63Document7 pages4 - Serial 89985-120-63Katherine Toloza AcostaNo ratings yet

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalDocument17 pagesKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadNo ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Teadit 2236 Low-E PackingDocument18 pagesTeadit 2236 Low-E PackingK C Tharun KumarNo ratings yet

- Material Test ReportDocument7 pagesMaterial Test Reportjuan carlos suaNo ratings yet

- Transformer Oil Testing Lab - NABL Accredited (HTTP://WWW - Powerelectronical.com)Document3 pagesTransformer Oil Testing Lab - NABL Accredited (HTTP://WWW - Powerelectronical.com)mustafa1805100% (2)

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Document4 pagesPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbNo ratings yet

- EJX910A EJX930A CF1 Certificate - Us PDFDocument9 pagesEJX910A EJX930A CF1 Certificate - Us PDFSudar WantoNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- 84518-56 MM RevisedDocument1 page84518-56 MM RevisedDeepak MehtaNo ratings yet

- Instruction Manual: NXDS Scroll PumpDocument52 pagesInstruction Manual: NXDS Scroll PumpCarlos BertoliNo ratings yet

- LL Certificate PrototypeDocument1 pageLL Certificate Prototypetilakthakar1No ratings yet

- Spotcheck Penetrant, SKL-SP2: CertificationDocument3 pagesSpotcheck Penetrant, SKL-SP2: CertificationCarlos Eduardo Alvarez SantiagoNo ratings yet

- A0705260-Taa00001ne - 200512 Re17 Re17sDocument3 pagesA0705260-Taa00001ne - 200512 Re17 Re17saelbaroudy390No ratings yet

- TECHNICAL DATA FUSE LINK TYPE T (15 38 KV) WEBDocument1 pageTECHNICAL DATA FUSE LINK TYPE T (15 38 KV) WEBSantiago EspitiaNo ratings yet

- Mcerts Forbes Marshal Insitu ProbeDocument8 pagesMcerts Forbes Marshal Insitu ProbeKunal KumarNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- Technical Data: 1. DescriptionDocument4 pagesTechnical Data: 1. DescriptionCanh RocNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Imkon Gaz/SC20075-1 IMKON GAZ SERVIS/GEO-20364Document25 pagesImkon Gaz/SC20075-1 IMKON GAZ SERVIS/GEO-20364Жасур ТашпулатовNo ratings yet

- Complete Solution For Industrial Valves: Neway ValveDocument24 pagesComplete Solution For Industrial Valves: Neway ValveLuis Felipe Cortes PachecoNo ratings yet

- FPCC Base Oil SpecificationDocument1 pageFPCC Base Oil SpecificationGolden RosesNo ratings yet

- Seta Verification Materials: STVM MTVMDocument2 pagesSeta Verification Materials: STVM MTVMdchyNo ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- Concrete AdmixtureDocument12 pagesConcrete AdmixtureahmetatayevNo ratings yet

- 380 1 PDFDocument7 pages380 1 PDFJimyTeránAgudeloNo ratings yet

- Leser Certificate For Global ApplicationDocument2 pagesLeser Certificate For Global ApplicationThiago Souza da SilvaNo ratings yet

- Environmental Product Declaration: LC 10W 350ma Fixc C SNCDocument14 pagesEnvironmental Product Declaration: LC 10W 350ma Fixc C SNCCNo ratings yet

- Test Certificate: Highway Industries Ltd. (Sahnewal)Document1 pageTest Certificate: Highway Industries Ltd. (Sahnewal)Deepak MehtaNo ratings yet

- Spotcheck, SKC-S: CertificationDocument3 pagesSpotcheck, SKC-S: Certificationnasser saldaña quinteroNo ratings yet

- 19C01K SKC-SDocument3 pages19C01K SKC-ScamodiNo ratings yet

- Certificados Solis S6 SeriesDocument39 pagesCertificados Solis S6 SeriesUdayanga WickramasingheNo ratings yet

- Pall PCM400 Series Fluid Cleanliness Monitor: BenefitsDocument2 pagesPall PCM400 Series Fluid Cleanliness Monitor: BenefitsafsalmohmdNo ratings yet

- Leser Certificate For Global ApplicationDocument2 pagesLeser Certificate For Global ApplicationThiago Souza da SilvaNo ratings yet

- VK102 K5.6 12987 PendentDocument7 pagesVK102 K5.6 12987 PendentPhung BaoNo ratings yet

- Material Test ReportDocument5 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- P-005 Liquid Penetant Testing ProcedureDocument13 pagesP-005 Liquid Penetant Testing ProcedureSaheb YadavNo ratings yet

- Certificado Liquidos PenetrantesDocument4 pagesCertificado Liquidos PenetrantesJaneth AguilarNo ratings yet

- bd501n CGBDocument4 pagesbd501n CGBIrlan LeiteNo ratings yet

- Micology - ED174459 PDFDocument717 pagesMicology - ED174459 PDFAvraham ZentliNo ratings yet

- Macario Biology W1Document6 pagesMacario Biology W1Roberto MendozaNo ratings yet

- Chapter 2 Problems 2.9 2.10Document3 pagesChapter 2 Problems 2.9 2.10juan carlos0% (1)

- Taeley of Dicashs: HezardDocument14 pagesTaeley of Dicashs: HezardAkash0% (1)

- 3e. ARK-Lab-Thermal Expansion of WaterDocument20 pages3e. ARK-Lab-Thermal Expansion of WaterBibi Rabeya 1721771No ratings yet

- List of Tables No. Particulars Page No.: FSSAI Standard Shrikhand CompositionDocument3 pagesList of Tables No. Particulars Page No.: FSSAI Standard Shrikhand CompositionAshutosh MasihNo ratings yet

- Bishop ScoreDocument3 pagesBishop ScoreAlain SánchezNo ratings yet

- 1602 3315 1 SMDocument6 pages1602 3315 1 SMAsirah CollectionNo ratings yet

- MRS (Main Receiving Substation)Document4 pagesMRS (Main Receiving Substation)Rahul Gautam100% (4)

- Shift SelectorDocument24 pagesShift SelectorMarco AchinaNo ratings yet

- CBC - Electronic Products Assembly and Servicing NC IIDocument92 pagesCBC - Electronic Products Assembly and Servicing NC IIWilfredo Dalangon Langomez100% (3)

- Magnetic Eye TrackingDocument7 pagesMagnetic Eye Trackinghub23No ratings yet

- Microplate Shaker: MB100-2A/MB100-4A Thermo Shaker Incubator For Plates MK100-2A/MK100-4A Incubator For Plates MX100-4ADocument1 pageMicroplate Shaker: MB100-2A/MB100-4A Thermo Shaker Incubator For Plates MK100-2A/MK100-4A Incubator For Plates MX100-4AzealouseveNo ratings yet

- F MM AssignmentsDocument9 pagesF MM AssignmentsMuhammad HarisNo ratings yet

- Lees' Loss Prevention OverpressureDocument2 pagesLees' Loss Prevention OverpressureNoel Federer SarkarNo ratings yet

- Grammar Review: The World's Strangest LawsDocument2 pagesGrammar Review: The World's Strangest LawsAlesia GalvanNo ratings yet

- Effects of Carbohydrate Crystallization On Stability of Dehydrated Foods and Ingredient FormulationsDocument9 pagesEffects of Carbohydrate Crystallization On Stability of Dehydrated Foods and Ingredient FormulationsIsra CFNo ratings yet

- Alokasi Biaya Berbasis AktivitasDocument31 pagesAlokasi Biaya Berbasis AktivitasfiryalfitriyahNo ratings yet

- SDS H2PLC Miconazole CRM 2 H2P 42 5GMDocument8 pagesSDS H2PLC Miconazole CRM 2 H2P 42 5GMAFI FARMANo ratings yet

- Zomato - Case StudyDocument8 pagesZomato - Case StudyBhadrhi PrazaathNo ratings yet

- SDS DC High Grout 210Document11 pagesSDS DC High Grout 2104919404No ratings yet

- 18 Lecture 04-05-2020Document32 pages18 Lecture 04-05-2020Shashank Cooled RanaNo ratings yet

- Crisis ManagementDocument206 pagesCrisis ManagementHanz MoralesNo ratings yet

- Marketing Strategies of Different Local, Domestic and Multinational Brands of Pesticides in Nizamabad District of TelanganaDocument107 pagesMarketing Strategies of Different Local, Domestic and Multinational Brands of Pesticides in Nizamabad District of TelanganaGaurav Baluni100% (1)

- 3 Hydrocarbon Phase BehaviourDocument45 pages3 Hydrocarbon Phase BehaviourMD. ASIF ALL AZADNo ratings yet

- Catalogo CS-PH-6 PH-4 (Hydril)Document4 pagesCatalogo CS-PH-6 PH-4 (Hydril)Ronal Borrero100% (4)

- Intuitive Medicine Summit 2022 Day 5Document7 pagesIntuitive Medicine Summit 2022 Day 5Paul Ioan PopescuNo ratings yet

- Ug DentalDocument4 pagesUg Dentaldeepak162162No ratings yet

- List - (Annexure H)Document59 pagesList - (Annexure H)shrutiNo ratings yet

- RC Two-Way Slabs Strengthened With CFRP StripsDocument6 pagesRC Two-Way Slabs Strengthened With CFRP Stripsvishwanath malalanayakeNo ratings yet

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- Theory and Calculation of Heat Transfer in FurnacesFrom EverandTheory and Calculation of Heat Transfer in FurnacesRating: 3 out of 5 stars3/5 (4)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesFrom EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Piping Design for Industrial Facilities: Understanding Codes and StandardsFrom EverandPiping Design for Industrial Facilities: Understanding Codes and StandardsRating: 4 out of 5 stars4/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsFrom EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsRating: 4.5 out of 5 stars4.5/5 (10)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsFrom EverandMechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsNo ratings yet