Professional Documents

Culture Documents

84518-56 MM Revised

Uploaded by

Deepak MehtaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

84518-56 MM Revised

Uploaded by

Deepak MehtaCopyright:

Available Formats

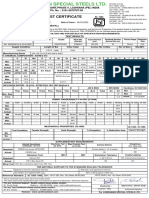

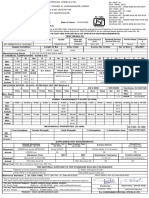

VARDHMAN SPECIAL STEELS LTD.

QF / R&D / 01

IATF 16949 : 2016

C-58 FOCAL POINT, PHASE III, LUDHIANA(PB.) INDIA Certificate NO : 37659-2008-AQ-IND-IATF

ISO 17025 : 2017

Ph. No.0161-2670707-09

Certificate NO : TC -7438

TEST CERTIFICATE ISO 14001 : 2015

Certificate NO : 261680-2018-AE-IND-RVA

ISO 45001 : 2018

Certificate NO : 10000414502-MSC-RVA-IND

ISO 9001 : 2015

TEST CERTIFICATE NO.: BLB530LAB2203192 Date of Issue : 18-05-2022

Certificate NO : 39216-2008-AQ-IND-RVA

To: HIGHWAY INDUSTRIES LTD.(MANGLI)

We certify that the material described below fully conforms to IS:7283-1992. Chemical Composition and Mechanical Properties of the product tested in accordance with

the Scheme of Testing and Inspection contained in the BIS Certification Marks licence No. CM/L-9700028216 are as indicated below against each order No. etc.

(PLEASE REFER TO IS:7283-1992 FOR DETAILS OF SPECIFICATION REQUIREMENTS)

TEST RESULTS

Order No. & Date Class & Design. Grade Heat No. Cast Section Finished Section Finish Shape Reductio

(Cast No.) (mm) (Nominal Size mm) n

S61-22000479/10.0 10-05-2022 20MNCR5+HH 00084518 200 x 200 56 Round 16.23

Supply Condition Length of Bar Color Code Invoice No. & Date No. of Bars Qty.(MT)

Hot Rolled 4.0-6.0 meter Violet

Manufacturing Route EAF-LRF-VD-CCP With EMS & AMLC

% CHEMICAL COMPOSITION - ASTM E 415

C Si Mn S P Ni Cr Mo Cu Sn Al Ti Ca B V Nb

Min. 0.180 - 1.150 0.012 - - 1.150 - - - 0.020 - - - - -

Max. 0.210 0.350 1.400 0.030 0.025 0.350 1.300 0.120 0.250 - 0.045 0.0100 0.0015 - - -

Actual 0.193 0.290 1.355 0.018 0.014 0.060 1.250 0.015 0.075 0.005 0.024 0.0020 0.0010 0.0002 0.0070 0.0017

Gases O2 N2 H2 D.I. Value Grain Size % Carbon % Manganese Decarb (mm) Micro Structure

In PPM ASTM E 1019 (IS:4748/ASTM E112) Equivalent Equivalent (IS:6396)

IS:228

Min. - 80.0 - - ASTM 5.0 or finer - - 1% of section Pearlite + Ferrite

max

Max. 25.0 160.0 2.7 - - -

Actual 15.0 115.0 1.4 - 7.0/7.5 - - 0.25 mm Pearlite + Ferrite

INCLUSION RATING - IS:4163 / ASTM E45A/ ISO 4967,Method A

A B C D JIS G 0555 DIN 50602 Hardness- IS:1500/1586

Thin Thick Thin Thick Thin Thick Thin Thick A B+C Total K3 K4 Min. -

Max. Req. - - - - - - - - - - - 20

- -

15 Max. 280 BHN

Actual - - - - - - - - - - - -

15.0 13.0

- Actual 225-245 BHN

JOMINY HARDENABILITY IN HRC (IS 3848)

mm 1mm 1.5 mm 2 mm 3 mm 4 mm 5 mm 6 mm 6.35 mm 7 mm 8 mm 9 mm 10 mm 11 mm 12 mm 13 mm

- - - - - 41.0 - - - - - 37.0 - - -

Min.

Max. - - - - - 45.0 - - - - - 41.0 - - -

Actual - - - - - 42.50 - - - - - 39.00 - - -

MM 14 mm 15 mm 17 mm 18 mm 19 mm 20 mm 25 mm 30 mm 35 mm 40 mm 45 mm 50 mm 55 mm 60 mm

Min. - - - - - - 29.0 - - - - - - -

Max. - - - - - - 33.0 - - - - - - -

Actual - - - - - - 30.50 - - - - - - -

MECHANICAL PROPERTIES (IS:1608) IS:1499 / IS:1598

Test Condition Tensile Strength Yield Strength % Elongation % Reduction Area Impact Strength

Min - - - - -

-

Max - - - - -

Actual - - - - - -

SUPPLEMENTARY REQUIREMENTS

Internal Soundness Step Down Test Blue Fracture Test Straightness

Surface Defects

(ASTM E381 / IS11371) (IS 4075) (IS 10138) mm / meter max.

C2R2S2 max as per ASTM E381 As per IS 4075 - Surface defect < 1% of section 3.0

Required

Actual C2R2S2 max OK - OK OK

Ultrasonic Test MFLT MPI Dimension Tolerance Ovality/Lobbing

Required Manual UST at 2mm FBH - Yes +/-0.50 mm 75% of dimensional tolerance

Actual 100% Bars done-OK - 100% Bars done-OK OK OK

Mixup Test 100% Bars checked by Spark Test ,XRF Test

THE MATERIAL SUPPLIED TO THE STANDARD ROLLING TOLERANCES

Material is free fro radioactive elements Al/N2= 2.08 against 2.0 Min

Remarks

%Cu+10*Sn = 0.125 against 0.45 max. Sb=0.0005 against 0.007 max.

Reference Standard IS: 7283 -1992 IS-HT- 208, Rev. -01, Date-09.05.2022 NPDP-220521, Rev.-00, Date-09.05.2022

Above mentioned results relate only to the sample tested

This report shall not be reproduced except in full without the approval of laboratary / Authorised signatory

For any Technical Support / Quality related issues please contact -

Mr. Dinesh Singh Mobile no. : 081466-25586 , email : met5.vss@vardhman.com Checked by : Approved by : Dinesh Singh

For any Test Certificate related issues please contact -

Engineer - R&D Authorised Signatory

Mr. K.K. Shukla Mobile no. : 075080-02659 , email : met2.vss@vardhman.com

Website : www.vardhmansteel.com For VARDHMAN SPECIAL STEELS LTD.

You might also like

- Test Certificate: Highway Industries Ltd. (Sahnewal)Document1 pageTest Certificate: Highway Industries Ltd. (Sahnewal)Deepak MehtaNo ratings yet

- Inspection and Test Plan (ITP) WeldingDocument3 pagesInspection and Test Plan (ITP) WeldingMuhammed Abo-Fandood100% (5)

- OMR pipe fittings certificate analysisDocument1 pageOMR pipe fittings certificate analysisslimane AIT-IDIRNo ratings yet

- 26-05-2022 13-15-03-465 PDFDocument1 page26-05-2022 13-15-03-465 PDFQualityNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Inspection Report: Setcore Arabia Petroleum ServiceDocument1 pageInspection Report: Setcore Arabia Petroleum ServiceMahmoud SalahNo ratings yet

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarNo ratings yet

- Offshore Testing Services Lab ReportDocument3 pagesOffshore Testing Services Lab ReportKandula RajuNo ratings yet

- Certificate of ComplianceDocument7 pagesCertificate of ComplianceNabilah HusnaNo ratings yet

- Setcore Arabia Petroleum Service Inspection ReportDocument1 pageSetcore Arabia Petroleum Service Inspection ReportMahmoud SalahNo ratings yet

- 6 Ulma (1759-1)Document1 page6 Ulma (1759-1)Mygame 1402No ratings yet

- A325M - M24x70Document3 pagesA325M - M24x70nam nguyengiangNo ratings yet

- MILL TEST CERTIFICATE FOR 304 STAINLESS STEELDocument1 pageMILL TEST CERTIFICATE FOR 304 STAINLESS STEELMANIMARAN QC100% (1)

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Chemical Analysis Report (Pmi / Spectro - Oes) : Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.LDocument1 pageChemical Analysis Report (Pmi / Spectro - Oes) : Naser M. AL-Baddah & Partner General Trading & Contracting Co. W.L.Lm.aliNo ratings yet

- Round Bar Incoloy 825 Dia 40 MM 4 - ApprovedDocument6 pagesRound Bar Incoloy 825 Dia 40 MM 4 - ApprovedBogdan CăpățînăNo ratings yet

- 0.MVR 2020 030Document4 pages0.MVR 2020 030vinuNo ratings yet

- Ss 316l 3.0 MTC NewDocument2 pagesSs 316l 3.0 MTC NewSahil Hashmi100% (1)

- Nouveaux Certificate Conforms AWS A5.17 E7018 Welding WireDocument1 pageNouveaux Certificate Conforms AWS A5.17 E7018 Welding WireharikrishnanNo ratings yet

- NABL accredited temperature controller calibration certificateDocument1 pageNABL accredited temperature controller calibration certificateCustomer SupportNo ratings yet

- Calibration Certificate DetailsDocument1 pageCalibration Certificate Detailssathish K KumarNo ratings yet

- Calibration Certificate for Compression Testing MachineDocument2 pagesCalibration Certificate for Compression Testing MachineSatyendra kumar YadavNo ratings yet

- 1687938333795-United Kingdom - DNV UK - MERD00002CDDocument6 pages1687938333795-United Kingdom - DNV UK - MERD00002CDQasim JummaniNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01Document392 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01Neil JavierNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150Document150 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150QC ManagerNo ratings yet

- Structural Steel Fabrication Inspection and Test PlanDocument3 pagesStructural Steel Fabrication Inspection and Test Plansivagnanam sNo ratings yet

- A325M - M24x100Document3 pagesA325M - M24x100nam nguyengiangNo ratings yet

- Inspection Certificate Type 3.1 DIN EN10204Document1 pageInspection Certificate Type 3.1 DIN EN10204INAM OlsztynNo ratings yet

- Non Destructive Examination Request (NDER) : Doc. No Rev. No Date NotesDocument2 pagesNon Destructive Examination Request (NDER) : Doc. No Rev. No Date Noteskeymal9195No ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- VENDOR ITP - BALL VALVE (LOT-2Document3 pagesVENDOR ITP - BALL VALVE (LOT-2VIVEK TIWARINo ratings yet

- Certificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inDocument1 pageCertificate of Conformance: Qa@nouveaux - in WWW - Nouveaux.inharikrishnanNo ratings yet

- !certificate of !calibration: International Agent For"Contracting EstDocument8 pages!certificate of !calibration: International Agent For"Contracting EstZara BhaiNo ratings yet

- Material Test ReportDocument7 pagesMaterial Test Reportjuan carlos suaNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Kok04200 Material TracabilityDocument41 pagesKok04200 Material Tracabilityqamar qateebNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh MehtaNo ratings yet

- Essar MTCDocument1 pageEssar MTCGowtham Vishvakarma33% (3)

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- R1118111-S30002-COL-C00000-20019-H03-Rev.C QCDocument37 pagesR1118111-S30002-COL-C00000-20019-H03-Rev.C QCDIBYENDU BERA100% (1)

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- JSW Steel LimitedDocument1 pageJSW Steel LimitedVenkatesh KumarNo ratings yet

- Kolkata: Calibration: Ofcalibration: IDocument4 pagesKolkata: Calibration: Ofcalibration: IjamilNo ratings yet

- CV of BDocument6 pagesCV of BSyed Mohamed Gani GaniNo ratings yet

- 183-19 Wpqc-W162-6''-Asme XiDocument1 page183-19 Wpqc-W162-6''-Asme Xibouchoucha jebaliNo ratings yet

- Welders Qualification Test Record For Approval: Marjan Development ProgramDocument8 pagesWelders Qualification Test Record For Approval: Marjan Development ProgramJoni Carino SuniNo ratings yet

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- Saudi Aramco WPS Procedure ApprovalDocument7 pagesSaudi Aramco WPS Procedure ApprovalAkansha SharmaNo ratings yet

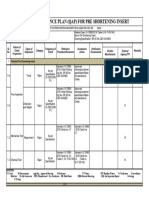

- Pre Shortening Insert QAPDocument1 pagePre Shortening Insert QAPtibindas2463No ratings yet

- Scope of SupplyDocument5 pagesScope of Supplyhammad21No ratings yet

- Coupler Plate DP TestDocument1 pageCoupler Plate DP Testshindemitesh17No ratings yet

- JSW Steel Coated Products Test CertificatesDocument10 pagesJSW Steel Coated Products Test CertificatesBernice AkotoNo ratings yet

- Calibration Certificate for Laboratory StirrerDocument1 pageCalibration Certificate for Laboratory StirrerSales GoldClassNo ratings yet

- Annexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 301 315Document15 pagesAnnexure IV - QCP - Electrical - and - C&I 2021 07 05 02 - 57 - 28 301 315mrherp153No ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- Saatvik QAP-72 Cell Full CellDocument4 pagesSaatvik QAP-72 Cell Full Cellvenkatraman JNo ratings yet

- Supply Specification Coating / Painting For Parts With High Corrosive Stress DBL 7391Document21 pagesSupply Specification Coating / Painting For Parts With High Corrosive Stress DBL 7391Deepak Mehta100% (1)

- Quantitative Evaluation of Structural Alloy Steel Banded StructureDocument8 pagesQuantitative Evaluation of Structural Alloy Steel Banded StructureDeepak MehtaNo ratings yet

- Heat Treatment Analysis Report SummaryDocument1 pageHeat Treatment Analysis Report SummaryDeepak MehtaNo ratings yet

- 84518-56 MM RevisedDocument1 page84518-56 MM RevisedDeepak MehtaNo ratings yet

- 84518-56 MM RevisedDocument1 page84518-56 MM RevisedDeepak MehtaNo ratings yet

- BMW Flange Crack Issue AnalyzedDocument12 pagesBMW Flange Crack Issue AnalyzedDeepak MehtaNo ratings yet

- Highway Industries LTD (Auto Division) Site-III, Ludhiana. Heat Treatment Analysis ReportDocument3 pagesHighway Industries LTD (Auto Division) Site-III, Ludhiana. Heat Treatment Analysis ReportDeepak MehtaNo ratings yet

- Vessel and Conveyors - VPDDocument4 pagesVessel and Conveyors - VPDAntonio Mizraim Magallon SantanaNo ratings yet

- Medical Services Recruitment Board (MRB)Document20 pagesMedical Services Recruitment Board (MRB)durai PandiNo ratings yet

- Excerpts From The Way of The Samurai (Shīdo) : Primary Source Document With Questions (DBQS)Document2 pagesExcerpts From The Way of The Samurai (Shīdo) : Primary Source Document With Questions (DBQS)Valeria MontalvaNo ratings yet

- DOE V Rhodes College Ammended Motion For TRODocument19 pagesDOE V Rhodes College Ammended Motion For TROSouwesterdocs100% (1)

- Faktor OrganisasiDocument9 pagesFaktor OrganisasiNur Fatin NabilahNo ratings yet

- Ho'oponopono ! - The Power of ForgivenessDocument6 pagesHo'oponopono ! - The Power of ForgivenessParainNo ratings yet

- Exercise 15 Signal TransductionDocument4 pagesExercise 15 Signal TransductionTrina Rose AutidaNo ratings yet

- 255 Introduction Vocational Service enDocument12 pages255 Introduction Vocational Service enDmitri PopaNo ratings yet

- Mumbai: City of DreamsDocument14 pagesMumbai: City of DreamsAnika WahalNo ratings yet

- Standardized Trade Types Fact SheetDocument2 pagesStandardized Trade Types Fact SheetRik100% (1)

- Holzma PR Hob and Ex Linger Enu 18533Document7 pagesHolzma PR Hob and Ex Linger Enu 18533esfandiar232477No ratings yet

- Position Paper For The Art Controversy "Poleteismo" of Mideo CruzDocument2 pagesPosition Paper For The Art Controversy "Poleteismo" of Mideo CruzAalayah Gwendel Wayne CarumbaNo ratings yet

- CV of Dr. Mohammad TahirDocument12 pagesCV of Dr. Mohammad TahirMuhammad FayyazNo ratings yet

- Learn From Customers to Improve Products and ServicesDocument8 pagesLearn From Customers to Improve Products and ServicesQuan Hoang AnhNo ratings yet

- Dental Cements: Dr. Hamida KhatunDocument39 pagesDental Cements: Dr. Hamida Khatunsakib samiNo ratings yet

- Social Engineering For Pentester PenTest - 02 - 2013Document81 pagesSocial Engineering For Pentester PenTest - 02 - 2013Black RainNo ratings yet

- First Aid KitDocument15 pagesFirst Aid Kitdex adecNo ratings yet

- G25M R TransmissionDocument29 pagesG25M R TransmissionMaksym VovkNo ratings yet

- Quotation SS20230308 100KVAR APFC PANEL VIDHYA WIRESDocument4 pagesQuotation SS20230308 100KVAR APFC PANEL VIDHYA WIRESsunil halvadiyaNo ratings yet

- Emebet Kebede FINALDocument65 pagesEmebet Kebede FINALTefeNo ratings yet

- Group L2 Nitish at Solutions UnlimitedDocument10 pagesGroup L2 Nitish at Solutions UnlimitedMani ThomasNo ratings yet

- Resume Masroor 3Document3 pagesResume Masroor 3mohammad masroor zahid ullahNo ratings yet

- Choose the Right Low Boy Trailer ModelDocument42 pagesChoose the Right Low Boy Trailer ModelOdlnayer AllebramNo ratings yet

- Unit 2: Marketing Processes and Planning: Assignment BriefDocument4 pagesUnit 2: Marketing Processes and Planning: Assignment BriefGharis SoomroNo ratings yet

- Kuruk Etra:: Dharma-K Etra Śalya-ParvaDocument1 pageKuruk Etra:: Dharma-K Etra Śalya-ParvaRavinder Khullar100% (1)

- Logging Levels in Log4j - Tutorialspoint ExamplesDocument3 pagesLogging Levels in Log4j - Tutorialspoint ExamplesJai PannuNo ratings yet

- Pharmacist Licensing Requirements by StateDocument21 pagesPharmacist Licensing Requirements by StateBio DataNo ratings yet

- TECHNICALPAPER2Document8 pagesTECHNICALPAPER2spiderwebNo ratings yet

- Environmental, Health and Safety Guidelines For Textiles ManufacturingDocument20 pagesEnvironmental, Health and Safety Guidelines For Textiles ManufacturingHitesh ShahNo ratings yet

- 10-09 Oct-Eng-NLDocument4 pages10-09 Oct-Eng-NLdhammadinnaNo ratings yet