Professional Documents

Culture Documents

Certificado Liquidos Penetrantes

Uploaded by

Enrique AntonioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificado Liquidos Penetrantes

Uploaded by

Enrique AntonioCopyright:

Available Formats

Certification

Spotcheck, SKL-WP2

Date: 10/24/2016

Purchase Order:

Batch #: 16K04K

It is hereby certified that when tested at the time of manufacture, the above listed material and batch

number meets the requirements of and has been tested for Sulfur and Halogens according to:

ASME Boiler and Pressure Vessel Code, 2004, 2007, 2010, 2013 and 2015 Edition, Section V,

Nondestructive Examination, including 2005, 2006, 2008, 2009b, and 2011a Addenda,

Article 6 Paragraph T-640 and Article 24 as applicable.

ASME Boiler and Pressure Vessel Code, 1995, 1998 and 2001 Edition, Section V Nondestructive

Examination, including 1999, 2000, 2002 and 2003 Addenda, Article 6 Paragraph T-640 and Article

24 as applicable.

ASME Boiler and Pressure Vessel Code, 1986, 1989 and 1992 Edition, Section V , Nondestructive

Examination, Article 6 including 1992 Addenda, Paragraph T-625, 1993 Addenda Paragraph T-640

and Article 24 as applicable.

ASTM E-165-92, ASTM E-165-94, ASTM E-165-95, ASTM E-165-02,ASTM E-165-09,

ASTM E-165/E-165M-12, Paragraph 7.1.

MIL-STD-271F(SH) June 27, 1986, Paragraphs 5.3 and 5.3.1, including Notice 1 Paragraph 5.6.1

June 21, 1993.

NAVSEA T9074-AS-GIB-010/271(April 30, 1997 including Notice 1, September 11, 2014 Rev. 1 )

Paragraph 5.3.1 and 5.6.2.

MIL-STD-2132D, February 11, 2003, Paragraphs 7.1, 7.1.2 and 7.1.3, Appendix C, Paragraph 40.

The following test results were obtained:

96 0.0096 wt., % of residue. CL+F___________ppm__________

Sulfur__________ppm__________ <10 <0.0010 wt., % of residue

NA

Cleaner residue (see note 3)_________________ NA

g/100g _________________ g/100ml

It is further certified that this material does not contain mercury as a basic element and that no mercury

bearing equipment has been used in its manufacture.

Notes:

1. Our batch number appears on the bottom of all aerosol cans and on the label of all bulk containers.

2. Most specifications require test results to be stated in percent but some require parts per million (ppm). To convert percent figures to parts per million move the

decimal four places to the right.

3. The above certification gives the results obtained at the time of manufacture. Age and use may alter the properties of any material.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

FORM NO F-1568 R-7/16 magnaflux.com

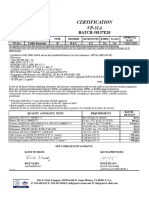

Certification

Spotcheck, SKL-WP2

Date: 10/24/2016

Purchase Order:

Batch #: 16K04K

It is hereby certified that the above listed inspection material and batch number meets the requirements of

AMS 2644F and is approved by the U.S. Air Force as listed on QPL-AMS-2644

When tested according to paragraph 4.3.2, Sampling Plan A, the following test results were obtained:

4.2.2.1 Penetrant Tests:

Flash Point (PMCC), 3.3.3

239 F

Viscosity, 3.3.4 ( 8.7 cs. Nominal)

Fluorescent Brightness, 3.3.8.3.2 (FP-4PE Standard) 8.71 cs@100 F

NA %

Water Tolerance (Method A only), 3.3.8.5

16.32 %

Removability, 3.3.8.6 PASS

4.2.2.1 Emulsifier Tests:

Flash Point (PMCC), 3.3.3

NA F

Viscosity, 3.3.4 ( cs. Nominal)

Water Content (Method D Only), 3.3.9.6 NA cs@100 F

NA %

4.2.2.3 Developer Tests:

Developer Fluorescence, 3.3.10.2 NA

Developer Removability, 3.3.10.4 NA

Redispersibility, 3.3.10.5 NA

3.3.11.4 Remover Tests:

Penetrant Removal, 4.4.11.2 NA

It is further certified that this material meets the requirements of ASTM E 1417, Paragraph 5.1.

Batch Numbers appear on labels of bulk containers and on bottoms of aerosol cans.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

FORM NO F-1579E R2/16 magnaflux.com

Certification

SKL-WP2

Date: 10/24/2016

Purchase Order:

Batch #: 16K04K

We hereby certify that the Penetrate inspection material

Type SKL-WP2 , Batch No 16K04K

Manufactured in October, 2016 furnished on the above order number

meets the requirements of EN ISO 3452-2, with the following results.

Individual Property Section Requirement Result

Appearance 6.1 Red Liquid PASS

Sensitivity (30m panel) 6.2 Sensitivity Level (1(<75%) or 2 (75%)) 2

Density 6.3 0.839-0.927@ 20C (68F) 0.884

Viscosity 6.4 7.83-9.57 cST@37.8 C (100F) 8.71

Flashpoint 6.5 >101C (213F) 239

Washability 6.6 Residue equal or less than standard PASS

Corrosive Properties (Mg) 6.11 No evidence of staining, pitting or PASS

corrosion

Water Tolerance 6.10 >5% 16.32

*Testing in accordance with 5.4.1 Table 2 as applicable

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

Form No. 3452SKLWP2 R-2/16 magnaflux.com

You might also like

- Columns for Gas Chromatography: Performance and SelectionFrom EverandColumns for Gas Chromatography: Performance and SelectionNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: Certificationjcarlos7411No ratings yet

- Spotcheck Penetrant, SKL-SP2: CertificationDocument3 pagesSpotcheck Penetrant, SKL-SP2: CertificationCarlos Eduardo Alvarez SantiagoNo ratings yet

- Spotcheck, SKL-WP2: CertificationDocument3 pagesSpotcheck, SKL-WP2: CertificationcamodiNo ratings yet

- 19e02k SKL-SP2 PDFDocument3 pages19e02k SKL-SP2 PDFJulian AdaraqueNo ratings yet

- Certificado Revelador Skd-S 2Document3 pagesCertificado Revelador Skd-S 2Enrique AntonioNo ratings yet

- Spotcheck, SKC-S: CertificationDocument3 pagesSpotcheck, SKC-S: Certificationnasser saldaña quinteroNo ratings yet

- 19C01K SKC-SDocument3 pages19C01K SKC-ScamodiNo ratings yet

- Certificado Liquidos PenetrantesDocument4 pagesCertificado Liquidos PenetrantesJaneth AguilarNo ratings yet

- Revelador 19C18K - SKD-S2Document4 pagesRevelador 19C18K - SKD-S2Ivan Morales AguilarNo ratings yet

- Certificado de Revelador PDFDocument3 pagesCertificado de Revelador PDFCarlos Eduardo Alvarez SantiagoNo ratings yet

- Water Suspendible ZP-5B: CertificationDocument2 pagesWater Suspendible ZP-5B: Certificationisraelita77671No ratings yet

- Spotcheck Penetrant SKD-S2: CertificationDocument4 pagesSpotcheck Penetrant SKD-S2: CertificationIvan Morales AguilarNo ratings yet

- Spotcheck Developer SKD-S2: CertificationDocument3 pagesSpotcheck Developer SKD-S2: Certificationnasser saldaña quinteroNo ratings yet

- #14M10K Removedor SKC-S PDFDocument2 pages#14M10K Removedor SKC-S PDFPilar Medrano MenaNo ratings yet

- Certification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Document3 pagesCertification: 155 Harlem Ave. Glenview, IL 60025 P: 1-847-657-5300Pilar MedranoNo ratings yet

- 18a18k Zyglo ZP 9fDocument3 pages18a18k Zyglo ZP 9fJhon Eder OrozcoNo ratings yet

- 11k19k Skl-sp2 CertificadoDocument2 pages11k19k Skl-sp2 CertificadoEduardo Isla Millar100% (1)

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022gauravNo ratings yet

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022Document2 pagesBatch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022gauravNo ratings yet

- PT Test CertificateDocument2 pagesPT Test Certificateஅன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018Document2 pagesBatch Test Certificate: Form No: F/QC/008/07 Rev:03 /2018sanjayprakash1979No ratings yet

- Batch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019Document2 pagesBatch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019அன்புடன் அஸ்வின்No ratings yet

- Batch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Document2 pagesBatch Test Certificate: Date: 04/01/2014 Product: SKD-S2 Batch No: 14A03 Mfd. In: Jan' 2014Structures ProductionNo ratings yet

- 08E17KDocument2 pages08E17KRonny AndalasNo ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- 22B21 2Document1 page22B21 2vinothNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Batch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022Document1 pageBatch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022gauravNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationvenkiNo ratings yet

- 14A Magnaglo Powder: CertificationDocument2 pages14A Magnaglo Powder: CertificationInspectorNo ratings yet

- Batch Test Certificate: Less Than 0.0025 Less Than 0.0025Document3 pagesBatch Test Certificate: Less Than 0.0025 Less Than 0.0025venkiNo ratings yet

- Pruevas No DestructivasDocument2 pagesPruevas No DestructivasCeo EcNo ratings yet

- 7HF Prepared Bath: CertificationDocument1 page7HF Prepared Bath: CertificationEric Figueroa UribeNo ratings yet

- Batch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023Document3 pagesBatch Test Certificate: Date:23/06/2023 Product: ZP-4B Batch No:23F1019 Mfd. In: JUNE 2023venkiNo ratings yet

- 7HF Prepared Bath: CertificationDocument1 page7HF Prepared Bath: CertificationSantiago Hernadez RodriguezNo ratings yet

- Inspection Certificate: Manufacture DateDocument2 pagesInspection Certificate: Manufacture Datemaheshmalaichamy007No ratings yet

- Batch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019Document3 pagesBatch Test Certificate: Date: 29/03/2019 Product: ZP-4 B Batch No: 19C1019 Mfd. In: March 2019அன்புடன் அஸ்வின்No ratings yet

- Sksp2redpenDocument2 pagesSksp2redpenJamal Mohamed RahamathullahNo ratings yet

- Certificate of CertificationDocument2 pagesCertificate of CertificationMuhammad Bilal KhattakNo ratings yet

- Date: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17KDocument2 pagesDate: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17Kisraelita77671No ratings yet

- Mercon V SpecificationDocument22 pagesMercon V Specificationocto widodoNo ratings yet

- 8A Red Powder: CertificationDocument1 page8A Red Powder: CertificationNguyễn ChiếnNo ratings yet

- Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialDocument3 pagesInspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialAbee CungNo ratings yet

- 8A Red Powder: CertificationDocument1 page8A Red Powder: CertificationJuan Diego ArizabalNo ratings yet

- 18M02Document1 page18M02Shahnawaz PathanNo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificatevinothNo ratings yet

- Inspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above MaterialDocument3 pagesInspection Certificate: We Hereby Certify That When Tested at The Time of Manufacture, The Above Materialmaheshmalaichamy007No ratings yet

- Particulas Magneticas Grey PDFDocument1 pageParticulas Magneticas Grey PDFLiek FoNo ratings yet

- Tinte Penetrante 1124467Document1 pageTinte Penetrante 1124467Diego SilvaNo ratings yet

- 0850 02Document5 pages0850 02janiNo ratings yet

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalDocument17 pagesKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadNo ratings yet

- Work Instruction FOR: Spectro AnalysisDocument3 pagesWork Instruction FOR: Spectro AnalysismahendraNo ratings yet

- Def Stan 80-34 Issue 1995Document17 pagesDef Stan 80-34 Issue 1995Said AdingniNo ratings yet

- QP Transformer PDFDocument6 pagesQP Transformer PDFmanoj_2027No ratings yet

- Certification VP-31A: Batch # 8137E20Document1 pageCertification VP-31A: Batch # 8137E20César Antonio Vázquez MoralesNo ratings yet

- Astm D 1264Document4 pagesAstm D 1264IDewa Ayu Ananda WidhiyaniNo ratings yet

- LPG ChecklistDocument2 pagesLPG ChecklistMisamis Oriental Gasul CenterNo ratings yet

- Hoja de Seguridad Liquido PenetranteDocument2 pagesHoja de Seguridad Liquido PenetranteEnrique AntonioNo ratings yet

- E 2033 - 99 (2013)Document11 pagesE 2033 - 99 (2013)Enrique Antonio100% (2)

- Catalogo y Tablas Widos 4900Document55 pagesCatalogo y Tablas Widos 4900Enrique Antonio0% (1)

- E 2446 - 16Document14 pagesE 2446 - 16Enrique Antonio100% (2)

- E 2007 - 10 (2016)Document23 pagesE 2007 - 10 (2016)Enrique Antonio100% (1)

- Especificacion Tecnica R-EGDDocument1 pageEspecificacion Tecnica R-EGDEnrique AntonioNo ratings yet

- 17B10K PDFDocument3 pages17B10K PDFEnrique AntonioNo ratings yet

- Astm F436M PDFDocument5 pagesAstm F436M PDFEnrique AntonioNo ratings yet

- Astm F436Document5 pagesAstm F436caop217No ratings yet

- Astm - E165 LP PDFDocument20 pagesAstm - E165 LP PDFEnrique AntonioNo ratings yet

- Astm E436Document5 pagesAstm E436Enrique AntonioNo ratings yet

- Awwa C110 PDFDocument64 pagesAwwa C110 PDFEnrique AntonioNo ratings yet

- Awwa C110 PDFDocument64 pagesAwwa C110 PDFEnrique AntonioNo ratings yet

- Awwa D101 PDFDocument12 pagesAwwa D101 PDFEnrique AntonioNo ratings yet

- ANSI AWWA C203a-99Document1 pageANSI AWWA C203a-99Bruno Arturo Tejada MendozaNo ratings yet

- Awwa C200 (1997) PDFDocument32 pagesAwwa C200 (1997) PDFFelipe67% (3)

- Awwa C214Document22 pagesAwwa C214Enrique AntonioNo ratings yet

- E1418 10Document6 pagesE1418 10Enrique AntonioNo ratings yet

- Awwa C213 PDFDocument22 pagesAwwa C213 PDFEnrique AntonioNo ratings yet

- Awwa D101 PDFDocument12 pagesAwwa D101 PDFEnrique AntonioNo ratings yet

- Awwa C209Document22 pagesAwwa C209Enrique Antonio100% (3)

- Awwa M11Document185 pagesAwwa M11Enrique AntonioNo ratings yet

- Awwa C208 PDFDocument28 pagesAwwa C208 PDFEnrique AntonioNo ratings yet

- Awwa C208 PDFDocument28 pagesAwwa C208 PDFEnrique AntonioNo ratings yet

- Astm A53Document21 pagesAstm A53Enrique AntonioNo ratings yet

- ISO - 15620-2000 - Solda Por FricçãoDocument40 pagesISO - 15620-2000 - Solda Por FricçãoCristian Rodeghel100% (1)

- UT Testing-Section 0Document16 pagesUT Testing-Section 0Charlie Chong100% (2)

- CBT Body of Knowledge - Rev0Document7 pagesCBT Body of Knowledge - Rev0Partha Sarathi Sadhukhan0% (1)

- PMT QM Mep 004Document25 pagesPMT QM Mep 004AMIT SHAHNo ratings yet

- 4 of 16 Engg Standard TC-3480Document32 pages4 of 16 Engg Standard TC-3480Rathawit SingpanjanateeNo ratings yet

- QC CV SampleDocument11 pagesQC CV SampleSikander NawazNo ratings yet

- EKOSCAN Catalog Calibration BlockDocument28 pagesEKOSCAN Catalog Calibration BlockWawan SaputraNo ratings yet

- Inspection Test Plan For SSBG Burner For HGG: FLS Document NoDocument3 pagesInspection Test Plan For SSBG Burner For HGG: FLS Document NoDaniel CamposNo ratings yet

- Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used For RadiographyDocument8 pagesDesign, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used For RadiographyAndrea GonzálezNo ratings yet

- S. Senthilkumar CV FormatDocument6 pagesS. Senthilkumar CV FormatdashNo ratings yet

- Inspection TankDocument22 pagesInspection Tanksbmmla100% (1)

- SPCC GuidanceDocument6 pagesSPCC GuidancejoesuhreNo ratings yet

- 2019-MANUAL-Flaw Detector PartDocument9 pages2019-MANUAL-Flaw Detector PartDanny Milton Silva VasquezNo ratings yet

- MTechDocument42 pagesMTechRahul YuvarajNo ratings yet

- Catastrophic Rupture of Heat Exchanger - Tesoro Anacortes RefineryDocument160 pagesCatastrophic Rupture of Heat Exchanger - Tesoro Anacortes RefineryoluninjaaNo ratings yet

- Sop MTDocument6 pagesSop MTEddy Dwi CahyonoNo ratings yet

- 32 Samss 005Document33 pages32 Samss 005Selvakpm06No ratings yet

- Fabrication Procedure For Pressure Vessel, Boiler, Hydrant Pillar & Pressure Containing Piping NO. COIN/FPS/001/V/2018Document20 pagesFabrication Procedure For Pressure Vessel, Boiler, Hydrant Pillar & Pressure Containing Piping NO. COIN/FPS/001/V/2018PT.Composites Indonesia100% (2)

- Chapter 51Document611 pagesChapter 51phanthanhhungNo ratings yet

- 1.introduction of NDT PDFDocument19 pages1.introduction of NDT PDFaleventNo ratings yet

- Project Procurement Process ControlDocument4 pagesProject Procurement Process Controlakramsayeed100% (1)

- Capability List Rev. 37Document14 pagesCapability List Rev. 37Vadim RiabovNo ratings yet

- Career Objective: Sajid Ahamed Doha - Qatar Mob: 5572090, 4982808 EmailDocument3 pagesCareer Objective: Sajid Ahamed Doha - Qatar Mob: 5572090, 4982808 EmailSajid AhamedNo ratings yet

- 1000-Igcc-G000-Isgp-G00000-Qa-6050-00002 03aDocument28 pages1000-Igcc-G000-Isgp-G00000-Qa-6050-00002 03aAhmedNo ratings yet

- Directions of Use BDRDocument2 pagesDirections of Use BDRazam RazzaqNo ratings yet

- Magnetic Particle InspectionDocument36 pagesMagnetic Particle InspectionEthem GüngörNo ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.14 (Material Handling) PDFDocument20 pagesModule 7 (Maintenance Practices) Sub Module 7.14 (Material Handling) PDFshareyhouNo ratings yet

- E1441-11 Guía Estándar para Tomografía Computarizada CT ImagingDocument33 pagesE1441-11 Guía Estándar para Tomografía Computarizada CT Imagingfredy lopezNo ratings yet

- DM 002Document25 pagesDM 002Jonathan Romero AlfaroNo ratings yet

- Doc. No.: IPEG-6389-MIFE (1) - 8830-TP-001-0001 Title: Quality Assurance Plan ForDocument8 pagesDoc. No.: IPEG-6389-MIFE (1) - 8830-TP-001-0001 Title: Quality Assurance Plan ForPrakash RajNo ratings yet