Professional Documents

Culture Documents

Brake

Uploaded by

Baby SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brake

Uploaded by

Baby SinghCopyright:

Available Formats

MEC TN H-13, M180 Training Handout

CERTIFICATION COURSE

IN

TRACTOR ENGINEERING

2020

CERTIFICATION COURSE IN TRACTOR ENGINEERING

Credit for Credit for

Sr. Course Teaching

Course Name attending the completing the

No. Code period

class assignment

1 MEC TR Transmission 05 05 05

RATIONALE

The Transmission is the most important part of any Tractor. Study of transmission, its

working conditions and its functions are necessary for a Tractor Engineer. Tractor

Engineer is supposed to have full knowledge of sub-systems of the transmission &

their maintenance.

OBJECTIVES

After study of this course student will be able to

▪ Understand the ‘Basic transmission terminology’ & understand various parts,

functions and constructional details of transmission.

▪ Understand ‘Transmission assembly’ applicable to Tractor.

▪ Understand different models of transmission for utility as a power drive unit

in Tractor.

▪ Be conversant with working of sub-systems of transmission and their use.

▪ Understand maintenance of transmission.

COURSE CONTENTS

BRAKE H-13, M180

▪ PTO – Definition, function & types of PTO

▪ PTO Operation, How to engage & disengage PTO

▪ PTO driven Implements

▪ Brakes – Function & types

▪ Brake system – Do’s & Don’ts

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 1

MEC TR H-13, M180 Training Handout

BRAKE

BRAKING SYATEM friction. When a moving element is

brought in to contact with a

The braking system is an important stationary element, the motion of

system in the tractors used to slow the moving element is affected. This

down or stop the tractor motion. It is due to frictional force, which act

is also used to prevent the tractor in opposite direction of the motion

from moving when it is stationary. and converts the kinetic energy into

During field operations it helps in heat energy.

taking sharp turns by applying

differential brakes on the two rear CONSERVATION OF ENERGY

wheels.

The braking system exists to convert

The operation performed in braking the energy of a vehicle in motion

is the reverse of that carried out in into thermal energy, more

accelerating. During accelerating the commonly referred to as heat. From

heat energy of the fuel is converted basic physics, the kinetic energy of a

into the kinetic energy of the body in motion is defined as:

tractor, whereas in braking the

kinetic energy of the tractor is

converted into heat.

Again, just as when driving the

vehicle the torque of the engine Where m = the mass (commonly

produces a tractive effort at the thought of as weight) of the vehicle

peripheries of the driving wheels, in motion

so, when the brakes are applied the Where v = the velocity (commonly

braking torque introduced at the known as speed) of the vehicle in

brake drums produces a negative motion

tractive effort or retarding effort at Ideally, this energy is completely

the peripheries of the braking absorbed by the braking system.

wheels. While this is not entirely the case,

Consequently, the power dissipated for a stopping event at maximum

by the brakes, and therefore the deceleration most of the vehicle’s

heat generated, is very large. kinetic energy is converted into

thermal energy.

PRICIPLE OF OPRATION

Brakes works on the principle of

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 2

MEC TR H-13, M180 Training Handout

It follows then that the temperature Basic considerations and

rise of the braking system is requirements:

• Directly proportional to the The total retarding force acting on a

mass of the vehicle in motion. vehicle includes braking force, tyre

• Directly proportional to the drag, friction losses in the wheel

square of the velocity of the bearings and the transmission

vehicle in motion. system, the force exerted by the

vehicle to drive the engine, the

A DRIVING WHEEL CAN BE effect of road gradient and wind

resistance.

BRAKED IN TWO WAYS

If all these forces together so

happen to equal the weight of the

Directly, by means of brakes acting

vehicle, then it would slow down or

on a drum attached to the wheel;

decelerate at the rate of

(automobiles)

approximately 9.8 m/s2 or 32

Or indirectly, through the

ft/s2.This is the same rate as that at

transmission by a brake acting on a

which a body falling freely would

drum on the main shaft of the gear

accelerate, were it not for air

box, or on the bevel pinion, or

resistance, under the force of

worm, shaft of the final drive.

gravity. The rate of acceleration or

(Tractor)

deceleration, due to a body being

acted upon by a force equal to its

Indirect brake, being geared down

own weight, is known as “g”.

to the road wheels, can exert a

If the vehicle slows down or

larger braking torque on them than

decelerate at the rate of

if it acted directly on them.

approximately 9.8 m/s2 or 32 ft/s2

If the final drive ratio is 4 to 1, then

or ‘g’, the braking will be called

the braking torque exerted on each

100% braking.

road wheel is twice the braking

It is therefore convenient to talk in

torque exerted on the brake drum

terms of 0.5g, 0.85g and so on,

by the brake, that is, the total

instead of expressing the actual

braking torque is four times the

value in either m/s2 or ft/s2.

torque on the brake drum.

Likewise, it is convenient to talk of

Thus, brakes acting on the engine

braking force as a percentage of the

side of the final drive are much

weight of the vehicle, so that for

more powerful than those acting on

example a 50 % braking force would

the wheels directly.

provide 0.5g deceleration on a level

road.

BRAKE EFFICIENCY

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 3

MEC TR H-13, M180 Training Handout

In automobile practice, however, it and

has long been customary to refer to (c) Disc type.

the braking force relative to the

weight of the vehicle in terms of INTERNAL EXPANDING SHOE

braking efficiency, so that a 0.5g TYPE

deceleration is conveniently

Two brake shoes made of frictional

expressed as a 50% braking

material fitted on the inside of the

efficiency.

brake drum are held away from the

High braking efficiency is required as drum by means of springs. One end

on many occasions the brakes are of each shoe is fulcrum whereas the

required to stop the vehicle in other is free to move by the action

emergency. However higher brake of a cam which in turn applies force

efficiency not only leads to stopping on the shoes.

in a shorter time, may also cause

injury to the driver operator due to

high decelerating forces and

dislodging of loads in the trolley.

Higher braking efficiency also causes

rapid wear of the brakes and there

is more risk of losing control of the

vehicle. Braking efficiencies of the

order of 50-80% enable to stop

within reasonable distance.

However the stopping distance

varies with the type of road The movement of the cam is caused

conditions and condition of the by the brake pedal through the

tyres. linkage. The drum is mounted on the

rear axle whereas the shoe assembly

CLASSIFICATION OF BRAKES is stationary and mounted on the

back plate.

Brake can be classified as:

(1) Mechanical brake EXTERNAL CONTRACTING

(2) Hydraulic brake SHOE

(3) Power Assisted Brake

External contracting brakes are

sometimes used for parking brakes

1. MECHANICAL BRAKE can be

on motor vehicles, for cranes,

classified as:

and for controlling the speed of

(a) Internal expanding shoe type

auxiliary equipment drive shafts.

(b) External contracting shoe type

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 4

MEC TR H-13, M180 Training Handout

anchored opposite the point where

the pressure is applied. In addition

to supporting the band, the

anchor allows adjustment of the

brake lining clearance. Other

adjusting screws and bolts are

provided at the ends of the band.

DISC BRAKE

In operation, the brake band (or

Two actuating discs have holes

shoe) of an external contracting

drilled in each disc in which steel

brake is tightened around the

balls are placed. When the brake

rotating drum by moving the brake

pedal is depressed, the links help to

lever. The brake band is made

move the two discs in opposite

of comparatively thin, flexible steel,

directions. This brings the steel balls

shaped to fit the drum, with a

to shallow part of the holes drilled in

frictional lining riveted to the inner

the disc. As a result, the two discs

surface (fig). His flexible band

are expanded, and braking discs are

cannot withstand the high pressure

pressed in between the discs and

required to produce the friction

the stationary housing. The braking

needed to stop a heavily loaded or

discs are directly mounted on the

fast-moving vehicle, but it

differential shaft, which ultimately

works well as a parking brake or

transfers

hold brake

the traveling effect to the

Figure shows an external

differential shaft.

contracting brake. The brake band is

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 5

MEC TR H-13, M180 Training Handout

and the entire system turns to a

HYDRAULIC BRAKE pressure system. Immediately, the

piston of the wheel cylinder slides

Hydraulic brake system is based on

outward which moves the brake

the principle of Pascal’s law. The

shoes to stop the rotating drum.

brake fluid is filled in the master

When the pedal is released, the

cylinder. When the pedal is

return spring of the master cylinder

depressed, the piston of the master

moves the piston back to its

cylinder is forced into the cylinder

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 6

MEC TR H-13, M180 Training Handout

TRACTOR BRAKING SYATEM ▪ While driving ‘ON ROAD’, the

two pedals are latched

The purpose of the brakes in an together, both brakes will

automobile is to slow down or stop operate in unison and the

the vehicle, enable control of the same braking effort will be

vehicle to be retained when imposed on both wheels

descending long hills and also to ▪ While driving ‘IN FIELD’,

hold the vehicle stationary even in application of one foot pedal

an inclined position. slows the rear wheel on the

side applied. Differential

The brake system of a tractor is action speeds up the other

different from an automobile (car, wheel in the same ratio the

Bus etc.) in two respect. braked wheel slows down,

1. The front wheels of a tractor thus accelerating the turning

do not have any brake. of the tractor and reducing

2. For both rear wheels, there the turning radius.

are two different brake pedals

BRAKE IN TRACTOR

TWO FUNCTIONS OF BRAKES

First function: First, in emergencies In tractors, the wheel brakes are

they must bring the tractor to rest in operated by a foot pedal and are the

the shortest possible distance. ones used on most occasions; they

▪ For this, it needs large braking are sometimes referred to as the

torques to the brake drums. service brakes.

▪ Heat dissipation hardly matter The brakes on the rear wheels can

when emergency stops are generally be operated also by a

considered. hand lever and are used chiefly for

Second function: Secondly, they holding the tractor when it is parked

must enable control of the tractor to and are consequently called parking

be retained when descending long brakes but as they can, of course, be

hills. used in emergencies they are

▪ This dissipate large quantities sometimes called emergency

of heat with large brakes.

temperature rise. Friction brakes are used as wheel

brakes in tractors. They transform

Third Function of Brake in tractor the kinetic energy of the parts that

The tractor is provided with two rub against one another into

foot pedals. They can be operated thermal energy and a small amount

individually or locked together to of mechanical material removal.

operate simultaneously. The parts firmly attached to the

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 7

MEC TR H-13, M180 Training Handout

wheels (brake drums or discs, as the In Tractors Brakes are mechanically

case may be) rub on the non- actuated. Brake pedal free play

rotating components (brake shoes ensures that the brakes are totally in

or linings). The friction converts the disengaged condition & not partially

kinetic energy of the vehicle into engaged.

heat. The better the braking effect,

the greater the heat that is created. When we press a properly adjusted

The contact surfaces are subjected BRAKE pedal in a tractor, the pedal

to very high stress by heat and travels without much resistance

friction. initially. During this travel of the

For this reason, commercial vehicle pedal, we do not get any brake

brake is usually internally action.

ventilated. This initial BRAKE pedal travel is

In tractor, the brakes are totally called Brake Pedal free play.

sealed. After the initial travel, when we

further press the pedal, the

The brakes are controlled by two- resistance from the pedal increases

foot pedals and one hand lever to a much higher level compared to

which operate on a cross shaft. The previous travel & brake engagement

two-foot pedals can be operated also starts.

individually or locked together to

operate simultaneously. The hand As the tractor is used, the amount of

lever is used as a parking brake only. free play in the brake pedal will

Application of one-foot pedal slows increase & can be adjusted

the rear wheel on the side applied. externally through linkages so that

Differential action speeds up the there is recommended play before

other wheel in the same ratio the the brakes start grabbing.

braked wheel slows down, thus TRACTOR BRAKING SYATEM

accelerating the turning of the

tractor and reducing the turning The purpose of the brakes in an

radius. automobile is to slow down or stop

When the two pedals are latched the vehicle, enable control of the

together, both brakes will operate in vehicle to be retained when

unison and the same braking effort descending long hills and also to

will be imposed on both wheels. The hold the vehicle stationary even in

pedals can be locked with the hand an inclined position.

lever in the engaged position for

parking the tractor. The brake system of a tractor is

different from an automobile (car,

BRAKE PEDAL FREE PLAY Bus etc.) in two respect.

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 8

MEC TR H-13, M180 Training Handout

1. The front wheels of a tractor braked wheel slows down,

do not have any brake. thus accelerating the turning

2. For both rear wheels, there of the tractor and reducing

are two different brake pedals the turning radius.

▪

TWO FUNCTIONS OF BRAKES ▪ BRAKE IN TRACTOR

▪

First function: First, in emergencies ▪ In tractors, the wheel brakes

they must bring the tractor to rest in are operated by a foot pedal

the shortest possible distance. and are the ones used on

▪ For this, it needs large braking most occasions; they are

torques to the brake drums. sometimes referred to as the

▪ Heat dissipation hardly matter service brakes.

when emergency stops are ▪ The brakes on the rear wheels

considered. can generally be operated

Second function: Secondly, they also by a hand lever and are

must enable control of the tractor to used chiefly for holding the

be retained when descending long tractor when it is parked and

hills. are consequently called

▪ This dissipate large quantities parking brakes but as they

of heat with large can, of course, be used in

temperature rise. emergencies they are

sometimes called emergency

Third Function of Brake in tractor brakes.

The tractor is provided with two ▪ Friction brakes are used as

foot pedals. They can be operated wheel brakes in tractors. They

individually or locked together to transform the kinetic energy

operate simultaneously. of the parts that rub against

▪ While driving ‘ON ROAD’, the one another into thermal

two pedals are latched energy and a small amount of

together, both brakes will mechanical material removal.

operate in unison and the ▪ The parts firmly attached to

same braking effort will be the wheels (brake drums or

imposed on both wheels discs, as the case may be) rub

▪ While driving ‘IN FIELD’, on the non-rotating

application of one foot pedal components (brake shoes or

slows the rear wheel on the linings). The friction converts

side applied. Differential the kinetic energy of the

action speeds up the other vehicle into heat. The better

wheel in the same ratio the the braking effect, the greater

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 9

MEC TR H-13, M180 Training Handout

the heat that is created. The BRAKE PEDAL FREE PLAY

contact surfaces are subjected

to very high stress by heat ▪ In Tractors Brakes are

and friction. mechanically actuated. Brake

▪ For this reason, commercial pedal free play ensures that the

vehicle brake is usually brakes are totally in disengaged

internally ventilated. condition & not partially engaged.

▪ In tractor, the brakes are ▪ When we press a properly

totally sealed. adjusted BRAKE pedal in a tractor,

▪ the pedal travels without much

▪ The brakes are controlled by resistance initially. During this

two-foot pedals and one hand travel of the pedal, we do not get

lever which operate on a any brake action.

cross shaft. The two-foot ▪ This initial BRAKE pedal travel is

pedals can be operated called Brake Pedal free play.

individually or locked ▪ After the initial travel, when we

together to operate further press the pedal, the

simultaneously. The hand resistance from the pedal

lever is used as a parking increases to a much higher level

brake only. compared to previous travel &

▪ Application of one-foot pedal brake engagement also starts.

slows the rear wheel on the ▪ As the tractor is used, the amount

side applied. Differential of free play in the brake pedal will

action speeds up the other increase & can be adjusted

wheel in the same ratio the externally through linkages so

braked wheel slows down, that there is recommended play

thus accelerating the turning before the brakes start grabbing.

of the tractor and reducing

the turning radius. TYPES OF BRAKES IN MAHINDRA

▪ When the two pedals are TRACTORS

latched together, both brakes

will operate in unison and the There are 2 types of brakes in

same braking effort will be Mahindra tractors

imposed on both wheels.

▪ The pedals can be locked with 1) Dry Disc Brake

the hand lever in the engaged 2) Oil Immersed Brake

position for parking the

tractor.

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 10

MEC TR H-13, M180 Training Handout

DRY DISC BRAKE The 1.5” to 1.75” (38 mm – 45 mm)

of free play at the top of the brake

As the name suggest, these brakes pedal ensures free rotation of LINED

are designed for operating in DRY DISC BRAKE without rubbing.

condition. Heat is absorbed by the

BRAKE HOUSING, BULL CAGE & OIL IMMERSED BRAKE

Transmission case. As the name suggest, these brakes

are designed for operating in WET

condition. Heat is absorbed by the

OIL which acts as a coolant.

In Mahindra, the tractor with

REGULAR Oil Immersed Brake has a

sticker “LUBRITECH BRAKING

SYSTEM”.

Lubritech Braking System is wet disc

type of brakes. It has common

Hydraulics & transmission oil.

Transmission case acts as a reservoir

for both transmission & Hydraulics

oil. (The Hydraulic housing is open

at the bottom). The brake liners that

are partially submerged in the

transmission oil get continuous

supply of oil from Hydraulic system.

This oil removes the excess heat

from the brakes thereby maintains

In DRY DISC BRAKE, a gap is

maintained between the Brake liner, Constant coefficient of friction,

Housing, Bull Cage & Actuating Disc. smooth brakes operation and

The sum of all these gaps multiplied provides longer life of brakes.

by linkage ratios is known as Brake The friction liners are specially

Pedal Free Play. It's quite a designed for excellent performance

distinctive feel on the brake pedal. and because of the lower coefficient

of friction obtainable, the single

The recommended free play is 1.5” discs of the dry form are replaced by

to 1.75” (38 mm – 45 mm). The packs of several plates as in a

brake pedal free play adjustment is multiple-plate clutch.

very important.

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 11

MEC TR H-13, M180 Training Handout

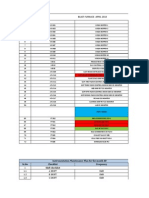

Do's

Ensure proper quantity &

1 grade of oil (Tract Elf MM) in

the transmission.

Friction liners to be changed

2 when the thickness becomes

4.15mm and less.

Lined friction disc to be

3 handled with care to avoid

damage to liners.

New friction disc must be

soaked for minimum of one

4

hour on the recommended

grade of oil before fitment.

Intermediate plate & return

spring of actuating assembly

5

should be replaced during

replacement of liners.

Ensure that the friction discs

Benefits of Oil Immersed Brake: 6 slide freely on the splined

shaft.

In every brake overhauling

1. Long Life of Brake Liners &

replace gasket between end

other parts. 7

cover and housing & diff lock

2. Very less Frequency of

oil seal.

adjustment.

Replace copper gasket &

3. Improved Braking Efficiency at

plunger spring of swing

higher temperature (Good 8

arrestor. Remove the swing

Fade characteristics).

arrestor & reset the plunger.

4. Consistency in performance

9 Ensure proper sealing.

over a prolonged period.

5. Smooth Pedal Operation. Brake adjustment should be

10

6. Longer transmission life due done as per the SOP.

to continuous filtration of oil.

7. Longer life of hydraulic pump Don'ts

due to large reservoir of oil. Do not use non-recommended

1

grade of oil.

DO’S & DON’TS OF OIL IMMERSED Do not adjust the brake

BRAKE SYSTEM 2 linkages for a pedal travel less

than 65 mm.

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 12

MEC TR H-13, M180 Training Handout

Avoid cleaning or degreasing 1. Different manufacturers

3 of friction liners with chemical recommend different oil for

agents or acids. Transmission / OIB. Do not

Do not use non recommended interchange Trolley with

4

grade of liners. lifting mechanism.

Automatic swing arrestor 2. Even for similar tractor, check

should not be adjusted or the condition of oil in the

5 removed during any time Trolley with lifting mechanism

other than brake liner before interchanging it.

replacement. 3. Oil for OIB comes from Orifice

Do not remove the adjuster Filter of Hydraulic system.

plunger from swing arrestor Clean Orifice Filter during

6

sub assy. without the re - each service.

setting tool. 4. Do not switch off the engine

in down gradient.

Following precautions to be taken 5. When a tractor is being

for Oil immersed Brake system: towed, do not use brake

(since engine is in off

condition).

Mahindra Excellence Centre – Nagpur, Mohali & Zaheerabad Page 13

You might also like

- Fluid Coupling &torque ConverterDocument5 pagesFluid Coupling &torque ConverterArsh Gautam UD100% (1)

- CEC Accredited Design Guidelines For GCPV PDFDocument20 pagesCEC Accredited Design Guidelines For GCPV PDFccwei713No ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Chapter 12 (Torque Converters)Document20 pagesChapter 12 (Torque Converters)ZIBA KHADIBI100% (2)

- Braking SystemDocument14 pagesBraking SystemMichael SerraNo ratings yet

- SGT 700Document4 pagesSGT 700pramodtryNo ratings yet

- Dynamics of Machinery 2 Marks All 5 UnitsDocument14 pagesDynamics of Machinery 2 Marks All 5 UnitsDHINAKARANVEEMAN100% (2)

- Substation DesignDocument7 pagesSubstation DesignAnkit Patel100% (1)

- N2 PurgingDocument5 pagesN2 PurgingSubbarayan SaravanakumarNo ratings yet

- Brake Efficiency CalculationDocument11 pagesBrake Efficiency Calculationdevi saravananNo ratings yet

- Chapter 10 (Standard Transmission) PDFDocument42 pagesChapter 10 (Standard Transmission) PDFZIBA KHADIBINo ratings yet

- Tecumseh To Tecumseh Cross RefDocument64 pagesTecumseh To Tecumseh Cross RefDiego100% (8)

- Cost Benefit Methodology For Optimal Design of Offshore Transmission Systems PDFDocument86 pagesCost Benefit Methodology For Optimal Design of Offshore Transmission Systems PDFmuhannad11061975No ratings yet

- Maximum Engine Force Per Gear As Function of Vehicle Speed. This Particular Engine Has A Torque Limit of 400Nm and A Power Limit of 280hpDocument4 pagesMaximum Engine Force Per Gear As Function of Vehicle Speed. This Particular Engine Has A Torque Limit of 400Nm and A Power Limit of 280hpNIKASH maniNo ratings yet

- T11 4WD Service Manual PDFDocument40 pagesT11 4WD Service Manual PDFAxlesNo ratings yet

- PowertrainDocument13 pagesPowertrainso.sorrounding factNo ratings yet

- An Investigation of The Influence of Inter - Wheel Differentiak of 4WD VehicleDocument9 pagesAn Investigation of The Influence of Inter - Wheel Differentiak of 4WD VehicleRajeevNo ratings yet

- An Investigation of The Influence of Inter-Wheel Differentials On The Kinetic and Dynamic of 4WD VehicleDocument9 pagesAn Investigation of The Influence of Inter-Wheel Differentials On The Kinetic and Dynamic of 4WD VehicleNguyen Van QuyenNo ratings yet

- 3 - Braking PerformanceDocument28 pages3 - Braking PerformanceSumran ShahidNo ratings yet

- 8 S STEERINGEFFORTDocument6 pages8 S STEERINGEFFORTPrateek KesarwaniNo ratings yet

- Calculation of Steering Effort for Hydraulic and Electronic Power Steering SystemsDocument6 pagesCalculation of Steering Effort for Hydraulic and Electronic Power Steering Systemssaran kumarNo ratings yet

- 8 S STEERINGEFFORTDocument6 pages8 S STEERINGEFFORTQuốc KhánhNo ratings yet

- STC TRS Conv 03 Supplement Mech PDFDocument83 pagesSTC TRS Conv 03 Supplement Mech PDFZahoor Ahmed100% (1)

- Wheel Slip and Adhesion in LocomotivesDocument82 pagesWheel Slip and Adhesion in LocomotivesriajulNo ratings yet

- Irjet V5i5960 PDFDocument6 pagesIrjet V5i5960 PDFAhmadIzzatFahmiNo ratings yet

- Design of A Drivetrain For Sae Baja RaciDocument9 pagesDesign of A Drivetrain For Sae Baja Raciragavendra marimuthuNo ratings yet

- ClutchDocument16 pagesClutchBaby SinghNo ratings yet

- Xu 2016Document8 pagesXu 2016Ali ShamsodiniNo ratings yet

- Torque SteerDocument7 pagesTorque SteerAyushNo ratings yet

- Regenerative Braking System Group 7Document12 pagesRegenerative Braking System Group 7A-16 Sanket GhadageNo ratings yet

- Tractive Effort Curves in Gearbox AnalysisDocument4 pagesTractive Effort Curves in Gearbox Analysisdeepak_gupta_pritiNo ratings yet

- Load Sharing Methods of Backstops 2004 01Document10 pagesLoad Sharing Methods of Backstops 2004 01Ruben SalgadoNo ratings yet

- Transmission (Mechanics)Document10 pagesTransmission (Mechanics)KiranNo ratings yet

- Regen BrakinDocument9 pagesRegen BrakinYogi ChanderNo ratings yet

- 2.automobile IJAuERD DESIGNANDANALYSISOFBRAKEROTOR HARSHALNIKAMDocument11 pages2.automobile IJAuERD DESIGNANDANALYSISOFBRAKEROTOR HARSHALNIKAMSaleh AlotaibiNo ratings yet

- Simulation and Control of An Automotive ClutchDocument6 pagesSimulation and Control of An Automotive ClutchSali ÁdámNo ratings yet

- 15 Ishan BajpaiDocument2 pages15 Ishan BajpaiKylo RenNo ratings yet

- Automotive ChassisDocument22 pagesAutomotive ChassisSathistrnpcNo ratings yet

- Regenerative Braking System: NtroductionDocument4 pagesRegenerative Braking System: NtroductionJawadahmed QureshiNo ratings yet

- Rollover of Heavy Vehicles: Chairman's Technical ColumnDocument5 pagesRollover of Heavy Vehicles: Chairman's Technical ColumnBob RockNo ratings yet

- Performance Optimization and Fe Analysis of Marine Fender: Manish G. Dobariya Sumant P. PatelDocument3 pagesPerformance Optimization and Fe Analysis of Marine Fender: Manish G. Dobariya Sumant P. PatelMellynia saputriNo ratings yet

- Drive Train AssemblyDocument10 pagesDrive Train Assemblychandrakesh chauhanNo ratings yet

- Characterization of Electric Motor Drives For Traction ApplicationDocument6 pagesCharacterization of Electric Motor Drives For Traction ApplicationShivu5art workNo ratings yet

- MSD%20tech%20ArticleDocument6 pagesMSD%20tech%20ArticleEdgar Aponte RodriguezNo ratings yet

- Design, Development and Manufacturing of Braking System For ATVDocument5 pagesDesign, Development and Manufacturing of Braking System For ATVRodrigo bolaNo ratings yet

- Regenerative Braking in Automobiles: AbstractDocument6 pagesRegenerative Braking in Automobiles: AbstractInternational Journal of Engineering and TechniquesNo ratings yet

- Traction Control System NotesDocument58 pagesTraction Control System NotesKumar KartikeyNo ratings yet

- VDDC 2 Marks: Bethleham Institute of Engineering, Karungal Automobile DepartmentDocument8 pagesVDDC 2 Marks: Bethleham Institute of Engineering, Karungal Automobile DepartmentNIKASH maniNo ratings yet

- Dynamic Analysis of Gear Shifting MechanismDocument4 pagesDynamic Analysis of Gear Shifting MechanismMr. S. Thiyagu Asst Prof MECHNo ratings yet

- Research Paper Commented1Document4 pagesResearch Paper Commented1adildhkhNo ratings yet

- Chap4 Hydrodynamic TransmissionDocument5 pagesChap4 Hydrodynamic TransmissionIsaac NjorogeNo ratings yet

- Ksaeic Fisita00 G342Document5 pagesKsaeic Fisita00 G342Quốc KhánhNo ratings yet

- Vertical Dynamic Postural Model For SemiDocument8 pagesVertical Dynamic Postural Model For SemichipawayNo ratings yet

- Automobile EngieeringDocument28 pagesAutomobile EngieeringYogesh Kumar GaurNo ratings yet

- Enhancing The Performance of High Powered MotorcycDocument8 pagesEnhancing The Performance of High Powered Motorcycgabriel fagaNo ratings yet

- Understanding Causes of Rollover Crashes: Information BulletinDocument2 pagesUnderstanding Causes of Rollover Crashes: Information BulletinzecanNo ratings yet

- Irjet V5i4718 PDFDocument4 pagesIrjet V5i4718 PDFVinit YadavNo ratings yet

- MOD-04 - Machine PowerDocument36 pagesMOD-04 - Machine PowerAlexandra JNo ratings yet

- Evaluation of A Lightweight Friction Brake Disc Design For A Regenerative Braking SystemDocument9 pagesEvaluation of A Lightweight Friction Brake Disc Design For A Regenerative Braking Systemdivyanshu.krishnaniNo ratings yet

- Braking Systems ExplainedDocument15 pagesBraking Systems ExplainedArun ShankarNo ratings yet

- Electromagnetic Braking System for VehiclesDocument60 pagesElectromagnetic Braking System for VehiclesKiran V DattuNo ratings yet

- Simulated and Experimental Study of Antilock Braking System Using Grey Sliding Mode ControlDocument6 pagesSimulated and Experimental Study of Antilock Braking System Using Grey Sliding Mode ControlAli AkbarNo ratings yet

- Mathematical Modelling of Engineering Problems: Received: 25 October 2021 Accepted: 16 March 2022Document10 pagesMathematical Modelling of Engineering Problems: Received: 25 October 2021 Accepted: 16 March 2022Hailush TgNo ratings yet

- Debre-Markos University Drives ChapterDocument116 pagesDebre-Markos University Drives ChapterabebawalemkerNo ratings yet

- Automotive ServicingDocument5 pagesAutomotive ServicingLiezl SabadoNo ratings yet

- Eone Generator Gas Dryer BrochureDocument2 pagesEone Generator Gas Dryer BrochureDenis StancuNo ratings yet

- EJs For HRSG Boilers - USDocument4 pagesEJs For HRSG Boilers - USdanny buiNo ratings yet

- PDB - Multi V S R410Document148 pagesPDB - Multi V S R410Oscar Barres MoreiraNo ratings yet

- 40.00 EnForcer HF Full Line Brochure Page by page-LowResDocument6 pages40.00 EnForcer HF Full Line Brochure Page by page-LowResLuis Alberto Rivas GarciaNo ratings yet

- Vertiv Liebert EXL-S1-300-1200-kW-BrochureDocument16 pagesVertiv Liebert EXL-S1-300-1200-kW-BrochureSV Industrial SevicesNo ratings yet

- Mamuju Coal Fired Steam Power PlantDocument12 pagesMamuju Coal Fired Steam Power Plantkim deygabiNo ratings yet

- 0653 s16 QP 61Document20 pages0653 s16 QP 61yuke kristinaNo ratings yet

- WEG - Regulador Automático de Tensión - AVR-A-OPT-06 - Portugués, Inglés y EspañolDocument78 pagesWEG - Regulador Automático de Tensión - AVR-A-OPT-06 - Portugués, Inglés y EspañolFernando GraziadioNo ratings yet

- Automatika Parnog KotlaDocument5 pagesAutomatika Parnog KotlaKenan IbrahimiNo ratings yet

- Summary Electronic Engine Control Large EngineDocument1 pageSummary Electronic Engine Control Large EngineMohammed HamdeenNo ratings yet

- GE CatalogDocument3 pagesGE CatalogBob sageNo ratings yet

- A Visit To Attock Refineries Limited RawalpindiDocument4 pagesA Visit To Attock Refineries Limited Rawalpindijasminekhan100% (1)

- Resume PT - Asia Pasific Mineral CoalDocument1 pageResume PT - Asia Pasific Mineral Coalikbal rangerNo ratings yet

- Voltage doubler circuit types and switched capacitor voltage doublersDocument7 pagesVoltage doubler circuit types and switched capacitor voltage doublersGilberto ManhattanNo ratings yet

- Fujimcselection PDFDocument14 pagesFujimcselection PDFLloyd Bryne Cervantes LunzagaNo ratings yet

- Rolls - Royce, B35-40 V12AG (5100 KW)Document3 pagesRolls - Royce, B35-40 V12AG (5100 KW)Dexterous EngineeringNo ratings yet

- Inverter DatasheetDocument3 pagesInverter DatasheetYash GuptaNo ratings yet

- A Guide To Picking A Quality Energy AuditorDocument8 pagesA Guide To Picking A Quality Energy AuditorJoe AdehshinaNo ratings yet

- Safety Specifications and Electrical Specifications for 3in1 Pocket Autoranging DMMDocument2 pagesSafety Specifications and Electrical Specifications for 3in1 Pocket Autoranging DMMdt45No ratings yet

- H5000 Series User ManualDocument164 pagesH5000 Series User ManualDanish ShahNo ratings yet

- A Modeling and Simulation of Optimized Interconnection Between DC Microgrids With Novel Strategies of Voltage, Power and ControlDocument6 pagesA Modeling and Simulation of Optimized Interconnection Between DC Microgrids With Novel Strategies of Voltage, Power and ControlASHISHNo ratings yet

- Blast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFDocument11 pagesBlast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFShiva Prakasam PernetiNo ratings yet