Professional Documents

Culture Documents

Rur-06, Heat Recovery - CSLin

Uploaded by

Induru DasunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rur-06, Heat Recovery - CSLin

Uploaded by

Induru DasunCopyright:

Available Formats

The Selection and Design of a Heat

Recovery Application for Diesel

Generators Used in Alaskan Villages

Prasada Raghupatruni, Cheuen-Sen Lin, Dennis Witmer

Ed Bargar, Jack Schmid, Thomas Johnson

University of Alaska Fairbanks

refrigeration and air conditioning [5], heat for desalination, etc

Abstract— In rural Alaska, there are nearly 180 villages [6, 7, 8]. To optimize the benefit that heat recovery systems

consuming about 374,000 MWh of electric energy annually from can bring to the Alaskan villages, the engine performance

individual diesel generator facilities. For modern diesel engines, characteristics and operational conditions that have important

about 40% of fuel energy is released as waste heat from engine

effects on the performance of heat recovery systems have to

exhaust and turbocharger compressed air. If half of the released

heat was put to appropriate use, there would be a great fuel be understood. The important engine performance

savings. The purpose of this study was to select an appropriate characteristics and operational conditions may include diesel-

exhaust heat recovery application for Alaskan village diesel generator load, fuel composition, soot produced, and exhaust

generators and to study its feasibility and economic effect. gas corrosivity. Engine load and fuel composition will affect

the amount of heat to be recovered by the heat recovery

Recovery heat from the exhaust of Alaskan village diesel

system from the exhaust. Exhaust gas corrosivity and soot

generators has long been avoided due to the probable problems

of corrosion caused by sulfuric acid and sulfurous acid and content will affect the maintenance of the heat recovery

performance deterioration caused by corrosion and exhaust soot system [9].

accumulation. Since the new regulation that requires diesel

This project studies feasibility and economic effect of

engines to use ultra low sulfur diesel, the intensity of corrosion

and performance deterioration problems may be reduced mostly applying exhaust and charge air heat recovery to Alaskan

and the exhaust heat recovery may become feasible and village diesel generators. This paper focuses on studying the

economical. This report presents the selection process of an application of exhaust heat recovery. Recovery of heat from

appropriate heat recovery application for Alaskan village diesel the exhaust of Alaskan village diesel generators has long been

generators, the design of an experimental heat recovery system avoided due to the probable problems of corrosion caused by

for testing, and the result of the effect of exhaust on the fouling

sulfurous acid and sulfuric acid and performance deterioration

factor and corrosion of the heat recovery system. Also included

in this report is the result obtained from feasibility and economic caused by corrosion and exhaust soot accumulation. Decades

analysis. ago, attempts of recovering exhaust heat were tried and

discarded due to serious drawbacks caused by the systems

Index Terms – diesel, exhaust, heat recovery, [10]. Since then heat exchanger design [11, 12] and control

systems have been improved and a heat recovery system using

I. INTRODUCTION new industrial components may work better than systems of

In rural Alaska, there are nearly 180 villages consuming decades ago. In addition, the new regulation requires diesel

about 374,000 MWh of electric energy from individual diesel engines to use ultra low sulfur diesel fuel, the intensity of

generators [1]. During the process of producing electric corrosion [13] and performance deterioration problems may

power, there is unused heat from the engine. The single largest be reduced mostly and the exhaust heat recovery system may

amount of unused heat from the engine is the exhaust heat, become feasible and economical.

which contains about 30% of the fuel energy. If the waste heat In this study, space heating was the selected application for

were put to appropriate use, there would be great energy or exhaust heat recovery. The selection of space heating was due

fuel savings. Work, which studies the selection of the most to its potential in optimizing the economic benefit to Alaskan

appropriate engine heat recovery method, is needed as part of villages. Space heating, which included public space heating

the village economic development. using baseboard system and floor radiant systems, was also

There are many different heat recovery methods available proposed by Alaska energy authority as candidates for future

for capturing engine waste heat, such as thermal electric rural Alaska cogeneration development [4]. The following

conversion [2], heat to power conversion (e.g. Sterling sections describe details of the diesel generator and the heat

engines, steam engines) [3], direct heat application (e.g. space recovery system used for this study along with system

heating, community water loop heating) [4], heat for instrumentation, experimental results, and the final

conclusion.

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

1

II. TEST BED component as heating load, was designed according to the

This section discusses the test bed which included a diesel following requirements:

generator facilitated with digital load control capability and Apply existing technology,

details of the designed heat recovery system. Optimize overall efficiency for varying engine load (In

A. The Diesel Generator System general, village generator load ranging from 25% to 100%

of rated load).

This experiment was conducted at Energy Center,

Minimize corrosion to exhaust system.

University of Alaska Fairbanks using a DD50 diesel-generator

Meet back pressure requirement (13.8 kPa or 2 psi).

set. The generator was connected to a 250 kW external

Meet dimension constraints (very limited space).

resistive/reactive load bank from Load Tech for engine load

Be able to emulate different heating applications of Alaskan

control. Load bank was interfaced with LABVIEW IV system

villages.

for load control signals. Property of the diesel engine is listed

Be able to measure system and component performance.

in Table I. The diesel generator set and data acquisition

Be easy to maintain and do not increase maintenance

system were placed inside an ISO container while the load

frequency.

bank sitting outside of the ISO container (Figure 1).

Work under a wide range of ambient temperatures (-40oC

TABLE I to 33oC)

DIESEL ENGINE PROPERTY Be reliable

Number of cylinder: 4 Number of Stroke: 4 Based on the requirements, a heat recovery system was

Bore x Stroke: 130mm x 160mm Fuel Injection: Electronic unit

designed and installed. The system had three major sections:

injector the heat source section (Figure 2A), the heat sink or load

section (Figure 2B), and the pipe and control section (Figure

Aspiration: Turbocharged Displacement: 8.5 L

2C). The source section had a heat exchanger and auxiliary

Rated Power: 125 kW Rated Speed: 1200 rpm components to capture heat from engine exhaust. The heat

Exhaust Gas Recirculation: None Exhaust After treatment: None sink section had a unit heater and auxiliary components to

dissipate heat and was design to work in such a way that the

source or load had to be controlled at specific temperatures at

different engine loads. The pipe and control section was used

to transport working fluid between the heat source and the

heat sink and able to control the flow rate and pressure

distributions of the system.

Based on the computation results [13] and the availability

of commercial products for high temperature exhaust, a shell

and tube type of heat exchanger was selected. The exhaust gas

passed through the shell side and the liquid coolant through

the core side. For maintenance purposes, the core was

removable for cleaning when necessary. In order to have the

heat exchanger be able to absorb the most amount of heat, the

Figure 1 Diesel Generator Location designed size of the heat exchanger was based on the exhaust

condition at full engine load. For partial engine load

conditions, the heat recovery system was designed with

B. Exhaust Heat Recovery System parameters adjustable to make the coolant inlet and outlet

The exhaust heat recovery system, which included both temperatures match the requirements of different space

heat recovery component as heat source and heat dissipation heating applications. The coolant side temperatures used for

design (Table II) were selected based on the feed water

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

2

temperature of 65 oC typical of boilers used for baseboard with a safety margin. A bypass loop and a 3 way

heating. So a temperature of 77 oC would be adequate for pre-

From Hx

heating the boiler feed water. The inlet gas temperature used

To Hx

for design was the full load exhaust temperature and

Pump

Inlet

Flowmeter

(FTB 108)

Outlet

Figure 2C-1 Pipe and Control Elements (South half – inside of west

Heat exchanger (Hx) sidewall)

UUTR 804516SSS)

Figure 2A Heat Exchanger Section (On top of container)

Pump

To Unit Heater

Temp Control

Unit heater 3-way Valve

From Unit Heater

By-pass for

Temp Control

Figure 2C-2 Pipe and Control Elements (North half – inside of west

sidewall)

temperature control valve were selected for the control of the

Figure 2B Unit Heater Section (Outside of west sidewall of ISO outlet temperature of the load section by appropriately

Container)

distributing the total flow between the bypass loop and the

the outlet gas temperature was based on the condensation unit heater.

formation temperatures [14] of the corrosive components of

the exhaust and also based on the trade off between the cost The pipe and control section included the pipes between the

and the amount of heat to be recovered. Some of the details of heat exchanger section and the load section, a pump and other

the selected heat exchanger are shown in Table III. miscellaneous components (i.e. ball valves, expansion tank,

circuit setters, snubbers, dielectric unions, fittings, insulation

The heat dissipating capacity of the selected unit heater was material, etc.) were designed to control the system operation

above the expected maximum amount of heat absorption rate and to meet the needs for maintenance, instrumentation,

of the heat exchanger (i.e. 290,000 Btu/hr. for this system)

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

3

corrosion prevention, etc. The pump was selected based on the locations of the temperature sensors and the coolant flow

design flow rate and calculated total pressure drop [15] of the meter along the pipe system are shown in Figure 3. There

system with the effects of all the expected system components. were also 5 thermal couples installed at the heat exchanger

exhaust outlet to measure the instantaneous average

TABLE II temperatures of exhaust and 10 thermal couples installed on

INLET/OUTLET TEMPERATURES OF HEAT EXCHANGER

the outside walls of the heat exchanger tubes to monitor the

Inlet temperature Outlet temperature temperature drop across the heat exchanger. The exhaust

temperature at the inlet of the heat exchanger was obtained

Exhaust 540 0C 177 0C from a sensor came with the original engine generator set.

Coolant 77 0C 87 0C

TABLE III

HEAT EXCHANGER PARAMETERS

Quotation 1

Shell side Gas

Tube side Liquid

Gas pressure drop 0.31 PSI

Maintenance Removable core

Heat transfer area 87 ft2

Size 51”x28”x28”

Weight 725 lbs

Material of Tube- SS fin tube

construction Shell- SS inner wall

Insulation Integrated insulation

III. INSTRUMENTATION AND TEST PROCEDURE

A. Instrumentation Figure 3 Locations of Temperature Sensors and Flow Meter

The purpose of instrumentation was for system operation

monitoring and system data collection. Parameters to be In addition to the measurements mentioned above, engine

monitored and collected included temperatures, pressures, inlet air flow rate and property (i.e. temperature, pressure,

flow rate, and humidity. Sensors installed to the heat recovery humidity) and engine fuel consumption rate were also

system included temperature sensors, pressure gauges, and a measured and used for exhaust flow rate calculations. Details

flow meter. A National Instrument data acquisition system can be found in [16, 17]. Sensors for mass flow rates of fuel

(DAQ) was used to document the experimental readings. consumption and coolant flow were calibrated gravimetrically.

Temperature sensor signals were sent to a SCXI 1102 board B. Test Procedure

and the flow meter signal was sent to a SCXI1120 board of The heat recovery system was operated and monitored for

the DAQ system. Temperature data were used to estimate the nearly 350 hours after installation. The system was operated

system and components efficiencies, possibility of under generator rated load conditions (125 KW) for most of

condensation formation in exhaust pipe and heat exchanger, the time. The system was also operated under different engine

and fouling factors. Pressure data were used to monitor and loads (25%, 50%, and 75%) for performance testing. For each

evaluate the condition of the flow path and the functions of load, the heat recovery system was tested for three different

the components. The pressure data were occasionally checked types of space heating applications. For each type of

and recorded manually, but not recorded automatically. The application, the inlet or outlet coolant temperature of the heat

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

4

exchanger was controlled to the practicing temperature load (i.e. the sum of heat dissipated from the bypass pipe and

corresponding to the application. the unit heater) nearly constant.

During the first 150 hours of test, water was used as coolant

and the purpose was to investigate the performance of the TABLE IV

system and components and the effect of the exhaust heat ENGINE PERFORMANCE DATA AT 50th HOUR AND 100th HOUR

recovery system on engine performance. Several defects were Engine hours Exhaust T Turbocharger Fuel consum-

found (i.e. such as leakages and inappropriate calibrations of (Degree C) T (Degree C) ption (L/hr.)

some of the sensors) and fixed. At the 150th hour, the coolant Before the 542 122 34

was changed from water to 40% propylene and 60% water installation

mix to avoid freezing and the flow meter was recalibrated. 50th hour 540 142 34

After the 250th hour, one of the thermocouples was 100th hour 533 140 34

recalibrated and the time constant of the temperature control

TABLE V

valve was adjusted to limit the fluctuation in the temperature

PERFORMANCE DATA OF THE EXHAUST HEAT RECOVERY SYSTY

readings. During the period between 250th hour and 300th DURING THE PERION BETWEEN 250-HR AND 300-HR

hour, the engine was operated under full load. The data

obtained for this period were used to investigate the system Measured Data 10Hr 20Hr 30Hr 40Hr 50Hr

performance. During the period between 300th hour and 350th Exhaust Flow (Kg/s) 0.25 0.24 0.24 0.24 0.25

hour, the engine was operated under 4 different engine loads Exchanger exh inlet T (C) 511.5 503.0 487.0 495.9 517.1

(i.e. 25%, 50%, 75%, and 100% of rated load). The data

Exchanger exh outlet T C) 215.6 220.6 207.9 214.5 226.6

obtained during this period were used to investigate the effect

Coolant flow rate (Kg/s) 1.45 1.48 1.45 1.45 1.43

of the load on the performance of the heat recovery system.

This paper reports the results of system performance and Exchanger coolant inlet T (C) 76.89 76.53 77.07 77.03 75.82

Exchanger coolant outlet T

feasibility and economic analyses based on the data for (C) 88.45 87.05 87.74 87.53 87.34

conventional based board heating application with engine at

Before bypass (load) T (C) 88.02 86.79 87.36 87.00 86.83

full load.

After 3way valve (load) T (C) 76.91 76.94 77.08 76.75 75.52

Flow rate in bypass (Kg/s) 1.00 1.13 1.02 1.00 0.83

IV. RESULTS AND DISCUSSIONS

Flow across unit heater (Kg/s) 0.45 0.35 0.43 0.45 0.60

This section discusses the measured results, system Outside ambient T (C) -23.0 -30.0 -18.0 -15.0 -7.0

performance, and feasibility and economical analysis results.

Feasibility analysis includes the effect of the heat recovery The energy balance was checked between the heat absorbed

system on engine performance, system efficiency and from the exhaust side and heat dissipated from the load side.

reliability issues such as corrosion and soot accumulation. Figure 5 shows that the heat absorbed by coolant equals the

A. System Performance sum of heat dissipated with an error of less than 3%. It also

Based on the first 100 hours test data, no engine shows that the heat dissipated from the unit heater was higher

performance was found significantly altered. Some of the data for higher temperatures. This can be explained as, at higher

is listed in Table IV. Performance data of the exhaust heat ambient temperatures, the pipeline dissipates less heat which

recovery system obtained during the period between 250-hour needed to be compensated by increasing heat loss through the

and 300-hour is given in Table V. unit heater to maintain the inlet temperature of the heat

exchanger.

The performance data showed that the ambient temperature

has a noticeable effect on the flow distribution of the system Figure 6 shows the heat release rate from the exhaust and

between the bypass and the unit heater (Figure 4) as expected. the heat absorption rate of the coolant. The heat release rate of

The warmer the outdoor ambient temperature, the more the exhaust across the heat exchanger was based on enthalpy

coolant needed to pass through the unit heater to keep the heat change. The enthalpy was calculated based on the individual

mass percentages of the exhaust components after

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

5

combustion. The heat absorption rate was evaluated using the

coolant mass flow rate, specific heat and the temperature Heat released (kW)

difference between the heat exchanger inlet and outlet flow.

Heat absorbed (kW)

Flow rate in bypass (Kg/s) 80.00

Heat released /absorbed (kW)

Flow rate across unit heater (kg/s)

Ambient temperature (deg C) 70.00

1.2 0 60.00

-5 50.00

1 Temperature (deg C)

40.00

-10

Flow Rate (Kg/s)

0.8 30.00

-15

0.6 20.00

-20 10.00

0.4

-25 0.00

0.2 0 10 20 30 40 50

-30

Time (hrs)

0 -35

Figure 6 Heat Release vs Heat Absorption with respect to Time

0 20 40

time (hours) B. Observation of Soot Accumulation and Corrosion

Figure 4 Flow Distribution between Bypass and Unit Heater Both soot accumulation and corrosion were considered

critical parameters, as they were known to have negative

effect on the performance and maintenance of heat recovery

Heat absorbed by coolant (KW)

systems. This section presents the results obtained from the

Heat dissipated from unit heater (KW) observation of soot accumulation and corrosion inside the heat

Heat loss from pipe exchanger after 350 hours of operation of the exhaust heat

Ambient temperature (deg C) recovery system.

Over a span of 350 hours of run time, the total soot

70 0 produced by the exhaust gas was expected to be 4000 to 6000

60 -5 grams as much of the PM passes through the heat exchanger.

Temperature (deg C) .

Heat absorbed or heat

After the experiments, the heat exchanger was dismantled and

dissipated (KW) .

50 -10

cleaned and about 150 grams of soot was found to be

40 -15 accumulated, which is far less than the maximum of 6000

30 -20 grams. Figure 7 shows the soot accumulated on a arbitrarily

selected finned tube. This result matches a general believe that

20 -25

soot accumulated on a finned tubes may approach to its

10 -30 asymptote within a relatively short period of time [18]. With

0 -35 this small amount of soot accumulated, the heat exchanger

0 10 20 30 40 50 needs maintenance not more than twice a year, which is

considered no impact to the maintenance frequency of the

Time (hrs)

Figure 5 Energy Balance with respect to the Ambient Temperature diesel generator set.

When the heat exchanger was dismantled, the corrosion

The amount of heat absorbed by the coolant followed the

effect of exhaust gas on the heat exchanger was also

same trend as the heat released from exhaust across the heat

investigated by examining the surface for the existence of

exchanger.

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

6

corrosion spots on both tube and shell sides. No trace of any above $2 per gallon.

such corrosion was observed. The reason seems to be that the

The heat recovery system maintenance cost was based on

exhaust temperature was always kept above the dew point.

one day of labor ($75/hr) and a round trip flight ticket ($600)

This resulted in an absence of condensate in the heat

which comes to $1,200 for 6 months of engine operation. The

exchanger throughout the run time. The material, SS 316L,

maintenance costs also include additional money ($300) every

used to construct the inside of the heat exchanger may be the

year for supplies.

other reason.

0% 10%

Payback Time (yrs)

4

0

1.5 2 2.5 3 3.5 4

Fuel Price ($/gallon)

Figure 7 Soot Accumulations on the Fins Figure 8 Payback Time with Respect to Fuel Price and Interest Rate

Based on results described in the previous sections,

C. Economic Analysis and Feasibility applying exhaust heat recovery system to a diesel generator is

The economic analysis was done based on the present heat expected to cause no significant impact on performance and

recovery system and diesel generator used for this experiment maintenance frequency of the engine generator system and the

and an assumption of 100% use of the recovered heat. The payback time for a 100% use of recovered heat would be

heat recovery rate was taken to be 60 kW at rated load with 8 about 3 years based on the current fuel price.

hours per day. Other parameters used in this calculation

include: V. Conclusions

Initial cost of the recovery system = $30,000. An experimental work was conducted to check the

Installation cost = $ 5,000 ($75/hr x 8 hrs /day x 10 days). feasibility and economic effect of applying exhaust heat

Airfare, lodging, meals = $1,950 ($600/round trip + recovery to a diesel engine generator system. The collected

$90/day x 15 days). data and analysis results lead to the following conclusions:

Total capital cost = $37,950. 1. The performance of our exhaust heat exchanger was

Heat recovery per hour = 204,728 BTU. reliable and consistent.

Heating value for conventional fuel = 130,000 BTU/gal. 2. For the 125 kW diesel generator used in this

experiment, the rate of heat recovered from the

Pay back time [19] was calculated based on two different exhaust was about 60 kW.

interest rates and two different fuel prices. Figure 8 shows the 3. No effects were observed on the engine performance

calculated payback times with respective interest rates and and maintenance frequency due to the heat recovery

fuel prices. It is noticed that a reasonable payback time is system.

attainable with an interest rate of 10%and a fuel price of 4. According to the soot accumulation data obtained

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

7

from this experiment, the estimated time for heat 11. S. Lee, C. Bae, J. Jeon, and T. Han, “Effect of design parameters on the

performance of finned exhaust heat exchanger,” SAE paper 2003-01-

exchanger maintenance is less than two days per year. 3076.

5. Corrosion was not observed to be a problem in the 12. R. K. Shah, Fundamental of Heat Exchanger Design, John Wiley &

laboratory test of 350 hours. Sons, 2003.

13. P. R. Raghupatruni, “Performance Analysis of capture of heat energy

6. Based on experimental data obtained from this

from diesel engine exhaust,” M.S. thesis, Dept. Mech. Eng., Univ. of

experiment, the estimated payback time for a 100% Alaska Fairbanks, Fairbanks, Alaska, 2007.

use of recovered heat would be about 3 years for a fuel 14. V. Ganapathy, Minimizing Acid Condensation Concerns,

price of $2.5 per gallon. For 80% use of the recovered http://vganapathy.tripod.com/corros.html.

15. ASHRAE Handbook-Fundamentals, ASHRAE, 2005.

heat, the payback time would be 4 years. 16. A. Telang, “Testing of syntroleum fuels in diesel power plants suitable

7. Operation cost is largely case dependent. Influential for Alaska,” M.S. thesis, Dept. Mech. Eng., Univ. of Alaska Fairbanks,

parameters would include diesel fuel cost, the Fairbanks, Alaska, 2005.

17. S. Kanthikiran, “Properties and performance evaluation of syntroleum

application of the recovered heat, location of the synthetic diesel fuels,” M.S. thesis, Dept. Mech. Eng., Univ. of Alaska

power plant, etc. Fairbanks, Fairbanks, Alaska, 2005.

8. Performance and economic outcomes will be different 18. J. Grillot and G. Icart, “Fouling of a cylindrical probe and a finned tube

bundle in a diesel exhaust environment,” Experimental Thermal and

from one case to another. However, analysis is Fluid Science, Vol. 14, Issue 4, 1988, pp 442-454.

recommended before the installation of an exhaust 19. D.J. Leech, Economic and financial studies for engineers, John Wiley &

heat recovery system to a village generator set. Sons, 1982.

ACKNOWLEDGMENT

The authors are grateful to US-DOE-NETL for supporting

this project (contract number DE-FC26-01NT41248). Thanks

are also due to ICRC Corporation for providing the diesel

generator set used for the experiment and AVEC Corporation

for providing village diesel generator operation data used for

load pattern analysis.

References

1. Alaska Electric Power Statistics, Institute of Social and Economic

Research, University of Alaska Anchorage, Prepared for Alaska Energy

Authority, November 2003.

2. H. Schock, et al., “Thermoelectric conversion of waste heat to

electricity in an IC engine powered vehicle,” 2007 Diesel Engine-

Efficiency and Emissions Research Conference, Session 6, Aug. 2007.

3. D. J. Patterson and R. W. Kruiswyk, “An engine system approach to

exhaust waste heat recovery,” 2007 Diesel Engine-Efficiency and

Emissions Research Conference, Session 6, Aug. 2007.

4. Rural Alaska Energy Plan- Cogeneration Chapter, MAFA, Prepared for

Alaska Energy Authority, Dec. 2002.

5. J. Dakoozian, “Absorption chilling and ice production,” 2004 Alaska

Rural energy conference, Session 2B, 2004.

6. H. T. El-Dessouky,. “Fundamentals of Salt Water Desalination,”

Elsevier Science Ltd, 2002.

7. A. H. Khan, “Desalination Process and Multistage Flash Distillation

Practice” Elsevier Science, 1986.

8. Ground water data for Alaska, 2003,

http://waterdata.usgs.fov/ak/nwis/gw.

9. W. J. Marner, “Progress in gas-side fouling of heat-transfer surfaces,”

Applied Mechanics Reviews, Vol 43, No. 3, March 1990, pp 35-66.

10. D. A. Cramer, President, Summit Consulting Services, Inc, Personal

communication, February 2007.

Institute of the North • Anchorage, Alaska • 1 907 771.2444 • institute@institutenorth.org

www.arcticenergysummit.org

8

You might also like

- Introduction To Microelectronic Fabrication PDFDocument332 pagesIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- Dholpur Combined Cycle Power Plant ReportDocument59 pagesDholpur Combined Cycle Power Plant Reportdhananjay100% (2)

- Rare Watches (Christie's) 16. 05. 2016.Document236 pagesRare Watches (Christie's) 16. 05. 2016.Simon LászlóNo ratings yet

- Science9 Q4 Week2Document16 pagesScience9 Q4 Week2Maria Josie Lopez TumlosNo ratings yet

- Diesel Engine Power PlantDocument13 pagesDiesel Engine Power PlantUtol JasonNo ratings yet

- Pre-Paid Customer Churn Prediction Using SPSSDocument18 pagesPre-Paid Customer Churn Prediction Using SPSSabhi1098No ratings yet

- Design New Medium-Temperature Stirling Engine For Distributed Cogeneration ApplicationsDocument10 pagesDesign New Medium-Temperature Stirling Engine For Distributed Cogeneration ApplicationsLima CostaNo ratings yet

- Final LUS EvaluationDocument36 pagesFinal LUS EvaluationNextgenNo ratings yet

- Iso 22301 2019 en PDFDocument11 pagesIso 22301 2019 en PDFImam Saleh100% (3)

- Unilever PakistanDocument26 pagesUnilever PakistanElie Mints100% (3)

- Ormat Technologies Inc. - Organic Rankine Cycle Power Plant For Waste Heat Recovery - 2013-05-09Document5 pagesOrmat Technologies Inc. - Organic Rankine Cycle Power Plant For Waste Heat Recovery - 2013-05-09Anonymous Cxriyx9HIX100% (1)

- Organic Rankine Cycle Power PlantDocument6 pagesOrganic Rankine Cycle Power PlantPower PowerNo ratings yet

- Performance and Design Optimization of SDocument9 pagesPerformance and Design Optimization of Szaid AlkaissiNo ratings yet

- Applied Thermal Engineering 61 2013Document10 pagesApplied Thermal Engineering 61 2013AnisNo ratings yet

- Waste Heat Recovery Using Shell and Tube Heat ExchDocument5 pagesWaste Heat Recovery Using Shell and Tube Heat ExchJeff LangleyNo ratings yet

- Integrated Solar Power Plants (ISCC)Document13 pagesIntegrated Solar Power Plants (ISCC)carzanteNo ratings yet

- Energies Scott Base PDFDocument12 pagesEnergies Scott Base PDFSusan KrumdieckNo ratings yet

- ASHRAE Absorption ChillerDocument7 pagesASHRAE Absorption ChillerMinh TranNo ratings yet

- 2004 09 Building For The Future - Driving Absorption Chillers Using Heat Recovery - RyanDocument7 pages2004 09 Building For The Future - Driving Absorption Chillers Using Heat Recovery - RyanmeomeportabNo ratings yet

- Power From The Sun - Chapter 12Document53 pagesPower From The Sun - Chapter 12Martin mtawaliNo ratings yet

- Tan Diesel Internal CombustionDocument62 pagesTan Diesel Internal CombustionBryan Ray TanNo ratings yet

- Heat Transfer and Pressure DropDocument10 pagesHeat Transfer and Pressure DropSameer V KulkarniNo ratings yet

- Modeling of Internal Combustion Engine Based CogenerationDocument14 pagesModeling of Internal Combustion Engine Based CogenerationALEJANDRO CADENA DAZANo ratings yet

- Optimization of Lithium Bromide-Water Solar Absorption Cooling System With Evacuated Tube Collectors Using The GADocument9 pagesOptimization of Lithium Bromide-Water Solar Absorption Cooling System With Evacuated Tube Collectors Using The GAYalçın DurmuşoğluNo ratings yet

- Research PaperDocument3 pagesResearch PapersalihyassinNo ratings yet

- Refrig Vehi ElectrDocument11 pagesRefrig Vehi ElectrDaniel martínNo ratings yet

- NAWTEC13-3164: Optimizing Steam Turbine Generator OutputDocument14 pagesNAWTEC13-3164: Optimizing Steam Turbine Generator OutputAjiNo ratings yet

- Ijtee20110302087093 PDFDocument7 pagesIjtee20110302087093 PDFsaliyarumesh2292No ratings yet

- 10.1016 - J.RENENE.2013.05.039 Simulation Study of The Combination of Absorption Refrigeration and Ejector Expansion SystemsDocument12 pages10.1016 - J.RENENE.2013.05.039 Simulation Study of The Combination of Absorption Refrigeration and Ejector Expansion SystemsrezarossNo ratings yet

- Exhaust Gas Analysis of CI Engine With Co-GeneratiDocument10 pagesExhaust Gas Analysis of CI Engine With Co-GeneratijanakNo ratings yet

- Optimization of Energy Plants Including Water/lithium Bromide Absorption ChillersDocument23 pagesOptimization of Energy Plants Including Water/lithium Bromide Absorption ChillersIgor Maciel O. SilvaNo ratings yet

- Projeect PPT-1Document28 pagesProjeect PPT-1Shubham PawarNo ratings yet

- Projeect PPT-1Document28 pagesProjeect PPT-1Shubham PawarNo ratings yet

- Ocean ThermalDocument10 pagesOcean ThermalTienRienNo ratings yet

- Thermodynamic Performance of Molten Salt Heat StorDocument6 pagesThermodynamic Performance of Molten Salt Heat Stormxc2425No ratings yet

- Applied Thermal Engineering: P. Regulagadda, I. Dincer, G.F. NatererDocument7 pagesApplied Thermal Engineering: P. Regulagadda, I. Dincer, G.F. Natererjhugo_mirandaNo ratings yet

- Energy Conversion and Management: 2 Mingzhang Pan, Xingyan Bian, Yan Zhu, Youcai Liang, Fulu Lu, Gang XiaoDocument15 pagesEnergy Conversion and Management: 2 Mingzhang Pan, Xingyan Bian, Yan Zhu, Youcai Liang, Fulu Lu, Gang XiaoSebastian LopezNo ratings yet

- Combined Cycle Systems For The Utility IndustryDocument66 pagesCombined Cycle Systems For The Utility Industryarnoldbatista55No ratings yet

- In-Cylinder Heat Transfer in An Ericsson Engine Prototype: A. Fula, P. Stouffs and F.SIERRADocument6 pagesIn-Cylinder Heat Transfer in An Ericsson Engine Prototype: A. Fula, P. Stouffs and F.SIERRADriss ZiedNo ratings yet

- Energy, Exergyand Energy Audit Analysis of Vijayawada Thermal Power StationDocument8 pagesEnergy, Exergyand Energy Audit Analysis of Vijayawada Thermal Power Stationjhugo_mirandaNo ratings yet

- Conceptual Design and Performance Analysis of An Exhaust Gas Waste Heat Recovery System For A 10000TEU Container ShipDocument8 pagesConceptual Design and Performance Analysis of An Exhaust Gas Waste Heat Recovery System For A 10000TEU Container ShipМаксим АгеевNo ratings yet

- Waste Heat To Power ApplicationsDocument10 pagesWaste Heat To Power ApplicationsArul PrakashNo ratings yet

- Exergy Analysis of A Steam Power PlantDocument7 pagesExergy Analysis of A Steam Power PlantWilly Al KusariNo ratings yet

- Performance Analysis in Off Design Condition of Gas Trbine Air Bottoming Combined SystemDocument10 pagesPerformance Analysis in Off Design Condition of Gas Trbine Air Bottoming Combined SystemIrving Rosas JovenNo ratings yet

- Steam Tip Sheet #16Document2 pagesSteam Tip Sheet #16Muhammad NaeemNo ratings yet

- Call Us: Electrostatic Precipitator KnowledgebaseDocument12 pagesCall Us: Electrostatic Precipitator KnowledgebaseBalaji KannappanNo ratings yet

- Weast Hear Recovery 30.1 - 17Document8 pagesWeast Hear Recovery 30.1 - 17Alin GabrielNo ratings yet

- Recuperación de Calor de Sistemas de Refrigeración ASHRAEDocument8 pagesRecuperación de Calor de Sistemas de Refrigeración ASHRAEDiegoAlvarezHuguezNo ratings yet

- Analytical Design of 1 KW Capacity Lithium Bromide/Water Absorption Refrigeration SystemDocument15 pagesAnalytical Design of 1 KW Capacity Lithium Bromide/Water Absorption Refrigeration SystemTanjim FakirNo ratings yet

- Waste Heat Recoveryfor Offshore ApplicationsDocument10 pagesWaste Heat Recoveryfor Offshore ApplicationsBac DoNo ratings yet

- Alternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsDocument8 pagesAlternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsSyed Jiaul HoqueNo ratings yet

- Article CombinedCycleJournal GTbasedPowerPlantsGrowinStaDocument6 pagesArticle CombinedCycleJournal GTbasedPowerPlantsGrowinStaNorman IskandarNo ratings yet

- 2 - MTD - Volume 2 - 2018 - Faitar Corectat Negru PDFDocument4 pages2 - MTD - Volume 2 - 2018 - Faitar Corectat Negru PDFFaitar CatalinNo ratings yet

- DG Set SystemDocument14 pagesDG Set Systemankur yadavNo ratings yet

- Renewable Energy: Felipe Centeno, Khamid Mahkamov, Electo E. Silva Lora, Rubenildo V. AndradeDocument12 pagesRenewable Energy: Felipe Centeno, Khamid Mahkamov, Electo E. Silva Lora, Rubenildo V. AndradeAndres Mauricio Rojas MantillaNo ratings yet

- Centeno 2012Document50 pagesCenteno 2012Andres Mauricio Rojas MantillaNo ratings yet

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDocument5 pagesA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationNo ratings yet

- Multi-Objective Optimization of A Solar-Powered Triple-Effect Absorption Chiller For Air-Conditioning ApplicationsDocument7 pagesMulti-Objective Optimization of A Solar-Powered Triple-Effect Absorption Chiller For Air-Conditioning ApplicationsAlonso CobosNo ratings yet

- Digitalcommons@University of Nebraska - Lincoln Digitalcommons@University of Nebraska - LincolnDocument9 pagesDigitalcommons@University of Nebraska - Lincoln Digitalcommons@University of Nebraska - LincolnAarti ChameNo ratings yet

- Operation Management of Power Grid System With Renewable Energy Sources and Energy Storage System IntegrationsDocument6 pagesOperation Management of Power Grid System With Renewable Energy Sources and Energy Storage System IntegrationsJaafar AbbakarNo ratings yet

- Modeling of Gas Turbine Based Cogeneration System (2012)Document8 pagesModeling of Gas Turbine Based Cogeneration System (2012)Dominic angelNo ratings yet

- Performance Evaluation and Experiment System For Waste Heat Recovery of Diesel EngineDocument11 pagesPerformance Evaluation and Experiment System For Waste Heat Recovery of Diesel EnginePedro ferreiraNo ratings yet

- Development of Large-Capacity Indirect Hydrogen-Cooled Turbine Generator and Latest Technologies Applied To After Sales ServiceDocument7 pagesDevelopment of Large-Capacity Indirect Hydrogen-Cooled Turbine Generator and Latest Technologies Applied To After Sales Service권용수No ratings yet

- ThermoIII - Notes 1Document13 pagesThermoIII - Notes 1VictoriaNo ratings yet

- Development of A Small Solar Thermal Mechanical Pumping SystemDocument5 pagesDevelopment of A Small Solar Thermal Mechanical Pumping Systemebey_endunNo ratings yet

- A Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationFrom EverandA Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationNo ratings yet

- GST RATE LIST - pdf-3Document6 pagesGST RATE LIST - pdf-3Niteesh KumarNo ratings yet

- CLT Apllications NewestDocument49 pagesCLT Apllications NewestMackBrideNo ratings yet

- Lecture BouffonDocument1 pageLecture BouffonCarlos Enrique GuerraNo ratings yet

- Product Handbook Arendal 1961 Series SubwoofersDocument44 pagesProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicNo ratings yet

- M.SC Food NutritionDocument44 pagesM.SC Food Nutritionasu reddyNo ratings yet

- The Teacher Research Movement: A Decade Later: Cite This PaperDocument13 pagesThe Teacher Research Movement: A Decade Later: Cite This PaperAlexandre NecromanteionNo ratings yet

- Unit 20: TroubleshootingDocument12 pagesUnit 20: TroubleshootingDongjin LeeNo ratings yet

- Case Study McsDocument4 pagesCase Study McsManjushree PatilNo ratings yet

- Sousa2019 PDFDocument38 pagesSousa2019 PDFWilly PurbaNo ratings yet

- QSasDocument50 pagesQSasArvin Delos ReyesNo ratings yet

- BLG311 Cell Biology: Course Outline (Fall 2020)Document11 pagesBLG311 Cell Biology: Course Outline (Fall 2020)Emilija BjelajacNo ratings yet

- Module 5Document14 pagesModule 5shin roseNo ratings yet

- Uniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFDocument64 pagesUniden PowerMax 5.8Ghz-DSS5865 - 5855 User Manual PDFtradosevic4091No ratings yet

- Setting and Plot: Old YellerDocument8 pagesSetting and Plot: Old YellerWalid AhmedNo ratings yet

- Student Research Project Science ReportDocument8 pagesStudent Research Project Science Reportapi-617553177No ratings yet

- Catalogue - Central Battery SystemDocument12 pagesCatalogue - Central Battery SystemarifzakirNo ratings yet

- Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument39 pagesCode of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresIshor ThapaNo ratings yet

- Lecture 7 - Friction - NptelDocument18 pagesLecture 7 - Friction - Nptels_murugan02No ratings yet

- IPC PL 11 006 MS Auditors Issue 7.05Document32 pagesIPC PL 11 006 MS Auditors Issue 7.05saladinNo ratings yet

- The Limits of The Sectarian Narrative in YemenDocument19 pagesThe Limits of The Sectarian Narrative in Yemenهادي قبيسيNo ratings yet

- Bullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceDocument174 pagesBullying Report - Ending The Torment: Tackling Bullying From The Schoolyard To CyberspaceAlexandre AndréNo ratings yet

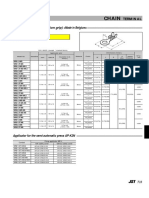

- Chain: SRB Series (With Insulation Grip)Document1 pageChain: SRB Series (With Insulation Grip)shankarNo ratings yet

- Eng03 Module Co4Document14 pagesEng03 Module Co4Karl Gabriel ValdezNo ratings yet