Professional Documents

Culture Documents

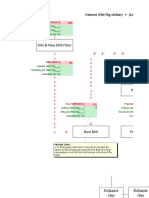

Cooler-2 Diagram

Uploaded by

Praveen Singh ChouhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooler-2 Diagram

Uploaded by

Praveen Singh ChouhanCopyright:

Available Formats

Green Color for Flow in NM3/Hr & Blue Color for Flow in Kg/Hr

To Kiln

Theortical Air 167700

203541 AQC Boiler Booster Fan 512020

800*C 530*C 150*C 176020

259884 130000 396915 150*C

Dummy ESP ESP Fan 138759

Cooler

Chimeny

150*C Fresh air 150*C

HAR Fans 258156 258156

As per running RPM 171312 25*C 336000

336000 220896

HAR Duct

Theoretical Air 203541 Nm3/Hr

Recirculating Air 258156 Nm3/Hr

Fresh Air 171312 Nm3/Hr

Stack Air 138759 Nm3/Hr

False air 170988 Nm3/Hr

39.8 %

False air Calculation in the System

S No. Particulars Unit Unit-2 Unit-8

1 O2 in Flue Gas at PH O/L % 4.5 4.2

Fuel Consumption (@ 9% of Clinker

2 prod assumed) TPH 18.5 12.6

Fuel analysis

4 Carbon % 85.3

5 Nitrogen % 0.4

6 Oxygen % 1.9

7 Hydrogen % 2.7

8 Sulphure % 6.9

9 Moisture % 2.0

10 Ash % 0.8

Theoretical Air Requirement for

11 Complete Combustion Kg/Kg of Fuel 11.0 11.0

12 Excess Air % 26.9 25.0

13 Actual mass of Air Kg/Kg of Fuel 14.0 13.8

Calculaed Total Mass of Air

14 supplied Kg/hr 259884 173521

Measured flow of fresh air cooler

15 Kg/hr 220896 129256

fans

16 Recirculating Air (On RPM Base Kg/hr 336000 206606

almost running at 90-95% )

ESP Fan Flow (Calculated On RPM

17 Kg/hr 512020 247348

Base)

Stack air (Difference of Cooler

18 Kg/hr 176020 40742

fanflow &Reciulating air)

19 False air quantity Kg/hr 215008 85007

20 False air % 39 25

System

Remarks for U-8

Taken instant reading from CCR

9% of clinker prod assumed

Calculated with affinity law of fans

73800 1485

(Q1/Q2=N1/N2)

You might also like

- KRIBHCO SHYAM FERTILISERS LTD AMMONIA PLANT PROCESS OVERVIEWDocument51 pagesKRIBHCO SHYAM FERTILISERS LTD AMMONIA PLANT PROCESS OVERVIEWSabeeh Faruqui100% (1)

- Sizing and Costing of Electrostatic PrecipitatorsDocument15 pagesSizing and Costing of Electrostatic PrecipitatorsarnettoNo ratings yet

- Basic of Chemistry For Class 12 by Bharat PanchalDocument11 pagesBasic of Chemistry For Class 12 by Bharat PanchalNemantNo ratings yet

- Alternative Fuel Requirements SolutionsDocument3 pagesAlternative Fuel Requirements SolutionsIrfan AhmedNo ratings yet

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Document2 pagesVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- WBCSD Cement Sustainability Initiative CO2 Emissions Inventory ProtocolDocument33 pagesWBCSD Cement Sustainability Initiative CO2 Emissions Inventory ProtocolRodrigo DíazNo ratings yet

- Process Measurements ScheduleDocument25 pagesProcess Measurements ScheduleShivesh RanjanNo ratings yet

- 1-Cement Manufacturing Process and SystemDocument75 pages1-Cement Manufacturing Process and Systemmlwbd2069No ratings yet

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- Process Control IEEE Eml RDocument40 pagesProcess Control IEEE Eml RFran JimenezNo ratings yet

- Coal Mill Ball Interlocks-V0.0Document11 pagesCoal Mill Ball Interlocks-V0.0Junaid MazharNo ratings yet

- Che10108 PDFDocument68 pagesChe10108 PDFChristian Del Barco100% (1)

- Plant InvesticationDocument3 pagesPlant InvesticationirfanNo ratings yet

- L-2 Fans 21.11.11Document5 pagesL-2 Fans 21.11.11Aaron HortonNo ratings yet

- The Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsDocument31 pagesThe Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsZegera MgendiNo ratings yet

- Condition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Document6 pagesCondition Monitoring of Grate Cooler Fan: ISO 2372 AND 3945Shandi Hasnul FarizalNo ratings yet

- Process - Operation - Optimization of The ETA Cooler - MugherDocument138 pagesProcess - Operation - Optimization of The ETA Cooler - Mugherzewdu dechasaNo ratings yet

- Pyro Heat Balance 8000TPD @23.03.2023Document2 pagesPyro Heat Balance 8000TPD @23.03.2023harikrushnaNo ratings yet

- PE Pyroprocessing Day 4 Volatilisation Balance Calculation: June 2004Document18 pagesPE Pyroprocessing Day 4 Volatilisation Balance Calculation: June 2004recaiNo ratings yet

- Cement Cooler EffDocument1 pageCement Cooler Effsafwat hassanNo ratings yet

- Rectangular Jet Air Nozzles and Swirler Improving Ignition and Flame FormationDocument24 pagesRectangular Jet Air Nozzles and Swirler Improving Ignition and Flame Formationhmaza shakeelNo ratings yet

- CoolerDocument10 pagesCoolerbudiNo ratings yet

- Fuel & Energy Comparison Between B/E & Air LiftDocument1 pageFuel & Energy Comparison Between B/E & Air LiftAbul Qasim QasimNo ratings yet

- Flowsheet& Theoretical HeatDocument35 pagesFlowsheet& Theoretical HeatRamachandrarao MaddaliNo ratings yet

- Heat Balance (Cooler 2)Document4 pagesHeat Balance (Cooler 2)Junaid Mazhar100% (1)

- Dimension Mills - UploadDocument5 pagesDimension Mills - UploadTIRIANTONo ratings yet

- Plant Location: Preheater Feed Preheater String - Calciner TypeDocument33 pagesPlant Location: Preheater Feed Preheater String - Calciner TypeDilnesa EjiguNo ratings yet

- Questionnaire Cement Plants-01 (1) .8.04Document9 pagesQuestionnaire Cement Plants-01 (1) .8.04Debajit BurhagohainNo ratings yet

- BurnersDocument19 pagesBurnerssameh ibrahemNo ratings yet

- LINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPADocument44 pagesLINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPAirfanNo ratings yet

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084No ratings yet

- Effects of Ash in ClinkerDocument16 pagesEffects of Ash in ClinkerirfanNo ratings yet

- Preheater & Precalciner Performance StudyDocument14 pagesPreheater & Precalciner Performance StudyDilnesa EjiguNo ratings yet

- Crash Stop Sample Raw MillDocument14 pagesCrash Stop Sample Raw MillAbhishekNo ratings yet

- Heat Balance DataDocument6 pagesHeat Balance DataOuaddani amineNo ratings yet

- Process Audit in Cement IndustryDocument64 pagesProcess Audit in Cement IndustryNITITN ASNANINo ratings yet

- HT-2.2 RMR Heat Belance 5 Stage T17 M7,9Document1 pageHT-2.2 RMR Heat Belance 5 Stage T17 M7,9GiequatNo ratings yet

- Energy Audit Guide for Improving EfficiencyDocument76 pagesEnergy Audit Guide for Improving Efficiencyphani5016No ratings yet

- Cooler Air Distribution CalculationDocument18 pagesCooler Air Distribution CalculationSatish KumarNo ratings yet

- Cpi CoolersDocument47 pagesCpi CoolersRobert BrownNo ratings yet

- Particle Size Distribution Analysis and Cyclone Testing ResultsDocument5 pagesParticle Size Distribution Analysis and Cyclone Testing ResultsThaigroup CementNo ratings yet

- Design parameters and production reports of Coal Mill No. 03Document6 pagesDesign parameters and production reports of Coal Mill No. 03Anoop TiwariNo ratings yet

- Find Absolute Humidity Using Temps and PressuresDocument7 pagesFind Absolute Humidity Using Temps and PressuresAnonymous 3ESYcrKPNo ratings yet

- Coal Drying (Dry Basis)Document9 pagesCoal Drying (Dry Basis)billyNo ratings yet

- Calciner Op Ex CalculationDocument9 pagesCalciner Op Ex CalculationNair YadukrishnanNo ratings yet

- Physical Stock Diagrams (01 July-2020)Document5 pagesPhysical Stock Diagrams (01 July-2020)Irshad HussainNo ratings yet

- IPMEA Power Standard - Compress Air GuideDocument6 pagesIPMEA Power Standard - Compress Air GuideJunaid MazharNo ratings yet

- EKO BESTWAY PROJECT - PPSXDocument22 pagesEKO BESTWAY PROJECT - PPSXJunaid MazharNo ratings yet

- GE Energy: Advancements in Particulate Emissions Control Technology For Industrial SourcesDocument43 pagesGE Energy: Advancements in Particulate Emissions Control Technology For Industrial Sourceszane truesdaleNo ratings yet

- 2 - Polytrack Cooler HydDocument168 pages2 - Polytrack Cooler Hydruchikaporwal2018No ratings yet

- Rotary Kiln HEAT UP CHARTDocument5 pagesRotary Kiln HEAT UP CHARTsyeedismailNo ratings yet

- Evaluación y cálculos de quemadores para hornos rotatoriosDocument13 pagesEvaluación y cálculos de quemadores para hornos rotatoriosRoberto Alanez EncinasNo ratings yet

- Brick specs comparison tableDocument1 pageBrick specs comparison tableSaji KumarNo ratings yet

- Performance Driven Maintenance Feb 52013Document25 pagesPerformance Driven Maintenance Feb 52013recaiNo ratings yet

- 15 QC Formulas for Sulfur Balance in KilnsDocument1 page15 QC Formulas for Sulfur Balance in Kilnszane truesdaleNo ratings yet

- Coriolis Part1Document20 pagesCoriolis Part1Krishna Bhanu SinghNo ratings yet

- Clinker Cooler Modification SolutionDocument24 pagesClinker Cooler Modification SolutionemadsabriNo ratings yet

- S.No. Particulars Units FLS: Performance Guarantees Pyro-Processing PlantDocument2 pagesS.No. Particulars Units FLS: Performance Guarantees Pyro-Processing Plantrashmiranjan1110No ratings yet

- Save Energy, Save the WorldDocument23 pagesSave Energy, Save the WorldSmit ShahNo ratings yet

- Kiln Eval Line IDocument1 pageKiln Eval Line IRaji SuriNo ratings yet

- Che 455 Fall 2009 Major 1 Phthalic Anhydride Production: BackgroundDocument20 pagesChe 455 Fall 2009 Major 1 Phthalic Anhydride Production: Backgroundاحمد الدلالNo ratings yet

- 0694-VU-40-PE.xlsxDocument2 pages0694-VU-40-PE.xlsxRufus D SNo ratings yet

- C13TE2A DatasheetDocument3 pagesC13TE2A DatasheetPowerTechNo ratings yet

- Unit 1 CH 07 Exergy Analysis - ReidDocument31 pagesUnit 1 CH 07 Exergy Analysis - ReidLorenzo Galindo Jr.No ratings yet

- Flow-induced vibration risks to piping systemsDocument6 pagesFlow-induced vibration risks to piping systemsLijukrishnanNo ratings yet

- Allen Practice Test Series - (2021-22)Document1 pageAllen Practice Test Series - (2021-22)Raghav KaranNo ratings yet

- Vibration Analysis and Control Exam QuestionsDocument4 pagesVibration Analysis and Control Exam QuestionsAshokNo ratings yet

- Equilibrium: The Extent of Chemical ReactionsDocument59 pagesEquilibrium: The Extent of Chemical Reactionsprathap_somaNo ratings yet

- Hand Panning for Copper Ore ConcentrationDocument4 pagesHand Panning for Copper Ore ConcentrationVincent Tayanes CuiNo ratings yet

- Journal 1210.5589 PDFDocument4 pagesJournal 1210.5589 PDFUdhamNo ratings yet

- Seminar On Gypsum ProductsDocument17 pagesSeminar On Gypsum ProductsHarish Khundrakpam0% (1)

- Micromachines 13 00224 v3Document17 pagesMicromachines 13 00224 v3Safdar AbbasNo ratings yet

- Triangulo de DuvalDocument8 pagesTriangulo de Duvalcarlos patrickNo ratings yet

- Acknowledgement PageDocument9 pagesAcknowledgement PagePrashant BarveNo ratings yet

- C1-Bin Rasheed-Polyurethane & Polyurea Coatings (Mr. M. Shafiq Randhawa)Document66 pagesC1-Bin Rasheed-Polyurethane & Polyurea Coatings (Mr. M. Shafiq Randhawa)AllanNo ratings yet

- Zinc Metal: Copper: Magnesium: Metal R: Zinc IonsDocument2 pagesZinc Metal: Copper: Magnesium: Metal R: Zinc IonstahjsalmonNo ratings yet

- The Comparison of Three Isomers of ButanolDocument5 pagesThe Comparison of Three Isomers of ButanolLilly0% (2)

- HPLC Nexera PHDocument2 pagesHPLC Nexera PHhectorNo ratings yet

- CH 01Document83 pagesCH 01samantha oroNo ratings yet

- HKDSE Physics Part - 2 MechanicsDocument17 pagesHKDSE Physics Part - 2 MechanicsdexterNo ratings yet

- 233 F3 Chemistry MSDocument4 pages233 F3 Chemistry MSNdi FlavourNo ratings yet

- 6 Uniform Circular MotionDocument83 pages6 Uniform Circular MotionRamachandranPerumal0% (1)

- FerromagnetismDocument48 pagesFerromagnetismkawtherahmedNo ratings yet

- Mud kit tests for drilling fluid propertiesDocument8 pagesMud kit tests for drilling fluid propertiesAlok SinghNo ratings yet

- ME Laboratory 1 Experiment No. 1Document7 pagesME Laboratory 1 Experiment No. 1Aaron Choco De GuzmanNo ratings yet

- Biochem Scale Up.Document9 pagesBiochem Scale Up.Ana Lorraine DalilisNo ratings yet

- Malt Extract MsdsDocument7 pagesMalt Extract MsdsSorin LazarNo ratings yet

- Download Photoionization And Photo Induced Processes In Mass Spectrometry Fundamentals And Applications Ralf Zimmermann all chapterDocument68 pagesDownload Photoionization And Photo Induced Processes In Mass Spectrometry Fundamentals And Applications Ralf Zimmermann all chapterross.thompson693100% (6)

- ExamDocument10 pagesExamEllen MarksNo ratings yet

- ENV220/925 Water Quality and Ecological Engineering SolutionsDocument6 pagesENV220/925 Water Quality and Ecological Engineering Solutionshi911hiNo ratings yet