Professional Documents

Culture Documents

Calibrador BS812

Calibrador BS812

Uploaded by

Alberto Ramirez0 ratings0% found this document useful (0 votes)

2 views1 pageThis document provides specifications for measuring the flakiness index of aggregates using sieves and thickness gauges. It lists the sieve sizes to be used to separate aggregate fractions. For each fraction, it gives the width of slots in the corresponding thickness gauge or special sieve used to measure flattened or elongated particles. It outlines the procedure, which involves sieving the sample, weighing the fractions, calculating percentages retained on each sieve, and gauging each fraction using sieves or thickness gauges to measure flaky particles. Dimensions and minimum masses for each fraction are also provided in a table.

Original Description:

Original Title

calibrador BS812

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for measuring the flakiness index of aggregates using sieves and thickness gauges. It lists the sieve sizes to be used to separate aggregate fractions. For each fraction, it gives the width of slots in the corresponding thickness gauge or special sieve used to measure flattened or elongated particles. It outlines the procedure, which involves sieving the sample, weighing the fractions, calculating percentages retained on each sieve, and gauging each fraction using sieves or thickness gauges to measure flaky particles. Dimensions and minimum masses for each fraction are also provided in a table.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageCalibrador BS812

Calibrador BS812

Uploaded by

Alberto RamirezThis document provides specifications for measuring the flakiness index of aggregates using sieves and thickness gauges. It lists the sieve sizes to be used to separate aggregate fractions. For each fraction, it gives the width of slots in the corresponding thickness gauge or special sieve used to measure flattened or elongated particles. It outlines the procedure, which involves sieving the sample, weighing the fractions, calculating percentages retained on each sieve, and gauging each fraction using sieves or thickness gauges to measure flaky particles. Dimensions and minimum masses for each fraction are also provided in a table.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

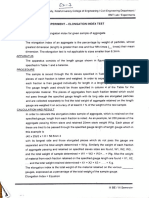

812-105.

1:1989

-These sizes marked on gauge

r 100 0 30 60 r 50 40 r30

63.0 50.0 37.5

to to 4.9

50.0 37.5 28.0 7.2

14.410.2* 10.0

rO

14.0 6.30

26.3

19728.0 TO

20.0 10.0

ro

33.9 20.0 14,0

Dimensions are in millimetres.

Essential dimensions (see tolerances given in Table 3).

Figure 1-Thickness gauge

7.2 Weigh each of the individual size-fractions

7 Procedure retained on the sieves, other than the 63.0 mm

sieve analysis in accordance with 7.3 BS test sieve, and store them in separate trays with

7.1 Carry out a

of BS 812-103.1:1985 using the sieves given in

their size marked on the trays.

Table 1 of that standard. NOTE Where the mass of any size-fraction is considered to be

clay or other subdivided by the methods

NOTE For aggregates which may contain excessive. the fraction may be

materials likely to c a u s e agglomeration of particles,

a sieve described in clause 6 of BS 812-102:1989 provided that themass

with 7.2 of BS 812-103.1:1985 should be of the subdivided fraction is not less than half the appropriate

analysis in accordance mass given in Table 3. Under such circumstances the rest of the

used.

modified and the appropriate

Discard all aggregates retained on

the 63.0 mm test procedure should be suitably

the 6.30 mm test correction factor applied to determine the mass of tlaky particles

sieve and all aggregate passing that would have been obtained had the whole of the original size-

fraction been gauged.

Sieve.

determination of 7.3 From the sums of the masses of the fractions in

Table 3 - Data for

flakiness index the trays (M), calculate the individual percentage

retained on each of the various sieves. Discard any

Aggregate size-fraction Width of slot Minimum

in thickness mass for fraction whose mass is 5 % or less of mass Mi

BS test sieve nominal gauge or

subdivision Record the mass remaining (M,

aperture size special sieve

7.4 Gauge each fraction by using either of the

100 % passing 100 % procedures given in 7.4.1 and 7.4.2.

retaineed

7.4.1 Using the special sieves, select the special

mm Kg

mm mm sieve (see 5.7) appropriate to the size-fraction under

33.9 +0.3 50 test. Place the whole of the size-fraction into the

63.0 50.0 sieve and shake the sieve until the majority of the

26.3 + 0.3 35

| 50.0 37.5 15 flaky particles have passed through the slots. Then

19.7 +0.3

37.5 28.0 gauge the particles retained by hand.

20.0 14.4 +0.15

| 28.0

14.0 10.2 +0.15 2 7.4.2 Using the gauge, select the thickness gauge

20.0

14.0 10.0 7.2 +0.1 1 (see 5.7) appropriate to the size-fraction under test

and gauge each particle of that size-fraction

6.30 4.9 +0.1 0.5

10.0 separately by hand.

BSI 02-2000

2

You might also like

- 2kW Free Energy Device - Don SmithDocument5 pages2kW Free Energy Device - Don SmithJake Mitchell81% (26)

- Sieve Analysis: Plate No. 1Document8 pagesSieve Analysis: Plate No. 1carl steven BicoNo ratings yet

- Interpretation of Geophysical Logs Coal.Document16 pagesInterpretation of Geophysical Logs Coal.Thamzez Nur AnomNo ratings yet

- Electricity, Electronics and Control Engineering Testbank (93 Pages)Document93 pagesElectricity, Electronics and Control Engineering Testbank (93 Pages)Pam G.No ratings yet

- Shape Tests For AggregatesDocument6 pagesShape Tests For AggregatesMohasin KamalNo ratings yet

- Flakiness & Elongation IndexDocument3 pagesFlakiness & Elongation Indexramzimusthafa100% (8)

- Manual Elongation Index Length GaugeDocument1 pageManual Elongation Index Length GaugeMax CedNo ratings yet

- Aggregate Shape Test (Flakiness Index & Elongation Index) Group 5 - Section 7Document9 pagesAggregate Shape Test (Flakiness Index & Elongation Index) Group 5 - Section 7Nazrul IzdhamNo ratings yet

- Elongation Index BS EN 933Document4 pagesElongation Index BS EN 933HushamNo ratings yet

- Flakiness Amp Elongation Group5 Sec7Document9 pagesFlakiness Amp Elongation Group5 Sec7Mahmoud MansourNo ratings yet

- Flakiness Index BS en 933-3 1997Document4 pagesFlakiness Index BS en 933-3 1997miljan.kovacevicNo ratings yet

- Aggregate Shape Test (Flakiness Index & Elongation Index) Group 5 - Section 7Document9 pagesAggregate Shape Test (Flakiness Index & Elongation Index) Group 5 - Section 7Beman EasyNo ratings yet

- Experiment-5 Flakiness Index (FI) Objective Theory: Minimum Mass of Test PortionDocument1 pageExperiment-5 Flakiness Index (FI) Objective Theory: Minimum Mass of Test PortionRefisa Jiru0% (1)

- Particle Size DistributionDocument10 pagesParticle Size DistributionSaraswati Noor100% (1)

- TABLE 2 Dimensions of Circular Washers: 8. Workmanship, Finish, and AppearanceDocument1 pageTABLE 2 Dimensions of Circular Washers: 8. Workmanship, Finish, and AppearanceGHULAM NABINo ratings yet

- Transportation Engineering Sessional I: Highway Materials and Traffic Engineering DesignDocument25 pagesTransportation Engineering Sessional I: Highway Materials and Traffic Engineering DesignJubayer HassanNo ratings yet

- Sieve Analysis of Coarse and Fine AggregateDocument16 pagesSieve Analysis of Coarse and Fine AggregateKendra Joy SendicoNo ratings yet

- Dry Mix DesignDocument7 pagesDry Mix DesignNeeraj ChaubeyNo ratings yet

- Materials TestDocument20 pagesMaterials TestDanish MohdNo ratings yet

- Lab Report - Particle Size Distribution (PSD) - Dry SievingDocument6 pagesLab Report - Particle Size Distribution (PSD) - Dry SievingSheikh BajunaidNo ratings yet

- Laboratory Experiment - Fine AggregateDocument4 pagesLaboratory Experiment - Fine AggregateNajiha KhairiNo ratings yet

- Gradation and Fineness Modulus of Fine AggregateDocument7 pagesGradation and Fineness Modulus of Fine AggregateAlbert JanssenNo ratings yet

- Experimental Program: 3.1 GeneralDocument26 pagesExperimental Program: 3.1 Generalshivanand hippargaNo ratings yet

- 2 - 9 - 38 PSD SieveDocument3 pages2 - 9 - 38 PSD Sievebebo94100% (2)

- Mix Design SpecificationDocument38 pagesMix Design SpecificationRohan Dhatbale100% (1)

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualDocument5 pagesFakulti Kejuruteraan Awam Universiti Teknologi Mara Pasir Gudang Laboratory ManualZaffira RahmanNo ratings yet

- Prac 2 Seive AnalysisDocument8 pagesPrac 2 Seive AnalysisPaul RwomwijhuNo ratings yet

- Determination of Partical Size Distribution of AggregateDocument4 pagesDetermination of Partical Size Distribution of Aggregaterapswal100% (7)

- Topic-3 Soil and Rock PropertiesDocument47 pagesTopic-3 Soil and Rock PropertiesJOHNDOETNo ratings yet

- Adobe Scan 07-Feb-2024Document5 pagesAdobe Scan 07-Feb-2024rajkumarmeena9462No ratings yet

- 4 Unified Soil Classification SystemDocument31 pages4 Unified Soil Classification SystemJaya RamNo ratings yet

- University of Duhok College of Engineering Civil Department 2 Year, 2017-2018Document11 pagesUniversity of Duhok College of Engineering Civil Department 2 Year, 2017-2018Dakheel malekoNo ratings yet

- Screening Analysis EXPERIMENTDocument10 pagesScreening Analysis EXPERIMENTJohnNo ratings yet

- Experiment 2 DETERMINATION OF PARTICLE SIZE DISTRIBUTION BY DRY SIEVINGDocument7 pagesExperiment 2 DETERMINATION OF PARTICLE SIZE DISTRIBUTION BY DRY SIEVINGsofea sukriNo ratings yet

- Marsal SisoDocument8 pagesMarsal SisoLaxman BaduwalNo ratings yet

- Flakiness Index and Elongation Index TestDocument8 pagesFlakiness Index and Elongation Index TestshuhadaNo ratings yet

- Coarse Aggregate Angularity NumberDocument5 pagesCoarse Aggregate Angularity NumberMohammad Tarequl AlamNo ratings yet

- Sieve Analysis Lab Report 2.0 UpdateDocument20 pagesSieve Analysis Lab Report 2.0 UpdateNicholas klassNo ratings yet

- Concrete - Bentonite - Mix Design - 2016 - 01 - 17 - 14 - 51 - 46 PDFDocument4 pagesConcrete - Bentonite - Mix Design - 2016 - 01 - 17 - 14 - 51 - 46 PDFLaxmana PrasadNo ratings yet

- Flakiness Gauge For Classification of Aggregate: Product ManualDocument4 pagesFlakiness Gauge For Classification of Aggregate: Product ManualramlanNo ratings yet

- Laboratory Report 2Document16 pagesLaboratory Report 2fajilagmago.angeldee.c210254No ratings yet

- Determination of Partical Size Distribution of AggregateDocument5 pagesDetermination of Partical Size Distribution of AggregateschoffilNo ratings yet

- Matriz Comparativa Llantas (INMETRO Vs NOM-086) PDFDocument6 pagesMatriz Comparativa Llantas (INMETRO Vs NOM-086) PDFJesús Antonio MárquezNo ratings yet

- Appendix - Final Report - KAMULIDocument26 pagesAppendix - Final Report - KAMULIOjullaIsaacNo ratings yet

- Data Collection and AnalysisDocument10 pagesData Collection and AnalysisChris ArtecoNo ratings yet

- Sieve Analysis of Fine AggregateDocument12 pagesSieve Analysis of Fine Aggregateنور أزلينNo ratings yet

- Investigating Size Reduction OkDocument13 pagesInvestigating Size Reduction OkRoselynNo ratings yet

- Density Void AnalysisDocument9 pagesDensity Void Analysisshuvobosu262No ratings yet

- Sieve Analysis TestDocument8 pagesSieve Analysis TestF1013 ShamimiNo ratings yet

- CMTC136REPORTG3Document5 pagesCMTC136REPORTG3himura kenshinNo ratings yet

- Sanjog Chhetri Sapkota CVP441Document15 pagesSanjog Chhetri Sapkota CVP441sanjog chhetriNo ratings yet

- Chapter 3: Engineering Classification of SoilDocument14 pagesChapter 3: Engineering Classification of Soilحسين عمران محيسنNo ratings yet

- 01-Sieve Analysis Coarse and Fine Aggregate.Document7 pages01-Sieve Analysis Coarse and Fine Aggregate.gsv988No ratings yet

- Determination of Fineness Modulus of Coarse Aggregates and Fine AggregateDocument3 pagesDetermination of Fineness Modulus of Coarse Aggregates and Fine Aggregatemalaya_mohantyNo ratings yet

- ECG426 - Week 3a - I - Soil Classification - Problematic Soil PDFDocument82 pagesECG426 - Week 3a - I - Soil Classification - Problematic Soil PDFanon_884442402No ratings yet

- TE LabDocument37 pagesTE Labpaddu116No ratings yet

- Grain Size DistributionDocument16 pagesGrain Size DistributionramishNo ratings yet

- Soil Classification1Document1 pageSoil Classification1Mohammed SalhinNo ratings yet

- Flakiness and Elongation Index of Aggregate PDFDocument4 pagesFlakiness and Elongation Index of Aggregate PDFSK Abdul KaiumNo ratings yet

- Linting WSP 400Document9 pagesLinting WSP 400Leil100% (1)

- Bilimeter OP ManualDocument16 pagesBilimeter OP ManualargonaiseNo ratings yet

- Designs of Surface Penstocks - Dr. KK MenonDocument132 pagesDesigns of Surface Penstocks - Dr. KK MenonGopal P100% (2)

- 1.periodic Properties & Variations of Properties Class 10, ICSEDocument29 pages1.periodic Properties & Variations of Properties Class 10, ICSEolga YunasNo ratings yet

- MNE-240SeriesWiring Not P4PDocument2 pagesMNE-240SeriesWiring Not P4Pchris eleetNo ratings yet

- Modeling and Analysis of Very Fast Transient Overvoltages in 400 KV GISDocument5 pagesModeling and Analysis of Very Fast Transient Overvoltages in 400 KV GISmohamad akbariNo ratings yet

- Types: (A) External PrestressingDocument32 pagesTypes: (A) External PrestressingAnnamalai VaidyanathanNo ratings yet

- Roofing With Filler Slab - Auroville WikiDocument1 pageRoofing With Filler Slab - Auroville WikiRevathi HariharanNo ratings yet

- Unit 5 - Week 3: Assignment 3Document5 pagesUnit 5 - Week 3: Assignment 3Selvakumar SubbaiahNo ratings yet

- 17ae73 As&c Module-2 ClassDocument47 pages17ae73 As&c Module-2 ClassSanjana ShivaprakashNo ratings yet

- BlowerDocument7 pagesBlowerghanshyam29998987100% (2)

- Activity No. 8 Impedance of Inductance, Resistance and Capacitance CircuitDocument5 pagesActivity No. 8 Impedance of Inductance, Resistance and Capacitance CircuitJohn Paul BaquiranNo ratings yet

- Crankshaft, Main Bearings and Shaft AlignmentDocument19 pagesCrankshaft, Main Bearings and Shaft AlignmentArbanas IvanNo ratings yet

- STUDY GUIDE GR 8Document3 pagesSTUDY GUIDE GR 8Jane BushNo ratings yet

- CanSat Descent Control System Design and ImplementationDocument5 pagesCanSat Descent Control System Design and ImplementationPusapati Saketh Varma ed21b048No ratings yet

- Lab Manual PH 111 - 221114 - 114032Document41 pagesLab Manual PH 111 - 221114 - 114032Chowdhury HasiburNo ratings yet

- Lesson 7.1 Presentation With AnswersDocument21 pagesLesson 7.1 Presentation With Answersmalobaid6No ratings yet

- Pipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, IncDocument10 pagesPipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, Inckaliya12100% (1)

- Editor Hfe Series: X-Ray Generators For Diagnostic RadiographyDocument4 pagesEditor Hfe Series: X-Ray Generators For Diagnostic RadiographyMonooBbuinoNo ratings yet

- Analyser Sampling SystemDocument20 pagesAnalyser Sampling SystemNBTC Tubes & PipesNo ratings yet

- The Hinode MissionDocument208 pagesThe Hinode Missionchris5gNo ratings yet

- Chapter 11 Slides-AubDocument43 pagesChapter 11 Slides-Aubpp9p2m5x5gNo ratings yet

- Air Conditioning Tools: Recovery, Recycling, and Recharging Systems MiscellaneousDocument16 pagesAir Conditioning Tools: Recovery, Recycling, and Recharging Systems Miscellaneousabduallah muhammadNo ratings yet

- MilnortopDocument76 pagesMilnortopJoshuaHaimMamouNo ratings yet

- Hannes Koerber Sandwich Composites ENDocument20 pagesHannes Koerber Sandwich Composites ENGhassan Al-RasheedNo ratings yet

- Roundness Measuring Instrument: RMI-D560C RMI-D420Document8 pagesRoundness Measuring Instrument: RMI-D560C RMI-D420Phạm DươngNo ratings yet

- HeatpipeDocument21 pagesHeatpipeNuleivNo ratings yet

- Pneumatic CylindersDocument10 pagesPneumatic Cylinderssaid ismailNo ratings yet