Professional Documents

Culture Documents

05100a CORTAMAZAROTA

Uploaded by

Ausencio Mayoral LopezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05100a CORTAMAZAROTA

Uploaded by

Ausencio Mayoral LopezCopyright:

Available Formats

632 South 3rd Street

P.O. Box 2816 Paducah, KY 42002

Phone: 270-444-0085

Fax:270-443-6180

Website: www.matweld.com

Email: customerservice@matweld.com

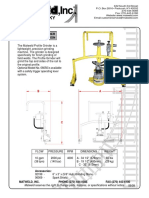

05100A WELD SHEAR

The Matweld Weld Shear is lightweight

and highly efficient. Spring centered flow

control valve permits safe and precise

shearing of a Thermite weld. The shield

totally protects fittings and hoses. The

adjustable hold downs are self locking

and will assure a safe clean cut.

FLOW PRESSURE DIMENSIONS WEIGHT

5 gpm 2000 psi A - 27" 98 lbs

(19 lpm) (140 bar) B -20" (44.54 kg)

C - 13"

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

2 02/01

GENERAL SAFETY PRECAUTIONS:

TOOL OPERATORS AND MAINTENANCE PERSONNEL MUST ALWAYS COMPLY WITH THE

SAFETY PRECAUTIONS GIVEN IN THIS MANUAL, AND WITH ALL STICKERS AND TAGS AT-

TACHED TO THE TOOL AND HOSE. ALL SAFETY PRECAUTIONS ARE GIVEN FOR YOUR SAFETY.

READ TO UNDERSTAND AND FOLLOW ALL SAFETY, MAINTENANCE AND OPERATION IN-

STRUCTIONS BEFORE YOU USE OR MAINTAIN THE TOOL. REVIEW THE MANUAL DAILY BE-

FORE USING THE TOOL. IN ADDITION, FOLLOW ALL SAFETY GUIDELINES GIVEN YOU BY

YOUR SUPERVISOR. DO NOT USE THE TOOL IF YOU HAVE ANY QUESTIONS ABOUT THE

OPERATION, SAFETY OR MAINTENANCE OF THIS TOOL. FAILURE TO FOLLOW THESE IN-

STRUCTIONS CAN RESULT IN PERSONAL INJURY OR EQUIPMENT DAMAGE.

MATWELD HAS NO CONTROL OVER TOOL USE OR OPERATION ONCE IT LEAVES THE

MATWELD PLANT. MATWELD HAS NO CONTROL OVER OPERATOR OR MAINTAINER SELEC-

TION. THE CUSTOMER MUST ASSUME RESPONSIBILITY FOR THE TOOLS SUITABILITY FOR

A PARTICULAR FUNCTION, FOR ANYONE USING THE TOOL OR MAINTAINING THE TOOL RE-

GARDING THEIR FITNESS TO USE THE TOOL OR REPAIR THE TOOL, UNDERSTANDING OF

THE OPERATION AND SAFETY AND MAINTENANCE MANUAL, INTELLIGENCE TO USE GOOD

JUDGMENT NECESSARY TO WORK SAFELY AND EFFICIENTLY WITHOUT ENDANGERING

THEMSELVES OR BYSTANDERS IN THE WORK AREA.

DO NOT OPERATE THE TOOL UNTIL YOU HAVE BEEN THOROUGHLY AND PROPERLY

TRAINED OR UNDER THE SUPERVISION OF AN INSTRUCTOR.

CHECK POWER SOURCE DAILY TO DETERMINE IF CORRECT FLOW AND PRESSURE ARE

AVAILABLE. NEVER EXCEED FLOWS OR PRESSURES FOR THE TOOL BEING USED. PER-

SONAL INJURY OR DAMAGE TO THE TOOL CAN RESULT.

OPERATORS MUST CLEAR THE WORK AREA OF NON-ESSENTIAL PERSONNEL. FLYING

DEBRIS CAN CAUSE SERIOUS INJURY.

THE OPERATOR MUST BE FAMILIAR WITH ALL PROHIBITED WORK AREAS SUCH AS UN-

SAFE GRADES, POOR FOOTING AREAS AND OVERHEAD HAZARDS.

MAINTAIN BALANCE AND PROPER FOOTING AT ALL TIMES. NEVER OVERREACH TO THE

EXTENT THAT A BROKEN PART OR SUDDEN MOVEMENT OF THE TOOL CAN CAUSE YOU

TO LOSE YOUR BALANCE AND FALL, OR CAUSE INJURY TO YOUR SELF OR SOMEONE

ELSE.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

3 02/01

WHEN WORKING NEAR ELECTRICAL CONDUCTORS, ALWAYS ASSUME THAT THE CON-

DUCTORS ARE ENERGIZED AND THAT HOSES AND CLOTHING CAN CONDUCT HARMFUL

ELECTRICITY. USE HOSES LABELED AND CERTIFIED AS NON-CONDUCTIVE.

DO NOT OPERATE THE TOOL AT EXCESSIVE FLUID TEMPERATURES OPERATOR DIS-

COMFORT AND POTENTIAL BURNS CAN RESULT AT HIGH OIL TEMPERATURES.

NEVER WEAR LOOSE CLOTHING THAT CAN GET ENTANGLED IN THE WORKING PARTS

OF THE TOOLS OR BE CARELESS WITH HANDS, FEET OR OTHER BODY PARTS AROUND

THE WORKING PARTS OF THE TOOLS. HYDRAULIC TOOLS EXERT HIGH TORQUE AND

FORCE AND CAN CAUSE SERIOUS INJURY OR DEATH IF IMPROPERLY USED.

TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE, ALL TOOL REPAIR, MAINTENANCE

OR SERVICE MUST ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY TRAINED

PERSONNEL.

ALWAYS WEAR SAFETY EQUIPMENT SUCH AS OIL INJECTION RESISTANT WORK GLOVES,

SAFETY GLASSES, SAFETY BOOTS, EAR PROTECTION AND OTHER SAFETY APPAREL

DICTATED BY YOUR SUPERVISOR APPLICABLE FOR THE JOB YOU ARE DOING AND THE

TOOL YOU ARE USING.

DO NOT CLEAN INSPECT OR REPAIR THE TOOL WHILE CONNECTED TO THE POWER

SOURCE. ACCIDENTAL ENGAGEMENT OF THE TOOL CAN CAUSE SERIOUS PERSONAL

INJURY.

OIL INJECTION HAZARD EXISTS WITH THIS TOOL. OIL INJECTION IS A CONDITION WHERE

HYDRAULIC OIL IS INJECTED UNDER THE SKIN FROM PRESSURE IN THE LINE. ALWAYS

WEAR GLOVES AND REPAIR ANY LEAKS IMMEDIATELY. NEVER CARRY A TOOL BY THE

HOSES.

DO NOT USE DAMAGED EQUIPMENT. IMMEDIATELY REPLACE ANY DAMAGED HOSES,

FITTINGS, OR OTHER COMPONENTS SHOWING WIRE BRAID, NICKS, CUTS, DAMAGE OR

ABRASIONS. FAILURE TO DO SO MAY RESULT IN EQUIPMENT DAMAGE AND / OR PER-

SONAL INJURY OR DEATH.

CLEAN UP ANY OIL OR FLUID SPILLS IMMEDIATELY.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

4 02/01

HAVE SUPERVISOR ADD ADDITIONAL PRECAUTIONS RELATING TO THE SPECIFIC

WORK AREA AND LOCAL SAFETY REGULATIONS BELOW:

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

5 02/01

05100A WELD SHEAR

SAFETY PRECAUTIONS:

1. ALWAYS WEAR SAFETY EQUIPMENT SUCH AS GLOVES, SAFETY GLASSES, EAR

PROTECTION, SAFETY SHOES, AND OTHER REQUIRED SAFETY EQUIPMENT.

2. DO NOT WEAR CLOTHING WHICH MAY BECOME ENTANGLED IN THE TOOL.

3. KEEP HANDS CLEAR OF WORK AREA AT ALL TIME.

4. ALWAYS KEEP WORK AREA FREE OF TOOLS OR ANY OTHER OBJECTS WHICH MAY

IMPAIR SOUND FOOTING.

5. CAUTION - OIL INJECTION HAZARD EXISTS WITH THIS TOOL. OIL INJECTION IS A

CONDITION WHERE THE HYDRAULIC OIL IS FORCED UNDER THE SKIN THROUGH

PRESSURE IN THE LINE. ALWAYS WEAR GLOVES AND REPAIR LEAKS IMMEDIATELY.

6. BECAUSE OF THE HIGH FIELD WELD TEMPERATURES, IT IS EXTREMELY IMPORTANT

TO CHECK FOR WORN HOSES, NICKS, CUTS, AND/OR LEAKS BEFORE EACH SHEAR

OPERATION. HYDRAULIC OIL HAS A FLASH POINT OF APPROX. 400 DEGREE F. A LEAK

DIRECTED INTO THE WELD AREA (1900° F) WILL CAUSE A FIRE AND POSSIBLE SERI-

OUS INJURY OR DEATH.

7. DO NOT CLEAN OR INSPECT THE TOOL WHILE IT IS CONNECTED TO THE POWER SOURCE.

ACCIDENTAL ENGAGEMENT OF THE TOOL CAN CAUSE SERIOUS INJURY.

8. ALWAYS CHECK WORK AREA FOR ANY TRASH WHICH MY IGNITE FROM SPARKS, WELD

SPLATTER OR SLAG.

9. ALWAYS CHECK THE WORK AREA FOR SMOLDERING TIES OR TRASH BEFORE LEAV-

ING SITE.

10. NEVER STRIKE HOLD DOWNS WITH ANY OBJECT TO LOOSEN SHEAR FROM THE

RAIL.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

6 02/01

05100A WELD SHEAR

MODEL NO: 05100A

FLOW: 5 GPM (19 LPM)

PRESSURE: 2000 PSI (140 BAR)

MAX BACK PRESSURE: 250 PSI (17 BAR)

OPERATION:

PLACE THE SHEAR ON THE RAIL PRIOR TO SETTING UP THE WELD TO ADJUST

THE HOLD DOWN LEGS. AFTER HOLD DOWN LEGS ARE ADJUSTED, REMOVE

SHEAR FROM RAIL TO PREPARE WELD.

1. WITH THE POWER SOURCE IN THE OFF POSITION, CONNECT THE HOSES. DO

NOT DRAG THE SERVICE HOSES BY PULLING WITH THE TOOL. LOOP THE SERVICE

HOSE IN THE WORK AREA IN SUCH A WAY TO RELIEVE STRESS ON THE HOSE AND

QUICK DISCONNECT FITTINGS WHILE WORKING. BE AWARE OF HOSE LOCATION

AT ALL TIMES.

2. WHEN THE WELD IS READY TO BE CUT, POSITION TWO PEOPLE, ONE ON EACH

SIDE OF THE SHEAR. THEY SHOULD CAREFULLY PLACE THE SHEAR OVER THE

WELD AND LOCK IT INTO PLACE WITH THE HOLD DOWN LEGS.

3. TURN THE POWER SOURCE ON TO SUPPLY 5 GPM.

4. MOVE THE HANDLE TO SIDE THAT IS LABELED SHEAR TO MAKE THE CUT.

5. AFTER SHEAR IS COMPLETE, MOVE THE HANDLE THE OPPOSITE DIRECTION (LABELED

RETRACT) TO RETRACT THE SHEAR BLADES.

6. TURN POWER SOURCE OFF.

7. TO REMOVE SHEAR FROM THE RAIL, LOOSEN HOLD DOWNS, POSITION TWO

PEOPLE, ONE ON EACH SIDE OF THE SHEAR, AND CAREFULLY REMOVE FROM

THE RAIL.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

7 02/01

05100A WELD SHEAR

MAINTENANCE:

1. AS THE BLADES WEAR, THE GAP MAY BE CLOSED BY ADJUSTING THE CYLINDER ROD

NUTS ON THE CENTER PLATE OF THE SHEAR. A 1/32 GAP IS RECOMMENDED.

2. INSPECT HOSES DAILY. AT THE FIRST SIGN OF ANY ABRASION OR CUT TO THE

COVER, THE HOSES MUST BE CHANGED.

3. CHECK ALL FASTENERS DAILY.

4. USE ONLY RECOMMENDED HYDRAULIC OILS. NEVER USE ATF OR MOTOR OIL.

SUGGESTED HYDRAULIC OILS:

AMOCO RYKON MV CITGO A/W ALL TEMP

SUN 2105 MOBIL D.T.E. 15

CHEVRON EP-MV TEXACO RANDO HD-AZ

IF YOUR LOCAL DISTRIBUTOR DOES NOT CARRY ANY OF THE ABOVE SUGGESTED

HYDRAULIC OILS USE THE FOLLOWING GUIDELINES:

VISCOSITY @ 100° F

100-190SUS

VISCOSITY INDEX

MIN.150

EACH APPLICATION IS DIFFERENT, IF THERE ARE ANY QUESTIONS CONCERNING THE

RIGHT CHOICE FOR YOUR PARTICULAR APPLICATION CALL MATWELD FOR ASSISTANCE.

5. HAVE TOOL INSPECTED, AT LEAST ANNUALLY, BY A MATWELD OR MATWELD QUALIFIED

SERVICE REPRESENTATIVE TO DETERMINE IF TOOL IS IN NEED OF SAFETY CHANGES

OR WORN PART REPLACEMENT.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

8 02/01

05100A WELD SHEAR

GENERAL NOTES:

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

9 02/01

05100A

WELD SHEAR

REV.2 01/02

19

26 11

35

2 34 15

37 33

1

3

32

38

33 20

34 37 14

32 13 35

16

27

10

24

36

12

17

6

15

37

14

36 4

17

8 18

27 37

9 29

24

21 24 31 25

4

28

29

24 30 22

25

22 28

25 29

28

5

7

30

31

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

10 02/01

05100A

WELD SHEARPARTS LIST

REV.2 01/02

ITEM NO. PART NO. DESCRIPTION QTY.

1 00145 QUICK DISCONNECT COUPLER 1

2 00146 QUICK DISCONNECT NIPPLE 1

3 00905A VALVE - SPRING CENTER 1

4 00908 SHEAR CYLINDER 2

5 05101 WELD SHEAR FRAME 1

6 05131 VALVE BRACKET 1

7 05103 FRONT HOLD DOWN 2

8 05108 CENTER HOLD DOWN 2

9 05110 SHEAR CENTER PLATE 1

10 05130 FITTING GUARD 1

11 05112 SAFETY SHIELD 1

12 05113 SAFETY SHIELD LOWER 1

13 05114 HOLD DOWN BRACKET SHIELD 1

14 05115A HOSE CYLINDER EXTENSION 2

15 05116A HOSE CYLINDER RETRACT 2

16 A2048 5/16-18 NYLOCK NUT 2

17 2501-04-06 3/8NPT X ¼ MJIC 90 EL 2

18 A6308 5/16-18 X 1 FLAT HEAD BOLT 2

19 A1001 1/4-20 X ¾ GR. 5 ZP. 1

20 A2062 1/4-20 NUT INSERT 1

21 A1021 5/16-18 X ¾ GR. 5 ZP. 2

22 A1083 1/2-13 X 1-1/2 GR. 5 ZP. 4

24 A2000 3/4-16 HEX NUT ZP. 4

25 A1465 3/4-16 JAM NUT 6

26 A2190 ¼ SAE FLAT WASHER ZP 1

27 A2191 5/16 SAE FLAT WASHER ZP 4

28 A2194 1/2 SAE FLAT WASHER ZP 4

29 A2197 3/4 SAE FLAT WASHER ZP 4

30 A6105 ½ X 1 SPRING PIN 4

31 A6079 3/16 X 1 SPRING PIN 4

32 409-06-06 3/8 FP X 3/8 MP 90 EL 2

33 3/8X2-1/2-80 3/8 X 2-1/2 NIPPLE 2

34 5406-08-06 1/2X 3/8 HEX BUSHING 2

35 2601-04-04-04 1/4 NPT X 1/4 MJIC T 2

36 2501L-04-04 1/4NPT X 1/4 MJIC 90 EL 2

37 5406-06-04 3/8 X 1/4 BUSHING 4

38 5502-04-04 1/4 STREET EL 90 1

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

11 02/01

REVIEW OF HYDRAULIC PRINCIPLES

A. TOOL CIRCUIT

1. HYDRAULIC FORMULAS:

CID X RPM GPM X PSI

GPM = 231 HP = 1714 (.85)

1456.9

Example: HP required to deliver 10 GPM at 1500 PSI.

10 GPM X 1500 PSI = 15000 = 10.3 HP

1456.9 1456.9

(subtract back pressure for tool HP)

Estimated HP delivered by pump or used by tool.

PSI

GPM 500 1,000 1,500 2,000 2,500 3,000

3 1.03 2.06 3.09 4.12 5.15 6.18

5 1.72 3.43 5.15 6.86 8.58 10.30

10 3.43 6.86 10.3 13.70 17.20 20.60

15 5.15 10.30 15.40 20.60 25.70 30.90

2. BACK PRESSURE

BACK PRESSURE MEASURED AT THE TOOL RETURN PORT MUST NOT EXCEED THE MANU-

FACTURERS BACK PRESSURE RATING. MOST MANUFACTURERS LIST THE MAXIMUM BACK

PRESSURE FOR THEIR HYDRAULIC TOOLS AT 250 PSI. BACK PRESSURE MEASURED ON

THE RETURN SIDE OF THE TOOL IS THE FORCE REQUIRED TO GET THE OIL BACK TO THE

TANK. IN ALMOST ALL CASES THE LOWER THE BACK PRESSURE THE BETTER THE TOOL

PERFORMANCE. FIRST, THE BACK PRESSURE IS SUBTRACTED FROM THE MAXIMUM TOOL

PRESSURE TO ARRIVE AT A MAXIMUM TOOL OPERATING PRESSURE. FOR EXAMPLE, TOOLS

WITH 2000 PSI OPERATING PRESSURE ARE INSTALLED ON A SYSTEM WITH 250 PSI BACK

PRESSURE. THIS LEAVES1750 PSI AS A MAXIMUM TOOL PRESSURE. IMAGINE A SYSTEM

WITH 500 PSI BACK PRESSURE. 2000 MINUS 500 PSI BACK PRESSURE LEAVES ONLY 1500

PSI FOR THE TOOL. SECOND, TOOLS ARE DESIGNED FOR PRESSURE TO BUILD ON THE

PRESSURE SIDE OF THE TOOL. IF TOO MUCH PRESSURE BUILDS ON THE RETURN SIDE,

NOT ONLY IS PERFORMANCE EFFECTED, BUT SEALS MAY BLOW. THIS IS WHY IT IS VERY

IMPORTANT TO DIRECT THE FLOW INTO THE TOOL CORRECTLY. REVERSING THE HOSES

TO TEST MAY RESULT IN BLOWN SEALS, DAMAGE TO THE TOOL, AND PERSONAL INJURY.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

12 02/01

05100A WELD SHEAR

DECAL LEGEND:

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

13 02/01

05100A WELD SHEAR

GENERAL NOTES:

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

14 02/01

LIMITED WARRANTY

MATWELD, INC., PADUCAH, KY., WARRANTS TO THE ORIGINAL PURCHASE OF THIS PROD-

UCT THAT THE PRODUCT WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP

FOR THE PERIOD OF ONE (1) YEAR AFTER THE DELIVERY OF SUCH PRODUCT TO THE CUS-

TOMER. OTHER EQUIPMENT AND PARTS USED, BUT NOT MANUFACTURED BY MATWELD

INC. ARE COVERED DIRECTLY BY THE WARRANTY OF THE MANUFACTURER OF THOSE PROD-

UCTS. PROOF OF PURCHASE MUST BE DOCUMENTED INCLUDING REFERENCE TO A SE-

RIAL NUMBER LOCATED ON EACH TOOL. THE PURCHASERS ONLY REMEDIES UNDER THIS

LIMITED WARRANTY SHALL BE LIMITED AT MATWELDS SOLE OPTION TO THE FOLLOWING:

REPAIR, REPLACEMENT OR REFUND OF THE PURCHASE PRICE OF THE DEFECTIVE PROD-

UCTS. EACH OF THESE REMEDIES REQUIRES TIMELY NOTIFICATION OF THE DEFECT IN

THE PRODUCT AND SUBSTANTIATION THAT THE PRODUCT HAS BEEN PROPERLY STORED,

MAINTAINED AND USED. MATWELDS OBLIGATIONS HEREUNDER EXTEND ONLY TO THE

PURCHASER OF THE PRODUCT AND NOT TO ANY THIRD PARTY.

AS A CONDITION PRECEDENT TO MATWELDS OBLIGATION HEREUNDER, THE DEFECTIVE PROD-

UCT MUST NOT HAVE BEEN ALTERED OR MODIFIED WITHOUT THE EXPRESS WRITTEN AP-

PROVAL OF MATWELD, INC. THE PRODUCT MUST NOT HAVE BEEN SUBJECTED TO DELIBER-

ATE DAMAGE, SHIPPING DAMAGE, NEGLECT, TAMPERING BY UNAUTHORIZED PERSONNEL OR

DAMAGE BY IMPROPER USE, STORAGE OR MAINTENANCE. SERIAL NUMBERS MUST NOT HAVE

BEEN ALTERED, DEFACED OR REMOVED. SUCH ACTION VOIDS LIMITED WARRANTY.

EXCLUSIONS TO LIMITED WARRANTY

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRIT-

TEN OR ORAL, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED

WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITED WARRANTY DOES NOT COVER NORMAL WEAR AND TEAR ITEMS SUCH AS FIL-

TERS, HOSES, COUPLERS, BITS, SOCKETS, AUGERS, AND BATTERIES.

LIMITATION OF LIABILITY

EXCEPT AS PROVIDED ABOVE, MATWELD SHALL IN NO EVENT BE LIABLE OR RESPONSIBLE

FOR ANY INJURY, LOSS OR DAMAGE, DIRECT, INCIDENTAL OR CONSEQUENTIAL, ARISING

OUT OF THE USE OR MISUSE OR INABILITY TO USE THE PRODUCT, HOWEVER CAUSED AND

ON ANY THEORY OF LIABILITY INCLUDING, WITHOUT LIMITATIONS, BREACH OF CONTRACT,

TORT, (INCLUDING NEGLIGENCE OR STREET LIABILITY) AND NOT WITHSTANDING ANY FAIL-

URE OF ANY REMEDY HEREIN OF ITS ESSENTIAL PURPOSE, EVEN IF MATWELD WAS AWARE

OF THIS POSSIBILITY OF SUCH DAMAGE. MATWELDS LIMITED WARRANTY AS SET FORTH

ABOVE SHALL NOT BE ENLARGED, DIMINISHED OR AFFECTED BY, AND NO OBLIGATION OR

LIABILITY SHALL ARISE OR GO OUT OF THE RENDERING OF TECHNICAL ADVICE OR SER-

VICE BY MATWELD OR ITS AGENTS. THE FOREGOING MAY NOT BE CHANGED EXCEPT BY

WRITTEN AGREEMENT SIGNED BY AN AUTHORIZED OFFICER OF MATWELD, THE REMEDIES

SET FORTH HEREIN ARE EXCLUSIVE.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

15 02/01

CUSTOMER INFORMATION:

Name _____________________________________________________

Company___________________________________________________

Serial # of your Matweld tool___________________________________

( Upon receiving your Matweld tool, make sure to list serial number above so that a good record is kept for

order information.)

MATWELD HYDRAULIC TOOL LIST

All Matweld Hydraulic Tools operate at

5 or 10 GPM @ 2000 PSI

POWER UNITS:

07000 HYDRA POWERED MODULAR SYSTEM

02900 DIESEL 1-10 GPM OR 2-5 GPM

(OPTIONAL CATALYTIC EXHAUST AND/OR MSHA CERTIFIED)

00100 GASOLINE 1-10 GPM OR 2-5 GPM

02050 GASOLINE 1-5 GPM

05500 TWIN POWER DUAL CIRCUIT UNIT 1-10 GPM OR 2-5 GPM & 5000 WATT GENERATOR

TRACK TOOLS:

01600A 1 IMPACT WRENCH

04500D ½ IMPACT DRILL

00800A 16 RAIL SAW

03900A REVERSING RAIL SAW

01100 SPIKE PULLER

01300A TIE TAMPER

01400 SPIKE DRIVER

01500 RAIL DRILL

01000 CHAIN SAW

03500 SELF FEED RAIL DRILL

GRINDERS:

04600 & 04650 STRAIGHT STONE CW & TRIGGER VERSION

04700 & 04750 STRAIGHT STONE CCW & TRIGGER VERSION

04800 & 04850 CUPSTONE & TRIGGER VERSION

00700 RAIL SURFACING GUIDE

02400 10 OR 14 FROG AND SWITCH GRINDER

05900 FROG/PROFILE GRINDER - ON/OFF FLOW CONTROL

05950 FROG/PROFILE GRINDER - SAFETY TRIGGER

06000 PROFILE GRINDER

05400 ANGLE GRINDER

OTHER PRODUCTS:

HYDRAULIC MANIFOLDS

HYDRAULIC TEST GAUGES

HOSE REELS

HYDRAULIC HOSES

ACCESSORIES

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

16 02/01

You might also like

- Kobelco sk350-8Document394 pagesKobelco sk350-8Harlinton descalzi91% (77)

- Chop Saw - 251938 - M2500LW2 - Task Force 10in Cmpd. Miter SawDocument64 pagesChop Saw - 251938 - M2500LW2 - Task Force 10in Cmpd. Miter SawJacob B100% (3)

- EN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDocument35 pagesEN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDarío Ache EmeNo ratings yet

- 120CU20 ManualDocument228 pages120CU20 ManualVăn Tuấn NguyễnNo ratings yet

- DEWALT DW708 12 Double-Bevel Sliding Compound Miter ManualDocument54 pagesDEWALT DW708 12 Double-Bevel Sliding Compound Miter ManualClaudio RosaNo ratings yet

- Model ES HogStunnerDocument28 pagesModel ES HogStunnerDarwin TierraNo ratings yet

- B-64483EN 02 Connection HardwareDocument608 pagesB-64483EN 02 Connection HardwareDmitry100% (1)

- MR-96A Service Manual V3.0 enDocument57 pagesMR-96A Service Manual V3.0 enHussain Amir Ali0% (1)

- Abb CL-LMRDocument296 pagesAbb CL-LMRInajá FerreiraNo ratings yet

- Sample Maintenance Sheet: TrailerDocument2 pagesSample Maintenance Sheet: TrailerTrisNo ratings yet

- 10 GPM 1" Impact WrenchDocument22 pages10 GPM 1" Impact WrenchMaria Teresa Fernández OlavarrietaNo ratings yet

- User ManualDocument18 pagesUser Manualjuniorcoutino2209No ratings yet

- Profile Grinder 06050 Trigger VersionDocument16 pagesProfile Grinder 06050 Trigger VersionMaria Teresa Fernández OlavarrietaNo ratings yet

- 03900a GuitarraDocument22 pages03900a GuitarraAusencio Mayoral LopezNo ratings yet

- 01600A 5 GPM 1" Impact Wrench: See Impact Accessories Next PageDocument22 pages01600A 5 GPM 1" Impact Wrench: See Impact Accessories Next PageMaria Teresa Fernández OlavarrietaNo ratings yet

- 00100K Dual Circuit Power Unit: AccessoriesDocument34 pages00100K Dual Circuit Power Unit: AccessoriesMaria Teresa Fernández OlavarrietaNo ratings yet

- Knight Reel Auggie 3060 Operators Manual PDFDocument34 pagesKnight Reel Auggie 3060 Operators Manual PDFWest BeefNo ratings yet

- Manual - Scribe Saw (Kentmaster SC650)Document21 pagesManual - Scribe Saw (Kentmaster SC650)yuNo ratings yet

- Hobart Om-2175 User & Service ManualDocument321 pagesHobart Om-2175 User & Service ManualNasir AhmedNo ratings yet

- Instructions AND Parts Manual: STW-2000 Programmable Stiffener WelderDocument32 pagesInstructions AND Parts Manual: STW-2000 Programmable Stiffener WelderJuan RodriguezNo ratings yet

- EN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDocument48 pagesEN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDarío Ache EmeNo ratings yet

- Operation and Maintenance Manual With Illustrated Parts List For 120DZ20 120 kVA, 3 Phase, 115/200 Volt, 400 Hz. Generator SetDocument222 pagesOperation and Maintenance Manual With Illustrated Parts List For 120DZ20 120 kVA, 3 Phase, 115/200 Volt, 400 Hz. Generator Setonukvedat7219No ratings yet

- Operation and Maintenance Manual With Illustrated Parts List For 120DZ20 120 kVA, 3 Phase, 115/200 Volt, 400 Hz. Generator SetDocument222 pagesOperation and Maintenance Manual With Illustrated Parts List For 120DZ20 120 kVA, 3 Phase, 115/200 Volt, 400 Hz. Generator SetMansoor AliNo ratings yet

- Manual Soldadora de AlambreDocument40 pagesManual Soldadora de AlambreVictor Hugo PerezNo ratings yet

- S3186 SmartStart EngDocument21 pagesS3186 SmartStart Engไพฑูรย์ กุดศาลาNo ratings yet

- Wilton Belt and Disc Sanding Machine: Operating Instructions - Parts ManualDocument24 pagesWilton Belt and Disc Sanding Machine: Operating Instructions - Parts ManualKrish KrishnaNo ratings yet

- 90CU420 ManualDocument230 pages90CU420 ManualLider Taller100% (1)

- 500141A Hobartgpu PDFDocument212 pages500141A Hobartgpu PDFTerry Jamu100% (3)

- Polipastos CM Valuestar ManualDocument29 pagesPolipastos CM Valuestar ManualJoako TorresNo ratings yet

- Installation InstructionsDocument38 pagesInstallation InstructionsNestor Rhamses Garcia SantiagoNo ratings yet

- Users Manual Sysdrive 3G3JV PDFDocument244 pagesUsers Manual Sysdrive 3G3JV PDFduartemr1No ratings yet

- GD-070 PK-500 Linear OscillatorDocument56 pagesGD-070 PK-500 Linear OscillatorSgly ZemogNo ratings yet

- Manual Variador J7 PDFDocument177 pagesManual Variador J7 PDFminitecoNo ratings yet

- Om 2098Document236 pagesOm 2098Francisco NavarroNo ratings yet

- Om 2003 OperationDocument106 pagesOm 2003 OperationJacksonNo ratings yet

- Craftsman 7-1/2" Radial Arm Miter SawDocument64 pagesCraftsman 7-1/2" Radial Arm Miter SawmrdirsirNo ratings yet

- User Manual Servo Motor and Drive I531Document476 pagesUser Manual Servo Motor and Drive I531alone160162No ratings yet

- SM5ce - V3 SawDocument9 pagesSM5ce - V3 SawBryan DixNo ratings yet

- Revolver Cih-14: Case Ih & NH: Operator S ManualDocument30 pagesRevolver Cih-14: Case Ih & NH: Operator S Manualalaynnastaabx786No ratings yet

- Wilton Operators Manual 14-Inch Vertical Band Saws Model 8201Document32 pagesWilton Operators Manual 14-Inch Vertical Band Saws Model 8201ullwnNo ratings yet

- Instructions AND Parts Manual Go-Fer Iii-Ox Go-Fer Iii-Pl Go-Fer Iii-WdDocument22 pagesInstructions AND Parts Manual Go-Fer Iii-Ox Go-Fer Iii-Pl Go-Fer Iii-Wdmilenko CortesNo ratings yet

- SK58Document21 pagesSK58Paulo Costa SilvaNo ratings yet

- SheeterDocument11 pagesSheeterNicko InoveroNo ratings yet

- 90 Cu 24Document214 pages90 Cu 24Aliksan TasdemirNo ratings yet

- Om-2130b User & Service ManualDocument238 pagesOm-2130b User & Service ManualNasir AhmedNo ratings yet

- Deadbreak Apparatus Connectors: 600 A 15/25 and 35 KV Class Deadbreak Protective Cap Installation InstructionsDocument4 pagesDeadbreak Apparatus Connectors: 600 A 15/25 and 35 KV Class Deadbreak Protective Cap Installation InstructionsNguyen Anh TuNo ratings yet

- 750to850 Retrofit-A2Document38 pages750to850 Retrofit-A2이성종No ratings yet

- 1248-000 1 - 2 - Nut Busting Impact Wrench - 8.5 AmpDocument18 pages1248-000 1 - 2 - Nut Busting Impact Wrench - 8.5 AmpSiamakNo ratings yet

- Operator'S Manual: 30cc String Trimmers and BrushcutterDocument26 pagesOperator'S Manual: 30cc String Trimmers and BrushcutterAlicia GonzalezNo ratings yet

- Service Manual RouterDocument64 pagesService Manual RouterharyantoNo ratings yet

- Dent Repair Stud Welder Model 08878Document12 pagesDent Repair Stud Welder Model 08878renspurNo ratings yet

- Wire Feed Welder Campbell HausfeldDocument44 pagesWire Feed Welder Campbell Hausfeldcamaro67427No ratings yet

- Universal Bugomatic With AHC LIT UBOM AHC IPM 0211Document32 pagesUniversal Bugomatic With AHC LIT UBOM AHC IPM 0211revelkNo ratings yet

- WeldSkill 155 - 185 Operating ManualDocument88 pagesWeldSkill 155 - 185 Operating ManualBarry ThomasNo ratings yet

- Vebm090100 WF550-3 T-3Document394 pagesVebm090100 WF550-3 T-3Baciu NicolaeNo ratings yet

- Electric Hoist 40765Document10 pagesElectric Hoist 40765Mark Ramirez100% (1)

- 10" Single-Bevel Sliding Compound Miter Saw: Instruction ManualDocument28 pages10" Single-Bevel Sliding Compound Miter Saw: Instruction ManualMagnumRelux MendezNo ratings yet

- Generac-Guardian-Diagnostic-Repair-Manual Liquid Cooled 1.5LDocument115 pagesGenerac-Guardian-Diagnostic-Repair-Manual Liquid Cooled 1.5Lomar contrerasNo ratings yet

- Manual MitsubishiDocument173 pagesManual MitsubishiMaria Cristina MendesNo ratings yet

- Omron Vs Mini j7Document177 pagesOmron Vs Mini j7Güray ÖZÜERLER100% (1)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Lincoln 3Document50 pagesLincoln 3RZ EmiNo ratings yet

- Bomba KWP BlocDocument28 pagesBomba KWP BlocKevin OchoaNo ratings yet

- Manual de Servicio 5329 (Ingles)Document305 pagesManual de Servicio 5329 (Ingles)Tutcom Nguyen Thanh TrungNo ratings yet

- LED VideowallDocument11 pagesLED VideowallIvan AphoninNo ratings yet

- Baker - 690981 PDFDocument24 pagesBaker - 690981 PDFAsep SuhermanNo ratings yet

- KR-G11 User Guider AlarmDocument21 pagesKR-G11 User Guider AlarmJuan DuqueNo ratings yet

- Amm 24-00Document10 pagesAmm 24-00Leandro CalientoNo ratings yet

- Davis Tube TesterDocument2 pagesDavis Tube TesterCV Dharma UtamaNo ratings yet

- Week 5 ABS ESP TCS SystemsDocument72 pagesWeek 5 ABS ESP TCS SystemsahmedaboshadyNo ratings yet

- INSTRUMENTATION LAB Manual PDFDocument55 pagesINSTRUMENTATION LAB Manual PDFNanda Kishore ReddyNo ratings yet

- Current Fault Codes: Code Text StatusDocument3 pagesCurrent Fault Codes: Code Text StatusnaftaliNo ratings yet

- Hartridge AVM2-PCDocument112 pagesHartridge AVM2-PCPlanning khmwNo ratings yet

- E153FPTcServiceManualA05 PDFDocument69 pagesE153FPTcServiceManualA05 PDFMarcio Antonio MachadoNo ratings yet

- Service Manual: F1N /K1G /L1G /N1G /S1G /N1SDocument70 pagesService Manual: F1N /K1G /L1G /N1G /S1G /N1SRyan ChouNo ratings yet

- L293D Motor Driver ICDocument4 pagesL293D Motor Driver ICUnknown424No ratings yet

- Tonepad BigmuffDocument2 pagesTonepad BigmuffWasabiRockNo ratings yet

- Boss 332 545 551 Use - Maintenance ManualDocument140 pagesBoss 332 545 551 Use - Maintenance ManualbadrezzineNo ratings yet

- Electrical Power Solution and Solar Power System (1) (Autosaved)Document71 pagesElectrical Power Solution and Solar Power System (1) (Autosaved)tin mg mgNo ratings yet

- SAIDEEPA Top Hammer Catalogue - CompressedDocument36 pagesSAIDEEPA Top Hammer Catalogue - Compressedantonio rodriguesvieiraNo ratings yet

- Migmaster 250: Welding PackagesDocument36 pagesMigmaster 250: Welding PackagesFarhan WartiansyahNo ratings yet

- Spare Parts MP25Document49 pagesSpare Parts MP25roccosoze78No ratings yet

- Ao2 PTB 18 10 Oxygen Sensor User ManualDocument2 pagesAo2 PTB 18 10 Oxygen Sensor User ManualEdward BennettNo ratings yet

- Xgi 1500 Combiners: Increased Design Flexibility For SOLECTRIA XGI 1500Document2 pagesXgi 1500 Combiners: Increased Design Flexibility For SOLECTRIA XGI 1500Baggi NNo ratings yet

- Compressor - Version 2 - From 04.2013 - 20230125 - 141828Document8 pagesCompressor - Version 2 - From 04.2013 - 20230125 - 141828Mosleh AbdelkaderNo ratings yet

- Parts Manual: B30D & B25D 6X6 MKV AdtDocument150 pagesParts Manual: B30D & B25D 6X6 MKV AdtTeknik MakinaNo ratings yet

- Wireless Digital Code Lock With A Status DisplayDocument19 pagesWireless Digital Code Lock With A Status Display95sagar95No ratings yet

- Innoswitch-Ep Family Datasheet PDFDocument34 pagesInnoswitch-Ep Family Datasheet PDFanand shekhawatNo ratings yet