Professional Documents

Culture Documents

01600A 5 GPM 1" Impact Wrench: See Impact Accessories Next Page

Uploaded by

Maria Teresa Fernández OlavarrietaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01600A 5 GPM 1" Impact Wrench: See Impact Accessories Next Page

Uploaded by

Maria Teresa Fernández OlavarrietaCopyright:

Available Formats

632 South 3rd Street

P.O. Box 2816 • Paducah, KY 42002

270-444-0085

Fax: 270-443-6180

Website: www.matweld.com

Email: customerservice@matweld.com

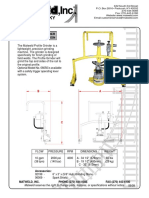

01600A 5 GPM

1” IMPACT WRENCH

The 1” Impact Wrench is capable of

handling the toughest jobs. Crossing,

frog or track bolts are no problem for

this rugged tool. Optional handles

allow the operator to modify the tool to

provide an efficient, safe and ergo-

nomic work position for the task at

hand. A torque adjustment knob “dials

in” the torque from 0-3500 ft lb. De-

signed for 5 gpm operation, permits

simultaneous use of another 5 gpm

toll on the Matweld Dual Circuit Power

Unit, maximizing efficiency of a multi-

man crew.

A B

FLOW PRESSURE DIMENSIONS WEIGHT

5 gpm 2000 psi A - 17 1/2” (444mm) 31 lbs

(19 lpm) (140 bar) B - 8” (203mm) (14.06 kg)

C - 9” (229mm)

See Impact accessories next page

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice. 07/09

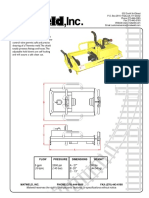

ACCESSORIES

Part Number Description

01635 Stand Up Handle

01650 Torque Adjustment Gauge

01665 (3) 7/8” Impact Socket

01667 (1) 1 1/8” Impact Socket

01669 Crossing Handle

01670 (1) 1 5/15” Impact Socket

01677 (2) 1 1/2” Impact Socket

01680 (2) 1 5/8” Impact Socket

01685 (2) 1 13/16” Impact Socket

01686 (2) 1 7/8” Impact Socket

01690 (2) 2 3/16” Impact Socket

10000-1 Socket Retaining Ring 2.13” Diameter

10000-2 Socket Retaining Ring 2.38” Diameter

10000-3 Socket Retaining Ring 1.75” Diameter

10000-4 Socket Retaining Ring 2.63” Diameter

Note: For proper size retaining ring, match number in parentheses of socket ordered with last digit of

retaining ring part number.

Other size sockets and retaining rings available upon request.

1005111 Fast Pack front end impact assembly. Complete, assembled and

packed with grease ready to install.

01600V VHS Video - video highlighting operation, safety and routine

maintenance of the Matweld 1” Impact Wrench.

01669 Crossing Handle 01635 Stand Up Handle

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

2

GENERAL SAFETY PRECAUTIONS:

TOOL OPERATORS AND MAINTENANCE PERSONNEL MUST ALWAYS COMPLY WITH THE SAFETY

PRECAUTIONS GIVEN IN THIS MANUAL, AND WITH ALL STICKERS AND TAGS ATTACHED TO THE

TOOL AND HOSE. ALL SAFETY PRECAUTIONS ARE GIVEN FOR YOUR SAFETY. READ TO UNDER-

STAND AND FOLLOW ALL SAFETY, MAINTENANCE AND OPERATION INSTRUCTIONS BEFORE YOU

USE OR MAINTAIN THE TOOL. REVIEW THE MANUAL DAILY BEFORE USING THE TOOL. IN ADDITION,

FOLLOW ALL SAFETY GUIDELINES GIVEN TO YOU BY YOUR SUPERVISOR. DO NOT USE THE

TOOL IF YOU HAVE ANY QUESTIONS ABOUT THE OPERATION, SAFETY OR MAINTENANCE OF THIS

TOOL. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY OR

EQUIPMENT DAMAGE.

MATWELD HAS NO CONTROL OVER TOOL USE OR OPERATION ONCE IT LEAVES THE MATWELD

PLANT. MATWELD HAS NO CONTROL OVER OPERATOR OR MAINTAINER SELECTION. THE CUS-

TOMER MUST ASSUME RESPONSIBILITY FOR THE TOOL’S SUITABILITY FOR A PARTICULAR FUNC-

TION, FOR ANYONE USING THE TOOL OR MAINTAINING THE TOOL REGARDING THEIR FITNESS TO

USE THE TOOL OR REPAIR THE TOOL, UNDERSTANDING OF THE OPERATION AND SAFETY AND

MAINTENANCE MANUAL, INTELLIGENCE TO USE GOOD JUDGMENT IS NECESSARY TO WORK

SAFELY AND EFFICIENTLY WITHOUT ENDANGERING THEMSELVES OR BYSTANDERS IN THE

WORK AREA.

• DO NOT OPERATE THE TOOL UNTIL YOU HAVE BEEN THOROUGHLY AND PROPERLY TRAINED

OR UNDER THE SUPERVISION OF AN INSTRUCTOR.

• CHECK POWER SOURCE DAILY TO DETERMINE IF CORRECT FLOW AND PRESSURE ARE

AVAILABLE. NEVER EXCEED FLOWS OR PRESSURES FOR THE TOOL BEING USED. PER-

SONAL INJURY OR DAMAGE TO THE TOOL CAN RESULT.

• OPERATORS MUST CLEAR THE WORK AREA OF NONESSENTIAL PERSONNEL. FLYING DEBRIS

CAN CAUSE SERIOUS INJURY.

• THE OPERATOR MUST BE FAMILIAR WITH ALL PROHIBITED WORK AREAS SUCH AS UNSAFE

GRADES, POOR FOOTING AREAS AND OVERHEAD HAZARDS.

• MAINTAIN BALANCE AND PROPER FOOTING AT ALL TIMES. NEVER OVERREACH TO THE EX-

TENT THAT A BROKEN PART OR SUDDEN MOVEMENT OF THE TOOL CAN CAUSE YOU TO

LOSE YOUR BALANCE AND FALL, OR CAUSE INJURY TO YOUR SELF OR SOMEONE ELSE.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

3

• WHEN WORKING NEAR ELECTRICAL CONDUCTORS, ALWAYS ASSUME THAT THE CONDUC-

TORS ARE ENERGIZED AND THAT HOSES AND CLOTHING CAN CONDUCT HARMFUL ELECTRIC-

ITY. USE HOSES LABELED AND CERTIFIED AS NONCONDUCTIVE.

• DO NOT OPERATE THE TOOL AT EXCESSIVE FLUID TEMPERATURES OPERATOR DISCOM-

FORT AND POTENTIAL BURNS CAN RESULT AT HIGH OIL TEMPERATURES.

• NEVER WEAR LOOSE CLOTHING THAT CAN GET ENTANGLED IN THE WORKING PARTS OF THE

TOOLS OR BE CARELESS WITH HANDS, FEET OR OTHER BODY PARTS AROUND THE WORK-

ING PARTS OF THE TOOLS. HYDRAULIC TOOLS EXERT HIGH TORQUE AND FORCE AND CAN

CAUSE SERIOUS INJURY OR DEATH IF IMPROPERLY USED.

• TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE, ALL TOOL REPAIR, MAINTENANCE OR

SERVICE MUST ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY TRAINED PERSON-

NEL.

• ALWAYS WEAR SAFETY EQUIPMENT SUCH AS OIL INJECTION RESISTANT WORK GLOVES,

SAFETY GLASSES, SAFETY BOOTS, EAR PROTECTION AND OTHER SAFETY APPAREL DIC-

TATED BY YOUR SUPERVISOR APPLICABLE FOR THE JOB YOU ARE DOING AND THE TOOL

YOU ARE USING.

• DO NOT CLEAN INSPECT OR REPAIR THE TOOL WHILE CONNECTED TO THE POWER

SOURCE. ACCIDENTAL ENGAGEMENT OF THE TOOL CAN CAUSE SERIOUS PERSONAL INJURY.

• OIL INJECTION HAZARD EXISTS WITH THIS TOOL. OIL INJECTION IS A CONDITION WHERE

HYDRAULIC OIL IS INJECTED UNDER THE SKIN FROM PRESSURE IN THE LINE. ALWAYS WEAR

GLOVES AND REPAIR ANY LEAKS IMMEDIATELY. NEVER CARRY A TOOL BY THE HOSES.

• DO NOT USE DAMAGED EQUIPMENT. IMMEDIATELY REPLACE ANY DAMAGED HOSES, FITTINGS,

OR OTHER COMPONENTS SHOWING WIRE BRAID, NICKS, CUTS, DAMAGE OR ABRASIONS.

FAILURE TO DO SO MAY RESULT IN EQUIPMENT DAMAGE AND / OR PERSONAL INJURY OR

DEATH.

• CLEAN UP ANY OIL OR FLUID SPILLS IMMEDIATELY.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

4

HAVE SUPERVISOR ADD ADDITIONAL PRECAUTIONS RELATING TO THE SPECIFIC WORK AREA

AND LOCAL SAFETY REGULATIONS BELOW:

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

5

01600A IMPACT WRENCH

SAFETY PRECAUTIONS:

1. ALWAYS WEAR PROTECTIVE EQUIPMENT SUCH AS GLOVES, SAFETY GLASSES, EAR PROTECTION

AND SAFETY SHOES.

2. DO NOT WEAR CLOTHING WHICH MAY BECOME ENTANGLED IN THE TOOL.

3. ALWAYS KEEP WORK AREA FREE OF TOOLS OR ANY OTHER OBJECTS WHICH MAY IMPAIR SOUND

FOOTING.

4. CAUTION - OIL INJECTION HAZARD EXISTS WITH THIS TOOL. OIL INJECTION IS A CONDITION WHERE

THE HYDRAULIC OIL IS FORCED UNDER THE SKIN THROUGH PRESSURE IN THE LINE. ALWAYS WEAR

GLOVES AND REPAIR LEAKS IMMEDIATELY.

5. DO NOT CARRY THE TOOL BY THE PIGTAIL HOSES.

6. DO NOT OVER TORQUE TRACK AND FROG BOLTS.

7. DO NOT USE DEFECTIVE SOCKETS OR THOSE NOT MANUFACTURED FOR IMPACT WRENCHES.

8. DO NOT ATTEMPT TO LOOSEN LOCKED UP WRENCH WITH ANY HAND TOOL. DISCONNECT FROM

POWER SOURCE AND THEN REPAIR WRENCH.

9. USE A SOCKET RETAINING RING TO KEEP SOCKET ON THE ANVIL.

OPERATION:

1. WITH THE POWER SOURCE IN THE “OFF” POSITION. CONNECT THE HOSES. DO NOT DRAG THE

SERVICE HOSE BY PULLING WITH THE TOOL. LOOP THE SERVICE HOSE IN THE WORK AREA IN

SUCH A WAY TO RELIEVE STRESS ON THE HOSE AND QUICK DISCONNECT FITTINGS WHILE WORK-

ING. BE AWARE OF HOSE LOCATIONS AT ALL TIMES.

2. CONNECT THE TOOL TO THE POWER SOURCE SERVICE HOSE.

3. TURN THE POWER SOURCE TO THE “ON” POSITION TO SUPPLY 5 GPM TO THE IMPACT WRENCH.

4. TO TIGHTEN BOLTS, PUSH THE ROTATION VALVE (LOCATED ON THE

RIGHT REAR OF THE IMPACT WRENCH) “IN” AND ROTATE CLOCK-

WISE TO LOCK IN PLACE. TO LOOSEN BOLT, PUSH VALVE “IN”

SLIGHTLY AND ROTATE COUNTERCLOCKWISE TO SPRING

OUT.

5. PULL THE TRIGGER TO ACTIVATE THE IMPACT WRENCH.

6. NEVER OPERATE THE WRENCH ON ANY HIGHER FLOW

THAT 5 GPM. THE TOOL IS DESIGNED TO ACCEPT ONLY

THE RECOMMENDED 5 GPM AND WILL MALFUNCTION AND

OVERHEAT THE OIL IF USED OTHERWISE.

7. TURN THE POWER SOURCE “OFF” BEFORE DISCONNECTING TOOL.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

6

MAINTENANCE:

1. CHECK TOOL DAILY FOR PROPER OPERATION, LEAKS, OR DAMAGE.

2. INSPECT HOSES DAILY. REPLACE CUT, BURNED, OR OTHERWISE DAMAGED HOSES.

3. KEEP QUICK DISCONNECT COUPLERS CLEAN AND LUBRICATED.

4. USE HYDRAULIC FLUIDS THAT COMPLY WITH HTMA SPECIFICATION 5.7, THE HYDRAULIC FLUID

SHOULD HAVE A VISCOSITY BETWEEN 100 AND 400 SSU (20-82 CENTISTOKES) AT THE MAXI-

MUM AND MINIMUM EXPECTED OPERATING TEMPERATURES. PETROLEUM BASED HYDRAULIC

FLUIDS WITH ANTI-WEAR PROPERTIES AND A VISCOSITY INDEX OF OVER 140 WORK FOR A

WIDE RANGE OF OPERATING CONDITIONS.

THE FOLLOWING OILS MEET HTMA SPECIFICATION 5.7:

AMOCO RYKON MV CITGO A/W ALL TEMP

SUNVIS 706 MOBIL D.T.E. 13

CHEVRON EP-MV TEXACO “RANDO” HDAZ

OTHER FLUIDS THAT MEET OR EXCEED THIS SPECIFICATION CAN BE USED.

*SEE COLD WEATHER OPERATION HYDRAULIC OIL NOTE.

5. HAVE TOOL INSPECTED, AT LEAST ANNUALLY, BY MATWELD OR A MATWELD QUALIFIED SER-

VICE REPRESENTATIVE TO DETERMINE IF TOOL IS IN NEED OF SAFETY CHANGES OR WORN

PART REPLACEMENT.

6. CONTACT MATWELD ON A PERIODIC BASIS, AT LEAST ANNUALLY, FOR SERVICE BULLETINS,

SAFETY NOTICES, OR OTHER IMPORTANT INFORMATION PERTAINING TO THIS TOOL.

COLD WEATHER OPERATION:

HYDRAULIC SYSTEM PERFORMANCE IS AFFECTED WHEN THE TEMPERATURE DROP BELOW

50 F. THEREFORE MEASURES SHOULD BE TAKEN TO PRE-WARM TOOLS AND FLUIDS BEFORE

OPERATING.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

7

01600A IMPACT WRENCH

HAMMER INSTALLATION:

ALTHOUGH THE HAMMERS ARE IDENTICAL PARTS,

THEY MUST BE INSTALLED IN OPPOSING POSI-

TIONS FOR PROPER OPERATION. WHEN PROP-

ERLY FITTED INSIDE THE HAMMER FRAME THE

RELIEF CUT SIDES WILL FACE ONE ANOTHER BUT

THE HAMMER PIN NOTCH POSITION WILL BE 180

DEGREES OPPOSITE EACH OTHER.

hammer pin notch

relief cut

relief cut

hammer pin notch

REPAIR AND TROUBLE SHOOTING:

1. IMPACT WRENCH OVERHEATS…

• OPERATE WRENCH ON 5 GPM

2. IMPACT WRENCH SPINS BUT WON’T IMPACT…

• INSPECT FRONT END FOR BROKEN HAMMER PINS OR OTHER BROKEN PARTS.

3. IMPACT WRENCH ONLY WORKS IN ONE DIRECTION…

• CHECK FRONT END FOR BROKEN PARTS

• CHECK REVERSING VALVE FOR BENT STEM OR TRASH ON ONE OR MORE VALVE PARTS

4. IMPACT WRENCH WORKS SLOW AND HAS LOW POWER…

• CHECK THAT TORQUE ADJUSTMENT VALVE IS SCREWED IN AND NOT ADJUSTED ALL

THE WAY OUT.

•CHECK THAT FLOW IS 5 GPM AND SYSTEM PRESSURE IS SET AT 2000 PSI

5. TRIGGER STICKS…

• CHECK FOR DIRT OR CLEARANCE IN TRIGGER HOUSING

• CHECK FOR REVERSE FLOW (PIGTAILS OR QD’S RECENTLY CHANGED)

• CHECK BACKPRESSURE ON RETURN LINE (AT TOOL RETURN SHOULD BE 150 PSI OR

LESS).

6. HYDRAULIC OIL RUNNING OUT OF FRONT END…

• REPLACE FRONT SHAFT SEAL USING PART NO. 01612 SHAFT SEAL KIT

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

8

01600A IMPACT WRENCH

TORQUE / TENSION CALIBRATION PROCEDURE:

(USING MATWELD PART #01650 – TORQUE GAUGE)

1. INSTALL TEST GAUGE IN PRESSURE LINE AT TOOL AND CONNECT TO POWER SOURCE SUPPLY HOSES –

5 GPM.

2. REFER TO BOLT TIGHTENING CHART SPECIFICATION REQUIRED FOR THE GRADE AND SIZE BOLT BEING

USED. (ALWAYS FOLLOW MANUFACTURER’S RECOMMENDATIONS.)

3. LOOSEN LOCK COLLAR ON TORQUE ADJUSTMENT KNOB.

4. IF TORQUE ADJUSTMENT KNOB IS TURNED ALL THE WAY IN, BACK ADJUSTMENT KNOB OUT ONE AND A

HALF TURNS COUNTERCLOCKWISE TO DECREASE INITIAL TORQUE.

5. BEGIN TIGHTENING BOLT, KEEPING A CLOSE WATCH ON THE TORQUE GAUGE. TURN THE ADJUSTMENT

KNOB IN CLOCKWISE INCREASING THE PRESSURE UNTIL THE DESIRED SETTING IS REACHED.

6. LOOSEN AND RETIGHTEN THE TEST BOLT A COUPLE OF TIMES TO VERIFY THE SETTING.

7. RETIGHTEN THE LOCK COLLAR.

8. TORQUE GAUGE MAY BE REMOVED ONCE DESIRED TORQUE IS SET.

WARNING!!! OVER-TORQUING BOLTS WILL CAUSE BOLT FAILURE UNDER TRAFFIC.

TIGHTENING CHART:

GRADE 5 – TRACK AND FROG BOLTS:

SIZE WRENCH PSI TORQUE FT. LB. TENSION LB.

3/4” 460 300 21,500

7/8” 500 485 29,500

1” 540 730 39,000

1 1/8” 565 900 46,000

1 3/8” 750 1700 69,000

GRADE 8 – TRACK AND FROG BOLTS:

SIZE WRENCH PSI TORQUE FT. LB. TENSION LB.

3/4” 470 400 28,000

7/8” 525 640 36,000

1” 600 960 50,000

1 1/8” 670 1360 63,000

1 3/8” 890 2500 95,000

NOTE:

REFER TO THE WRENCH CALIBRATION INSTRUCTIONS ON THE PREVIOUS PAGE OR FOLLOW GUIDELINES SET

FORTH BY THE RAILROAD. IF THE TORQUE SETTING OF A PARTICULAR FASTENER TYPE IS CRITICAL, THE

WRENCH SHOULD BE SET AS CLOSE TO THE DESIRED TORQUE AS POSSIBLE AND A CALIBRATED TORQUE

WRENCH USED TO VERIFY OR CHECK THE FASTENER TORQUE PERIODICALLY.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

9

REVIEW OF HYDRAULIC PRINCIPLES

A. TOOL CIRCUIT

1. HYDRAULIC FORMULAS:

CID X RPM GPM X PSI

GPM = 231 HP = 1714 (.85)

1456.9

Example: HP required to deliver 10 GPM at 1500 PSI.

10 GPM X 1500 PSI = 15000 = 10.3 HP

1456.9 1456.9

(subtract back pressure for tool HP)

Estimated HP delivered by pump or used by tool.

PSI

GPM 500 1,000 1,500 2,000 2,500 3,000

3 1.03 2.06 3.09 4.12 5.15 6.18

5 1.72 3.43 5.15 6.86 8.58 10.30

10 3.43 6.86 10.3 13.70 17.20 20.60

15 5.15 10.30 15.40 20.60 25.70 30.90

2. BACK PRESSURE

BACK PRESSURE MEASURED AT THE TOOL RETURN PORT MUST NOT EXCEED THE MANUFAC-

TURERS BACK PRESSURE RATING. MOST MANUFACTURERS LIST THE MAXIMUM BACK PRES-

SURE FOR THEIR HYDRAULIC TOOLS AT 250 PSI. BACK PRESSURE MEASURED ON THE RETURN

SIDE OF THE TOOL IS THE FORCE REQUIRED TO GET THE OIL BACK TO THE TANK. IN ALMOST

ALL CASES THE LOWER THE BACK PRESSURE THE BETTER THE TOOL PERFORMANCE. FIRST,

THE BACK PRESSURE IS SUBTRACTED FROM THE MAXIMUM TOOL PRESSURE TO ARRIVE AT A

MAXIMUM TOOL OPERATING PRESSURE. FOR EXAMPLE, TOOLS WITH 2000 PSI OPERATING

PRESSURE ARE INSTALLED ON A SYSTEM WITH 250 PSI BACK PRESSURE. THIS LEAVES 1750 PSI

AS A MAXIMUM TOOL PRESSURE. IMAGINE A SYSTEM WITH 500 PSI BACK PRESSURE. 2000 MINUS

500 PSI BACK PRESSURE LEAVES ONLY 1500 PSI FOR THE TOOL. SECOND, TOOLS ARE DE-

SIGNED FOR PRESSURE TO BUILD ON THE PRESSURE SIDE OF THE TOOL. IF TOO MUCH PRES-

SURE BUILDS ON THE RETURN SIDE, NOT ONLY IS PERFORMANCE EFFECTED, BUT SEALS MAY

BLOW. THIS IS WHY IT IS VERY IMPORTANT TO DIRECT THE FLOW INTO THE TOOL CORRECTLY.

REVERSING THE HOSES TO TEST MAY RESULT IN BLOWN SEALS, DAMAGE TO THE TOOL, AND

PERSONAL INJURY.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

10

01600A IMPACT WRENCH

SEAL KIT INFORMATION:

SEAL KIT FOR MOTORS

MANUFACTURED PRIOR TO APRIL 2003

#01631 - INTERNAL SEAL KIT #01612 - SHAFT SEAL KIT

CALL MATWELD BEFORE ORDERING IF YOU HAVE QUESTIONS CONCERNING WHICH MOTOR

YOU HAVE .

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

11

01600A IMPACT WRENCH

SEAL KIT INFORMATION:

SEAL KIT FOR MOTORS WITHOUT BEARING

MANUFACTURED AFTER APRIL 2003

WITHOUT BEARING

MOTOR SEAL HOUSING

FORMED PLASTIC SEAL

LARGE O-RING

BACKING WASHER

RETAINING RING

NO. 02599 INTERNAL SEAL KIT FOR MOTOR

OVAL SEAL

FORMED PLASTIC SEAL

FLUID SEAL

NO. 02598 SHAFT SEAL KIT

DUST SEAL

#02599 - INTERNAL SEAL KIT #02598 - 18mm SHAFT SEAL KIT

CALL MATWELD BEFORE ORDERING IF YOU HAVE QUESTIONS CONCERNING WHICH MOTOR

YOU HAVE .

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

12

01600A IMPACT WRENCH

SEAL KIT INFORMATION:

SEAL KIT FOR MOTORS WITHOUT BEARING

MANUFACTURED AFTER APRIL 2003

WITH BEARING SPLINE ADAPTOR SHAFT

BEARING BLOCK

BEARING

MOTOR SEAL HOUSING

BACKING WASHER O-RING

RETAINING RING

O-RING

NO. 02597 SHAFT SEAL KIT

FLUID SEAL

FORMED PLASTIC SEAL

DUST SEAL LARGE O-RING

NO. 02599 INTERNAL SEAL KIT FOR MOTOR

OVAL SEAL

FORMED PLASTIC SEAL

#02599 - INTERNAL SEAL KIT #02597 - 20mm SHAFT SEAL KIT

CALL MATWELD BEFORE ORDERING IF YOU HAVE QUESTIONS CONCERNING WHICH MOTOR

YOU HAVE .

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

13

01600A IMPACT WRENCH

REVISION 5

13

12/18/05

10

14

40

24

52

29

47

17

P

44

28

27

26

46

26

T

45

30

18

25

43

49

42

19

44

23

48

41

33

50

52

51

40

36

32

22

21

37

20

39

54

55

8

TRIGGER HANDLE

54

56

01660

16

40

34

6

35

9

53

10

5

11

4

3

57

10

58

12

13

FAST PACK

2

1005111

10

38

15

14

1

31

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

14

01600A IMPACT WRENCH

REVISION 5

12/18/05

ITEM NO. PART NO. DESCRIPTION QUANTITY

*1 A5448 5/16-18 x 1 SHCS 2

*2 01603 HAMMER CASE w/ BUSHING 1

*3 01604 HAMMER CASE BUSHING 1

*4 01630 O-RING HAMMER CASE 1

*5 01605 ANVIL 1” SQUARE DRIVE 1

*6 01606 HAMMERPIN 2

*7 01608 HAMMER FRAME 1

*8 01609A SPLINEADAPTER 1

9 A2050 3/8-16 NYLOCK NUT 1

10 A2192 3/8” SAE FLAT WASHER 4

11 01629 SIDE HANDLE 1

12 A1043 3/8-16 x 1 1/4 HEX HEAD BOLT 1

13 A3811 3/8 LOCK WASHER 2

14 A1042 3/8-16 x 1 HEX HEAD BOLT 2

15 00106 HANDLE GRIP 2

*16 01607 HAMMER 2

17 00145 QUICK DISCONNECT COUPLER 1

18 00146 QUICK DISCONNECT NIPPLE 1

19 00816 PIGTAIL HOSE ASSEMBLY 2

**20 A1002 1/4-20 x 1 HEX HEAD BOLT 4

**21 A2190 1/4 SAE FLAT WASHER 4

**22 01656 NYLON SPACER 2

23 01623 TRIGGER VALVE 1

24 01645-01 HANDLE ADAPTER PLATE 1

25 A6314 3/8-16 x 1 FLAT HEAD SOCKET SCREW 1

26 A5490 3/8-16 x 6 1/2 SHCS 2

27 A5495 3/8-16 x 7 SHCS 2

28 01621 TORQUE ADJUSTMENT VALVE 1

29 315L-08 1/2 NPT x #10 JIC LONG CONNECTOR 1

30 315-08-08 1/2 NPT x #8 JIC CONNECTOR 1

31 A5449 5/16-18 x 1 1/4 HEX HEAD BOLT 2

32 02502 HYDRAULIC MOTOR 1

33 02599 INTERNAL SEAL KIT 1

34 02598 SHAFT SEAL KIT 1

*35 01613C ADAPTER 1

36 01617 VALVE HOUSING w/ PLUGS 1

37 01614A REVERSING VALVE ASSEMBLY 1

*38 A3812 5/16” LOCK WASHER 2

**39 A1024 5/16-18 x 1 1/2 HEX HEAD BOLT 2

**40 A2191 5/16 SAE FLAT WASHER 4

**41 01651 FRONT BRACKET 1

**42 01658 TRIGGER HANDLE BRACKET 1

**43 A5602 1/4-20 x 5/16 SET SCREW 1

**44 A3816 WELL NUT - RUBBER INSERT 2

**45 01654 HANDLE 1

**46 01659 HANDLE GRIP 1

**47 01652 REAR HANDLE BRACKET 1

**48 A6905 3/16 x 5/8 SHOULDER BOLT 1

**49 01655 TRIGGER 1

**50 01653 TRIGGER BLOCK 1

**51 01657 TRIGGER LINK #50 1

**52 A2163 USS 3/8” FLAT WASHER 2

53 01611 RETAINING RING 1

54 02512 THRUST BEARING WASHER 2

55 02513 THRUST BEARING 1

56 A2048 5/16-18 NYLOCK NUT 2

*57 01603-03 HAMMER CASE BUSHING OUTSIDE O-RING 1

*58 01603-02 HAMMER CASE BUSHING INSIDE O-RING 1

ITEMS NOTED WITH A “*” ARE INCLUDED IN “FAST PACK KIT” PART NO. 1005111

ITEMS NOTED WITH A “**” ARE INCLUDED IN “REAR HANDLE ASSEMBLY KIT” PART NO. 01660

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

15

01600A IMPACT WRENCH

01669 CROSSING HANDLE:

ITEM NO. PART NO. QUANTITY DESCRIPTION

1 A2048 1 5/16-18 NYLOCK NUT

2 A2191 1 5/16 SAE FLAT WASHER

*3 A2192 4 3/8 SAE FLAT WASHER

4 01669-02 1 TRIGGER LEVER ASSEMBLY

5 A6950 1 DIA. 3/8 x 2-3/4 SHOULDER BOLT

6 01669-03 1 ACTUATOR ROD ASSEMBLY

7 01669-05 1 CROSSING HANDLE PLUNGER

8 A7000 1 DIA. 3/8 x 1-3/4 SHOULDER BOLT

9 01669-04 1 CROSSING HANDLE GUIDE

10 01639 1 ACTUATOR FORK

11 A6206 1 DIA. 6 x 30 METRIC SPRING PIN

12 01669-01 1 CROSSING HANDLE FRAME

13 A2190 5 1/4-20 SAE FLAT WASHER

14 A1006 3 1/4-20 x 2 HEX HEAD BOLT

*15 A1043 1 3/8-16 x 1-1/4 HEX HEAD BOLT

*16 A3811 3 3/8 LOCK WASHER

17 A2163 1 3/8 SAE FLAT WASHER

18 A2046 3 1/4-20 NYLOCK NUT

*19 A1041 1 3/8-16 X 3/4 HEX HEAD BOLT

20 01669-06 1 CROSSING HANDLE PIVOT LEVER

* ITEMS SOLD IN BOLT KIT TO ATTACH HANDLE TO IMPACT WRENCH

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

16

01600A IMPACT WRENCH

016STAND UP HANDLE:

ITEM NO. PART NO. QUANTITY DESCRIPTION

1 A2046 2 1/4-20 NYLOCK NUT

2 A2048 1 5/16-18 NYLOCK NUT

3 A2191 1 5/16 SAE FLAT WASHER

4 01636 1 HANDLE ASSEMBLY

5 A2190 4 1/4 SAE FLAT WASHER

6 A1004 2 1/4-20 X 1 1/2 HEX HEAD BOLT

7 A6930 1 DIA. 3/8 X 1 SHOULDER BOLT

8 01638 1 ACTUATOR ROD ASSEMBLY

*9 A2192 4 3/8 SAE FLAT WASHER

*10 A2050 2 3/8-16 NYLOCK NUT

11 01639 1 ACTUATOR

12 01641 1 SPACER

*13 A3811 2 3/8 LOCK WASHER

*14 A1043 2 3/8-16 X 1 1/4 HEX HEAD BOLT

*15 A1041 1 3/8-16 X 3/4 HEX HEAD BOLT

16 01637 1 EXTENSION ARM ASSEMBLY

17 01640 1 TRIGGER

18 A6920 1 DIA. 3/8 X 1/4 SHOULDER BOLT

19 00106 2 HANDLE GRIP

* ITEMS SOLD IN BOLT KIT TO ATTACH HANDLE TO IMPACT WRENCH

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

17

01600A IMPACT WRENCH

DECAL LEGEND:

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

18

LIMITED WARRANTY

MATWELD, INC., PADUCAH, KY., WARRANTS TO THE ORIGINAL PURCHASE OF THIS PRODUCT

THAT THE PRODUCT WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP FOR THE

PERIOD OF ONE (1) YEAR AFTER THE DELIVERY OF SUCH PRODUCT TO THE CUSTOMER.

OTHER EQUIPMENT AND PARTS USED, BUT NOT MANUFACTURED BY MATWELD INC. ARE COV-

ERED DIRECTLY BY THE WARRANTY OF THE MANUFACTURER OF THOSE PRODUCTS. PROOF

OF PURCHASE MUST BE DOCUMENTED INCLUDING REFERENCE TO A SERIAL NUMBER LOCATED

ON EACH TOOL. THE PURCHASER’S ONLY REMEDIES UNDER THIS LIMITED WARRANTY SHALL BE

LIMITED AT MATWELD’S SOLE OPTION TO THE FOLLOWING: REPAIR, REPLACEMENT OR REFUND

OF THE PURCHASE PRICE OF THE DEFECTIVE PRODUCTS. EACH OF THESE REMEDIES RE-

QUIRES TIMELY NOTIFICATION OF THE DEFECT IN THE PRODUCT AND SUBSTANTIATION THAT THE

PRODUCT HAS BEEN PROPERLY STORED, MAINTAINED AND USED. MATWELD’S OBLIGATIONS

HEREUNDER EXTEND ONLY TO THE PURCHASER OF THE PRODUCT AND NOT TO ANY THIRD

PARTY.

AS A CONDITION PRECEDENT TO MATWELD’S OBLIGATION HEREUNDER, THE DEFECTIVE PROD-

UCT MUST NOT HAVE BEEN ALTERED OR MODIFIED WITHOUT THE EXPRESS WRITTEN APPROVAL

OF MATWELD, INC. THE PRODUCT MUST NOT HAVE BEEN SUBJECTED TO DELIBERATE DAMAGE,

SHIPPING DAMAGE, NEGLECT, TAMPERING BY UNAUTHORIZED PERSONNEL OR DAMAGE BY IM-

PROPER USE, STORAGE OR MAINTENANCE. SERIAL NUMBERS MUST NOT HAVE BEEN ALTERED,

DEFACED OR REMOVED. SUCH ACTION VOIDS LIMITED WARRANTY.

EXCLUSIONS TO LIMITED WARRANTY

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN

OR ORAL, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WAR-

RANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITED WARRANTY DOES NOT COVER NORMAL WEAR AND TEAR ITEMS SUCH AS FILTERS,

HOSES, COUPLERS, BITS, SOCKETS, AUGERS, AND BATTERIES.

LIMITATION OF LIABILITY

EXCEPT AS PROVIDED ABOVE, MATWELD SHALL IN NO EVENT BE LIABLE OR RESPONSIBLE FOR

ANY INJURY, LOSS OR DAMAGE, DIRECT, INCIDENTAL OR CONSEQUENTIAL, ARISING OUT OF THE

USE OR MISUSE OR INABILITY TO USE THE PRODUCT, HOWEVER CAUSED AND ON ANY THEORY

OF LIABILITY INCLUDING, WITHOUT LIMITATIONS, BREACH OF CONTRACT, TORT, (INCLUDING NEG-

LIGENCE OR STREET LIABILITY) AND NOT WITHSTANDING ANY FAILURE OF ANY REMEDY HEREIN

OF ITS ESSENTIAL PURPOSE, EVEN IF MATWELD WAS AWARE OF THIS POSSIBILITY OF SUCH

DAMAGE. MATWELD’S LIMITED WARRANTY AS SET FORTH ABOVE SHALL NOT BE ENLARGED,

DIMINISHED OR AFFECTED BY, AND NO OBLIGATION OR LIABILITY SHALL ARISE OR GO OUT OF

THE RENDERING OF TECHNICAL ADVICE OR SERVICE BY MATWELD OR ITS AGENTS. THE FORE-

GOING MAY NOT BE CHANGED EXCEPT BY WRITTEN AGREEMENT SIGNED BY AN AUTHORIZED

OFFICER OF MATWELD, THE REMEDIES SET FORTH HEREIN ARE EXCLUSIVE.

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

19

IMPORTANT SAFETY NOTICE

PLEASE OBEY

IT’S THE LAW!

YOU MUST WEAR EYE PROTECTION. ALL HAMMER OPERATIONS REQUIRE EYE PROTEC-

TION FOR BOTH THE USER OF THE TOOL, AND BY OTHERS WHO MAY BE EXPOSED TO THE

FLYING PARTICLES. THE OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION (OSHA) IS

CHARGED TO ENFORCE THE MANDATED CODE OF FEDERAL REGULATIONS GOVERNING

THE USE OF EYE PROTECTION DURING HAMMERING OPERATIONS.

1. NEVER USE A MODIFIED, DAMAGED, WELDED, ABUSED, OR WORN HAMMER ACCESSORY

TOOL.

2. USE ACCESSORY TOOL ONLY WITH THE HYDRAULIC TOOL IT IS DESIGNED FOR.

3. NEVER STRIKE ACCESSORY WITH ANY HAND HELD INSTRUMENT AND BE CAREFUL DURING

TRANSPORT AND MOVEMENT NOT TO STRIKE THE TOOL AGAINST ANOTHER HARDENED

SURFACE.

4. MAKE SURE THAT THE ACCESSORY IS PROPERLY SECURED WITH THE DESIGNED RETAINER.

THE RETAINER SHOULD NEVER BE USED IF IT IS DAMAGED OR WORN.

5. DO NOT COME IN PHYSICAL CONTACT WITH THE WORKING END OF AN ACCESSORY DURING

OPERATION OF THE HAMMER. ALWAYS WEAR SAFETY BOOTS AND APPAREL DURING HAMMER-

ING OPERATIONS.

6. INSPECT SHANKS AND ADAPTERS DAILY AND REPLACE IF ANY INDICATIONS OF FATIGUE OR

WEAR ARE FOUND.

7. NEVER LEAN ON TOOL OR USE IT FOR PRYING.

ALL OF THE ABOVE

SHOULD BE REVIEWED

WITH AND UNDERSTOOD

BY THE END USER OF

THIS PRODUCT!

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

20

01600A IMPACT WRENCH

GENERAL NOTES:

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

21

CUSTOMER INFORMATION:

Name _____________________________________________________

Company___________________________________________________

Serial # of your Matweld tool___________________________________

(Upon receiving your Matweld tool, make sure to list serial number above so that a good record is kept for

order information.)

MATWELD HYDRAULIC TOOL LIST

All Matweld Hydraulic Tools operate at 5 or 10 GPM @ 2000 PSI

POWER UNITS:

00100K – GASOLINE POWERED (1) 10 GPM OR (2) 5 GPM CIRCUITS

02900A – DIESEL (1) 10 GPM OR (2) 5 GPM CIRCUITS

(OPTIONAL CATALYTIC EXHAUST AND/OR MSHA CERTIFIED)

05500 – TWIN POWER DUAL CIRCUIT (1) 10 GPM OR (2) 5 GPM CIRCUITS & 5000 WATT GENERATOR

02050K – GASOLINE POWERED (1) 5 GPM

03700A – ELECTRIC POWER (1) 10 GPM OR (2) 5 GPM CIRCUITS

GRINDERS:

09200A – PRECISION FROG GRINDER

06000 – PROFILE GRINDER

06900 & 06900A – MULTI-PURPOSE GRINDER (TRIGGER VERSION AVAILABLE)

05900 – FROG/PROFILE GRINDER (TRIGGER VERSION AVAILABLE)

00700 – RAIL SURFACING GUIDE

04600 – STRAIGHT STONE CW ROTATION (TRIGGER VERSION AVAILABLE)

04700 – STRAIGHT STONE CCW ROTATION (TRIGGER VERSION AVAILABLE)

07500 – CHAMFER TOOL

04800 – CUP STONE GRINDER (TRIGGER VERSION AVAILABLE)

00600C – CUP STONE GRINDER

05400 – ANGLE GRINDER

05600 – BULL NOSE GRINDER

02400 – 10” OR 14” FROG AND SWITCH GRINDER

TRACK TOOLS:

03900A – REVERSING RAIL SAW

05100A & 05100B – POWER WELD SHEAR 00800A – 16” RAIL SAW

03500 – SELF FEED RAIL DRILL 05000 – HAND PUMP WELD SHEAR

01600A – 5 GPM 1” IMPACT WRENCH 01500 – RAIL DRILL

04500D – 1/2” HYDRAULIC DRILL IMPACT WRENCH 02500 – 10 GPM 1” IMPACT WRENCH

08200 – TAMPER 03100C – RAIL PULLER

02800 – 60 TON BRIDGE SPREADER 08300 – SPIKE DRIVER

01200 – SPRING ANCHOR APPLICATOR 07650 – HYDRAULIC CLIP TOOL

01100A – SPIKE PULLER (SINGLE, 2 STAGE &TRIGGER VERSIONS AVAILABLE)

OTHER PRODUCTS:

HYDRAULIC MANIFOLDS

HYDRAULIC TEST GAUGES

HOSE REELS

HYDRAULIC HOSES

ACCESSORIES

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180

Matweld reserves the right to change parts, features, or specifications without notice.

07/09

22

You might also like

- Nur1 230 Fundamentals of Canadian NursingDocument1,666 pagesNur1 230 Fundamentals of Canadian NursingSamantha Lau100% (4)

- 10-inch Compound Miter Saw Laser GuideDocument64 pages10-inch Compound Miter Saw Laser GuideJacob B100% (2)

- FJM10-45 Glass Edging Machine Operation ManualDocument29 pagesFJM10-45 Glass Edging Machine Operation ManualMichael L HerreraNo ratings yet

- EN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDocument35 pagesEN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDarío Ache EmeNo ratings yet

- DEWALT DW708 12 Double-Bevel Sliding Compound Miter ManualDocument54 pagesDEWALT DW708 12 Double-Bevel Sliding Compound Miter ManualClaudio RosaNo ratings yet

- ES and ESS Stunner ManualDocument28 pagesES and ESS Stunner ManualDarwin TierraNo ratings yet

- CZ1440G-1 e Manual BookDocument57 pagesCZ1440G-1 e Manual Bookkurnia wanNo ratings yet

- 7800 Controller Manual 87-0021 - RevE - 021411Document50 pages7800 Controller Manual 87-0021 - RevE - 021411Dario Yañez CNo ratings yet

- Genetics MnemonicsDocument7 pagesGenetics MnemonicsAnnapurna Dangeti100% (1)

- 10 GPM 1" Impact WrenchDocument22 pages10 GPM 1" Impact WrenchMaria Teresa Fernández OlavarrietaNo ratings yet

- User ManualDocument18 pagesUser Manualjuniorcoutino2209No ratings yet

- 03900a GuitarraDocument22 pages03900a GuitarraAusencio Mayoral LopezNo ratings yet

- Profile Grinder 06050 Trigger VersionDocument16 pagesProfile Grinder 06050 Trigger VersionMaria Teresa Fernández OlavarrietaNo ratings yet

- 05100a CORTAMAZAROTADocument16 pages05100a CORTAMAZAROTAAusencio Mayoral LopezNo ratings yet

- 00100K Dual Circuit Power Unit: AccessoriesDocument34 pages00100K Dual Circuit Power Unit: AccessoriesMaria Teresa Fernández OlavarrietaNo ratings yet

- Wilton Belt and Disc Sanding Machine: Operating Instructions - Parts ManualDocument24 pagesWilton Belt and Disc Sanding Machine: Operating Instructions - Parts ManualKrish KrishnaNo ratings yet

- SELF FEED Rail DrillDocument20 pagesSELF FEED Rail DrillKarlos 6:No ratings yet

- SM5ce - V3 SawDocument9 pagesSM5ce - V3 SawBryan DixNo ratings yet

- Knight Reel Auggie 3060 Operators Manual PDFDocument34 pagesKnight Reel Auggie 3060 Operators Manual PDFWest BeefNo ratings yet

- Wilton Operators Manual 14-Inch Vertical Band Saws Model 8201Document32 pagesWilton Operators Manual 14-Inch Vertical Band Saws Model 8201ullwnNo ratings yet

- WeldSkill 155 - 185 Operating ManualDocument88 pagesWeldSkill 155 - 185 Operating ManualBarry ThomasNo ratings yet

- Drill: Instruction ManualDocument12 pagesDrill: Instruction Manualcahaya subuhNo ratings yet

- Operation Manual: Mag-Con™Document8 pagesOperation Manual: Mag-Con™hamid hoorshadNo ratings yet

- ecs1Document12 pagesecs1Roberlei PereiraNo ratings yet

- Makita UC4020ADocument108 pagesMakita UC4020AAlexandru ZsoldNo ratings yet

- Catalogue of Spare Parts and Instructions ManualDocument11 pagesCatalogue of Spare Parts and Instructions ManualNicko InoveroNo ratings yet

- Trav-L-Cutter: Model E & H/E Standard & Atmospheric 02-000-01,-02,-03,-04Document56 pagesTrav-L-Cutter: Model E & H/E Standard & Atmospheric 02-000-01,-02,-03,-04parokotNo ratings yet

- Jarvis: Model SEC 230 - 4, 230 - 4LN Circular Breaking SawDocument16 pagesJarvis: Model SEC 230 - 4, 230 - 4LN Circular Breaking SawLilian KuhnenNo ratings yet

- Fuji Frenic 5000vg7s Users ManualDocument679 pagesFuji Frenic 5000vg7s Users ManualsunhuynhNo ratings yet

- Angle Grinder Instruction ManualDocument56 pagesAngle Grinder Instruction ManualLiviu HendresNo ratings yet

- Vibrator RotationDocument7 pagesVibrator RotationAlan LazarteNo ratings yet

- 101i-Super C Hydraulic Saw ManualDocument68 pages101i-Super C Hydraulic Saw Manualgeorge israelNo ratings yet

- Coples Viva Type V, VS, VSX, Sizes 110-460Document4 pagesCoples Viva Type V, VS, VSX, Sizes 110-460Andrés RamírezNo ratings yet

- sealey SMS2008Document3 pagessealey SMS2008cabuloNo ratings yet

- Tap SPDOpInstDocument6 pagesTap SPDOpInstjschaudtNo ratings yet

- Torque Wrenches: STW101 STW1011 STW102 STW103 STW104 STW200 STW201.V2 STW202 STW1012Document3 pagesTorque Wrenches: STW101 STW1011 STW102 STW103 STW104 STW200 STW201.V2 STW202 STW1012isidroNo ratings yet

- Rebitadora Rivit Riv938ManualDocument48 pagesRebitadora Rivit Riv938ManualRobson LimeiraNo ratings yet

- Manual - Scribe Saw (Kentmaster SC650)Document21 pagesManual - Scribe Saw (Kentmaster SC650)yuNo ratings yet

- MAKITA - Llave Impacto 6905H - ManualDocument64 pagesMAKITA - Llave Impacto 6905H - Manualmarco antonio talavera salazarNo ratings yet

- Specifications TorqueDocument20 pagesSpecifications Torquethoma111s100% (2)

- Hobart Om-2175 User & Service ManualDocument321 pagesHobart Om-2175 User & Service ManualNasir AhmedNo ratings yet

- 12m Shaft 580w Pencil Concrete VibratorDocument12 pages12m Shaft 580w Pencil Concrete VibratorDj MacNo ratings yet

- Tru-Weld: Operations ManualDocument30 pagesTru-Weld: Operations ManualFernando Martinez BravoNo ratings yet

- SM-281A Tube Roller Specifications and Operating InstructionsDocument4 pagesSM-281A Tube Roller Specifications and Operating InstructionsesmaeelNo ratings yet

- User Manual Servo Motor and Drive I531Document476 pagesUser Manual Servo Motor and Drive I531alone160162No ratings yet

- EN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDocument48 pagesEN-Series All-Electric Pressure Washers and Steam Cleaners: Electric Motor Driven, Electrically HeatedDarío Ache EmeNo ratings yet

- 5" Multi-Jaw Bench Vise: Operator's ManualDocument6 pages5" Multi-Jaw Bench Vise: Operator's ManualHamid HojatiNo ratings yet

- DK10Document18 pagesDK10wellingtonsoares349No ratings yet

- 47158Document16 pages47158Rosania SanchesNo ratings yet

- 10" Single-Bevel Sliding Compound Miter Saw: Instruction ManualDocument28 pages10" Single-Bevel Sliding Compound Miter Saw: Instruction ManualMagnumRelux MendezNo ratings yet

- Instructions AND Parts Manual: STW-2000 Programmable Stiffener WelderDocument32 pagesInstructions AND Parts Manual: STW-2000 Programmable Stiffener WelderJuan RodriguezNo ratings yet

- 206B-FF Flange Facer ManualDocument22 pages206B-FF Flange Facer ManualKmelt39No ratings yet

- Manual Atahs InstDocument9 pagesManual Atahs InstblaktionNo ratings yet

- Powerful Zip Saw GuideDocument24 pagesPowerful Zip Saw GuideGaby CharcopaNo ratings yet

- TB60 Manual_lrDocument24 pagesTB60 Manual_lrjonathan.t.d.1985No ratings yet

- Dermatomo Zimmer UsuarioDocument22 pagesDermatomo Zimmer Usuariosjurado.nexpNo ratings yet

- User Manual Lincat Lpp35Document23 pagesUser Manual Lincat Lpp35Urip S. SetyadjiNo ratings yet

- Sierra Circular - SEC 280-4Document24 pagesSierra Circular - SEC 280-4cristian andres quiceno mayaNo ratings yet

- Riv 912Document48 pagesRiv 912Hotline LeadecNo ratings yet

- Manual Policorte CompletoDocument36 pagesManual Policorte CompletoDivino CésarNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- 00100K Dual Circuit Power Unit: AccessoriesDocument34 pages00100K Dual Circuit Power Unit: AccessoriesMaria Teresa Fernández OlavarrietaNo ratings yet

- AISI 10B22 Steel DatasheetDocument2 pagesAISI 10B22 Steel DatasheetMaria Teresa Fernández OlavarrietaNo ratings yet

- Application Bulletin: Routine Determination of Copper in Brass, Bronze, German Silver and Electroplating BathsDocument4 pagesApplication Bulletin: Routine Determination of Copper in Brass, Bronze, German Silver and Electroplating BathsMaria Teresa Fernández OlavarrietaNo ratings yet

- Tables of Metallurgical Thermochemistry - Kubaschewski, AlcockDocument74 pagesTables of Metallurgical Thermochemistry - Kubaschewski, AlcockAlejandro Lee100% (3)

- CT1, CT2, CT5 and CT8 Study Plan UK Exams September 2013Document8 pagesCT1, CT2, CT5 and CT8 Study Plan UK Exams September 2013Mohamed ArafaNo ratings yet

- Drug Suffixes Cheat Sheet Sorted AlphabeticallyDocument3 pagesDrug Suffixes Cheat Sheet Sorted Alphabeticallystudynote155No ratings yet

- DVTDocument7 pagesDVTAnggun SafariantiniNo ratings yet

- Postpartum Discharge Instructions - Howard County General Hospital, Johns Hopkins MedicineDocument7 pagesPostpartum Discharge Instructions - Howard County General Hospital, Johns Hopkins MedicineA.No ratings yet

- Dummy Activity 2Document17 pagesDummy Activity 2James NielNo ratings yet

- LIST OF REGISTERED DRUGS As of December 2012: DR No Generic Brand Strength Form CompanyDocument22 pagesLIST OF REGISTERED DRUGS As of December 2012: DR No Generic Brand Strength Form CompanyBenjamin TantiansuNo ratings yet

- Customs and Taboos of Bidayuh CommunityDocument16 pagesCustoms and Taboos of Bidayuh Communitykhairul ikhwanNo ratings yet

- BENEDICT JORDAN L. LIMOS ENVIRONMENTAL AND SANITARY ENGINEERING PROFILEDocument2 pagesBENEDICT JORDAN L. LIMOS ENVIRONMENTAL AND SANITARY ENGINEERING PROFILEMaria Theresa LimosNo ratings yet

- Zamora Assignment #4 (Cmca)Document5 pagesZamora Assignment #4 (Cmca)Elizabeth ZamoraNo ratings yet

- Defensive Driving Course Sabah SkillsDocument1 pageDefensive Driving Course Sabah SkillsKatheza Abd TaufikNo ratings yet

- Word form siêu khó làm chao đảo thế giới ảo (nguồn tổng hợpDocument9 pagesWord form siêu khó làm chao đảo thế giới ảo (nguồn tổng hợpVu Ngoc Quynh AnhNo ratings yet

- South 24 Parganas Disaster Management ContactsDocument123 pagesSouth 24 Parganas Disaster Management ContactsLibrary My book storeNo ratings yet

- Bring Nursing Theory to Life Global HealthDocument4 pagesBring Nursing Theory to Life Global HealthAsyroful Anam GucioNo ratings yet

- 2nd Summative TestDocument4 pages2nd Summative TestMarie Antonette Aco BarbaNo ratings yet

- Lucrare Stiintifica ParodontologieDocument4 pagesLucrare Stiintifica ParodontologieReduceriAvonNo ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Impact On LGBTQ IssuesDocument2 pagesImpact On LGBTQ IssuesAngel BirringNo ratings yet

- Feeding The Mind - PresentationDocument11 pagesFeeding The Mind - Presentationapi-708898253No ratings yet

- Union Christian College Health Ethics TheoriesDocument14 pagesUnion Christian College Health Ethics TheoriesMel Ligen DIANANo ratings yet

- PhD Thesis AcknowledgementDocument3 pagesPhD Thesis AcknowledgementNeelamegam DevarasuNo ratings yet

- M24L40Document7 pagesM24L40Andenet AshagrieNo ratings yet

- POLITRAUMATISMODocument13 pagesPOLITRAUMATISMOJOSENo ratings yet

- High-Dose Corticosteroids Improve The Prognosis of Bell 'S Palsy Compared With Low-Dose Corticosteroids: A Propensity Score AnalysisDocument6 pagesHigh-Dose Corticosteroids Improve The Prognosis of Bell 'S Palsy Compared With Low-Dose Corticosteroids: A Propensity Score AnalysisRiyanti DeviNo ratings yet

- Guidelines ERASC Part 1 PDFDocument15 pagesGuidelines ERASC Part 1 PDFkintanNo ratings yet

- Yee Mee Sticker (Final)Document4 pagesYee Mee Sticker (Final)SARAH JANENo ratings yet

- Sterilization Consent Form: LDSS-3134Document1 pageSterilization Consent Form: LDSS-3134Jack TedescoNo ratings yet

- Pregnancy Complications and Labor ManagementDocument22 pagesPregnancy Complications and Labor ManagementDon Oliveros ÜNo ratings yet

- A Therapy Session Wish If OnlyDocument11 pagesA Therapy Session Wish If OnlyNurilaMakashevaNo ratings yet