Professional Documents

Culture Documents

Thermo-Lag 270 Product Flyer

Uploaded by

BERSE MAJU INDONESIACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermo-Lag 270 Product Flyer

Uploaded by

BERSE MAJU INDONESIACopyright:

Available Formats

Thermo-Lag 270

A P P L I C AT I O N S

PETROCHEMICAL PLANTS

POWER PLANTS

STEEL & ALUMINUM MILLS

MANUFACTURING FACILITIES

F E AT U R E S

› Meets international and North

American cable protection standards

› FM Global approved for interior and

exterior use

› Tested to International

Electrotechnical Commission (IEC)

A water-based, fire-resistant, standards

and fire retardant coating › 65-minute circuit integrity protection

at 63 mils (1.6 mm)

applied directly to electrical › 2-hour flame propagation protection

cables to maintain circuit at 63 mils (1.6 mm)

integrity and retard flame

› Class A (Class 1) rated for flame

spread & smoke development

propagation. › 0% Ampacity derating

› Water-based

PRODUCT DETAILS Thermo-Lag 270 was designed to provide protection

› Flexible and durable

for electrical cables during a fire. It works by inhibiting the combustion

› Allows easy replacement of cables

process and reducing heat transmission to the protected cables. The

coating envelops the protected cables with a fire-resistant and fire › Manufactured to ISO 9001 standards

retardant jacket that protects against flame propagation and maintains

circuit integrity during a fire.

Thermo-Lag 270 is an economical and maintenance-free way to protect

cables from fire exposure. It is suitable for exterior and interior use to

protect cables in electrical equipment, cable trays, and control rooms.

It is a reliable and proven cable protection coating that is easily applied

directly to cables.

Thermo-Lag 270 has successfully passed extensive 3rd party testing

to IEC (International Electrotechnical Commission) standards and has

been tested and approved by FM Global @ 63 mils (1.6 mm).

Thermo-Lag 270

Quality Product Backed by Quality Service

› Carboline Company has been solving tough corrosion and fireproofing problems since 1947

› Industrial service centers and sales offices located around the world

› Over 20 worldwide manufacturing locations with a global network of sales and technical support

› Industry leading field service and technical engineering support team

› Certified to ISO 9001

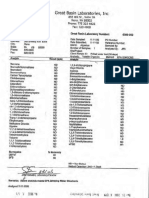

Thermo-Lag 270 Test Data

TEST METHOD RESULTS THICKNESS LABORATORY

Circuit Integrity @ 1,940°F (1,060°C) (IEC 60331-11-21) 65 minutes* 63 mils (1.6 mm) Exova Warringtonfire

Flame Propagation (IEC 60332-3-22) 120 minutes 63 mils (1.6 mm) Intertek (ITS)

Flame Spread (ASTM E84) Class A (Class 1) 63 mils (1.6 mm) FM Global

Smoke Development (ASTM E84) Class A (Class 1) 63 mils (1.6 mm) FM Global

Ampacity (EPS 96202) 0% derating 63 mils (1.6 mm) FM Global

Weathering (FM 3971) Exterior rated 63 mils (1.6 mm) FM Global

Halogen Gas Content (IEC 60754) Pass (<5.0 mg/g HCl) N/A Intertek (ITS)

Passed

Accelerated Aging (DIN EN ISO 4892-2) N/A Intertek (ITS)

(No loss in fire properties)

* 90 minute circuit integrity can be achieved at a thickness of 118 mils (3.0 mm) based on alternate limiting temperature of 2.012°F (1,100°C).

Thermo-Lag 270 Physical Data

TEST 12.6

Weight per Gallon 10.6 lb (4.8 kg)

Hardness (ASTM D2240) Shore D 30-40

Flexibility Excellent

Abrasion Resistance Very Good

Impact Resistance Excellent

Solids by Volume 53%

V.O.C. 0.24 lb/gal (28 g/l)

Coverage (Per Gallon) 13.5 ft2 @ 1/16” (1.6 mm)

Shelf Life 12 Months

*All values derived under controlled laboratory conditions.

Carboline Company

Global Headquarters

2150 Schuetz Road

01-46-0320-522

St. Louis, MO 63146 USA

PH: +1-314-644-1000

www.carboline.com

You might also like

- SuperLite LL-XL 120Document2 pagesSuperLite LL-XL 120Marija MilenkovicNo ratings yet

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Makrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsDocument2 pagesMakrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsAbdelmajid HmNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- Lifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMDocument2 pagesLifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMkevinwz1989No ratings yet

- FT Temflex 165Document2 pagesFT Temflex 165Felipe AndresNo ratings yet

- Datasheet BASF Entertite G SPF PDFDocument2 pagesDatasheet BASF Entertite G SPF PDFKhin Sandi KoNo ratings yet

- 06 HPS6 DatasheetDocument2 pages06 HPS6 Datasheet张浩No ratings yet

- Cera Board 100Document2 pagesCera Board 100Javier TrujillanoNo ratings yet

- Prysmian Esp Cable DW 205 R PDFDocument2 pagesPrysmian Esp Cable DW 205 R PDFJava Cable Center50% (2)

- Flame Tracker Dry 325: No Water Cooling Needed!Document2 pagesFlame Tracker Dry 325: No Water Cooling Needed!Yeco MachineryNo ratings yet

- Electra: Applications Special FeaturesDocument3 pagesElectra: Applications Special FeaturesmohmdNo ratings yet

- 3M 2800-2802-2805 Data SheetDocument2 pages3M 2800-2802-2805 Data SheetMichael TadrosNo ratings yet

- Custom Made Movement Joint ProfileDocument2 pagesCustom Made Movement Joint Profileemrah turerNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Safe - N - Silent Pro Product Data Sheet IndiaDocument2 pagesSafe - N - Silent Pro Product Data Sheet IndiaMd Farid AhmedNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- 660 860 RevcDocument16 pages660 860 RevcsureshthuppallamNo ratings yet

- 20Mncr5: Steel GradeDocument3 pages20Mncr5: Steel GradeRajat DubeyNo ratings yet

- E Shield6421 Datasheet PDFDocument1 pageE Shield6421 Datasheet PDFYo ANo ratings yet

- Ge Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Document2 pagesGe Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Ionut DeaconuNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Block InsulationDocument2 pagesBlock Insulation1repsaperuNo ratings yet

- Tilara Polyplast EcatalogueDocument16 pagesTilara Polyplast EcatalogueRohit ChudasamaNo ratings yet

- ArmaSoundRD 240 ESDocument4 pagesArmaSoundRD 240 ESSuthi Sae DanNo ratings yet

- MICRO SWITCH Flame-Proof Limit Switches: GXS SeriesDocument8 pagesMICRO SWITCH Flame-Proof Limit Switches: GXS SeriesSatya BarikNo ratings yet

- MultimediaDocument4 pagesMultimediaVIVEK SAININo ratings yet

- Stanvac 2Document4 pagesStanvac 2Tamba PasaribuNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Scotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Document2 pagesScotch Super 33+ Vinyl Electrical Tape: Data Sheet November 2020Kishan MohtaNo ratings yet

- Technical Data Sheet: Perspex CCDocument2 pagesTechnical Data Sheet: Perspex CCResist IkatNo ratings yet

- Fireproof ROOF Panels Technical InformationDocument4 pagesFireproof ROOF Panels Technical InformationMarko MiticNo ratings yet

- Ultraviolet Flame Detector: Omniguard Model 660Document2 pagesUltraviolet Flame Detector: Omniguard Model 660carlosNo ratings yet

- ESP Cables: Exploration & ProductionDocument2 pagesESP Cables: Exploration & ProductionHimawan Sigit NugrohoNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- 718 Stangard Egf (NV)Document5 pages718 Stangard Egf (NV)Sandeep gangulyNo ratings yet

- Tubotc1300 Tubotc1300 3 G000100131Document5 pagesTubotc1300 Tubotc1300 3 G000100131Lesly Meza WillarsNo ratings yet

- ForsterDocument46 pagesForsterscribdme123No ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- Shell Diala S3 ZX-IG DriedDocument2 pagesShell Diala S3 ZX-IG DriedAnonymous oAbjbl4HNo ratings yet

- Shell Diala S3 ZX-IGDocument2 pagesShell Diala S3 ZX-IGAnonymous oAbjbl4HNo ratings yet

- Interwall Ficha Tecnica Plazcarb Policarbonato Solido 2018 PDFDocument2 pagesInterwall Ficha Tecnica Plazcarb Policarbonato Solido 2018 PDFandy reyesNo ratings yet

- Tecatron Gf40 Black en All 201711Document2 pagesTecatron Gf40 Black en All 201711JorgeMariscalNo ratings yet

- Electraray Supervised Hearing Impaired Hazardous Location Strobe Warning LightDocument2 pagesElectraray Supervised Hearing Impaired Hazardous Location Strobe Warning LightJose Luis Lobo MorenoNo ratings yet

- 300.024 Lustran Elite 1891Document2 pages300.024 Lustran Elite 1891Enrique ChavezNo ratings yet

- OilStar A105-100Document2 pagesOilStar A105-100LuisNo ratings yet

- MEDC CU1SEM120T06RNR2BR Sirene de Segurança Ficha Tecnica Catalogo DatasheetDocument2 pagesMEDC CU1SEM120T06RNR2BR Sirene de Segurança Ficha Tecnica Catalogo DatasheetPeter PenhaNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Scotch: Super 33+ Vinyl Electrical TapeDocument2 pagesScotch: Super 33+ Vinyl Electrical TapeDonato PirroNo ratings yet

- Durafide 6165A6 TDSDocument6 pagesDurafide 6165A6 TDSCassianNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- NC20B1NL 2 UsansiDocument7 pagesNC20B1NL 2 UsansiBERSE MAJU INDONESIANo ratings yet

- Sanitile Wall Coatings Brochure - 111616Document8 pagesSanitile Wall Coatings Brochure - 111616BERSE MAJU INDONESIANo ratings yet

- ISO 12944 Brochure - 011921Document16 pagesISO 12944 Brochure - 011921BERSE MAJU INDONESIANo ratings yet

- Marine Market Brochure - Letter - 0120-LoDocument5 pagesMarine Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- OEM Market Brochure - Letter - 0120-LoDocument5 pagesOEM Market Brochure - Letter - 0120-LoBERSE MAJU INDONESIANo ratings yet

- 10 Year Limited WarrantyDocument2 pages10 Year Limited WarrantyBERSE MAJU INDONESIANo ratings yet

- Food & Beverage Market Brochure - 0519-LoDocument8 pagesFood & Beverage Market Brochure - 0519-LoBERSE MAJU INDONESIANo ratings yet

- Rust Bullet Abs CertificationDocument3 pagesRust Bullet Abs CertificationBERSE MAJU INDONESIANo ratings yet

- Unr - Acid - Test Chemical Resistant Cert RBDocument1 pageUnr - Acid - Test Chemical Resistant Cert RBBERSE MAJU INDONESIANo ratings yet

- San241 - 2006za - Potable Water Cert RBDocument1 pageSan241 - 2006za - Potable Water Cert RBBERSE MAJU INDONESIANo ratings yet

- Certificate Rust Bullet - EPA - Drinking WaterDocument2 pagesCertificate Rust Bullet - EPA - Drinking WaterBERSE MAJU INDONESIANo ratings yet

- MSDS RelugolixDocument5 pagesMSDS RelugolixRahul ShitoleNo ratings yet

- Igneous Rock TexturesDocument18 pagesIgneous Rock TexturesWWW.1580.L0GN.CFNo ratings yet

- ROAD TO MY LEWIS ActivityDocument1 pageROAD TO MY LEWIS ActivityCristy SevillaNo ratings yet

- 8 AdsorptionDocument85 pages8 AdsorptionRush WahabNo ratings yet

- Capacitors (Modified) by Sanjay PandeyDocument8 pagesCapacitors (Modified) by Sanjay PandeySanjay Pandey100% (1)

- Paper 2 Paper With Solution ChemistryDocument14 pagesPaper 2 Paper With Solution ChemistryddssdsfsNo ratings yet

- Carbopol® Ultrez 21 Polymer: The Lubrizol Corporation 29400 Lakeland Boulevard Wickliffe, Ohio 44092 Tel: (440) 943-4200Document7 pagesCarbopol® Ultrez 21 Polymer: The Lubrizol Corporation 29400 Lakeland Boulevard Wickliffe, Ohio 44092 Tel: (440) 943-4200Ana Paula JimenezNo ratings yet

- Material Take-Off List: Rev. CodeDocument6 pagesMaterial Take-Off List: Rev. CodeSIVANo ratings yet

- Comparison of Water Saturation Models Based On Well Logging Data: A Case Study of MX Field in Malay BasinDocument9 pagesComparison of Water Saturation Models Based On Well Logging Data: A Case Study of MX Field in Malay BasinG.A. PermanaNo ratings yet

- Tropic Ocean Silicon MetalDocument14 pagesTropic Ocean Silicon MetalLin FarrellNo ratings yet

- Diaphragm Design GuideDocument29 pagesDiaphragm Design GuideJaher Wasim100% (1)

- Aaac Astm B All Aluminium Alloy ConductorDocument6 pagesAaac Astm B All Aluminium Alloy ConductorIngenieria DyconNo ratings yet

- Value EngineeringDocument20 pagesValue EngineeringSakshi SinghNo ratings yet

- Concrete Mix Design ManualDocument30 pagesConcrete Mix Design ManualsiswosukartoNo ratings yet

- Instrumen GCC PDFDocument10 pagesInstrumen GCC PDFSteven SantiagoNo ratings yet

- FOUNDATION RCD of Footings 1 Square FTGDocument5 pagesFOUNDATION RCD of Footings 1 Square FTGChris Michelle JapinNo ratings yet

- Performance-Based Seismic Design of Reinforced Concrete Beam-Column Joints, Zhongguo GuanDocument6 pagesPerformance-Based Seismic Design of Reinforced Concrete Beam-Column Joints, Zhongguo GuanQurrain MirNo ratings yet

- Improving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat TreatmentDocument11 pagesImproving Mechanical Properties of Alsi10Mg Aluminum Alloy Using Ultrasonic Melt Treatment Combined With T6 Heat Treatmentפּואַ פּוגאַNo ratings yet

- TOS 5 Unit 2a Design of Doubly Reinforced BeamsDocument7 pagesTOS 5 Unit 2a Design of Doubly Reinforced BeamsKshitija100% (1)

- Bitustick - XL-Material Safety Data SheetDocument2 pagesBitustick - XL-Material Safety Data Sheetaldred_chezka100% (1)

- Ha Coating On Ti 3.1Document9 pagesHa Coating On Ti 3.1Truong DucQuangNo ratings yet

- Case Study On Operational Inspection of A Fluidised Bed Combustion BoilerDocument31 pagesCase Study On Operational Inspection of A Fluidised Bed Combustion Boilerparthi20065768No ratings yet

- Data Sheet: Experiment 1: Chemical ReactionsDocument17 pagesData Sheet: Experiment 1: Chemical ReactionsLinh NguyễnNo ratings yet

- Weld Design SpreadsheetDocument4 pagesWeld Design SpreadsheetAli AkbarNo ratings yet

- Mindmap 1 PDFDocument1 pageMindmap 1 PDFnoorafifahabubakarNo ratings yet

- Cement BoardDocument5 pagesCement BoardYsabella May Sarthou CervantesNo ratings yet

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanDocument13 pagesCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaNo ratings yet

- Pulpling of Wood EditedDocument6 pagesPulpling of Wood EditedMuhammad Omar Khan GhouriNo ratings yet

- BT Reviewer PrelimsDocument3 pagesBT Reviewer PrelimsDianalen RosalesNo ratings yet

- SECTION 05530 Gratings Rev 1Document17 pagesSECTION 05530 Gratings Rev 1Mohsin ShaikhNo ratings yet