Professional Documents

Culture Documents

Lockout/ Tagout - 7 Steps: Equipment Restart Sequence - 4 Steps

Lockout/ Tagout - 7 Steps: Equipment Restart Sequence - 4 Steps

Uploaded by

Conner0 ratings0% found this document useful (0 votes)

28 views1 pageThe document provides a quick reference guide for lockout/tagout procedures with 7 steps:

1) Survey the machine for energy sources and record them. Consult specific write-ups where available.

2) Notify affected workers that machinery will be locked out.

3) Shut down the machine using normal controls.

Original Description:

Original Title

A-129_E_202104

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a quick reference guide for lockout/tagout procedures with 7 steps:

1) Survey the machine for energy sources and record them. Consult specific write-ups where available.

2) Notify affected workers that machinery will be locked out.

3) Shut down the machine using normal controls.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views1 pageLockout/ Tagout - 7 Steps: Equipment Restart Sequence - 4 Steps

Lockout/ Tagout - 7 Steps: Equipment Restart Sequence - 4 Steps

Uploaded by

ConnerThe document provides a quick reference guide for lockout/tagout procedures with 7 steps:

1) Survey the machine for energy sources and record them. Consult specific write-ups where available.

2) Notify affected workers that machinery will be locked out.

3) Shut down the machine using normal controls.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

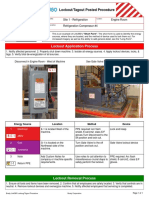

QUICK REFERENCE GUIDE

SURVEY the machine for sources of

1 energy and record these on the Job

Hazard Analysis (DC-83). Consult specific

procedural write-up for that particular

Lockout/

machine or system where available.

NOTIFY affected workers that

Tagout

2

–7 Steps

machinery or equipment will

be locked out.

SHUT DOWN the machine or system.

3 Turn off the equipment using the

normal controls (stop button, on/off

switch, valve, or other). Equipment Restart

Sequence

4

ISOLATE the equipment from any

energy sources. (For example, unplug it,

–4 Steps

flip the circuit breaker off, or close the

CHECK to make sure all tools

main valve.) Ensure that all sources of 1

and rags have been removed

energy are isolated in the proper order.

from the machine or system,

guards have been installed,

LOCK OUT the equipment by fastening a and all workers are clear of

5 padlock to each energy control device. the equipment.

ADD A TAG with contact information,

dates, and time. If multiple individuals VERIFY that the stop button is

2

are working on equipment, multiple engaged or the control switch

locks may be necessary. is in the “off/neutral” position.

REMOVE all lockout/tagout

DISSIPATE any residual energy, such as 3

equipment from energy

6 that found in springs, hydraulic systems, isolating devices. Each worker

and raised or elevated parts, by

is responsible for removing his

repositioning, blocking, or bleeding

own lock and tag.

down.

RESTORE energy according to

4

A competent person should VERIFY that the write-up procedure

7 the energy source has been isolated and outlined for each machine or

that the equipment will not start. system.

A-129-E 4/21

You might also like

- FTM 3100 - FTM3200 Service ManualDocument34 pagesFTM 3100 - FTM3200 Service ManualKo Azani76% (21)

- Brady Link360 Lockout Tagout Short FormDocument2 pagesBrady Link360 Lockout Tagout Short FormReynaldo GrantNo ratings yet

- Example Lockout Procedure Hot Water BoilerDocument2 pagesExample Lockout Procedure Hot Water BoilerRuben Rosales50% (4)

- Procedure For Lock Out Tag OutDocument10 pagesProcedure For Lock Out Tag OutBineesh100% (1)

- Lockout Tagout ProgramDocument6 pagesLockout Tagout ProgramYuli AstutyNo ratings yet

- Lock Out - Tag Out Program: (LO/TO)Document18 pagesLock Out - Tag Out Program: (LO/TO)Mejora ContinuaNo ratings yet

- Ev 006Document6 pagesEv 006Budhi HermawanNo ratings yet

- Lockout Tagout Standard Safety TrainingDocument13 pagesLockout Tagout Standard Safety TrainingSajjad Afzal100% (1)

- HIDC HSE 006 Lock Out Tag Out (LOTO) AwarenessDocument16 pagesHIDC HSE 006 Lock Out Tag Out (LOTO) AwarenessMuhammad SaqibNo ratings yet

- General Lockout - Tagout ProcedureDocument2 pagesGeneral Lockout - Tagout ProcedurelhNo ratings yet

- Lock Out Tag OutDocument47 pagesLock Out Tag OutAldrien CabinteNo ratings yet

- Lock Out Tag OutDocument2 pagesLock Out Tag OutPablo Arreola RomeroNo ratings yet

- Lock and TagDocument4 pagesLock and TagIoana UrsanNo ratings yet

- Lockout Tagout TrainingDocument26 pagesLockout Tagout Trainingeileen_muu485No ratings yet

- CAT-06 Hazardous Energy Control-EnglishDocument13 pagesCAT-06 Hazardous Energy Control-EnglishGemNo ratings yet

- lotoFINALDocument19 pageslotoFINALElvyn Fabellore HerreraNo ratings yet

- Applications of Lockout 1Document23 pagesApplications of Lockout 1sivakumarNo ratings yet

- Sand 2009-0818 P LOTO ChecklistDocument2 pagesSand 2009-0818 P LOTO Checklist正玄No ratings yet

- Sand 2009-0818 P LOTO ChecklistDocument2 pagesSand 2009-0818 P LOTO ChecklistparthaNo ratings yet

- Presentación LOTODocument16 pagesPresentación LOTOChNo ratings yet

- LOTODocument13 pagesLOTOElmerjr NavarezNo ratings yet

- Elec Hazard Awareness Study GuideDocument5 pagesElec Hazard Awareness Study GuideBố Đăng KhánhNo ratings yet

- WKS 6 Forest Harvesting Lockout Sawmill IsolationDocument4 pagesWKS 6 Forest Harvesting Lockout Sawmill IsolationJuan Ismael Carmona RodríguezNo ratings yet

- Lock Out & Tag Out (LOTO) HSE Presentation HSE FormatsDocument16 pagesLock Out & Tag Out (LOTO) HSE Presentation HSE FormatsasepNo ratings yet

- 4 Tag-Out SDRRMDocument3 pages4 Tag-Out SDRRMsharmaneNo ratings yet

- Lockout/tagoutDocument13 pagesLockout/tagoutLaxman BadiniNo ratings yet

- LOTO Template ProgramDocument13 pagesLOTO Template Programyemi adelakun100% (1)

- Sample Loto ProcedureDocument4 pagesSample Loto ProcedureSkariah MathewsNo ratings yet

- Loto VeneervisionDocument2 pagesLoto Veneervisionapi-362234935No ratings yet

- Lockout Tagout: Lock KEY TAGDocument1 pageLockout Tagout: Lock KEY TAGThanh Tung DongNo ratings yet

- Plans Lo ToDocument6 pagesPlans Lo ToidahssNo ratings yet

- Electrical Safety: Casimiro L. Flores JRDocument23 pagesElectrical Safety: Casimiro L. Flores JRJoseph CeaNo ratings yet

- OSH Answers Fact Sheets LOTODocument7 pagesOSH Answers Fact Sheets LOTOAjiwuriNo ratings yet

- OSH Answers Fact Sheets LOTODocument7 pagesOSH Answers Fact Sheets LOTOAjiwuriNo ratings yet

- Industrial Process Control Lab: Student's Lab ReportDocument5 pagesIndustrial Process Control Lab: Student's Lab ReportNoumanShabbirNo ratings yet

- Lockout Tagout ProcedureDocument7 pagesLockout Tagout ProcedureKadesh Hanah McCarthyNo ratings yet

- Chapter 5 SAFETY PROCEDURES AND METHODSDocument28 pagesChapter 5 SAFETY PROCEDURES AND METHODSMelchor CarabayasNo ratings yet

- 7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftDocument5 pages7 Global Golden Rules of Safety - Rule 5 - LOTO & Work Permit - DraftPedro ViegasNo ratings yet

- Sample Lockout Procedure: PurposeDocument6 pagesSample Lockout Procedure: PurposeamenieNo ratings yet

- LOTODocument22 pagesLOTORahma Dinda MelatiNo ratings yet

- Lockout Tagout TRNG GuideDocument7 pagesLockout Tagout TRNG GuideSyed Mujtaba Ali Bukhari100% (1)

- PL Toolboxtalk LockouttagoutDocument1 pagePL Toolboxtalk LockouttagoutRomanuSNo ratings yet

- Wiring Installation: Ours CrewDocument11 pagesWiring Installation: Ours CrewMuhammad Azri Bin TokimanNo ratings yet

- Lock Out Tag Out LOTO 1660024098Document16 pagesLock Out Tag Out LOTO 1660024098richardNo ratings yet

- LOTODocument16 pagesLOTOAbdullah MunawirNo ratings yet

- Electrical Safety With LOTO ProgramDocument30 pagesElectrical Safety With LOTO ProgramJohn Lloyd GenerosoNo ratings yet

- ANSI ListDocument10 pagesANSI ListchdiNo ratings yet

- Standard Device Function NumbersDocument2 pagesStandard Device Function NumbersMihai PopescuNo ratings yet

- MANY0521A.GB - Technical Manual Metacentre VSD BoxDocument39 pagesMANY0521A.GB - Technical Manual Metacentre VSD Boxmiguel angel vanegas medinaNo ratings yet

- Lock Out Tag OutDocument13 pagesLock Out Tag OutsexyrustyNo ratings yet

- Lockout ProceduresDocument10 pagesLockout ProceduresHs supervisorsNo ratings yet

- Mod11 Lockout-TagoutDocument15 pagesMod11 Lockout-TagoutMhanna AYNo ratings yet

- MANY0702A.GB - Technical Manual Metacentre DX BoxDocument31 pagesMANY0702A.GB - Technical Manual Metacentre DX Boxmiguel angel vanegas medinaNo ratings yet

- Safe Work Practices: LockoutDocument2 pagesSafe Work Practices: Lockoutrnp2007123No ratings yet

- Safe Work Practices Safe Work Practices: Lock and Tag All SourcesDocument5 pagesSafe Work Practices Safe Work Practices: Lock and Tag All SourcesRedy SaputroNo ratings yet

- MELSEC-A-QnA (Large), AnS-QnAS (Small) Transition Examples - L08121edDocument176 pagesMELSEC-A-QnA (Large), AnS-QnAS (Small) Transition Examples - L08121edAym BrNo ratings yet

- Lock Out Tag Out ProceduresDocument9 pagesLock Out Tag Out ProceduresyawarhassanNo ratings yet

- Controlling Hazardous Energy: Lockout/TagoutDocument18 pagesControlling Hazardous Energy: Lockout/TagoutroisNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Skin EffectDocument5 pagesSkin EffectFawzy Abd AlgawadNo ratings yet

- Siemens Air Cooled Generators Sgen 1000a Brochure enDocument4 pagesSiemens Air Cooled Generators Sgen 1000a Brochure enmanohar_033No ratings yet

- Fuso FODocument6 pagesFuso FOdenykNo ratings yet

- Serdi 4.5Document4 pagesSerdi 4.5Yeam_90No ratings yet

- Unbalanced Faults Analysis in Grid - Connected PV System - ListhianneDocument6 pagesUnbalanced Faults Analysis in Grid - Connected PV System - Listhiannesalomy ndjakoNo ratings yet

- Small Power Distribution BoardsDocument6 pagesSmall Power Distribution BoardsSARAVANANo ratings yet

- Robotic 3D PDFDocument56 pagesRobotic 3D PDFAndy ReynoldsNo ratings yet

- Charlynn S4000Document9 pagesCharlynn S4000MeuMundoMinecraftNo ratings yet

- Potenciometros MultivueltasDocument20 pagesPotenciometros MultivueltasRaul E. SoliNo ratings yet

- Esa Estro Burner ControllerDocument32 pagesEsa Estro Burner ControllerguillaumeNo ratings yet

- DMfit Catalog 18.09.15Document23 pagesDMfit Catalog 18.09.15Sinergroup Water Filters Water Purifiers Water SoftenersNo ratings yet

- Hypertherm Powermax 190C Plasma Hand Torch PartsDocument2 pagesHypertherm Powermax 190C Plasma Hand Torch Partssask100100% (1)

- CLICKING NOISE NissanDocument5 pagesCLICKING NOISE NissanBenNo ratings yet

- Mitsubishi: Technical Service BulletinDocument11 pagesMitsubishi: Technical Service BulletinKonstantinNo ratings yet

- Company ProfileDocument8 pagesCompany ProfileArun GuptaNo ratings yet

- ManualDocument5 pagesManualrpichoNo ratings yet

- Electronic Capacity Control PDFDocument68 pagesElectronic Capacity Control PDFPablo GutiérrezNo ratings yet

- Module 09 Shorts & PinsDocument21 pagesModule 09 Shorts & PinsTai Shu WornNo ratings yet

- Simplified Lithium-Ion (Li+) Battery-Charger TestingDocument7 pagesSimplified Lithium-Ion (Li+) Battery-Charger TestingpekiilicNo ratings yet

- 05.04 Shaffer T LWSDocument5 pages05.04 Shaffer T LWSJuan Gabriel Hernandez LunaNo ratings yet

- Lesson Plan HANDTOOLSDocument4 pagesLesson Plan HANDTOOLSJeric Boloso Garferio Lpt50% (2)

- Compact 7-En ManualDocument22 pagesCompact 7-En ManualcprryanNo ratings yet

- G3616 Gas Engine Electrical System: Mids AdvisorDocument2 pagesG3616 Gas Engine Electrical System: Mids AdvisorDiego Ruben PalavecinoNo ratings yet

- D-30 Parts R2Document39 pagesD-30 Parts R2naokito AkemiNo ratings yet

- 2 0L SdiDocument20 pages2 0L SdiMohd FairusNo ratings yet

- VPMP Polytechnic, Gandhinagar VPMP Polytechnic, Gandhinagar: Enrollment NoDocument2 pagesVPMP Polytechnic, Gandhinagar VPMP Polytechnic, Gandhinagar: Enrollment NoAbbhinav JaiinNo ratings yet

- Honda CRF110F Service Repair ManualDocument10 pagesHonda CRF110F Service Repair ManualΕυθυμης ΖουμπαδελληςNo ratings yet

- L03 (1) 2laaDocument45 pagesL03 (1) 2laaCarlos Alberto NievesNo ratings yet

- Rapid Rig BrochureDocument6 pagesRapid Rig BrochureKKC WP-ILSNo ratings yet