Professional Documents

Culture Documents

RT41034102019

Uploaded by

Stephen JacsiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT41034102019

Uploaded by

Stephen JacsiCopyright:

Available Formats

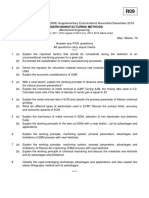

Code No: RT41034 R13 Set No.

1

IV B.Tech I Semester Supplementary Examinations, October/November-2019

UNCONVENTIONAL MACHINING PROCESSES

(Mechanical Engineering)

Time: 3 hours Max. Marks: 70

Question paper consists of Part-A and Part-B

Answer ALL sub questions from Part-A

Answer any THREE questions from Part-B

*****

PART–A (22 Marks)

1. a) What is meant by conventional and unconventional machining process? [4]

b) What are the economic aspects of ECM process? [4]

c) What are the principle components of EDM process? [3]

d) Mention advantages and limitation of LBM process? [4]

e) Differentiate between nontransferred and transferred mode of a plasma torch? [4]

f) Explain about the principle of water jet machining. [3]

PART–B (3x16 = 48 Marks)

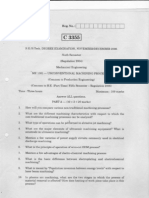

2. a) Classify the common nontraditional methods. Give a list of such operations. [8]

b) Discuss the effects of the amplitude and frequency of vibrations, abrasive grain

size and mass flow rate on the rate of material removal and surface finish

obtainable in ultrasonic machining. [8]

3. a) Explain the mechanism of material removal during ECG and how is different

from ECM? [8]

b) Explain the working principle of chemical machining with neat sketch. [8]

4. a) Explain the function of dielectric fluid in EDM. Name the common dielectric

fluids used in EDM. [8]

b) Explain the principle of Wire EDM with suitable diagram. [8]

5. a) Discuss about the generation of laser during LBM process. [8]

b) Explain the working principle of electron beam machining. [8]

6. a) Describe the commonly used gas mixture in plasma machining and their

corresponding work materials. [8]

b) Explain the principle of plasma generation and mechanism of metal removal in

plasma arch machining. [8]

7. a) What is the abrasive water jet machining? Explain its principle of operation. [8]

b) With a neat sketch, explain abrasive flow machining process. [8]

1 of 1

WWW.MANARESULTS.CO.IN

|''|'||||''|'''|'|'|

You might also like

- Printed Batteries: Materials, Technologies and ApplicationsFrom EverandPrinted Batteries: Materials, Technologies and ApplicationsSenentxu Lanceros-MéndezNo ratings yet

- UNCONVENTIONAL MACHINING PROCESSES MechaDocument4 pagesUNCONVENTIONAL MACHINING PROCESSES Mechaamit bhaleraoNo ratings yet

- Nanotechnology Commercialization: Manufacturing Processes and ProductsFrom EverandNanotechnology Commercialization: Manufacturing Processes and ProductsNo ratings yet

- Unconventional Machining Processes Exam QuestionsDocument4 pagesUnconventional Machining Processes Exam QuestionsSATISHNo ratings yet

- Advanced Battery MaterialsFrom EverandAdvanced Battery MaterialsChunwen SunNo ratings yet

- JntuK CAD/CAM Question PaperDocument4 pagesJntuK CAD/CAM Question PaperANILKUMAR KONDANo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- WWW - Manaresults.co - In: Set No. 1Document4 pagesWWW - Manaresults.co - In: Set No. 1Ravikiran Le-333No ratings yet

- Set No. 1: C 0 T/RCC C 0 CDocument5 pagesSet No. 1: C 0 T/RCC C 0 CSrinivasa Rao GNo ratings yet

- RR 410309 Unconventional Machining ProcessesDocument4 pagesRR 410309 Unconventional Machining ProcessesSRINIVASA RAO GANTANo ratings yet

- JntuK CAD/CAM Question PaperDocument1 pageJntuK CAD/CAM Question PaperANILKUMAR KONDANo ratings yet

- 9A03708 Modern Manufacturing MethodsDocument4 pages9A03708 Modern Manufacturing MethodssivabharathamurthyNo ratings yet

- JntuK CAD/CAM Question PaperDocument4 pagesJntuK CAD/CAM Question PaperANILKUMAR KONDANo ratings yet

- 127JH052019Document2 pages127JH052019Mohan ReddyNo ratings yet

- 117JH112017Document2 pages117JH112017Mohan ReddyNo ratings yet

- 156dc - Unconventional Machining ProcessesDocument1 page156dc - Unconventional Machining Processesrohitchanakya76No ratings yet

- 9A03708 Modern Manufacturing Methods (2) 412541Document1 page9A03708 Modern Manufacturing Methods (2) 412541nilima gNo ratings yet

- WWW - Manaresults.Co - In: Unconventional Machining ProcessesDocument2 pagesWWW - Manaresults.Co - In: Unconventional Machining ProcessesMohan ReddyNo ratings yet

- WWW - Manaresults.co - In: Set No. 1Document4 pagesWWW - Manaresults.co - In: Set No. 1abin brothersNo ratings yet

- ADVANCED MANUFACTURING PROCESSES April 2018 PDFDocument2 pagesADVANCED MANUFACTURING PROCESSES April 2018 PDFshardul jagdaleNo ratings yet

- IV B.Tech Power Plant Engineering Exam QuestionsDocument5 pagesIV B.Tech Power Plant Engineering Exam Questions347kranthiNo ratings yet

- FebruaryMarch 2022Document1 pageFebruaryMarch 2022rohitchanakya76No ratings yet

- Non Destructive Evaluation Question PaperDocument4 pagesNon Destructive Evaluation Question PaperRam Prasad YadavNo ratings yet

- BMS College of Engineering, Bangalore-560019: IiiiiiiiiiiDocument2 pagesBMS College of Engineering, Bangalore-560019: IiiiiiiiiiisidharthNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- February 2023Document2 pagesFebruary 2023rohitchanakya76No ratings yet

- qn1 WellcompletionDocument1 pageqn1 Wellcompletionlovely petsNo ratings yet

- WWW - Manaresults.co - In: Set No. 1Document1 pageWWW - Manaresults.co - In: Set No. 1abin brothersNo ratings yet

- RT 31036042019Document1 pageRT 31036042019Kondu RamanaiahNo ratings yet

- WWW - Manaresults.Co - In: III B. Tech I Semester Regular/Supplementary Examinations, October/November-2016 MetrologyDocument4 pagesWWW - Manaresults.Co - In: III B. Tech I Semester Regular/Supplementary Examinations, October/November-2016 MetrologyKKNo ratings yet

- RT42034A042018Document4 pagesRT42034A042018Prakash GadideshNo ratings yet

- WWW - Manaresults.Co - In: Set No. 1Document4 pagesWWW - Manaresults.Co - In: Set No. 1syedinthiyazNo ratings yet

- Jntuworld: R05 Set No. 2Document4 pagesJntuworld: R05 Set No. 2vanamgouthamNo ratings yet

- M&SE Dec 2011Document4 pagesM&SE Dec 2011simalaraviNo ratings yet

- RT31036112018 PDFDocument1 pageRT31036112018 PDFKKNo ratings yet

- B.E./B.Tech. Degree Examinations Question Paper for Unconventional Machining ProcessesDocument2 pagesB.E./B.Tech. Degree Examinations Question Paper for Unconventional Machining ProcessessaranNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document2 pagesQuestion Paper Code:: (10×2 20 Marks)saranNo ratings yet

- (4959) - 1041 B.E. (Mechanical Engineering) Advanced Manufacturing Processes (2012 Pattern) (Semester - I) (End Sem.) (402045D) (Elective - II)Document4 pages(4959) - 1041 B.E. (Mechanical Engineering) Advanced Manufacturing Processes (2012 Pattern) (Semester - I) (End Sem.) (402045D) (Elective - II)N1234mNo ratings yet

- Set No. 1: Code No: RT42034ADocument4 pagesSet No. 1: Code No: RT42034AsrinivasNo ratings yet

- qn2 WellcompletionDocument1 pageqn2 Wellcompletionlovely petsNo ratings yet

- B) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyDocument1 pageB) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyMilan MottaNo ratings yet

- rr211003 Instrumentation ComponentsDocument8 pagesrr211003 Instrumentation ComponentsSrinivasa Rao GNo ratings yet

- Ucm Anna Univ Question PapersDocument24 pagesUcm Anna Univ Question PapersNarayanan SubramanianNo ratings yet

- Electronic Measurements and Instrumentation July 2017Document1 pageElectronic Measurements and Instrumentation July 2017vishnu vardhanNo ratings yet

- WWW - Manaresults.Co - In: Set No. 1Document1 pageWWW - Manaresults.Co - In: Set No. 1Krishna Vasishta KavuturuNo ratings yet

- Metrology exam questions and answersDocument4 pagesMetrology exam questions and answersKKNo ratings yet

- Set No. 1Document4 pagesSet No. 1venkee84No ratings yet

- R7410309 Unconventional Machining ProcessesDocument1 pageR7410309 Unconventional Machining ProcessessivabharathamurthyNo ratings yet

- UCMP IAT2 SET A With CoDocument1 pageUCMP IAT2 SET A With Cojayaraman ponnambalamNo ratings yet

- Power Plant Engineering Multiple Choice QuestionsDocument4 pagesPower Plant Engineering Multiple Choice QuestionsYelax Des RêvesNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)gowrisankarNo ratings yet

- R7410309 Unconventional Machining ProcessesDocument1 pageR7410309 Unconventional Machining ProcessessivabharathamurthyNo ratings yet

- WWW - Manaresults.co - In: Utilization of Electrical EnergyDocument1 pageWWW - Manaresults.co - In: Utilization of Electrical EnergyDr Maheswari C - PSGCTNo ratings yet

- Time 3 HRS.) : 2 Part 'B' in Rest of The Sheets of Answer SheetDocument24 pagesTime 3 HRS.) : 2 Part 'B' in Rest of The Sheets of Answer SheetSaurabh Kumar 53No ratings yet

- B.E. (Mechanical Engineering) : Advanced Manufacturing Processes (2012 Pattern) (Semester - I)Document3 pagesB.E. (Mechanical Engineering) : Advanced Manufacturing Processes (2012 Pattern) (Semester - I)N1234mNo ratings yet

- WWW - Manaresults.co - In: Set No. 1Document4 pagesWWW - Manaresults.co - In: Set No. 1Sathya Bhuvaneswari KavalaNo ratings yet

- Set No. 1Document4 pagesSet No. 1Manjari ArasadaNo ratings yet

- Production TechnologyDocument4 pagesProduction TechnologysandchinniNo ratings yet

- r05310303 Production TechnologyDocument4 pagesr05310303 Production TechnologySrinivasa Rao GNo ratings yet

- DOM LAB ManualDocument45 pagesDOM LAB ManualStephen JacsiNo ratings yet

- AHPMEDocument1 pageAHPMEStephen JacsiNo ratings yet

- Me1975 Material Selection and Design: Two Marks QuestionDocument2 pagesMe1975 Material Selection and Design: Two Marks QuestionStephen JacsiNo ratings yet

- (A) (OR) (B) - (A) - (OR) (B)Document2 pages(A) (OR) (B) - (A) - (OR) (B)Stephen JacsiNo ratings yet

- Anna University Practical Exam MarksDocument3 pagesAnna University Practical Exam MarksStephen JacsiNo ratings yet

- Me1975 Material Selection and Design: Two Marks QuestionDocument2 pagesMe1975 Material Selection and Design: Two Marks QuestionStephen JacsiNo ratings yet

- Me1975 Material Selection and Design: Two Marks QuestionDocument2 pagesMe1975 Material Selection and Design: Two Marks QuestionStephen JacsiNo ratings yet

- DRC QP 4Document3 pagesDRC QP 4Stephen JacsiNo ratings yet

- DRC QP 3Document2 pagesDRC QP 3Stephen JacsiNo ratings yet

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.Stephen JacsiNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.Stephen JacsiNo ratings yet

- Estimation QP 1Document4 pagesEstimation QP 1Stephen JacsiNo ratings yet

- DatasheetDocument35 pagesDatasheetHeru susantoNo ratings yet

- How Tall A Column in Block Caving 2014-May-2Document11 pagesHow Tall A Column in Block Caving 2014-May-2carlo cerruttiNo ratings yet

- CFD Analysis of A Wickless Heat Pipe: January 2018Document8 pagesCFD Analysis of A Wickless Heat Pipe: January 2018Optimuz TsNo ratings yet

- 01 02 JournalDocument2 pages01 02 JournalDavisha DixonNo ratings yet

- GRAVEL Packer Tool OperationDocument7 pagesGRAVEL Packer Tool OperationCerón Niño Santiago100% (2)

- Kirchhoff-Love Plate Theory - Wikipedia, The Free EncyclopediaDocument12 pagesKirchhoff-Love Plate Theory - Wikipedia, The Free EncyclopediaV ARUL RAJNo ratings yet

- A Typical Coal-Fired Power Plant Generates 1000 MW of Usable - QuizletDocument6 pagesA Typical Coal-Fired Power Plant Generates 1000 MW of Usable - QuizletBipin MishraNo ratings yet

- MTH108 Courseoutline F2023Document7 pagesMTH108 Courseoutline F2023ahmeddhillon1No ratings yet

- The Basic Theory of Crowning Industrial RollersDocument8 pagesThe Basic Theory of Crowning Industrial RollersJuan Carlos CárdenasNo ratings yet

- ResEng2 Exam-2018Document4 pagesResEng2 Exam-2018Nijat AhmadovNo ratings yet

- 2CDX CatalogueDocument4 pages2CDX CatalogueDMA ASIANo ratings yet

- RsDocument3 pagesRsAmul KotharkarNo ratings yet

- Lecture 6-7 Synthesis of Simple Planar MechanismsDocument12 pagesLecture 6-7 Synthesis of Simple Planar MechanismsmayankmaroliyaNo ratings yet

- Applied Architectural StructuresDocument471 pagesApplied Architectural StructuresSimonas PurneckasNo ratings yet

- WB Harmonic Shaker TableDocument10 pagesWB Harmonic Shaker TablenetkasiaNo ratings yet

- Maths S1 SBDocument252 pagesMaths S1 SBGAKWAYA AubinNo ratings yet

- Mitta 2021 2D Mater. 8 012002Document29 pagesMitta 2021 2D Mater. 8 012002César Arturo Niño CarmonaNo ratings yet

- Visual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)Document29 pagesVisual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)MAXX ENGINEERS100% (1)

- Probe Calibration WIPS - CHCDocument10 pagesProbe Calibration WIPS - CHCMarcosNo ratings yet

- Create Sheet Metal Bracket in SOLIDWORKSDocument16 pagesCreate Sheet Metal Bracket in SOLIDWORKSChokri AtefNo ratings yet

- Open System (1) ThermodynamicDocument38 pagesOpen System (1) ThermodynamicSakinah KamalNo ratings yet

- Physical Science SHS 24.1 Worksheet 3Document2 pagesPhysical Science SHS 24.1 Worksheet 3Ser Louis Fetilo FabunanNo ratings yet

- Reynolds Experiment (Body)Document13 pagesReynolds Experiment (Body)mutencoNo ratings yet

- Hydraulics - Civil Engineering Questions and Answers Page 3Document6 pagesHydraulics - Civil Engineering Questions and Answers Page 3umairNo ratings yet

- Foam protection Incubator POWer cord Instruction bookletDocument15 pagesFoam protection Incubator POWer cord Instruction bookletsanthosh100% (1)

- ASTM E1085-09 (Analysis of Low-Alloy Steels by XRF)Document6 pagesASTM E1085-09 (Analysis of Low-Alloy Steels by XRF)Said Mohamed100% (1)

- Ce122:Hydrology: Kristine R. Cervancia, Rce, MsceDocument19 pagesCe122:Hydrology: Kristine R. Cervancia, Rce, MsceKristine CervanciaNo ratings yet

- Barber, T. (2007) A Study of Water Surface Deformation Due To Tip Vortices Wing-In-Ground Effect, Journal of Ship Research, 51 (02), Pp. 182-186.Document5 pagesBarber, T. (2007) A Study of Water Surface Deformation Due To Tip Vortices Wing-In-Ground Effect, Journal of Ship Research, 51 (02), Pp. 182-186.Samson Paul PintoNo ratings yet

- Intuitive Intelligence: Accessing The Wisdom of Head, Heart and HaraDocument5 pagesIntuitive Intelligence: Accessing The Wisdom of Head, Heart and HaradNo ratings yet

- Gaudi ColumnasDocument14 pagesGaudi Columnasmariana avila alvarezNo ratings yet