Professional Documents

Culture Documents

9A03708 Modern Manufacturing Methods

Uploaded by

sivabharathamurthyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9A03708 Modern Manufacturing Methods

Uploaded by

sivabharathamurthyCopyright:

Available Formats

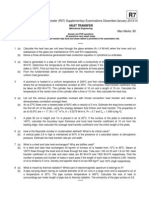

Code: 9A03708 B.

Tech IV Year I Semester (R09) Regular Examinations November 2012

1

MODERN MANUFACTURING METHODS

(Mechanical Engineering)

Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1.

Max. Marks: 70

Explain the need for the use of non-traditional machining processes compared to the traditional ones.

2. (a) Discuss the effects of the following parameters on MRR as applied to usm process: (i) Amplitude and frequency of vibrations. (ii) Grain size. (iii) Applied static load. (iv) Effect of slurry. (b) Discuss briefly the advantages and disadvantages of ultrasonic machining. 3. (a) With a neat sketch explain the working principle of abrasive jet machining. (b) Mention the advantages and applications of water jet machining. 4. Explain the principle, working and advantages of electro chemical machining process.

5. (a) Explain the mechanics of material removal in electrical discharge machining. (b) What are the functions served by the dielectric fluid in EDM? 6. Explain the process of laser beam machining highlighting the applications, advantages and disadvantages of the process.

7. (a) What is the principle involved in chemical machining? Explain with suitable sketches. (b) What is the role of Maskants and Etchants in chemical machinery? Name few. 8. What is rapid prototyping? Explain the process of stereo lithography for manufacturing prototypes.

*****

Code: 9A03708 B.Tech IV Year I Semester (R09) Regular Examinations November 2012

2

MODERN MANUFACTURING METHODS

(Mechanical Engineering)

Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1.

Max. Marks: 70

Give a comparison of the non-traditional processes in terms of process, material removal rate and applications.

2. (a) Explain how material is removed in ultrasonic machining. (b) Briefly explain the functions of transducer and tool cone in usm. 3. With a neat sketch explain the principle of working of water jet machining highlighting the advantages and limitations of the process. What are the various Electro chemical processes used for material removal? Enumerate the principle differences in working in these processes.

4.

5. (a) Explain the principle of EDM with a neat sketch. (b) What are the characteristics required for a good electrode material in electrical discharge machining? 6. Explain the principle, applications, merits and demerits of electron beam machining of process.

7. (a) Explain plasma Arc machining process with a neat sketch. (b) Mention advantages, disadvantages and applications of plasma Arc machining process. 8. How are rapid prototyping techniques different than conventional techniques? Explain the process of selective laser sintering in producing prototypes? *****

Code: 9A03708 B.Tech IV Year I Semester (R09) Regular Examinations November 2012

3

MODERN MANUFACTURING METHODS

(Mechanical Engineering)

Time: 3 hours Answer any FIVE questions All questions carry equal marks *****

Max. Marks: 70

1. (a) Explain the reasons, why the non-traditional machining processes are used. (b) Explain the basic differences between traditional and non-traditional machining process. 2. Explain the principle and working of ultrasonic machining process. List out the advantages and applications of the process. What is abrasive water jet machining? Explain its principle of operation.

3.

4. (a) Explain the process parameters that affect the material removal rate and surface quality in electro chemical machining. (b) Explain the principle of Electro chemical grinding. 5. (a) What are the important parameters that control the material removal rate in electrical discharge machining? Briefly explain any two factors. (b) Write a short note on wire electric discharge machining process. 6. What is electron beam machining? Sketch its set up and indicate its main elements on it? What are the advantages and disadvantages of the process? Explain the steps involved in chemical machining with sketch. What are the advantages and applications of the process?

7.

8. (a) Explain the principle of operation of magnetic abrasive finishing process. (b) Explain the principle applications of electro stream drilling process. *****

Code: 9A03708 B.Tech IV Year I Semester (R09) Regular Examinations November 2012

4

MODERN MANUFACTURING METHODS

(Mechanical Engineering)

Time: 3 hours Answer any FIVE questions All questions carry equal marks *****

Max. Marks: 70

1. (a) What do you understand by the term non-traditional machining methods? What is their importance? (b) Classify the common non-traditional methods. Give a list of such operations. 2. With a neat sketch explain the elements involved in the ultrasonic machining process.

3. (a) What is abrasive jet machining process? Explain its principle of operation. (b) What are the main advantages, disadvantages and industrial applications of abrasive jet machining? 4. (a) What are the principle features of ECM process? Briefly explain the working of an electro chemical machine. (b) What are the functions served by the Electrolyte in electro chemical machining? 5. (a) Explain the generation and control of Electron beam in electron beam machining process. (b) Explain the advantages and industrial applications of electron beam machining process. 6. Explain the process parameters that effect the material removal rate and surface quality in plasma machining.

7. (a) Explain why the tool shape in EDM should be complimentary to the final form. (b) Draw a typical relaxation circuit used for the EDM power supply and derive the expression for the material removal rate. 8. What are the various rapid prototyping techniques available commercially? Explain the difference between selective laser sintering and stereo lithography in terms of principle of working. *****

You might also like

- DIY Guide Rails Plans VSC ToolsDocument22 pagesDIY Guide Rails Plans VSC ToolsMiguel TravahoNo ratings yet

- 1.machine Tool Design Assignment 2017Document6 pages1.machine Tool Design Assignment 2017Charles OndiekiNo ratings yet

- CM7202-Applied Materials EngineeringDocument6 pagesCM7202-Applied Materials EngineeringJayaraman TamilvendhanNo ratings yet

- Checklist - Internal Painting WorkDocument7 pagesChecklist - Internal Painting WorkR HarshavardhanaNo ratings yet

- Solvent Ink Parameters Flexo PrintingDocument3 pagesSolvent Ink Parameters Flexo Printingsherifamer85100% (1)

- Topside Painting and Corrosion Protection SpecificationDocument47 pagesTopside Painting and Corrosion Protection SpecificationRaimundo MirandaNo ratings yet

- Inspection & Test Plan FOR Concrete Work: Equipment Description: NADocument40 pagesInspection & Test Plan FOR Concrete Work: Equipment Description: NAYuvaraj PonrajNo ratings yet

- Duties of Welding InspectorDocument11 pagesDuties of Welding Inspectormuhammadazhar50% (2)

- MP 2 Unit II MachinabilityDocument15 pagesMP 2 Unit II MachinabilitySuraj NKNo ratings yet

- Chemical Machining Process OverviewDocument25 pagesChemical Machining Process OverviewAbhishek KumarNo ratings yet

- ANNA UNIVERSITY MECHANICAL ENGINEERING SIMULATION LAB EXAMDocument5 pagesANNA UNIVERSITY MECHANICAL ENGINEERING SIMULATION LAB EXAMAsst.Prof MECH100% (1)

- Anna University Exam Paper Theory of Metal Cutting: Production EngineeringDocument3 pagesAnna University Exam Paper Theory of Metal Cutting: Production EngineeringAkash Kumar DevNo ratings yet

- Assignment Question Set On Modern Manufacturing ProcessDocument1 pageAssignment Question Set On Modern Manufacturing ProcessSagar KhanNo ratings yet

- JNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESDocument1 pageJNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESConor StevensonNo ratings yet

- U2 Working & AuxiliaryDocument48 pagesU2 Working & AuxiliaryNurye Nigus100% (1)

- Sathyabama Question PaperDocument3 pagesSathyabama Question PaperamiestudentNo ratings yet

- Ch31 Solid-State WeldingDocument28 pagesCh31 Solid-State WeldingNaveen KumarNo ratings yet

- At8003 It - 1 QB MmaDocument1 pageAt8003 It - 1 QB MmaVinoth KumarNo ratings yet

- MF7203-Dec 16 THEORY-OF-METAL-FORMINGDocument3 pagesMF7203-Dec 16 THEORY-OF-METAL-FORMINGupender100% (1)

- ME 2252 MANUFACTURING TECHNOLOGY – II: Abrasive Processes and Gear CuttingDocument87 pagesME 2252 MANUFACTURING TECHNOLOGY – II: Abrasive Processes and Gear CuttingTariq Aziz100% (2)

- ME83691-Computer Aided Design and ManufacturingDocument15 pagesME83691-Computer Aided Design and Manufacturingraman thiru55No ratings yet

- Fitting Models: Semi Circular JointDocument2 pagesFitting Models: Semi Circular Jointsubba reddyNo ratings yet

- Me8501-Metrology and Measurements Course PlanDocument3 pagesMe8501-Metrology and Measurements Course PlanNeopolean0% (1)

- CAD/CAM Lab Course Outcomes SEODocument3 pagesCAD/CAM Lab Course Outcomes SEORammohan ReddyNo ratings yet

- Mechanics of Material - SyllabusDocument2 pagesMechanics of Material - SyllabusRahul PatilNo ratings yet

- MFT 2 TWO Marks With AnswersDocument28 pagesMFT 2 TWO Marks With AnswersThulasi RamNo ratings yet

- Mems Descriptive Question and Answers Jntu AnantapurDocument10 pagesMems Descriptive Question and Answers Jntu AnantapurSai kiran0% (1)

- Question Bank III B.Tech-II Sem Design of Machine Members-Ii Unit - I A Design of Curved Beams Short Answer QuestionsDocument11 pagesQuestion Bank III B.Tech-II Sem Design of Machine Members-Ii Unit - I A Design of Curved Beams Short Answer Questionsprasaad08No ratings yet

- ASSIGNMENT - Modelling and Simulation of Manufacturing SystemDocument1 pageASSIGNMENT - Modelling and Simulation of Manufacturing SystemShabbir WahabNo ratings yet

- RP Question BankDocument4 pagesRP Question BankAkshay IyerNo ratings yet

- Question Bank - All UnitsDocument11 pagesQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- 2mark With Answer UCM M.E 6004 PDFDocument22 pages2mark With Answer UCM M.E 6004 PDFl8o8r8d8s8i8v8100% (1)

- IIT Roorkee Advanced Manufacturing ProcessesDocument92 pagesIIT Roorkee Advanced Manufacturing Processesvishal guptaNo ratings yet

- 5 Machinability and Machining EconomicsDocument48 pages5 Machinability and Machining Economicssakali aliNo ratings yet

- Module 2Document7 pagesModule 2sathiaNo ratings yet

- Chapter 1 - Introduction To Hybrid Machining ProcessesDocument31 pagesChapter 1 - Introduction To Hybrid Machining ProcessesGAURAV KUMAR100% (1)

- Solved Problems (1) Draw The Cam Profile For Following ConditionsDocument6 pagesSolved Problems (1) Draw The Cam Profile For Following Conditionsrakesh kumarNo ratings yet

- ME8491 Engineering Metallurgy COURSE PLANDocument4 pagesME8491 Engineering Metallurgy COURSE PLANKarthick NNo ratings yet

- Electrical Actuation SystemDocument8 pagesElectrical Actuation SystemShriyash KamatNo ratings yet

- An Introduction To CNC MachinesDocument20 pagesAn Introduction To CNC MachinesBHAVESHNo ratings yet

- (Assignment) Manufacturing ProcessDocument1 page(Assignment) Manufacturing ProcessRAMAKANT RANA100% (1)

- Mid Semester Exam Paper Contains 02 PagesDocument2 pagesMid Semester Exam Paper Contains 02 PagesBabuli KumarNo ratings yet

- KINEMATICS OF MACHINERY: UNIT 2: VELOCITY & ACCELARATION: Objective Questions From Gate With SolutionsDocument7 pagesKINEMATICS OF MACHINERY: UNIT 2: VELOCITY & ACCELARATION: Objective Questions From Gate With SolutionsVenkateswar Reddy MallepallyNo ratings yet

- Design of Transmission System Question BankDocument18 pagesDesign of Transmission System Question BankAravind50% (2)

- Chap 3 DieterDocument25 pagesChap 3 DieterTumelo InnocentNo ratings yet

- Question Bank 3D PrintingDocument2 pagesQuestion Bank 3D PrintingSujit Mule100% (1)

- 02 Taylors Tool Life Problems UpdatedDocument2 pages02 Taylors Tool Life Problems Updated19G133 VASANTH B100% (1)

- Me8691-Computer Aided Design and ManufacturingDocument2 pagesMe8691-Computer Aided Design and ManufacturingGeorge Oliver100% (3)

- Manufacturing Process 1 Question BankDocument8 pagesManufacturing Process 1 Question Bankashok PradhanNo ratings yet

- Casting and Pattern Making ProcessesDocument11 pagesCasting and Pattern Making ProcessesAshok PradhanNo ratings yet

- Chapter 3 METROLOGY - IntroductionDocument14 pagesChapter 3 METROLOGY - IntroductionMadhu pspkNo ratings yet

- Engineering Workshop Notes, Viva Questions PDFDocument12 pagesEngineering Workshop Notes, Viva Questions PDFMbogi TokaNo ratings yet

- Me 8594 Dynamics of Machinery Unit 1 Online Video LectureDocument42 pagesMe 8594 Dynamics of Machinery Unit 1 Online Video LecturesankarNo ratings yet

- Dynamics of Machines Study MaterialDocument20 pagesDynamics of Machines Study Materialsara vanaNo ratings yet

- Lecture Notes Set 2 - Designing Mechatronic SystemsDocument14 pagesLecture Notes Set 2 - Designing Mechatronic SystemsMark AzzopardiNo ratings yet

- Me2304 - Engineering Metrology and Measurements Question Bank For Regulation 2008Document29 pagesMe2304 - Engineering Metrology and Measurements Question Bank For Regulation 2008Ashok Kumar Rajendran75% (4)

- Experimental Stress Analysis PaperDocument2 pagesExperimental Stress Analysis PaperAbdul FattahNo ratings yet

- Measurement question bank covering pressure, displacement, strain, flow, vacuum, velocity, acceleration and temperatureDocument3 pagesMeasurement question bank covering pressure, displacement, strain, flow, vacuum, velocity, acceleration and temperaturePrithvi ManwaniNo ratings yet

- UNIT-IV Question BankDocument3 pagesUNIT-IV Question BankParamasivam VeerappanNo ratings yet

- Design of Hydraulic and Pneumatic Systems - QPDocument11 pagesDesign of Hydraulic and Pneumatic Systems - QPKarthik SubramaniNo ratings yet

- ME 2354 Automobile Engineering 2009 6th Semester Anna UniversityDocument2 pagesME 2354 Automobile Engineering 2009 6th Semester Anna UniversityParanthaman GanapathyNo ratings yet

- Bcme NotesDocument112 pagesBcme NotesSms RajaNo ratings yet

- Powder Metallurgy Fig Q A For StudentsDocument6 pagesPowder Metallurgy Fig Q A For StudentsRavinder Antil100% (2)

- RR 410309 Unconventional Machining ProcessesDocument4 pagesRR 410309 Unconventional Machining ProcessesSRINIVASA RAO GANTANo ratings yet

- Ucm Anna Univ Question PapersDocument24 pagesUcm Anna Univ Question PapersNarayanan SubramanianNo ratings yet

- Control Systems (CS) Notes As Per JntuaDocument203 pagesControl Systems (CS) Notes As Per Jntuasivabharathamurthy100% (3)

- 07A4EC01 Environmental StudiesDocument1 page07A4EC01 Environmental StudiessivabharathamurthyNo ratings yet

- 9A13701 Robotics and AutomationDocument4 pages9A13701 Robotics and AutomationsivabharathamurthyNo ratings yet

- SSC Social Textbook (AP)Document100 pagesSSC Social Textbook (AP)sivabharathamurthyNo ratings yet

- SSC Telugu (FL) (AP)Document232 pagesSSC Telugu (FL) (AP)sivabharathamurthyNo ratings yet

- R7410407 Operating SystemsDocument1 pageR7410407 Operating SystemssivabharathamurthyNo ratings yet

- R7410506 Mobile ComputingDocument1 pageR7410506 Mobile ComputingsivabharathamurthyNo ratings yet

- R7312301 Transport Phenomena in BioprocessesDocument1 pageR7312301 Transport Phenomena in BioprocessessivabharathamurthyNo ratings yet

- R7311006 Process Control InstrumentationDocument1 pageR7311006 Process Control InstrumentationsivabharathamurthyNo ratings yet

- Code: R7311306: (Electronics & Control Engineering)Document1 pageCode: R7311306: (Electronics & Control Engineering)sivabharathamurthyNo ratings yet

- R7310506 Design & Analysis of AlgorithmsDocument1 pageR7310506 Design & Analysis of AlgorithmssivabharathamurthyNo ratings yet

- R7311205 Distributed DatabasesDocument1 pageR7311205 Distributed DatabasessivabharathamurthyNo ratings yet

- R5410201 Neural Networks & Fuzzy LogicDocument1 pageR5410201 Neural Networks & Fuzzy LogicsivabharathamurthyNo ratings yet

- 9A05707 Software Project ManagementDocument4 pages9A05707 Software Project ManagementsivabharathamurthyNo ratings yet

- R7310106 Engineering GeologyDocument1 pageR7310106 Engineering GeologysivabharathamurthyNo ratings yet

- R7310406 Digital CommunicationsDocument1 pageR7310406 Digital CommunicationssivabharathamurthyNo ratings yet

- R7311506 Operating SystemsDocument1 pageR7311506 Operating SystemssivabharathamurthyNo ratings yet

- R7310206 Linear Systems AnalysisDocument1 pageR7310206 Linear Systems AnalysissivabharathamurthyNo ratings yet

- R5310204 Power ElectronicsDocument1 pageR5310204 Power ElectronicssivabharathamurthyNo ratings yet

- R7310306 Heat TransferDocument1 pageR7310306 Heat Transfersivabharathamurthy100% (1)

- R5310406 Digital CommunicationsDocument1 pageR5310406 Digital CommunicationssivabharathamurthyNo ratings yet

- 9A21506 Mechanisms & Mechanical DesignDocument8 pages9A21506 Mechanisms & Mechanical DesignsivabharathamurthyNo ratings yet

- 9A15502 Digital System DesignDocument4 pages9A15502 Digital System Designsivabharathamurthy100% (1)

- 9A10505 Principles of CommunicationsDocument4 pages9A10505 Principles of CommunicationssivabharathamurthyNo ratings yet

- 9A05505 Operating SystemsDocument4 pages9A05505 Operating SystemssivabharathamurthyNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- 9A23501 Heat Transfer in BioprocessesDocument4 pages9A23501 Heat Transfer in BioprocessessivabharathamurthyNo ratings yet

- 9A04504 Digital IC ApplicationsDocument4 pages9A04504 Digital IC ApplicationssivabharathamurthyNo ratings yet

- 9A02505 Electrical Machines-IIIDocument4 pages9A02505 Electrical Machines-IIIsivabharathamurthyNo ratings yet

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyNo ratings yet

- Furniture Design - BOQ PDFDocument1 pageFurniture Design - BOQ PDFMadhumitha kannanNo ratings yet

- Repair Pro - Dr. Fixit Polymer Mortar HBDocument4 pagesRepair Pro - Dr. Fixit Polymer Mortar HBAdityaVikramVermaNo ratings yet

- Approval of Powder Coatings - Quick Guide: Working Group of Technical CommitteeDocument6 pagesApproval of Powder Coatings - Quick Guide: Working Group of Technical CommitteeF.Javier LobeiraNo ratings yet

- Perch Repair ProcDocument3 pagesPerch Repair ProcTomás ZamakonaNo ratings yet

- VentureDeckingInstallationInstructions LRDocument13 pagesVentureDeckingInstallationInstructions LRGhislainTremblayNo ratings yet

- Dremel Catalog 2013Document70 pagesDremel Catalog 2013wdowiuueNo ratings yet

- Technicut and Delcam Revolutionise Blisk MachiningDocument8 pagesTechnicut and Delcam Revolutionise Blisk MachiningjimNo ratings yet

- Annular Cutter Feeds and SpeedsDocument1 pageAnnular Cutter Feeds and SpeedsAnonymous JzEb8CXErNo ratings yet

- Fabrication CostDocument4 pagesFabrication CostVasudev BhanajiNo ratings yet

- PLT5110 B Rev ADocument2 pagesPLT5110 B Rev AArielNo ratings yet

- Jotafloor Solvent Free Primer - English (Uk) - Issued.Document3 pagesJotafloor Solvent Free Primer - English (Uk) - Issued.Mohamed FaragNo ratings yet

- Iso 10684Document26 pagesIso 10684Jay GaneshNo ratings yet

- Welding Procedure Qualification Record: Welded ToDocument6 pagesWelding Procedure Qualification Record: Welded ToParis VNo ratings yet

- Removal of Chromium From Tanning Wastewater by Chemical Precipitation and ElectrocoagulationDocument13 pagesRemoval of Chromium From Tanning Wastewater by Chemical Precipitation and ElectrocoagulationMiluska CaceresNo ratings yet

- Tds-Cpd-Sikalastic 601 BC-usDocument5 pagesTds-Cpd-Sikalastic 601 BC-usgamini pereraNo ratings yet

- Spayer Magnum 1019d - Parts - BreakdownDocument1 pageSpayer Magnum 1019d - Parts - Breakdowndoddy septianNo ratings yet

- For Public Comment: Draft Malaysian StandardDocument60 pagesFor Public Comment: Draft Malaysian StandardKeith ChooNo ratings yet

- Deutz Fahr Agrotron 100 Tractor Parts Catalogue ManualDocument22 pagesDeutz Fahr Agrotron 100 Tractor Parts Catalogue ManuallaopaodunNo ratings yet

- Premium Satin Enamel for Wood, Wall & MetalDocument6 pagesPremium Satin Enamel for Wood, Wall & MetalAr. Libin K BabyNo ratings yet

- Information Sheet 1.1-8: Welding Techniques & Procedures Learning ObjectivesDocument1 pageInformation Sheet 1.1-8: Welding Techniques & Procedures Learning ObjectivesRose Ann Pegarro AlamanNo ratings yet

- Epikote 828Document2 pagesEpikote 828Lê TiếnNo ratings yet

- Bunsen BurnerDocument5 pagesBunsen BurnerRachelHechanovaNo ratings yet

- Design of Single Point Cutting ToolDocument13 pagesDesign of Single Point Cutting ToolChinmay Das82% (11)

- Wood Powder in Lime Kilns PDFDocument16 pagesWood Powder in Lime Kilns PDFFerNo ratings yet