Professional Documents

Culture Documents

Lesson 9 - Estimating & Comparing Weld Metal Costs 4

Lesson 9 - Estimating & Comparing Weld Metal Costs 4

Uploaded by

Elwe SingoloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson 9 - Estimating & Comparing Weld Metal Costs 4

Lesson 9 - Estimating & Comparing Weld Metal Costs 4

Uploaded by

Elwe SingoloCopyright:

Available Formats

Lesson 9 - Estimating & Comparing Weld Metal Costs http://www.esabna.com/euweb/awtc/lesson9_8.

htm

Current

Lesson 1 Chapter

LESSON IX

The Basics of Arc Table of

Welding Contents

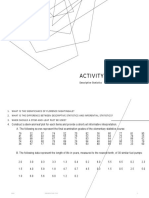

ELEC. DEPOSITION 2" 3" 4" 5"

LENGTH EFFICIENCY STUB STUB STUB STUB

60% 50.0% 45.0% 40.0% 35.0%

Lesson 2

Common Electric 65% 54.2% 48.7% 43.3% 37.9%

Arc Welding 12" 70% 58.3% 52.5% 46.6% 40.8%

Processes 75% 62.5% 56.2% 50.0% 43.7%

80% 66.6% 60.0% 53.3% 46.6%

STUB LOSS CORRECTION

60% 51.4% 47.1% 42.8% 38.5% Go To Test

TABLE FOR COATED

Lesson 3 65% 55.7% 51.1% 46.4% 41.8%

Covered Electrodes ELECTRODES

14" 70% 60.0% 55.0% 50.0% 45.0%

for Welding EFFICIENCY INCLUDING Print

75% 64.3% 58.9% 53.6% 48.2%

Mild Steels STUB LOSS

80% 68.5% 62.8% 57.1% 51.4%

FIGURE 5 60% 53.3% 50.0% 46.6% 43.3%

Lesson 4 65% 57.7% 54.2% 50.5% 46.9%

Glossary

Covered Electrodes 18" 70% 62.2% 58.3% 54.4% 50.5%

for Welding Low 75% 66.6% 62.5% 58.3% 54.2%

Alloy Steels 80% 71.1% 66.6% 62.2% 57.7%

9.2.6 Efficiency of Flux Cored Wires - Flux cored wires have a lower flux-to-metal ratio

Lesson 5 than coated electrodes, and thereby, a higher deposition efficiency. Stub loss need not be

Welding Filler Metals

for Stainless Steels considered since the wire is continuous. The gas shielded wires of the E70T-1 and E70T-2

types have efficiencies of 83%-88%. The gas shielded basic slag type (E70T-5) is 85%-90%

efficient with CO2 as the shielding gas, and the efficiency can reach 92% when a 75% argon, Turn Pages

Lesson 6 25% CO2 gas mixture is used. Use the efficiency figures in Figure 9 for your calculations if the

Carbon & Low Alloy

actual values are not known.

Steel Filler Metals -

GMAW,GTAW,SAW

9.2.6.1 The efficiency of the self-shielded types of flux cored wires has more variation

because of the large variety of available types that have been designed for specific applica- Search

Lesson 7

Flux Cored Arc tions. The high deposition general purpose type, such as E70T-4, is 81%-86%, depending on Chapter

Electrodes Carbon wire size and electrical stick-out. The chart in Figure 9 shows the optimum conditions for each (Faster

Low Alloy Steels Download)

wire size and may be used in your calculations.

Search

9.2.7 Efficiency of Solid Wires for GMAW - The efficiency of solid wires in GMAW is Document

Lesson 8 (Slower

very high and will vary with the shielding gas or gas mixture used. Using CO2 will produce the

Hardsurfacing Download)

Electrodes most spatter and the average efficiency will be about 93%. Using a 75% argon-25% CO2 gas

mixture will result in somewhat less spatter, and an efficiency of approximately 96% can be

expected. A 98% argon-2% oxygen mixture will produce even less spatter, and the average

Lesson 9

efficiency will be about 98%. Stub loss need not be considered since the wire is continuous.

Estimating &

Comparing Weld Figure 6 shows the average efficiencies you may use in your calculations if the actual effi-

Metal Costs ciency is not known.

Lesson 10

Reliability of Welding

Filler Metals

© COPYRIGHT 2000 THE ESAB GROUP, INC.

1 de 1 17/03/2016 10:58 p.m.

You might also like

- Sample TOS in Agri. Crop ProductionDocument20 pagesSample TOS in Agri. Crop ProductionNelgen100% (4)

- Installation and Operation Manual: 723PLUS Digital Speed Control For Reciprocating Engines - Analog Load SharingDocument176 pagesInstallation and Operation Manual: 723PLUS Digital Speed Control For Reciprocating Engines - Analog Load SharingMilton Andres Leon HernandezNo ratings yet

- Marketing Plan (Pizza Hut)Document13 pagesMarketing Plan (Pizza Hut)Anjali10183% (48)

- What Makes A MoatDocument5 pagesWhat Makes A MoatMohammed ShakilNo ratings yet

- Presentation On ShutteringDocument29 pagesPresentation On ShutteringMukul KumarNo ratings yet

- L&T SwitchgearDocument40 pagesL&T SwitchgearRemo GagalNo ratings yet

- Chloride 80-Net Ups ManualDocument126 pagesChloride 80-Net Ups ManualSleman Shackoor100% (2)

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocument7 pagesAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloNo ratings yet

- Lab Report 4Document17 pagesLab Report 4Lee Yann LynnNo ratings yet

- Eightcheck-3Wp Assay Sheet: Normal LevelDocument5 pagesEightcheck-3Wp Assay Sheet: Normal LevelLeonard OnsikNo ratings yet

- Handbook - Calculations3Document1 pageHandbook - Calculations3Anonymous 7IKdlmNo ratings yet

- Handbook - Calculations 3 PDFDocument1 pageHandbook - Calculations 3 PDFSmith SivaNo ratings yet

- Stub Loss Correction Table For Coated ElectrodesDocument1 pageStub Loss Correction Table For Coated ElectrodesTAMILNo ratings yet

- Lesson 9 - Deposition Charts CompletoDocument4 pagesLesson 9 - Deposition Charts CompletoElwe SingoloNo ratings yet

- Lesson 4 - Covered Electrodes For Welding Low Alloy Steels TablaDocument1 pageLesson 4 - Covered Electrodes For Welding Low Alloy Steels TablaElwe SingoloNo ratings yet

- DATA SHEET CABLE Commscope Cat5E 5NF4 4286104 - 10Document5 pagesDATA SHEET CABLE Commscope Cat5E 5NF4 4286104 - 10Dinatel ComercialNo ratings yet

- Homework N ° 1: Plot of The Isobars of The Binary MixtureDocument4 pagesHomework N ° 1: Plot of The Isobars of The Binary MixtureFahad AlasmiNo ratings yet

- Homework N ° 1: Plot of The Isobars of The Binary MixtureDocument4 pagesHomework N ° 1: Plot of The Isobars of The Binary MixtureFahad AlasmiNo ratings yet

- Chart Title: Nilai KekerasanDocument3 pagesChart Title: Nilai KekerasanIbnu AwallaNo ratings yet

- Hasil Perhitungan SPSS - EditDocument10 pagesHasil Perhitungan SPSS - EditKing AsNo ratings yet

- FPF Wpa 017Document1 pageFPF Wpa 017Iraj OsouliNo ratings yet

- Learning Activity in Lesson 3Document5 pagesLearning Activity in Lesson 3Carl Stephen Martinez TiongsonNo ratings yet

- Cable Selection Table For CapacitorDocument1 pageCable Selection Table For CapacitorShashiSharmaNo ratings yet

- AssignmentDocument1 pageAssignmentomonaedwin2No ratings yet

- Exercise 2 RefractionDocument2 pagesExercise 2 Refractionjj jonaNo ratings yet

- Experiment-3: 3.1 FrequenciesDocument3 pagesExperiment-3: 3.1 FrequenciesSoham GuptaNo ratings yet

- 3 - MMC FU510xSHy - GBDocument2 pages3 - MMC FU510xSHy - GBHanis AmnaniNo ratings yet

- Policy Report Overview SlidesDocument20 pagesPolicy Report Overview SlidesAFRICA GREEN AGENo ratings yet

- C4 Inlet Bellmouth Casing (Top & Bottom Half) Coating ThicknessDocument19 pagesC4 Inlet Bellmouth Casing (Top & Bottom Half) Coating ThicknessDave CheungNo ratings yet

- (2V300Ah/5HR) : SpecificationDocument1 page(2V300Ah/5HR) : SpecificationRodrigo Alvaro Centellas AzeroNo ratings yet

- Category 5E Utp Cable, 200Mhz: DescriptionDocument3 pagesCategory 5E Utp Cable, 200Mhz: Descriptionarya wirantaraNo ratings yet

- AU Solutions Price List 01nov2019 PDFDocument40 pagesAU Solutions Price List 01nov2019 PDFPrasenjit MaityNo ratings yet

- Smaw 8 Tos2nd QDocument2 pagesSmaw 8 Tos2nd QJoan NayveNo ratings yet

- Modelo de Capas - Luis TristanDocument10 pagesModelo de Capas - Luis TristanLuis Gerardo Tristan BaezNo ratings yet

- 2 Volt 252 A.H.: Long Service LifeDocument2 pages2 Volt 252 A.H.: Long Service LifeJuan EsNo ratings yet

- Cera BeadsDocument7 pagesCera BeadsRjNo ratings yet

- Schneider Cable Actassi - Category 6 U UTP Solid Cable Datasheet MEDocument1 pageSchneider Cable Actassi - Category 6 U UTP Solid Cable Datasheet MEislah muttaqinNo ratings yet

- Mm0385-Rb-Djella-Ro34m-Gw19Document1 pageMm0385-Rb-Djella-Ro34m-Gw19manuel radulescuNo ratings yet

- Mono P-Type 490-510W 1500VDocument2 pagesMono P-Type 490-510W 1500Vfernando fernandezNo ratings yet

- CC 80tabla03datos TransfDocument1 pageCC 80tabla03datos TransfVISTAR RT8No ratings yet

- 04TR 171006 20171115Document139 pages04TR 171006 20171115JayamkondanNo ratings yet

- Soil 2-12-2023Document2 pagesSoil 2-12-2023mido_20067581No ratings yet

- Eightcheck 32240822Document5 pagesEightcheck 32240822Andreas avellinus dwi noviyanto100% (1)

- Cobertura Curricular Por Curso 1° Semestre 2023Document8 pagesCobertura Curricular Por Curso 1° Semestre 2023Inter ValdiviaNo ratings yet

- Tami 0Document4 pagesTami 0Kurniawan Dwi PutraNo ratings yet

- Contact Angle ResultsDocument6 pagesContact Angle ResultsNikki MalferrariNo ratings yet

- Quantum Mechanics: A Mathematical IntroductionDocument144 pagesQuantum Mechanics: A Mathematical Introductionroyce.schaden20No ratings yet

- Cable SpecificationDocument2 pagesCable SpecificationThero T KemeloNo ratings yet

- Activity 2Document2 pagesActivity 2Mimi DamascoNo ratings yet

- IJD950Document1 pageIJD950Paul RyanNo ratings yet

- Screenshot 2022-07-14 at 12.30.24Document44 pagesScreenshot 2022-07-14 at 12.30.24zakkNo ratings yet

- Tarea Calidad Del AireDocument6 pagesTarea Calidad Del Airenatalia yeraldine orozco velandiaNo ratings yet

- SBST 1303 AssigmentDocument10 pagesSBST 1303 AssigmentFreshlynero JonalNo ratings yet

- Project Report CompressedDocument65 pagesProject Report Compressedroopa rupaNo ratings yet

- Republic of The Philippines Department of Education Region XI Division of Compostela Valley Grade 9 - Science Second Quarter ExaminationDocument1 pageRepublic of The Philippines Department of Education Region XI Division of Compostela Valley Grade 9 - Science Second Quarter ExaminationBillones Rebalde MarnelleNo ratings yet

- Republic of The Philippines Department of Education Region XI Division of Compostela Valley Grade 9 - Science Second Quarter ExaminationDocument1 pageRepublic of The Philippines Department of Education Region XI Division of Compostela Valley Grade 9 - Science Second Quarter ExaminationBillones Rebalde MarnelleNo ratings yet

- Research Methodology: Program Subject CodeDocument3 pagesResearch Methodology: Program Subject CodePhelelaniNo ratings yet

- Eighcheck LOW 31400821Document5 pagesEighcheck LOW 31400821mekhaun081475496No ratings yet

- SPINDODocument1 pageSPINDOYulfikaenis MachroniNo ratings yet

- Station Class Surge Arresters IEEE and IECDocument4 pagesStation Class Surge Arresters IEEE and IECVictor BaqueroNo ratings yet

- Jaring Laba-Laba Cakupan Program Puskesmas Panombeian Panei Dari Januari - Juli 2017Document5 pagesJaring Laba-Laba Cakupan Program Puskesmas Panombeian Panei Dari Januari - Juli 2017Jaya SaragihNo ratings yet

- Cobb Egg Weight and Mass ChartDocument3 pagesCobb Egg Weight and Mass ChartAlbert SupraptoNo ratings yet

- Tensile Test On Cast IronDocument15 pagesTensile Test On Cast IronElmer Ibanez JrNo ratings yet

- Stress StrainDocument17 pagesStress Straina.h.alkamyaniNo ratings yet

- 8-c AP 8286LB 8286NB 8285H ExpDate 19-Jan-2019Document9 pages8-c AP 8286LB 8286NB 8285H ExpDate 19-Jan-2019Titik WulandariNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal CostsDocument1 pageLesson 9 - Estimating & Comparing Weld Metal CostsElwe SingoloNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal Costs 13Document1 pageLesson 9 - Estimating & Comparing Weld Metal Costs 13Elwe SingoloNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal Costs 9Document1 pageLesson 9 - Estimating & Comparing Weld Metal Costs 9Elwe SingoloNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal Costs 8Document1 pageLesson 9 - Estimating & Comparing Weld Metal Costs 8Elwe SingoloNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal Costs 7Document1 pageLesson 9 - Estimating & Comparing Weld Metal Costs 7Elwe SingoloNo ratings yet

- Demag tc1200 SpecificationsDocument14 pagesDemag tc1200 SpecificationsElwe SingoloNo ratings yet

- Ewens-Bassett Notation Inorganic Compounds - KauffmanDocument3 pagesEwens-Bassett Notation Inorganic Compounds - KauffmanJuano Valls FerrerNo ratings yet

- BASF Oil-Fortification Flyer FADocument2 pagesBASF Oil-Fortification Flyer FAPranjal GoelNo ratings yet

- From Stagnation To Stillness: by Sadhguru Jaggi VasudevDocument2 pagesFrom Stagnation To Stillness: by Sadhguru Jaggi VasudevrosarioNo ratings yet

- Lesson Plan SsDocument3 pagesLesson Plan Ssapi-338469786No ratings yet

- At The End of This Section, OUW LL Be Able To:: SC A o TextDocument9 pagesAt The End of This Section, OUW LL Be Able To:: SC A o TextMarissa LaingNo ratings yet

- Accurate Shadow RemovalDocument16 pagesAccurate Shadow RemovalAnu RamanujamNo ratings yet

- 3 Functions - Respiration: Respiratory SystemDocument7 pages3 Functions - Respiration: Respiratory SystemFranz Patrick Legria, CPAC - SNNo ratings yet

- The Title of HapDocument2 pagesThe Title of HapArunava MisraNo ratings yet

- Westphal BalanceDocument3 pagesWestphal BalanceJade Carlo AntonioNo ratings yet

- UM08001 JLinkDocument407 pagesUM08001 JLinkMarcioMartinhoFerreiraNo ratings yet

- Ethical Behavior: Step 1-LearnDocument10 pagesEthical Behavior: Step 1-Learnprince husainNo ratings yet

- Chapter 1Document159 pagesChapter 1Adam M KumNo ratings yet

- Tugas CP 4Document19 pagesTugas CP 4mrr dwi lindawati100% (1)

- Vietnam Special Report - Vietnam Industrial Market - Time For A Critical Makeover May 2020 PDFDocument28 pagesVietnam Special Report - Vietnam Industrial Market - Time For A Critical Makeover May 2020 PDFmtuấn_606116No ratings yet

- Spec Sheet - Trimble GA530 AntennaDocument2 pagesSpec Sheet - Trimble GA530 AntennaDaniel magallanesNo ratings yet

- Safe Systems of Work 2Document23 pagesSafe Systems of Work 2Hossam AbdelmoneimNo ratings yet

- 20 Securities Selection and Portfolio Construction and EvaluationDocument24 pages20 Securities Selection and Portfolio Construction and EvaluationShaikh Saifullah KhalidNo ratings yet

- Java Servlet File Upload ExampleDocument5 pagesJava Servlet File Upload ExampleBharat SoniNo ratings yet

- Entrepreneurship Assignment No 1 M.Com 2 (Evening)Document3 pagesEntrepreneurship Assignment No 1 M.Com 2 (Evening)Aftab AlamNo ratings yet

- MECH 2 Module 3 Unit 3 Impulse and MomentumDocument12 pagesMECH 2 Module 3 Unit 3 Impulse and MomentumIya AsperinNo ratings yet

- Lesson Plan TechnologyDocument3 pagesLesson Plan Technologyapi-340918753No ratings yet

- Lori Hurley Resume 1-14Document2 pagesLori Hurley Resume 1-14api-224457575No ratings yet

- 60trans PDFDocument20 pages60trans PDFjucamenNo ratings yet

- Pat Bahasa Inggris Kelas 5Document2 pagesPat Bahasa Inggris Kelas 5SMPIP Insan RobbaniNo ratings yet

- Types of GroupsDocument380 pagesTypes of GroupsCCNo ratings yet