0% found this document useful (0 votes)

513 views20 pagesFOPX614System Description

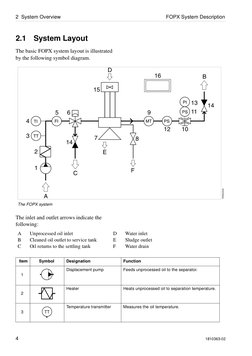

The document describes an FOPX separation system including a system overview describing key components and oil flow, and details of the ALCAP separation process used by the system. The process automatically adapts to changing water content in the unprocessed oil by continuously monitoring the oil and initiating actions like draining water or discharging sludge to maintain separation efficiency.

Uploaded by

Jerry ChenCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

513 views20 pagesFOPX614System Description

The document describes an FOPX separation system including a system overview describing key components and oil flow, and details of the ALCAP separation process used by the system. The process automatically adapts to changing water content in the unprocessed oil by continuously monitoring the oil and initiating actions like draining water or discharging sludge to maintain separation efficiency.

Uploaded by

Jerry ChenCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd