Professional Documents

Culture Documents

02.pre Check List (With Tool) For TR Installation - HEES A17-1018-1 - Rev.2 (2...

02.pre Check List (With Tool) For TR Installation - HEES A17-1018-1 - Rev.2 (2...

Uploaded by

Sohail AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02.pre Check List (With Tool) For TR Installation - HEES A17-1018-1 - Rev.2 (2...

02.pre Check List (With Tool) For TR Installation - HEES A17-1018-1 - Rev.2 (2...

Uploaded by

Sohail AhmedCopyright:

Available Formats

HEES A17-1018-1_rev.

2(2022)

Mandatory Pre Check list for

Transformer Installation

( )

HYUNDAI Electric

& Energy Systems

Contents (목차)

1. Introduction (도입)

1.1 Purpose of mandatory pre check list (현장 필수준비사항 체크리스트의 목적)

1.2 Client’s confirmation for site condition (고객 확인란)

2. Transformer installation process flow chart (변압기 설치 공정 흐름도)

3. Site condition check before Installation (설치전 현장 준비사항 확인)

3.1 Safety / environment regulation (안전/환경 규정)

3.2 Positioning of Transformer (변압기 안치)

3.3 Arrival of packing boxes (포장박스 도착 유무)

3.4 Construction of fire wall (방호벽 시공)

3.5 Transformer area condition (변압기 주변 여건)

3.6 Enough space to use crane (크레인 운용을 위한 공간)

3.7 Preparation of dry air (건조공기 준비)

3.8 Electric power at site (현장 내 전원 공급 유무)

3.9 Installation manpower (설치 인력)

3.10 Required tools & equipment (필요 공구 및 장비)

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022)

HYUNDAI Electric

1. Introduction (도입) & Energy Systems

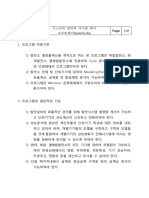

1.1 Purpose of mandatory pre check list (현장 필수 준비사항 체크리스트의 목적)

This is an essential requirement for the deputation of Hyundai Electric Transformer supervisor.

We, Hyundai Electric, need the client’s confirmation for the following site condition shown

following page to eliminate any idle time when supervisor arrives and does supervising

efficiently at site.

현장 필수 준비사항 체크리스트는 현대 일렉트릭 변압기 설치 슈퍼바이저의 투입전에 필수적으로 확인되어야 할 현장 준비사

항을 정리한 문서입니다. 원활한 변압기 설치 및 공정지연을 방지하기 위해 요청 드리오니, 각 페이지에 명시된 현장 준비사항

에 대한 확인을 부탁드립니다.

1.2 Client’s confirmation for site condition (현장상태에 대한 고객 확인란)

Please check "yes" or "no" in the “Checking by client" for site preparations of 10 items

specified on each page, and fill out and sign the customer information below.

각 페이지에 명시된 총 10가지의 현장준비 사항에 대해 “고객확인란”에 Yes 또는 No로 체크해 주시기 바라며, 아래에 명시된 고

객 정보에 대한 내용 기입 및 확인 서명을 부탁 드립니다.

Name of client (고객명) :

Name of site (현장명) :

Site address (현장 주소) :

Name of authorized personnel (현장 담당자) :

Signature (서명) :

Expected installation date of transformer (변압기설치 예상날짜) :

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 3

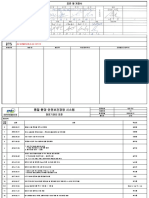

2. Transformer installation process flow chart

(변압기 설치 공정 흐름도)

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022)

2. Installation flow chart (설치 절차) HYUNDAI Electric

& Energy Systems

Initial inspection

(도착점검)

Parts assembly

(부품조립)

BCT & Bushing test prior to assembling

(조립전 BCT & 붓싱시험)

Internal lead connection & Assembling gas pipes

(내부결선 및 가스배관 조립)

Vacuum & oil filling / Circulation

(진공 & 절연유 주입 / 여과 작업)

Site test

(현장시험)

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 5

3. Site condition check

(현장준비상황 확인)

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022)

3.1 Safety/environment regulation (안전/환경 규정) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Special information about safety training and safety/environment regulation at site shall be

Yes □

shared with Hyundai Electric.

1

본 현장의 작업시에 고려해야 할 별도의 안전교육과 안전/환경 규정에 대한 정보는 현대 일

No □

렉트릭에게 사전에 알려주어야 합니다.

Hyundai electric’s request Client’s reply

If safety training is required before start installation, Please

inform us duration.

설치착수전에 안전교육을 이수해야 한다면, 이수기간에 대

한 정보를 공유해 주시기 바랍니다.

Should we get a work permit or submit approval request

before start each installation process?

각 공정을 진행하기 전에 작업허가를 받거나 승인요청서를

받아야 합니까?

Should we get a work permit or submit approval request

before start high place work for safety?

고소작업 전에 작업허가를 받거나 승인요청서를 제출해야

합니까?

Before worker enter the transformer inside, should we get a Client comment

work authorization?

변압기 내부작업을 진행하기 전에 별도의 작업승인을 받아

야 됩니까?

For oil treatment activity, should we submit approval

request document to get work permit?

절연유 공정을 위한 작업허가를 받기 위해 승인 서류를 제

출해야 합니까?

If there is special regulation at site, please inform us

detailed information.

만약 본 현장에서 작업시 참고해야 할 특별한 규정이 있다

면 그에 대한 상세정보를 공유해 주시기 바랍니다.

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 7

3.2 Positioning of transformer (변압기 안치) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

The positioning of transformer on its foundation has been completed and client shall send

Yes □

completion picture.

2.1

변압기는 기초의 정 위치에 안치되어야 하며, 고객은 안치완료 사진을 현대 일렉트릭과 공

No □

유해야 합니다.

♣ NOTE

Transformer shall be positioned on its

foundation before supervisor

dispatching for installation.

설치 슈퍼바이저가 현장에 투입되기전

에 변압기는 기초의 정 위치에 안치되

어야 합니다.

Client comment

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 8

3.2 Positioning of transformer (변압기 안치) HYUNDAI Electric

& Energy Systems

Photo Acknowledgment

NO. Description

by HE CSD

Please contact us after settling the transformer on the pad foundation with relevant site Yes □

2.2 photos.

Foundation의 변압기를 안착 한 후 관련 증빙 현장사진과 함께 연락바랍니다. No □

♣ NOTE

Please be noticed that the supervisor

deployment and mobilization request

Please attach the relevant site photos by client shall be received four (4) weeks in

advance.설치 슈퍼바이 배치 및 동원

요청은 4 주 전에 미리 접수되어야 합

니다.

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 9

3.3 Arrival of packing boxes (포장박스 도착유무) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

All packing boxes of transformer shall be available before arrival of supervisor at site and its

quantity is same compared to packing list submitted by manufacturer. Also it shall be kept

in safety place without damage in order to avoid the influence of weather. Yes □

3 모든 자재박스는 슈퍼바이저가 투입되기전에 현장에 준비되어야 하며, 포장박스의 수량은

현대 일렉트릭에서 제출한 포장목록과 비교하여 일치하여야 합니다. No □

또한 자재박스는 손상이 없는 상태에서 날씨로 인한 영향을 받지 않는 안전한 장소에 보관

되어야 합니다.

♣ NOTE

Before assembly, all packing box &

insulation oil shall be available at site.

절연유를 포함한 모든 자재박스는 현

장에 도착하여야 합니다.

Client comment

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 10

3.4 Construction of the firewall (방호벽 시공) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Yes □

Construction of the firewall of transformer area has been completed.

4

변압기는 기초 주변의 방호벽 시공이 완료되어 있어야 합니다.

No □

♣ NOTE

If we start transformer installation

under the condition that firewall is not

completed, it makes delay of

installation work.

방호벽 시공이 완료되지 않은 상태에

서 변압기 설치가 진행된다면 설치 지

연이 발생할 수 있습니다.

Client comment

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 11

3.5 Transformer area condition (변압기 주변 여건) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Transformer area has been cleaned as well without obstacle due to other process around

Yes □

transformer area and scaffolding, man-lifter & ladder shall be ready for high place work.

5

변압기 주변은 설치에 영향을 줄 수 있는 타 공정으로 인한 간섭물이 없는 상태여야 하며,

No □

고소작업을 위한 비계, 고소작업차 및 사다리가 준비되어 있어야 합니다.

♣ NOTE

scaffolding ladder The obstacle due to other process

makes delay of transformer

installation.

타 공정으로 인한 간섭물은 변압기 설

치 작업의 지연을 초래할 수 있습니다.

man-lifter Client comment

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 12

3.6 Enough space to use crane (크레인 운용을 위한 공간) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Enough space to use crane shall be available in front of each transformer without any

Yes □

abstacles. And during assembly stage, crane only for transformer should be at site.

6

크레인 운용을 위한 충분한 공간이 변압기 주변에 확보되어 있어야 합니다. 그리고 조립단

No □

계에서는 현장에 변압기 작업만을 위한 크레인이 준비되어야 합니다.

♣ NOTE

Crane is required ti lift heavy weight

parts and enough space for access &

operation should be available for

installation.

크레인은 외부부품을 들어올리기 위해

필요하며, 설치 시에 크레인의 접근 &

운용을 위한 충분한 공간이 확보되어

야 한다.

Client comment

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 13

3.7 Preparation of dry air (건조공기 준비) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Dry air & its accessory (hose, connecting adapter, regulator, etc.) shall be available at site. Yes □

7 건조공기 및 부속부품(주입호스, 연결아답터, 레귤레이터 등)이 현장에 준비되어 있어야 합

니다. No □

♣ NOTE

To reduce moisture saturation in

transformer inside, inject dry air during

assembly. Also, it is essential to

prevent accidents caused by oxygen

deficiency when worker enters

transformer inside to carry out bushing

lead connection & inside inspection.

외부의 수분이 변압기 내부로 유입되

지 않게 하기 위해 조립단계에서는 건

조공기를 변압기 내부에 주입해야 합

니다. 또한, 변압기 내부작업을 위해 작

업자가 내부로 들어갈 시 산소부족으

로 인한 안전사고를 막기 위해 건조공

기는 필수적으로 준비되어야 합니다.

Client comment

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 14

3.8 Electric power at site (현장 내 전원공급 유무) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Yes □

Enough capacity of electric power (or generator) and light shall be prepared.

8

충분한 용량의 전원 (또는 발전기)와 조명이 준비되어야 합니다.

No □

♣ NOTE

In cace that generator is available, it’s

capacity should be above 300kW for

equipment operation.

(For vacuum & oil filter machine)

현장에 발전기가 준비될 경우, 장비운

용을 위해 발전기의 용량은 300kW 이

상이 되어야 합니다.(진공기, 여과기용)

Client comment

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 15

3.9 Installation manpower (설치 인력) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Yes □

The skilled technicians and assistants shall be prepared as below.

9

변압기 설치 경험이 있는 숙련공 및 보조인원이 현장에 투입되어야 합니다.

No □

Detail Manpower

♣ NOTE

Skilled technicians means that he has

experiences of transformer installation

Initial inspection Skilled technician 2

minimum 5 years.

Assistant 2

(도착점검) 숙련공은 최소 5년 이상의 변압기 설치

경력이 있는 작업자를 의미합니다.

Skilled technician 4

Parts assembly Assistant 4

(부품조립) Electrician 2

BCT & Bushing test prior to assembling Skilled technician 2

(조립전 BCT & 붓싱시험) Assistant 3

Client comment

Skilled technician 2

Internal lead connection & Assembling gas pipes

Assistant 2

(내부결선 및 가스배관 조립)

Vacuum & oil filling / Circulation Operator 3

Assistant 3

(진공 & 절연유 주입 / 여과 작업)

Testing technician 2

Site test

Assistant 2

(현장시험)

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 16

3.10 Supervisor working hours (Supervisor 근무시간) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Our supervisor can conduct supervision based on the following working hours.

Supervisor는 아래 작업시간을 기준으로 감독업무를 수행할 수 있습니다. .

Weekdays : 08:00 ~ 17:00 (8 hours working)

Yes □

Weekend : 08:00 ~ 12:00 (4 hours working)

10 Supervision work of maximum 52 hours in a week is possible.

No □

일주일에 52시간의 supervision 업무가 가능합니다.

Two supervisors should be dispatched if you want to work beyond the above mentioned

Yes □

working hours, which may increase supervision costs.

위에 언급된 근무시간을 초과하여 작업이 진행되기를 원한다면, 2명의 supervisor가 파견되

No □

어야 하며, 이로인해 supervision 비용이 증가될수 있습니다.

♣ NOTE

Because Korea's labor standard time is limited to 52 hours in a Client comment

week, two supervisors should be dispatched if you want to

work beyond the mentioned working hours.

우리나라의 근로 기준시간이 일주일에 52시간 이내로 제한되어

있기 때문에, 위에 언급된 근무시간을 초과하여 작업이 진행되

기를 원한다면, 2명의 supervisor가 파견되어야 합니다.

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 17

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

NO. Description Checking by client

Yes □

All required tools and equipment(Initial inspection & assembly stage) shall be prepared.

11

설치에 필요한 공구 및 장비가 준비되어야 합니다.

No □

(1) The required tool and equipment (Initial inspection & assembly stage)

Description & Reference Preparation Description & Reference Preparation

No Q’ty No Q’ty

specification picture check specification picture check

Crane : 75 ton Regulator (with Yes □

Yes □

Capacity can be 5 hose & adapter) 1

1 1

changed by For dry air injection No □

installation condition No □

Pressure gauge Yes □

Shackle 4 per Yes □ To check pressure in

Working load : 6 1

2 each transformer

0.75ton, 1ton, 3ton, (-1.0~1.0kgf/cm2) No □

size No □

5ton

Lifting belt Spanner Yes □

2 per 4 per

Length : 1m, 2m, 4m, Yes □ 8, 10, 12, 14, 16, 17,

6m, 8m, 10m, 12m each 7 each

3 19, 24, 30, 32, 36,

Width : 1~4m more size size No □

46,75 (mm)

than 25mm, 6~12m No □

more than 50mm)

Ratchet wrench 4 per Yes □

1 per Yes □ 8

8, 10, 12, 14, 16, 17,

each

4

Chain block each 19, 24, 30, 32, 36, 46

1ton, 3ton, 5ton size No □

size (mm)

No □

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 18

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

Preparati Description & Reference Preparation

Description & Reference No Q’ty

No Q’ty on specification picture check

specification picture

check

Dry air

(Dew point :

Socket wrench 1 per Yes □ below -55℃)

8, 10, 12, 14, 16, 17, To inject dry air to

Yes □

9 each 20

19, 24, 30, 32, 36, 46 15 prevent moisture

size No □ B/T

(mm) saturation No □

*Quantity can be

changed by

Torque wrench 1 per Yes □ transformer capacity

Handle length :

10 each

250mm, 500mm,

size No □ Yes □

1000mm, 1500mm

16

Dew point tester 1

Min : -65℃

Handle socket 1 per No □

Yes □

8, 10, 12, 14, 16, 17, each

11

19, 24, 30, 32, 36, 46 size Insulation

(mm) No □

resistance Yes □

17 tester(Megger) 1

Hex key (Allen Injection kV :

1 per Yes □ No □

1, 2, 5 [kV]

12 key) each Unit : MΩ ~ GΩ

1.5~19 mm

size No □

0.06~0.75 inch CT tester Yes □

To check CT

Yes □ 18 1

polarity before start

13

Rags 30kg No □

vacuum

For cleaning

No □

Yes □

Adjust wrench 1 per

Yes □

Gloves 19 250mm, 300mm, each

14 20 450mm size

No □

For safety

No □

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 19

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

Description & Reference Preparation Description & Reference Preparation

No Q’ty No Q’ty

specification picture check specification picture check

Bushing power

factor tester Yes □ Spanner type of Yes □

20 To check if bushing 1 Torque wrench

26 1

is okay before No □ To check for torque

No □

assembly value

Oxygen meter Yes □

21

To check oxygen

1 Dry air

density in (Dew point :

transformer inside No □

below -55℃)

For break vacuum Yes □

15

27 & leak test

Yes □ B/T

Temp.-Humidity 1 * Quantity can be No □

22

meter changed by

No □

transformer

capacity.

Empty drum(or Yes □

23 basket) 5 Touch up paint

200 liter capacity No □ brush Yes □

28 Width(in) 1, 1EA 1+1+1

Alcohol Yes □ Width(in) 2, 1EA No □

24

5000mL

4 Width(in) 3, 1EA

To clean flange

surface No □

Yes □ ♣ NOTE

25 Flashlight 1 The calibrated equipment / materials shall be provided.

No □ 교정된 장비/자재들이 구비되어야 합니다.

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 20

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

Preparation

NO. Mandatory Description

Check by client

Dry air (Dew point : below -55℃) , Q’ty : 15 B/T Yes □

27 For break vacuum & leak test

* Quantity can be changed by transformer capacity. No □

♣ NOTE

Please attach the relevant site photos for “Dry air” by client

(To eliminate any idle time when supervisor arrives and does supervising If you choose “Yes” in check sheet,

efficiently at site.) Please attach the relevant site photos

for “Dry air” for our TFA reference and

record.

If you choose “No” in check sheet,

Please fill out the confirmed dated

when “Dry air” is prepared at site.

Confirmed date as (yyyy-mm-dd):

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 21

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

(2) The required tool and equipment (vacuuming & oil filling stage)

Description & Reference Preparation Description & Reference Preparation

No Q’ty No Q’ty

specification picture check specification picture check

Vacuuming Oil filteration

machine machine

It shall be prepared It shall be prepared

according to according to

transformer’s oil transformer’s oil Yes □

capacity. 3 capacity. 1

- Under 80,000L : Yes □ - Under 30,000L :

3,500L/min 4,000L/hour

No □

1 1 Filter :

-Over 80,000L : - 30,000L~80,000L :

6,000L/min

No □ 6,000L/hour ≤ 1 Mircron

•Mechanical booser - Over 80,000L :

pump : 10,000L/hour

1500㎥/h

•Ultimate vacuum Hose (for oil Yes □

degree : 4 filteration) 1

under 0.01 torr 2inch 30m x 2sets No □

Hose (for Yes □

Vacuum gauge 5 vacuuming) 1

(pirani or digital 3 per Yes □ 2inch 30m x 3sets No □

2 type) each Power supply or

Measuring range : size No □ Generator Yes □

0.01 ~ 20 torr

(1.33 ~ 2660 Pa) 6 (above 300kW) 1

For equipment No □

operation

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 22

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

Preparation

NO. Mandatory Description

Check by client

Vacuuming machine

It shall be prepared according to transformer’s oil capacity. Yes □

1 - Under 80,000L : 3,500L/min

- Over 80,000L : 6,000L/min No □

•Mechanical booser pump : 1500㎥/h

•Ultimate vacuum degree : under 0.01 torr

♣ NOTE

Please attach the relevant site photos for “Vacuuming machine” by client

If you choose “Yes” in check sheet,

(To eliminate any idle time when supervisor arrives and does supervising Please attach the relevant site photos

efficiently at site.) for “Dry air” for our TFA reference and

record.

If you choose “No” in check sheet,

Please fill out the confirmed dated

when “Dry air” is prepared at site.

Confirmed date as (yyyy-mm-dd):

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 23

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

Preparation

NO. Mandatory Description

Check by client

Oil filteration machine

It shall be prepared according to transformer’s

oil capacity. Yes □

3 - Under 30,000L : 4,000L/hour

- 30,000L~80,000L : 6,000L/hour No □

- Over 80,000L : 10,000L/hour

- Filter : ≤ 1 Mircron

- New Filter material shall be prepared by main EPC contractor.(mandatory requirement)

Please attach the relevant site photos for “ Oil filteration machine ” by client ♣ NOTE

(To eliminate any idle time when supervisor arrives and does supervising

If you choose “Yes” in check sheet,

efficiently at site.)

Please attach the relevant site photos

for “Dry air” for our TFA reference and

record.

If you choose “No” in check sheet,

Please fill out the confirmed dated

when “Dry air” is prepared at site.

Confirmed date as (yyyy-mm-dd):

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 24

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

Description & Reference Preparation Description & Reference Preparation

No Q’ty No Q’ty

specification picture check specification picture check

Hose adapter

with plug (1/2”, Yes □

2 per Yes □

8

1”, 2”, 3”, 4” each

size flange) No □

size No □

For hose – valve

connection

Yes □

Portable oil Yes □

9 tester 1 No □

0 ~ 80kV No □

Cleaned oil Yes □

storage tank

(for oil filling) No □

It should be Yes □

1

10 prepared

according to No □

transformer’s oil

capacity.(30.000LT

per tank)

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 25

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

Preparation

NO. Mandatory Description

Check by client

Cleaned oil storage tank

Yes □

10 (for oil filling)

It should be prepared according No □

to transformer’s oil capacity.(30.000LT per tank)

Please attach the relevant site photos for “Cleaned oil storage tank ” by

client ♣ NOTE

(To eliminate any idle time when supervisor arrives and does supervising

efficiently at site.) If you choose “Yes” in check sheet,

Please attach the relevant site photos

for “Dry air” for our TFA reference and

record.

If you choose “No” in check sheet,

Please fill out the confirmed dated

when “Dry air” is prepared at site.

Confirmed date as (yyyy-mm-dd):

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 26

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

(3) Optional tool and equipment (For cable wiring)

Description & Reference Preparation Description & Reference Preparation

No Q’ty No Q’ty

specification picture check specification picture check

Yes □

Yes □

5 Plier (long nose) 3

1 Cable cutter 2

No □

No □

Screw driver Yes □

1 per Yes □ Cable joint plier

Type : phillips (+), 6 2

2 each (Clamping tool)

flathead (-) No □

size No □

2, 3, 4, 5 (mm)

Yes □

Multi tester Yes □ 7 Wire stripper 2

2

3 (AC·V, AC·mA, No □

DC·V, DC·mA, Ω) No □

Clamp-on meter Yes □

4 To measure 1

current (mA) No □

♣ NOTE

If additional equipments/materials that were not mentioned above, are required, the contractor/purchaser shall prepare accordingly

based on the supervisor’s request.

만일 위에 언급되지 않은 추가장비/자재가 요구되어지면, 슈퍼바이저의 요청에 따라 계약자/구매자는 준비해야 합니다.

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 27

3.11 Required tools and equipment (필요 공구 및 장비) HYUNDAI Electric

& Energy Systems

(4) Test equipment (For site acceptance test) – listed equipment or equivalent

NO. TEST ITEM EQUIPMENT

1 Visual inspection -

2 Core/Clamp insulation resistance measurement. Megger MIT520/2

3 Winding insulation resistance measurement Megger MIT520/2

4 Ratio Test OMICRON CPC 100

5 Winding resistance measurement OMICRON CPC 100

6 Polarity and phase relationship check Test Board, Digital Multimeter, Clamp Meter

7 Measurement of impedance Test Board, Digital Multimeter, Clamp Meter

8 Measurement of exciting current OMICRON CPC 100 + CP TD1

9 Bushing CT test(polarity, resistance, current ratio) CT ANALYZER(OMICRON )

10 Capacitance and winding & bushing insulation power factor test OMICRON CPC 100 + CP TD1

11 Dielectric breakdown test for all Megger OTS 100 AF/2

12 Functional test on control panel & supervisory equipment Multimeter, Clamp Meter

13 Check of cooling fans and pumps Multimeter, Clamp Meter

14 Functional test of tap changer Multimeter, Clamp Meter

15 DEW POINT MEASUREMENT XPDM DEW POINT METER

16 Oil leakage test PRESSURE GAUGE, REGULATOR

17 SFRA test DOBLE M5400

♣ NOTE

If additional equipments/materials that were not mentioned above, are required, the contractor/purchaser shall prepare accordingly

based on the supervisor’s request.

만일 위에 언급되지 않은 추가장비/자재가 요구되어지면, 슈퍼바이저의 요청에 따라 계약자/구매자는 준비해야 합니다.

HYUNDAI Electric & Energy Systems (HEES A17-1018-1_rev.2(2022) 28

You might also like

- 전기공사 물량산출이론Document115 pages전기공사 물량산출이론정재우No ratings yet

- Mandatory Check List - Rev2 (150223) 3Document3 pagesMandatory Check List - Rev2 (150223) 3HlangaNo ratings yet

- Mandatory Check List - Rev2 (150223) 1Document3 pagesMandatory Check List - Rev2 (150223) 1HlangaNo ratings yet

- (Tieng Han) ( Ç Ç - ) SDC Ư Ê ºñ Àü  Common Spec - V011-0421 - v1.0Document72 pages(Tieng Han) ( Ç Ç - ) SDC Ư Ê ºñ Àü  Common Spec - V011-0421 - v1.0ducquan159No ratings yet

- (YOKOGAWA) DCS Introduction R0Document55 pages(YOKOGAWA) DCS Introduction R0Young-seok HwangNo ratings yet

- 신재생발전기+송전계통+연계+기술기준 전문Document70 pages신재생발전기+송전계통+연계+기술기준 전문kju765xyzNo ratings yet

- Mandatory Check List - Rev2 (150223) 4Document3 pagesMandatory Check List - Rev2 (150223) 4HlangaNo ratings yet

- 슈나이더 콘닥Document108 pages슈나이더 콘닥정정호No ratings yet

- 001-E1 + +kec+ + +1Document27 pages001-E1 + +kec+ + +1김은철No ratings yet

- 한국형발사체 75톤급 엔진의 총조립 과정에 대한 소개Document4 pages한국형발사체 75톤급 엔진의 총조립 과정에 대한 소개이재헌 서울 대학원 융합기계공학과 장학조교No ratings yet

- P-133-2013 화학공장의 인터록 관리에 관한 기술지침Document11 pagesP-133-2013 화학공장의 인터록 관리에 관한 기술지침정재열No ratings yet

- Comprehension of ConstructionDocument82 pagesComprehension of ConstructionRjeb mohamed100% (2)

- 2013 - 원전기기 내진검증의 기준과 적용 - 한국소음진동공학회Document2 pages2013 - 원전기기 내진검증의 기준과 적용 - 한국소음진동공학회오원재No ratings yet

- Static Friction Compensation For Enhancing Motor Control PrecisionDocument6 pagesStatic Friction Compensation For Enhancing Motor Control Precision양완철No ratings yet

- E-94-2011 산업용 기계설비의 전기장치 설치에 관한 기술 기준Document89 pagesE-94-2011 산업용 기계설비의 전기장치 설치에 관한 기술 기준정재열No ratings yet

- (IQS-701) Tiêu chuẩn quản lý tĩnh điện 정전기 관리표준 Rev.14 200612Document58 pages(IQS-701) Tiêu chuẩn quản lý tĩnh điện 정전기 관리표준 Rev.14 200612Dang Hoang DuNo ratings yet

- 오늘 하루 즐겁게Document13 pages오늘 하루 즐겁게박성관No ratings yet

- KEPIC - 2005년판 해설서Document381 pagesKEPIC - 2005년판 해설서Jangho AhnNo ratings yet

- DX300LC-5L 제원표Document16 pagesDX300LC-5L 제원표waltz6032No ratings yet

- (H&K TECH) Engineering Service - Rev.A - 20230111Document12 pages(H&K TECH) Engineering Service - Rev.A - 20230111NAM GUK LEENo ratings yet

- E-97-2011 석유화학공장의 전기설비 설치에 관한 기술지침Document16 pagesE-97-2011 석유화학공장의 전기설비 설치에 관한 기술지침정재열No ratings yet

- 기항타23-5900 9동부기초)Document2 pages기항타23-5900 9동부기초)Raehun ParkNo ratings yet

- (KISTEP 브리프) 해상 풍력발전Document48 pages(KISTEP 브리프) 해상 풍력발전won choiNo ratings yet

- E-170-2018 태양광 발전설비 설치에 관한 기술지침Document16 pagesE-170-2018 태양광 발전설비 설치에 관한 기술지침정재열No ratings yet

- 06 - (Eng) HiMSEN DF - ECS - Hardware DescriptionDocument14 pages06 - (Eng) HiMSEN DF - ECS - Hardware DescriptionVlad FreelancerNo ratings yet

- QD62,QD62E,QD62D 고속카운터 모듈-사용자메뉴얼 (상세편)Document102 pagesQD62,QD62E,QD62D 고속카운터 모듈-사용자메뉴얼 (상세편)JUNGNo ratings yet

- QD77MS 동기제어Document185 pagesQD77MS 동기제어JUNGNo ratings yet

- QD77MS (위치결정) 매뉴얼 (Ver A)Document942 pagesQD77MS (위치결정) 매뉴얼 (Ver A)Duckchan ChoiNo ratings yet

- E-85-2017 전기설비 설치상의 안전에 관한 기술지침Document26 pagesE-85-2017 전기설비 설치상의 안전에 관한 기술지침정재열No ratings yet

- E-85-2017 전기설비 설치상의 안전에 관한 기술지침 PDFDocument26 pagesE-85-2017 전기설비 설치상의 안전에 관한 기술지침 PDF정재열No ratings yet

- Guia03 DemoDocument17 pagesGuia03 DemoOswaldo TorresNo ratings yet

- 2023-09-04Document3 pages2023-09-04이한별No ratings yet

- 현대EDS 회사소개서 - 20240321 - 한수원Document32 pages현대EDS 회사소개서 - 20240321 - 한수원smdsahinNo ratings yet

- (별표18 2) KN61000 6 2산업환경에서의일반내성시험방법Document17 pages(별표18 2) KN61000 6 2산업환경에서의일반내성시험방법곽준영No ratings yet

- plant 건설사업의 업무흐름Document10 pagesplant 건설사업의 업무흐름이재혁No ratings yet

- 110523 피뢰접지카다로그Document20 pages110523 피뢰접지카다로그Namki LeeNo ratings yet

- English Ver - Development of Bi-Directional Charger With A Wide Voltage RangeDocument6 pagesEnglish Ver - Development of Bi-Directional Charger With A Wide Voltage RangeMahad NadeemNo ratings yet

- ASTM E1237 Strain GageDocument6 pagesASTM E1237 Strain GageJamesNo ratings yet

- Battery Charger (Tdc-9030a) ManualDocument15 pagesBattery Charger (Tdc-9030a) Manualauto etrustNo ratings yet

- 순간전압 강하 대책Document9 pages순간전압 강하 대책KI OHNo ratings yet

- (참고자료1) 바우처 제도 도입에 따른 위탁 참여 공공연구기관 리스트Document51 pages(참고자료1) 바우처 제도 도입에 따른 위탁 참여 공공연구기관 리스트johnNo ratings yet

- 현대 - 변속기제어장치 리콜 고객통지문 - 조치완료Document2 pages현대 - 변속기제어장치 리콜 고객통지문 - 조치완료Andrey DmitrovNo ratings yet

- Users Manual 4878179Document12 pagesUsers Manual 4878179TienNo ratings yet

- Komeco 2015Document27 pagesKomeco 2015Joonki YunNo ratings yet

- 전차선Document14 pages전차선후라보노No ratings yet

- E-164-2017 특정용도의 전기기계 기구 설치에 관한 기술지침Document20 pagesE-164-2017 특정용도의 전기기계 기구 설치에 관한 기술지침정재열No ratings yet

- ACP Facility Safety Surveillance System Installation: KAERI/TR-3257/2006Document33 pagesACP Facility Safety Surveillance System Installation: KAERI/TR-3257/2006Thomas CuerqNo ratings yet

- FR 5Document305 pagesFR 5Sidhi SadanNo ratings yet

- Glotec (PQ) Kor PDFDocument24 pagesGlotec (PQ) Kor PDFTompson StevenNo ratings yet

- Attachment 8.3.3 - Permit To Work Form Rev003 UpdatedDocument15 pagesAttachment 8.3.3 - Permit To Work Form Rev003 Updatedsammar RajputNo ratings yet

- 산업 - 환경설비공사 표준 시방서 - 국토해양부 PDFDocument1,011 pages산업 - 환경설비공사 표준 시방서 - 국토해양부 PDF정재열No ratings yet

- H 0장목차-210501.indd 1 2021-05-25 오전 9:55:17Document656 pagesH 0장목차-210501.indd 1 2021-05-25 오전 9:55:17moviecinema1111No ratings yet

- ★고정익항공기를 위한 운항기술기준 (국토교통부고시 제2022-572) - 본문Document413 pages★고정익항공기를 위한 운항기술기준 (국토교통부고시 제2022-572) - 본문이제원No ratings yet

- KR E-02100 변전소 등의 접지 (221209, Rev8)Document48 pagesKR E-02100 변전소 등의 접지 (221209, Rev8)bbobbo82No ratings yet

- 규격서 GateCycleDocument2 pages규격서 GateCycleOnnuri WonNo ratings yet

- KRCS 17040-00 KTX용 - 견인전동기 - 재생 PDFDocument28 pagesKRCS 17040-00 KTX용 - 견인전동기 - 재생 PDFAaron HendrycksNo ratings yet

- 승강기 교체공사 발주 및 공사감리Document28 pages승강기 교체공사 발주 및 공사감리hasukbongNo ratings yet

- (포스터) 용접형 긴급차단밸브 시트누출검사 대안Document1 page(포스터) 용접형 긴급차단밸브 시트누출검사 대안Jinyoung ChoiNo ratings yet

- 현대 양면 595WDocument2 pages현대 양면 595Wsw eNo ratings yet