Professional Documents

Culture Documents

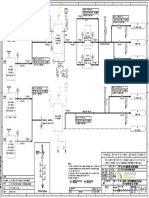

TM1M42742 Model

TM1M42742 Model

Uploaded by

SIL PROJECTSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TM1M42742 Model

TM1M42742 Model

Uploaded by

SIL PROJECTSCopyright:

Available Formats

8000 10 9 8 7 6 5 4 3 2 1

2

- REV No ZONE REVISIONS DATE SIGN

295 1830

1.2

4000

8000

NOTES:

+0.05

635 H6 0 ( ) 1. ESTIMATED NET WEIGHT = ~6000 kg.

Tolerances applicable if not specified (mm)

395 800 2. HEAVIEST MAINTENANCE LIFT = 2175 kg. (LOW SPEED SHAFT ASSY.)

3. CONNECTING PIPING MUST BE CLEANED BEFORE OPERATION.

0.8

2000

4000

CENTRE DISTANCE 4. UNIT OIL TEMPERATURE MUST BE 21°C MINIMUM BEFORE OPERATION.

01 5. DESIGN DIAMETRICAL BEARING CLEARENCE:

(230.6)

HIGH SPEED = 0.22 / 0.27 mm (AT SPLIT)

H 04

CLEARANCE

LOW SPEED = 0.19 / 0.24 mm

0.5

1000

2000

EYE BOLTS FOR P4 6. LOW SPEED END PLAY = 0.25/0.38 mm

LIFTING

JUNCTION BOX

(NTS)

LIFTING TOP 7. UNIT BACKLASH = 0.30/0.56 mm H

650

CASING ONLY 8. RTD'S DUPLEX, PLATINUM ELEMENT, RESISTANCE 100 OHMS AT 0°C

NO. OF TERMINALS 52T DIN CALIBRATION (0.00385 OHM/OHM/C) STAINLESS STEEL OVER BRAID

0.3

1000

315

WEATHER 9. VIBRATION EQUIPMENT SET POINTS ARE ESTIMATES ONLY, FIELD CONDITIONS WILL

AREA OF CLASSIFICATON INDICATE FINAL ALARAM AND SHUTDOWN VALUES WHICH MAY BE HIGHER OR LOWER

PROOF, IP-66 THAN THESE STARTING VALUES.

10. INDICATES CENTER OF GRAVITY

0.2

120

315

11.DURING THE BARRING GEAR OPERATION,THE SHAFT VIBRATION VALUES WILL

BE HIGHER THAN NORMAL OPERATION VALUES.A TRIP MULTIPLIER IS

RECOMMENDED IN THE CONTROL CIRCUIT TO SET THE ALARM AND TRIP

05 LIMITS 2 TO 3 TIMES THE RECOMMENDED NORMAL LIMITS TO AVOID TRIPPING

0.15

120

30

DELIVERY OF PRIME MOVER,DURING BARRING OPERATION

02 12.A MINIMUM SLOPE OF 1:10 SHALL BE MAINTAINED IN OIL DRAIN PIPE

850

LINE BETWEEN GEAR BOX AND LUBE OIL SYSTEM TANK TO FACILITATE

EASY GRAVITY FLOW

0.1

720

30

13.REFER GEAR BOX O & M MANUAL FOR LUBE OIL DETAILS

6

POWER 5.5 kW 14.HANDWHEEL SAFETY INTERLOCK :

DIMENSION 'LE' a) DO NOT START THE MOTOR, WHEN THE LIMIT SWITCH PLUNGER IS NOT ACTUATED.

SPEED 1465 RPM ACTUAL VALUE (HAND WHEEL IS IN POSITION)

0.08

*

WILL BE PUNCHED b) START THE MOTOR, WHEN LIMIT SWITCH PLUNGER IS ACTUATED.

3

6

VOLTAGE 415 V

G HERE (MOTOR GUARD IS IN POSITION) G

FREQUENCY 50 Hz 15.GEAR BOX PAINTING PROCEDURE WILL BE AS PER DOCCUMENT NO:- DD/F/01/44103

16.OIL MIST SEPERATOR SHALL BE PROVIDED IN LUBE OIL SYSTEM

0.05

35

0.5

EFFICIENCY IE3

3

XXXX

M6 KEY (OUTPUT) 34CrNiMo6 EN10083.3/817 M40 BS:970 2 x 1.5

*

(112)

50

1545

Tolerance

LUBE OIL SUMP QTY 5 LITRES HSS 2x8

Above

M5 BEARING CLASS 1A IS:2004 & GR.84 IS:25/ BS:3332 Gr.A

Upto

LUBE OIL GRADE ISO VG-320 EP LSS 2 x 26

M4 TOP & BOTTOM CASING CAST IRON FG-300 IS:210 3160

CG

430

M3 GEAR WHEEL SHAFT 42CrMo4 EN10083-3 370

P5

(140) '#' 300 300 '#' M2 GEAR WHEEL 17CrNiMo6 DIN 17210/ 1805

LUGS FOR 1 HOLE, M6X1P

08 2" NB FLANGE WITH TYP TYP M1 PINION SHAFT 18CrNiMo7-6-EN10084 80

LIFTING

825-0.5

GASKETS, FASTENERS OIL INLET DRILL & TAP 8 DEEP

MASS

0

GEAR BOX S/F 30 @ 4 PLACES

FOR OIL INLET ON BOTH SIDES SL.No DESCRIPTION MATERIAL

THIS END ACTIVE SUCTION AS SHOWN.MARKED AS '#' (kg)

(ANSI-B16.5, CLASS-150) OIL FLOW ON BOTH SIDE P5 CASING VIBRATION MEASURMENT 4

BLIND FLANGE MOC: MILD STEEL 70 OIL OUTLET 06 INDICATOR (PROVISION FOR CASING

VIBRATION TRANSDUCER) P4 MANUAL ROTATION FOR TURNING GEAR 1

OPEN FLANGE MOC: STAINLESS STEEL

P3 MOUNTING KEY PHASER PROBES 2

F F

P2 MOUNTING VIBRATION PROBES (RADIAL) 8

180

P1 MOUNTING COUPLING GUARD AT INPUT 1

80

F

F SL.No PROVISION MADE FOR QTY

TYP

TYP

20

325 730 08

20

2" NB FLANGE WITH 395 11 MOP DETAILS WILL BE CONFIRMED LATER 1

GASKET & FASTENERS 08 10 KEY- 36x20x275LG (OUTPUT) - (YIELD STRENGTH- 660 N/mm²) 2

1690 FOR CASING DRAIN 09 790 8" NB FLANGE WITH 09 EARTHING STUD WITH NUT - M10 2

ON BOTH SIDES GASKETS & FASTENERS

BOTH END BLANKED FOR OIL DRAIN ON BOTH 08 COUNTER FLANGES AT OIL INLET AND DRAIN,MOP SUCTION & DELIVERY 1 SET

(ANSI B16.5, CLASS-150) SIDES 07 VIBRATION & KEY PHASER PROBE ADAPTERS 8+2

MOC: MILD STEEL REAR END ACTIVE 06 JACKING SCREWS 4

(ANSI-B16.5,CLASS 150)

PUMP FOR MOC: MILD STEEL TURNING GEAR ARRANGEMENT WITH AUTO ENGAGEMENT & AUTO

REMOVAL ONLY DISENGAGEMENT CLUTCH, REDUCER, ELECTRIC MOTOR,

05 1 SET

HAND WHEEL, LIMIT SWITCH, MOTOR GAURD & SOFT STARTER PANEL

FOR PUMP WITH TIMER & CONNECTORS

REMOVAL WITH

E END COVER 04 JUNCTION BOX FOR RTD, RITTAL ENCLOSURE 1 E

*

03b EMBEDDED TYPE RTD: PT-100, 3 WIRE DUPLEX, GIC MAKE (FOR THRUST BRG) 2

*

03a STEM TYPE RTD: PT-100, 3 WIRE DUPLEX, GIC MAKE (FOR RADIAL BRG) 4

'D' 02 THERMOMETER: 6" DIAL TYPE, 0-150 C, BI-METALLIC, GIC MAKE 4

11 8 HOLES 40 DRILL THRU 01 AIR BREATHER -2" BSP 2

1690 SPOT FACE 90 X 2 DEEP

AS SHOWN (MAX TIGHTENING

TORQUE-2469.8Nm) FOR M36 BOLT GEAR BOX COLOUR SHADE SIGNAL BLUE (RAL -5005)

385 325 730 PROPERTY CLASS:8.8 IS:1367

VIBRATION EQUIPMENT LOW SPEED SHAFT ALARM - 63 µm

DIMENSION 'HE'

C.G. RING OD -0.03

40 P9 -0.09( ) SET POINTS

(DISPLACEMENT

SHUTDOWN - 100 µm

ALARM - 44 µm

(60)

280 TYP HIGH SPEED SHAFT

ACTUAL VALUE WINDAGE BAFFLE COUPLING INPUT PEAK TO PEAK) SHUTDOWN - 63 µm

HE = 60

WILL BE OD GUARD VIBRATION LIMITS ALARM - 5.5 mm/s

*

HOUSING

TYP

PUNCHED HERE MOUNTING

150

DO NOT SCALE. ASK IN CASE OF DOUBT

* C [VELOCITY (RMS)] SHUTDOWN- 8 mm/s

FACE E

5

20 A G DYNAMIC BALANCING GRADE API-613

TYP TURBINE LINE ~150 RPM

ALL DIMENSIONS ARE IN mm

BARRING SPEED AT

OF LS SHAFT

OF HS SHAFT

xxxx

D GENERATOR LINE ~18 RPM D

20

MAX. ALARM TRIP

OF GEARBOX

( )

MAX. ALLOWABLE STEADY THERMOMETER 85 C -- --

TYP

475

670

790

-0.03

40 P9 -0.09

415

BEARING TEMPERATURE FOR STEM TYPE RTD

395

150 93 C 100 C 107 C

TYP

TYP EMBEDDED TYPE RTD 100 C 108 C 115 C

(40)

SOUND PRESSURE LEVEL (AS PER AGMA 6025 D98) <=85 dB (A) @ 1m

TYP

335

1220 1.5

DIRECTION OF ROTATION OF I/P SHAFT

CCW

LOOKING FROM I/P SHAFT COUPLING END

D F H

TYP

DIRECTION OF ROTATION OF O/P SHAFT

110

B CCW

CG LOOKING FROM O/P SHAFT COUPLING END

= = HEAT LOAD 76681 kcal/hr

395

395

TYP

100

B B

(60)

LOAD /FOUNDATION BOLT REFER TABLE 1

270 OUTPUT 70 06 GD² VALUE W.R.T.LOW SPEED SHAFT TO BE CONFIRMED LATER

TYP TYP

4 HOLES, M24 X 2P THRU EFFICIENCY OF GEAR BOX AT 100% LOAD 98.6%

745

(55) 640 610 330 (55) FOR VERTICAL JACKING TURNING GEAR

GEAR BOX 21 C

876

TYP TYP TYP OPERATION (MIN)

C LUBRICATING C

30

FOUNDATION DETAILS OIL INLET ABOVE TURNING SPEED & MIN NORMAL MAX

SECTION F-F TEMPERATURE FOR CONTINOUS OPERATION

350

40 C 45 C 50 C

LE

280

275

481

QUANTITY OF LUBRICATING OIL REQUIRED 170 LPM @ 1.5 TO 2.0 bar

LUBRICATING OIL GRADE ISO VG-46 (R & O)

X X

DRIVEN EQUIPMENT GENERATOR

360 TABLE 1

OIL SEAL OD DRIVING EQUIPMENT STEAM TURBINE

FOUNDATION LOAD / BOLT SHAFT ASSEMBLY DESIGNATION L-R

FOR TURNING GEAR (+VE VALUE INDICATE LOAD ACTING UPWARDS & -VE VALUE INDICATE LOAD ACTING DOWNWARDS)

80

SHORT CIRCUIT FACTOR 6

230

REMOVAL WITH

TURNING GEAR BRACKET SYMBOL A B C D E F G H TYPE OF GEAR DOUBLE HELICAL

STATIC LOAD -9810 N -9810 N -9810 N SERVICE FACTOR 1.4 (MIN)

FOR TURNING GEAR DESIGN STANDARD AGMA-6011 J14

REMOVAL ONLY DYNAMIC LOAD +17812 N -876 N -18688 N

130 OUTPUT SPEED 1500 RPM

UNBALANCE LOAD 18 N 75 N 57 N

INPUT SPEED (NOMINAL\ACTUAL) 12000 \ 12053 RPM

DETAIL-AXIAL THERMAL GROWTH DETAIL - MECHANICAL & THERMAL MOVEMENT GEAR BOX RATED POWER 6370 kW

B +0.1 B

TYPE 85 2CW0038856 (Rev C) 20 HOLES, 8.3 0 (ALIGNMENT VALUES BASED ON 33 C (ALIGNMENT VALUES BASED ON 22 C TEMPERATURE

THRU EQUISPACED TEMPERATURE RISE ABOVE AMBIENT) RISE ABOVE AMBIENT)

P1 8 HOLES M12 X 20 DEEP

EQUISPACED ON 360 PCD

R1

.6 ON 170 0.03 PCD

AS SHOWN

( )

-0.03

36 P9 -0.09

07 P2 P3

0.19 QUANTITY

P.O.No. & DATE

ONE NUMBER

--DATED--

TYP

( )

-0.12

0.17

AS SHOWN

THIS DRAWING AND DESIGN IS THE PROPERTY

36 c9 -0.18

AND MUST NOT BE COPIED OR LENT WITHOUT

0.5 mm KEYWAY ADAPTER WITH DATA SHEET NO.

OF TRIVENI ENGINEERING & INDUSTRIES LTD

(FOR COUPLING R10 0.04 62OP42834_U1_643020001

GUARD MOUNTING) 'U' CUT TYP M10X1P TAPED HOLES

90 CUSTOMER M/s Uttam Energy Ltd

KEY AT 10 PLACES.

10

0.43

END CUSTOMER M/s Greenfuels Pvt Ltd

0.24

90

14 4 N

117.5

475

K

OF GEAR WHEEL SHAFT

TYP

OF PINION SHAFT

)

10

PURCHASER M/s SIEMENS LTD

5 D

20

K

+0.05

138 n6 +0.03

D E

E

V

145

45 V V PROJECT Uttam Energy Ac Greenfuels Pvt Ltd 1 X 6 MW

THEIR PERMISSION IN WRITING

45

188

(

22.5 OF GEAR BOX

Scale1:12 2022 NAME DATE

117

TYP

=

216-0.3

20 V

0

Dimensions in mm Drawn KIRAN 14/02

CENTER LINE OF SHAFTS

152 Surface Finish Weight in kg Checked SRIKANTH

=

UNIT COLD, SHAFTS AT REST

TYP 115

745

A (

+0.05

200 m6 +0.02 ) 180 DE

~ as cast

5-50 µ ~6000 Approved SRIKANTH

N E

262 NDE DOWEL 635 A

D

E

rough

5 TITLE: Cast\Forg No A1

D

14 POSITION 8-25 µ

4

Smooth

10

Location:

PARTIAL VIEW ALONG 'D' 10 5

10 SECTION B-B

1.6-8 µ GENERAL ARRANGEMENT Drg. No:

0.27

SCALE 1:12 Grind

SCALE 1:8

SECTION X-X G 0.25-1.6 µ OF GEAR BOX TM1M42742

SCALE: 1:3 Mirror

0.01 SCALE 1:4 GG MODEL HSG-635 W.O.No:-C.A07.00519 Sheet:1 OF 1 REV

0.012-0.25 µ

10 9 8 7 6 5 4 3 2 1

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PIPE Vs TUBEDocument3 pagesPIPE Vs TUBESIL PROJECTSNo ratings yet

- Banking InformationDocument1 pageBanking InformationSIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 43Document2 pagesIBR - 1950 - Reg. 43SIL PROJECTSNo ratings yet

- Knife Gate Valve 12 INCH 10Document1 pageKnife Gate Valve 12 INCH 10SIL PROJECTSNo ratings yet

- HV 1013Document4 pagesHV 1013SIL PROJECTSNo ratings yet

- Envelop Cover Address Print FormatDocument1 pageEnvelop Cover Address Print FormatSIL PROJECTSNo ratings yet

- Ippta JournalDocument83 pagesIppta JournalSIL PROJECTSNo ratings yet

- PR 4 ExamplesDocument12 pagesPR 4 ExamplesSIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 56 ADocument3 pagesIBR - 1950 - Reg. 56 ASIL PROJECTSNo ratings yet

- Ball Valve On-Off TypeDocument1 pageBall Valve On-Off TypeSIL PROJECTSNo ratings yet

- HV 1212Document4 pagesHV 1212SIL PROJECTSNo ratings yet

- Soda Converstion To CausticDocument1 pageSoda Converstion To CausticSIL PROJECTSNo ratings yet

- Butterfly Valve With DiaphragmDocument1 pageButterfly Valve With DiaphragmSIL PROJECTSNo ratings yet

- 100 V-Notch (Pulp)Document1 page100 V-Notch (Pulp)SIL PROJECTSNo ratings yet

- 18 (1) .03.08 Satia LTI MailDocument2 pages18 (1) .03.08 Satia LTI MailSIL PROJECTSNo ratings yet

- V Notch Ball ValveDocument1 pageV Notch Ball ValveSIL PROJECTSNo ratings yet

- 11 - Vibrating Screens VSTDocument2 pages11 - Vibrating Screens VSTSIL PROJECTSNo ratings yet

- Screw Thickeners - CAD - PrintDocument2 pagesScrew Thickeners - CAD - PrintSIL PROJECTSNo ratings yet

- 16 - Chest and TowerDocument2 pages16 - Chest and TowerSIL PROJECTSNo ratings yet

- 50 V-Notch Valve2Document1 page50 V-Notch Valve2SIL PROJECTSNo ratings yet

- E20 Green Fuel - Single Line Diagram (22.02.22)Document1 pageE20 Green Fuel - Single Line Diagram (22.02.22)SIL PROJECTSNo ratings yet

- For Paper Industry: Approach Flow Screen SPCDocument2 pagesFor Paper Industry: Approach Flow Screen SPCSIL PROJECTSNo ratings yet

- UntitledDocument27 pagesUntitledSIL PROJECTSNo ratings yet

- UntitledDocument5 pagesUntitledSIL PROJECTSNo ratings yet

- Uttam U: EnergyDocument1 pageUttam U: EnergySIL PROJECTSNo ratings yet

- TS Curve RPHDocument2 pagesTS Curve RPHSIL PROJECTS0% (1)

- 19 - Rectifier RollsDocument2 pages19 - Rectifier RollsSIL PROJECTSNo ratings yet

- 02 - Pulper Washer PWCDocument2 pages02 - Pulper Washer PWCSIL PROJECTSNo ratings yet

- Preliminary: DescriptionDocument1 pagePreliminary: DescriptionSIL PROJECTSNo ratings yet

- For Paper Industry: Deflakers DSTDocument2 pagesFor Paper Industry: Deflakers DSTSIL PROJECTSNo ratings yet