Professional Documents

Culture Documents

Design Of-30-Mva Tra-Damak Ss Rail Track

Design Of-30-Mva Tra-Damak Ss Rail Track

Uploaded by

Hikmat B. Ayer - हिक्मत ब. ऐर0 ratings0% found this document useful (0 votes)

5 views2 pagesDesign of-30-Mva Tra-damak Ss Rail Track

Original Title

Design of-30-Mva Tra-damak Ss Rail Track

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDesign of-30-Mva Tra-damak Ss Rail Track

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesDesign Of-30-Mva Tra-Damak Ss Rail Track

Design Of-30-Mva Tra-Damak Ss Rail Track

Uploaded by

Hikmat B. Ayer - हिक्मत ब. ऐरDesign of-30-Mva Tra-damak Ss Rail Track

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

CLIENT Nepal Electricity Authority TANSMISSION & SYSTEM OPERATION

PROJECSUPPLY AND CONSTRUCTION OF DAMAK SUBSTATION CONTRACT NO: KCD-66/04

SUBSTA132/33kV 30MVA DAMAK S/S

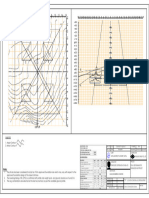

Design of 132/33KV 30MVA Transformer Foundation Rail Track way

Transformer Detail

Equipment Type : 30 MVA(3 Phase)

Length, L 6.0 m

Width, B 4.0 m

Height from PL, H 4.5 m

Weight, W 59740 Kgs

Ref drg no. SFZ11-30000-132 of 30MVA Transformer

of HUBEI SUNLIGHT ELECTRIC CO.,LTD

General inputs :

2

Net safe Bearing capacity, p= 58.86 KN/m2 =6*9.81 (6T/m )

1 Design of base foundation for rails

Shipping wt of transformer = 59740 kg

= 586.05 KN

C/C distance of rail track 2.04 m

Available length of rail = 6 m

provide individual slab length = 4 m

Provided base slab width = 3.04 m3/m

distance from rail center line to slab end = 0.50 m

Load coming on unit length of base slab 146.51 KN/m = 586.05 / 6

Case I : When wheels run on two parallel tracks

Design of base pad

Load coming on unit length of base slab 146.51235 KN/m

Weight of concrete base 10.20 KN/m = 2.04x 25x 0.2

Total 156.71 KN/m

SBC at toe level for dead load only 58.86 KN/m2 = 58.86

Required area of individual footing = 2.662 m

provided individual base slab length = 4 m

Required width of base slab = 0.67 m

Provided base slab width = 3.04 m

Provided area of base slab = 12.16 m2

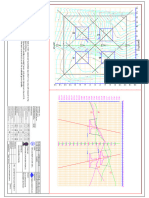

CLIENT Nepal Electricity Authority TANSMISSION & SYSTEM OPERATION

PROJECSUPPLY AND CONSTRUCTION OF DAMAK SUBSTATION CONTRACT NO: KCD-66/04

SUBSTA132/33kV 30MVA DAMAK S/S

Maximum bearing pressure developed = 48.19 KN/m2 = 146.51 / 3.04

< 58.86 KN/m2 OK.

Design of base pad

Net bearing pressure 48.19 KN/m2

Moment at middle of slab 25.07 KN-m/m = 48.19 x 2.04^2 / 8

Moment at cantilver part 6.02 KN-m/m = 48.19 x 0.5^2 / 2

Considered Moment = 25.07 KN-m/m

Design moment (factored @ 1.5) , Mu 37.61 KN-m/m = 1.5 x 25.07

Provided depth of base slab = 200.00 mm

Clear cover provided 50.00 mm

Effective depth, d 144 mm = 200 - 50- 12/2

2

Concrete Grade, fck = 20 N/mm

2

Steel Type, fy = 415 N/mm

We have

BM = 0.138 x fck x b x d2

d =(M2/(0.138 x fck x b)0.5 = 3.69 mm

taking b=1 m strip 1000.00 mm

To be in safe side take D = 200.00 mm

Effective depth d = 144.00 mm

For Area of steel required:

M=0.87*fy*Ast(d-fy*Ast/(b *fck))

or,37606443=0.87x415xAst(144-415xAst/(20x1000)

or,7.49Ast² + -51991Ast +6024.36 =0

Solving Quadratic equation

A B C

7.491788 -51991.2 37606443

2

X1

X1= 6119 479 mm

6119.479

2

X2= 820.2805 mm

2

Ast per m width = 820 mm

Minimum reinforcement from code- IS:456:clause 25.5.2.1 0.12 %

2

Mininimum Ast for 0.12% reinf. 173 mm /m

Max spacing, 3d or 450mm = 432 mm

Provide 12 φ bars @ 125 mm c/c at both top and bottom

2 2

= 905 mm /m, O.K. > 820 mm /m

For distribution reinforcement:

Provide 10 φ bars @ 150 mm c/c at both top and bottom

2 2

= 524 mm /m, O.K. > 173 mm /m

Check for punching against one wall

Punching perimeter 8m =2x4

Effective area for punching 1.15 m2 = 8 x 144/1000

Punching load 293.025 KN = 586.05 /2

2

Punching shear stress developed 0.560 N/mm

= 2.2 x 293.02x 1000 /(1.15x 1000 x 1000)

< 0.25 x sqrt(fck) = 1.118 N/mm2, O.K.

Hence Provide

Length of individual slab = 4 m

Width of slab = 3.04 m

Depth of slab = 200.00 mm

Tansverse Reinforcement bar = 12 φ bars @ 125 mm c/c at top and bottom

Longitudinal/distribution

reinforcement bar = 10 φ bars @ 150 mm c/c at top and bottom

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tower Profile and Tower Schedule Report - NKTLP-2Document63 pagesTower Profile and Tower Schedule Report - NKTLP-2Hikmat B. Ayer - हिक्मत ब. ऐर0% (1)

- District Rate-KathmanduDocument1 pageDistrict Rate-KathmanduHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Rate Analysis 2074-075 RoadDocument191 pagesRate Analysis 2074-075 RoadHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- DLDocument2 pagesDLHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Design of Gabion WallDocument2 pagesDesign of Gabion WallHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- DB RequirementDocument3 pagesDB RequirementHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- DD RequirementDocument4 pagesDD RequirementHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Tower Packing ListDocument15 pagesTower Packing ListHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Wind & Weight Span Report (132 KV MCKT)Document3 pagesWind & Weight Span Report (132 KV MCKT)Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Boundry Wall DesignDocument4 pagesBoundry Wall DesignHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- SLCDocument2 pagesSLCHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Boundry Wall Design (A)Document2 pagesBoundry Wall Design (A)Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- MCTLP Ap-15b-Ap-15bDocument1 pageMCTLP Ap-15b-Ap-15bHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Sugarkhal SS 33kV Switchyard Civil WorksDocument37 pagesSugarkhal SS 33kV Switchyard Civil WorksHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- ACCC Drake File 2Document29 pagesACCC Drake File 2Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- BIODATADocument4 pagesBIODATAHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- 33 KV Equipment DesignDocument1 page33 KV Equipment DesignHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Leg Profile-AP-62-AP-62Document1 pageLeg Profile-AP-62-AP-62Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Leg Profile of AP 47 01052022Document1 pageLeg Profile of AP 47 01052022Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Final Report of Kohalpur-Nepalgunj 132KV Transmisssion Line ProjectDocument100 pagesFinal Report of Kohalpur-Nepalgunj 132KV Transmisssion Line ProjectHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Leg Profile AP-13 Rev.1-AP-13Document1 pageLeg Profile AP-13 Rev.1-AP-13Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Leg Profile of AP-11Document1 pageLeg Profile of AP-11Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- APPD GA - QD+6m BEDocument1 pageAPPD GA - QD+6m BEHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Leg Profiles DDS - R2-AP-21-2Document1 pageLeg Profiles DDS - R2-AP-21-2Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Leg Profile-AP-62-1-AP-62-1Document1 pageLeg Profile-AP-62-1-AP-62-1Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Appd - Bom QD BBDocument24 pagesAppd - Bom QD BBHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- What Can Happen in 2023Document1 pageWhat Can Happen in 2023Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Leg Profile-AP-64-AP-64Document1 pageLeg Profile-AP-64-AP-64Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Revised Bom - Basic Tower - TB - 18.11.23Document11 pagesRevised Bom - Basic Tower - TB - 18.11.23Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- APPD BOM - QD+6m BEDocument6 pagesAPPD BOM - QD+6m BEHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet