Professional Documents

Culture Documents

Difference Between API 650 & API 620

Uploaded by

job saputraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Difference Between API 650 & API 620

Uploaded by

job saputraCopyright:

Available Formats

Designing storage tanks

Software based on the latest international codes enables straightforward

design of storage tanks in a range of load conditions

SCOTT MAYEUX and JANA MILLER

Intergraph

T

he design and mainte- of the following codes and various agenda items that are

nance of atmospheric and standards: important to the refinement

low pressure vessels for • American Petroleum Institute and development of the code.

oil storage is becoming ever (API) 650 As one would expect, all

more vital as crude oil storage • BS EN 14015:2004 aspects of the code, both

capacity utilisation rises and oil • API 620. analytical and non-analytical,

storage capacity grows glob- Tank design codes reflect the are addressed in the meetings.

ally. The US Energy culmination of decades of work But getting back to one of the

Information Administration by many dedicated individuals. previous questions, how do we

shows crude oil storage capac- Using these standards helps to decide how thick the wall of

ity utilisation rising steadily. ensure that tanks will be able the tank should be? The

to stand the rigours of the answer can be found in section

Standards for tank design elements and conditions to 5.6, Shell Design. In this

From the perspective of the which they are subjected. section, there are two methods

casual observer, these storage for consideration:

tanks just sit there doing their API 650 • 5.6.3 Calculation of Thickness

job day in, day out. And then The API 650 code is entitled by the 1-Foot Method

in a spark of enlightenment, Welded Steel Tanks for Oil • 5.6.4 Calculation of Thickness

questions start to pop into the Storage. At the time of this, the by the Variable Point Method.

minds of the curious: latest edition is the 12th, The 1-foot method computes

• How thick do the walls and addendum 2, January 2016. the required plate thickness at

floors of these structures have This code can be used for a distance of one foot above

to be? designs where the internal the bottom of each shell course

• Why are some tanks bolted pressure is less than or equal to and is applicable to tanks 200ft

down to the ground and others 2.5 psig. These tanks have (61m) and less in diameter. The

are not? historically been used to house basic equation in US customary

• What internal support struc- petroleum for use by chemical units looks something like this:

tures are needed if the tank has plants and power production

a fixed roof? facilities, as well as basic and 2.6𝐷𝐷 𝐻𝐻 − 1 𝐺𝐺

𝑡𝑡ℎ𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 = + 𝐶𝐶𝐶𝐶

𝑆𝑆

• What happens to a tank strategic reserves.

during a hurricane or A group of dedicated indi- The variable point method is

earthquake? viduals meet on a regular basis an alternative to the 1-foot

The answers to these ques- to maintain and update the 650 method and can be used for

tions are readily available. code. These sessions typically tanks in excess of 200ft in

They ultimately lie in the pages involve lengthy discussions of diameter. The variable point

www.eptq.com PTQ Q4 2016 1

equation in US units is as 5.21b in API 650 12th Edition, It is interesting to note that

follows: Addendum 2 is as follows: the maximum design pressure

for 14015 designs is 500 mbar

𝑡𝑡ℎ𝑡𝑡ℎ𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖𝑖 𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟𝑟 = 1.06 −

0.463𝐷𝐷 𝐻𝐻×𝐺𝐺

2.6𝐻𝐻×𝐷𝐷×𝐺𝐺

+ 𝐶𝐶𝐶𝐶 = 𝑃𝑃𝑃𝑃×𝐷𝐷! ×4.08 − 𝑊𝑊1 or about 7.25 psig. This is well

𝐻𝐻 𝑆𝑆 𝑆𝑆

Where: beyond the maximum of 2.5

Where: Pi is the design internal pres- psig allowed by API 650.

H is the design fluid height in sure in inches of water.

feet. D is the nominal diameter in API 620

D is the nominal tank diameter feet. Now that we have a couple of

in feet. W1 is the static weight of the answers to our questions, let us

G is the specific gravity of the tank components in pounds ask the next big one: what is

contents. force, which resist the pres- API 620 and how does it differ

S is the tank wall material sure/force uplift effect. from API 650?

allowable tensile stress for the The API 620 code is entitled

operating or test condition. BS EN 14015:2004 Design and Construction of Large,

CA is the corrosion allowance, BS EN 14015:2004 is the Welded, Low-Pressure Storage

if any. European design and analysis Tanks. After a quick review of

API 650 storage tanks are code for tanks. Its descriptive this code, it is readily apparent

often designed to work at title is Specification for the design that API 620 is a bit more tech-

temperatures of up to 500ºF and manufacture of site built, nologically advanced than its

(260ºC). For these higher vertical, cylindrical, flat bottomed, close cousin API 650. The main

temperature designs, the allow- above ground, welded, steel tanks difference, as mentioned

able stress of the material for the storage of liquids at ambi- earlier, is that this code has a

decreases. As a result, the ent temperature and above. higher range of design pres-

required wall thickness This EN code shares some sure (up to 15 psig).

increases in a linear fashion similarities with the API 650 API 620 is different from API

when using the 1-foot method code. Like API 650, EN 14015 650 in a number of other ways.

and in a slightly non-linear computes the shell course For example, API 620:

fashion when using the varia- required thickness via a fairly • Supports more varied types

ble point method. straightforward equation as of geometries (not just flat

In addition to causing hoop shown here: bottomed tanks).

stress and longitudinal stress in • Analyses a larger number of

𝐷𝐷

the tank wall, the slight inter- 𝑒𝑒 = 98𝑊𝑊 𝐻𝐻! − 0.3 + 𝑝𝑝 + 𝑐𝑐 types of components (like ellip-

20𝑆𝑆

nal pressure causes a tensile tical heads and exchanger

force (pressure × area) to be Where: components).

produced. This force pulls c is the corrosion allowance in • Accommodates a maximum

upward on the tank wall. This millimetres. design temperature of 250˚F.

positive upward force is coun- D is the tank diameter in • Supports specific calculations

tered by the weight of the tank metres. for openings in shells.

and roof (if not column-sup- e is the required thickness in • Offers different MDMT

ported). If the net force is millimetres. rules.

upward in any case or condi- Hc is the distance from the • Provides an explicit design

tion, the tank must be held bottom of the shell course methodology for the considera-

down by anchor bolts. under consideration as defined tion of both tensile and

The basic internal pressure in 9.2.1. compressive stresses on tank

case is just one example. There P is the design pressure at the elements.

are several other uplift formu- top of the tank in mbar. This final point really compli-

las in Tables 5.21a (metric) and S is the allowable stress for the cates matters. In the normal

5.21b (imperial), which must appropriate condition in N/ operation of a low pressure

also be considered. mm2. API 620 tank, it is easily

The net uplift due to design W is the density of the liquid conceivable that the stress in

pressure formula from Table under consideration in kg/l. the hoop direction is tensile

2 PTQ Q4 2016 www.eptq.com

while the axial or longitudinal ing the pressure until the given Analysis options and codes

stress is compressive. wall thickness is insufficient. Tank performs calculations in

Another scenario might be Not only do the shell courses accordance with the latest API

that the tank is under a slight and roof all have to be checked, Standards 620, 650 and 653.

vacuum. This case would but the roof to shell junction Analysis can also take into

generate a compressive stress must be analysed as well. This account wind, seismic and

in both the hoop and longitudi- process is tedious and settlement conditions plus

nal directions. time-consuming, not to calculate air venting require-

Because this represents a mention error-prone if you are ments to API 2000 Section 4.3.

potentially more severe condi- performing these calculations

tion, the allowable compressive by hand. Output and reports

stress must be computed at But this is where Intergraph After completing an analysis,

each point of concern and Tank comes in. Developed in users can view the results in a

compared to the actual the early 1990s, Tank is an tabular report or as a graphic

compressive stress. Then the analytical software solution diagram with associated data.

required thickness due to this that engineers and designers For convenience in verifying

condition can be determined. use to rate existing tanks and the results, the output reports

So, depending on the mode design new ones according to reference code sections used

in which the tank is operating, the design rules of interna- where applicable.

the wall could be fully under tional standards like API 650

compression in both directions, and API 653. In July 2016, a Material databases

fully under tension in both new analysis code was added Tank has many databases inte-

directions, or under a combina- to Tank. This new code is API gral to the package, which

tion of tension and 620. make it easy to select standard

compression. data for accurate analysis. A

API 620 computes and labels Data collection number of US and interna-

these unit forces as T1 and T2. The menu-driven interface of tional structural steel databases

When T1 and T2 are both in Tank enables the quick defini- are provided. Tank is delivered

tension, the required thickness tion of input and functions for with many material databases

is fairly straightforward to the accurate analysis of oil stor- to choose from. Of course, the

compute. It is just the maxi- age tanks to API standards. selections include those from

mum of the two values, Increased flexibility is the latest API 650 and 620

divided by the material allowa- provided by allowing users to standards.

ble stress, multiplied by the select any unit combination for

joint efficiency. Of course, the analyses or to produce reports. Tank design

corrosion allowance must be In addition, unit files are The following describes how

added to the final required completely user-definable so Intergraph Tank works for tank

thickness, if there is one. engineers are not bound by design.

When T1 and T2 are both program default settings. Even Figure 1 shows the main

compressive, the analysis existing jobs can be converted Tank design window. From

quickly becomes complex. In to any existing unit format. here, an engineer can select

this case, the tank wall is options and input the design

subject to buckling. The allow- User interface data for a tank. Once sufficient

able buckling stress must be The user interface in Tank information is submitted, the

calculated and is a function of presents only what is needed interactive 3D model is created

the thickness to radius ratio. at each point of information and displayed.

For API 620 designs, it is gathering. Therefore, users are Clicking on the icons in the

often required to determine the not burdened with ‘out-of-se- Input panel (see Figure 2)

maximum allowable working quence’ requirements for switches the data input and

pressure for both the internal information required for analy- allows information regarding

and external pressure cases. sis. You are asked for what is the roof, seismic loads, grillage,

This involves iteratively chang- needed, when it is needed. external pressure and so on to

www.eptq.com PTQ Q4 2016 3

be inputted. On some sections

of the input there are tabs.

Complete the data on each tab

as necessary.

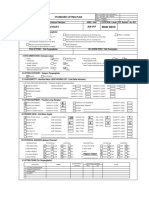

Tank analysis

After all of the tank data is

submitted, press the Analyze

button or F12 and TANK will

error check, analyse the data

and produce the output reports,

which contain the results of the

analysis. A typical output

report is shown in Figure 3.

Notice that the output

contains tables and code

formulas with variable substi-

Figure 1 Main design window of Tank software tutions. This helps users to

verify the software’s results

and figure out where all the

numbers come from.

A PDF document can quickly

be generated for records. Tank

version 2015 and later can

encapsulate and embed the 3D

model directly into the PDF.

You specifically need the

Adobe Reader DC to interact

with the 3D model. Non-Adobe

PDF readers do have the ability

Figure 2 Tank input panel to render and manipulate the

3D model.

The 3D PDF of the tank (see

Figure 4) is available from the

output report. A review of the

analysis results provides all the

information needed to proceed

with the design or evaluation

of the given geometry.

Conclusion

In this article, we have briefly

discussed three different tank

design codes, reviewed some

basic equations for internal

pressure design and done a

little comparison and contrast.

Tank design is complex and

can be confusing. Intergraph

Tank helps engineers perform

tank design easily and accu-

Figure 3 Tank output report rately to improve safety.

4 PTQ Q4 2016 www.eptq.com

TANK is a trademark of Intergraph.

Scott Mayeux is an Engineering Technical

Director with Intergraph, with 28 years of

experience in the software and oil and

gas industries. He is also an American

Society of Mechanical Engineers (ASME)

Code committee member who serves on

the Sub Group Heat Transfer Equipment

(SGHTE).

Jana Miller is an Engineering Solutions

Marketing Analyst with Intergraph, based

in Houston, Texas, and with 13 years

of experience in the process software

industry. Figure 4 PDF record of a tank design

www.eptq.com PTQ Q4 2016 5

You might also like

- PTQ q4 2016 Designing Storage TanksDocument4 pagesPTQ q4 2016 Designing Storage TanksJonathan RangelNo ratings yet

- API 620 ComparisonDocument5 pagesAPI 620 ComparisonMohamed ElfawalNo ratings yet

- API Tank StudyDocument100 pagesAPI Tank StudyraoNo ratings yet

- Difference Between API 650 and API 620 Tanks API 650 Vs API 620 With PDFDocument5 pagesDifference Between API 650 and API 620 Tanks API 650 Vs API 620 With PDFBogdan ChivulescuNo ratings yet

- Designing atmospheric storage tanks (ASTsDocument6 pagesDesigning atmospheric storage tanks (ASTsBramJanssen76100% (1)

- Api - 575 - Study - aid-API 653Document54 pagesApi - 575 - Study - aid-API 653CERTS100% (1)

- Designing Atmospheric Storage Tanks: Engineering PracticeDocument6 pagesDesigning Atmospheric Storage Tanks: Engineering PracticeTiar_Rahman_9553No ratings yet

- CAU2016 Tank PDFDocument21 pagesCAU2016 Tank PDFJagankumar100% (1)

- Storage Tank Design Using TANK Software and Re-Rating With API 620 API 579 With PDFDocument7 pagesStorage Tank Design Using TANK Software and Re-Rating With API 620 API 579 With PDFMinh Sang Phạm HuỳnhNo ratings yet

- Tank Info PDFDocument8 pagesTank Info PDFEric TingNo ratings yet

- Api 610Document11 pagesApi 610prakasharmyNo ratings yet

- Overview of API 682 Second Edition PDFDocument8 pagesOverview of API 682 Second Edition PDFWong DaNo ratings yet

- API 650 Tank Nozzle Load Allowable For Tank DiaDocument1 pageAPI 650 Tank Nozzle Load Allowable For Tank Diasemin prsesNo ratings yet

- Industrial Tank Talk 37Document2 pagesIndustrial Tank Talk 37hyperm2mNo ratings yet

- Tutorials Plus SolutionsDocument48 pagesTutorials Plus Solutionssultan iğrekNo ratings yet

- Comparison of Welded Steel Tank Design Standards APIDocument4 pagesComparison of Welded Steel Tank Design Standards APIAnggaNo ratings yet

- Sulzer-Bbt-Bbt BBT D E00585Document8 pagesSulzer-Bbt-Bbt BBT D E00585vikas guptaNo ratings yet

- What must to learnDocument1 pageWhat must to learnRafi RzyNo ratings yet

- WBIFR Systems GuideDocument27 pagesWBIFR Systems GuideneerajtrvNo ratings yet

- 620 TiDocument15 pages620 TiMSNo ratings yet

- Shell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.EngDocument8 pagesShell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.Engkhabiran100% (1)

- API575 Study GuideDocument57 pagesAPI575 Study GuideJoeMacEachernNo ratings yet

- Design and operation of a core barrel for high-temperature coringDocument7 pagesDesign and operation of a core barrel for high-temperature coringosamaNo ratings yet

- Floating Pan For Storage TanksDocument4 pagesFloating Pan For Storage TanksIndunil Prasanna Bandara WarnasooriyaNo ratings yet

- BREATHER VALVES - AUTOMATIC BLEEDER VALVES - API STANDARD 2000 - Storage Tank Engineering - Eng-TipsDocument3 pagesBREATHER VALVES - AUTOMATIC BLEEDER VALVES - API STANDARD 2000 - Storage Tank Engineering - Eng-TipsAndi SungNo ratings yet

- How To Determine Joint Efficiencies For Tank Inspection: About Simulator Resources BlogDocument4 pagesHow To Determine Joint Efficiencies For Tank Inspection: About Simulator Resources Blogmetal squad metal squadNo ratings yet

- API 650 & API 653 TrainingDocument56 pagesAPI 650 & API 653 TrainingSalah JallaliNo ratings yet

- Tank Selection COde - API 650Document2 pagesTank Selection COde - API 650Suresh Yadav0% (1)

- Choosing API 650 and API 620 TanksDocument7 pagesChoosing API 650 and API 620 TanksrajachemNo ratings yet

- 2nd Edition - Seal FAQsDocument9 pages2nd Edition - Seal FAQsphantuan080213No ratings yet

- BP Toledo v6 LoDocument20 pagesBP Toledo v6 LoMarcos ArraezNo ratings yet

- API 650 Part 1Document25 pagesAPI 650 Part 1Naveen RajNo ratings yet

- Erection Steel TankDocument86 pagesErection Steel TankDuke Maher Salem100% (1)

- API 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016Document31 pagesAPI 652/653 - How It Apply' S To Internal Tank Linings: Presented By: Darryl Corbin Nov. 18, 2016amit4179100% (1)

- Introd Duction To Api 547 2 EditionDocument11 pagesIntrod Duction To Api 547 2 EditionrahulNo ratings yet

- 03 Rpspl-Civil-Doc-La-01-30-01-20 PDFDocument75 pages03 Rpspl-Civil-Doc-La-01-30-01-20 PDFkapilNo ratings yet

- Revise Storage Tank InspectionsDocument17 pagesRevise Storage Tank InspectionsJacek100% (1)

- 100 Overview of Tank DesignDocument20 pages100 Overview of Tank Designkoparan35No ratings yet

- Costing Management For BegineerDocument8 pagesCosting Management For Begineeradonara_jeNo ratings yet

- Brochure 4 Pages 08.11 - Rev 1Document4 pagesBrochure 4 Pages 08.11 - Rev 1Ilham Yoga SaputraNo ratings yet

- 5 PDFDocument12 pages5 PDFmanojNo ratings yet

- Overview of API 682 and ISO 21049Document7 pagesOverview of API 682 and ISO 21049pedpixNo ratings yet

- What's New in API 610 11th EditionDocument4 pagesWhat's New in API 610 11th Editionshyam_anupNo ratings yet

- Labconco-9918500 Rev F Protector Storage Cabinets - Standard-Acid-solvent and Vacuum PumpDocument40 pagesLabconco-9918500 Rev F Protector Storage Cabinets - Standard-Acid-solvent and Vacuum PumpCalixto GrajalesNo ratings yet

- CST in IndonesiaDocument27 pagesCST in IndonesiaLukarsa2013No ratings yet

- Oil Storage Tank Project StandardsDocument10 pagesOil Storage Tank Project StandardsYusufNo ratings yet

- Goulds 3620i / 3640i: API 610 BB2 1 and 2 Stage, Between-Bearing, Radially Split PumpsDocument12 pagesGoulds 3620i / 3640i: API 610 BB2 1 and 2 Stage, Between-Bearing, Radially Split PumpsSergio Roa PerezNo ratings yet

- Api 600 II Clauses II Valve Design IIDocument1 pageApi 600 II Clauses II Valve Design IIAngga ErlanggaNo ratings yet

- Vdocuments - MX - Api 610 NotespdfDocument37 pagesVdocuments - MX - Api 610 Notespdfian.flako.idvNo ratings yet

- Pip Vesta002 Atmospheric Storage Tank Specification (Supplement To API Standard 650)Document19 pagesPip Vesta002 Atmospheric Storage Tank Specification (Supplement To API Standard 650)Rajesh PanchalNo ratings yet

- Engineering the CMOS Library: Enhancing Digital Design Kits for Competitive SiliconFrom EverandEngineering the CMOS Library: Enhancing Digital Design Kits for Competitive SiliconRating: 1 out of 5 stars1/5 (1)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Supercapacitors 101: A home Inventors HandbookFrom EverandSupercapacitors 101: A home Inventors HandbookRating: 5 out of 5 stars5/5 (1)

- Getstaff OGDocument121 pagesGetstaff OGjob saputraNo ratings yet

- FAB-2020-CPP1-grating Bunker Fuel Boat LandingDocument2 pagesFAB-2020-CPP1-grating Bunker Fuel Boat Landingjob saputraNo ratings yet

- Combine Crane PHE AW PlatformDocument11 pagesCombine Crane PHE AW Platformjob saputraNo ratings yet

- Ryco Hose Ends CatalogsDocument55 pagesRyco Hose Ends Catalogsjob saputraNo ratings yet

- Sprinter Markiersystem enDocument2 pagesSprinter Markiersystem enjob saputraNo ratings yet

- Bul HY14 M1 Commercial VLV SealKits 07-01-21Document20 pagesBul HY14 M1 Commercial VLV SealKits 07-01-21job saputraNo ratings yet

- Konversi UmumDocument1 pageKonversi Umumjob saputraNo ratings yet

- Bg4A & Bg4B Hydraulic Hoist: Installation, Maintenance and Service ManualDocument34 pagesBg4A & Bg4B Hydraulic Hoist: Installation, Maintenance and Service Manualridwansaungnage_5580No ratings yet

- Standard Lifting Plan COW PTWDocument5 pagesStandard Lifting Plan COW PTWjob saputraNo ratings yet

- Standard Lifting Plan COW PTW AWDocument5 pagesStandard Lifting Plan COW PTW AWjob saputraNo ratings yet

- Di 162 PDFDocument35 pagesDi 162 PDFcôngNo ratings yet

- 18vlpe07 Design of Semiconductor MemoriesDocument2 pages18vlpe07 Design of Semiconductor Memorieskruthikah apNo ratings yet

- Software, Firmware and Drivers For WD Products Importante1Document3 pagesSoftware, Firmware and Drivers For WD Products Importante1edmilosNo ratings yet

- Dataset For Neural NetworkDocument35 pagesDataset For Neural NetworkRanjan SatapathyNo ratings yet

- Python Comments: Creating VariablesDocument37 pagesPython Comments: Creating VariablesTanveer Ahmed100% (1)

- Fusion Lab Install InstructionsDocument6 pagesFusion Lab Install Instructionsmamai nebeNo ratings yet

- Gaurav Kumar ResumeDocument3 pagesGaurav Kumar Resumegaurav kumarNo ratings yet

- 400 - Lrcture 1 Problems DMDocument2 pages400 - Lrcture 1 Problems DMNatia ShpetishviliNo ratings yet

- Procedure To Create DeltaV RegistrationDocument16 pagesProcedure To Create DeltaV RegistrationSilvia Del RíoNo ratings yet

- Metodologias Implementacion ERPDocument8 pagesMetodologias Implementacion ERPCarolina Orellana MoralesNo ratings yet

- Cara Aktivasi Nero Burning ROM 2014Document1 pageCara Aktivasi Nero Burning ROM 2014tamamsampangNo ratings yet

- Core Banking Solutions CBS) - Meaning, Types, Benefits & TrendsDocument28 pagesCore Banking Solutions CBS) - Meaning, Types, Benefits & TrendsSantiagoTrilloNo ratings yet

- Introduction To Seaborn: Chris MoDocument18 pagesIntroduction To Seaborn: Chris MovrhdzvNo ratings yet

- Class Project P1 - Ph.1 - InitiatingDocument96 pagesClass Project P1 - Ph.1 - InitiatingMontellia GantNo ratings yet

- E Library ProjectDocument87 pagesE Library ProjectNil WangduNo ratings yet

- IPCAgility SecurityWhitePaper v32Document22 pagesIPCAgility SecurityWhitePaper v32HatemNo ratings yet

- DevOps Interview Questions - 1 PDFDocument224 pagesDevOps Interview Questions - 1 PDFNagapuri BalakrishnaNo ratings yet

- Flux Cube and WebLogic Application Servers General OverviewDocument14 pagesFlux Cube and WebLogic Application Servers General OverviewhaymanotNo ratings yet

- Lecture 4 - 5 - 6 - CSE - Microprocessor and Assembly LanguageDocument63 pagesLecture 4 - 5 - 6 - CSE - Microprocessor and Assembly LanguagefaridulNo ratings yet

- Java Module 1 Chapter 2Document20 pagesJava Module 1 Chapter 2Rohit BrlaNo ratings yet

- Ironcad 6 Getting - StartedDocument191 pagesIroncad 6 Getting - StartedCalin TrutaNo ratings yet

- The Sphere Packing Problem in 24 Dimension - ViazovskaDocument17 pagesThe Sphere Packing Problem in 24 Dimension - ViazovskaJoãoNo ratings yet

- RealDash Digital Signal MonitoringDocument2 pagesRealDash Digital Signal MonitoringMartin PerdomoNo ratings yet

- DX DiagDocument34 pagesDX DiagChrismaNo ratings yet

- db2 Working in LabDocument44 pagesdb2 Working in Labahw0000007No ratings yet

- Chapter 5Document21 pagesChapter 5oduniyiabimNo ratings yet

- Clever - Dispense - 04 - 05 e - V2Document67 pagesClever - Dispense - 04 - 05 e - V2Jozef SlivkaNo ratings yet

- Python 3 Oops Hands OnDocument7 pagesPython 3 Oops Hands OnrajeshNo ratings yet

- SACS-011 Sanitization StandardDocument12 pagesSACS-011 Sanitization StandardimohammadtariqueNo ratings yet

- SLT FormDocument8 pagesSLT Formcmukhongo_679153453No ratings yet