Professional Documents

Culture Documents

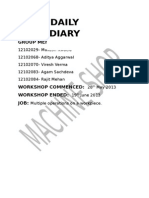

Workshop

Uploaded by

Muhammad Abtahee0 ratings0% found this document useful (0 votes)

4 views2 pagesThe document describes the procedure for preparing a fatigue test sample from an aluminum rod using a lathe machine. The key steps are:

1. An aluminum rod is cut to size and clamped in the lathe.

2. Turning operations are performed to reduce the diameter in stages and create features like inward curves and tapers.

3. Sanding is used to smooth the surfaces between operations to prepare the sample for fatigue testing.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes the procedure for preparing a fatigue test sample from an aluminum rod using a lathe machine. The key steps are:

1. An aluminum rod is cut to size and clamped in the lathe.

2. Turning operations are performed to reduce the diameter in stages and create features like inward curves and tapers.

3. Sanding is used to smooth the surfaces between operations to prepare the sample for fatigue testing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesWorkshop

Uploaded by

Muhammad AbtaheeThe document describes the procedure for preparing a fatigue test sample from an aluminum rod using a lathe machine. The key steps are:

1. An aluminum rod is cut to size and clamped in the lathe.

2. Turning operations are performed to reduce the diameter in stages and create features like inward curves and tapers.

3. Sanding is used to smooth the surfaces between operations to prepare the sample for fatigue testing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Fatigue test sample

Procedure:

First of all we performed turning on

the specimen to reduce it to the size

(7.8 mm in

diameter) we needed for this

experiment.

2. Then we used sand paper to

make its surface smooth so it can

perform more efficiently

during the experiment

First of all we performed turning

on the specimen to reduce it to

the size (7.8 mm in

diameter) we needed for this

experiment.

2. Then we used sand paper to

make its surface smooth so it can

perform more efficiently

during the experiment

Firstly, we cut 20mm dia Aluminum rod to 160mm length with hacksaw.

Now clamp the rod in lathe machine.

Turning tool will be used in tool post.

Perform facing operation on both ends.

Mark center at one end with drill using drill chuck on tail stock.

Clamp the specimen to spindle chuck with 10mm clamping space.

The center we marked earlier will be used to hold the specimen so that it spins with balance, this will

be done using dead center quill on tail stock.

Now we will do turning operation on sample from tail end towards spindle chuck at a length of

109.5mm and reduce its dia from 20mm to 7.9mm.

Now we will turn additional 17mm length of specimen to 14mm diameter.

Now a 2mm round cut tool will be used to create an inward curve as shown at point Ra.

1500 grit Sand paper will be used to smoothen the finishing.

Now specimen will be removed from chuck and will be clamped oppositely from that 14mm dia

portion.

Tool post will be untightened and we will set it at 60-degree angle.

Now we will mark the face of specimen at 14mm dia.

We will feed the tool and it will perform taper turning operation from the leading edge to a length of

28mm hence creating a slope of 6 degrees.

2000 grit sand paper will be used to smoothen the specimen.

Now tool post will be set as default.

Facing will be performed on the end reducing the dia to 11mm.

Excess material will be removed.

We will un clamp the specimen and its ready.

You might also like

- DIY Tri-Fold Futon BaseDocument27 pagesDIY Tri-Fold Futon BaseJosh Grantmorceau100% (3)

- Bug Baits Fortress InstructionsDocument9 pagesBug Baits Fortress InstructionsBenjamin Dunning86% (7)

- Slim Ballpoint Pen Hardware Kit: Preparing The Material BlanksDocument4 pagesSlim Ballpoint Pen Hardware Kit: Preparing The Material BlanksLachaud YvonNo ratings yet

- DIY Metal Bending ToolDocument30 pagesDIY Metal Bending Toolafrica school100% (1)

- How To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsDocument24 pagesHow To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsJose German Ojeda CruzNo ratings yet

- How To Build A QFH (Quadrifilar Helix Antenna) To Download Images From Weather SatellitesDocument19 pagesHow To Build A QFH (Quadrifilar Helix Antenna) To Download Images From Weather SatellitesJose Maria Garcia GarciaNo ratings yet

- Pneumatic Air Graver From BoltDocument69 pagesPneumatic Air Graver From BoltRuger B.No ratings yet

- Wood HingesDocument15 pagesWood HingesLuis Valens100% (1)

- Taper Turning by Taper Attachment MethodDocument4 pagesTaper Turning by Taper Attachment MethodZia JanNo ratings yet

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3No ratings yet

- Cutter Making David CreedDocument19 pagesCutter Making David CreedBruno Delsupexhe100% (1)

- Workshop RepDocument17 pagesWorkshop RepMuhammad AbtaheeNo ratings yet

- A Power File From An Angle GrinderDocument18 pagesA Power File From An Angle GrinderDeanNo ratings yet

- Easy To Build Stirling Engine FanDocument14 pagesEasy To Build Stirling Engine Fanpatel_kalpesh1241100% (1)

- Hammer Full ReportDocument9 pagesHammer Full ReportVince Ong100% (3)

- WorkshopDocument1 pageWorkshopMuhammad AbtaheeNo ratings yet

- Tensile SampleDocument3 pagesTensile SampleMuhammad AbtaheeNo ratings yet

- Lathe Report 1Document17 pagesLathe Report 1Muhammad AbtaheeNo ratings yet

- Tool Makers Clamp Write UpDocument5 pagesTool Makers Clamp Write Upmevansmetreel100% (1)

- Presentation of Key RingDocument2 pagesPresentation of Key RingJoydeep RoyNo ratings yet

- Veranda StepsDocument2 pagesVeranda StepsFe TusNo ratings yet

- Square ShoulderDocument1 pageSquare ShoulderMurtaza NaeemNo ratings yet

- Model - I Turning Operations Performed On A Given Mild Steel Work PieceDocument4 pagesModel - I Turning Operations Performed On A Given Mild Steel Work PiecejssrikantamurthyNo ratings yet

- TurningDocument9 pagesTurningAhmed RexNo ratings yet

- A Power File From An Angle GrinderDocument18 pagesA Power File From An Angle GrinderPrimos TotalesNo ratings yet

- AutoCAD ManualDocument8 pagesAutoCAD ManualSharvaniNo ratings yet

- Workshop Technology: EXPERIMENT 1: Hand and Machine Tools (Making A Pin Hammer)Document17 pagesWorkshop Technology: EXPERIMENT 1: Hand and Machine Tools (Making A Pin Hammer)Tan YikcongNo ratings yet

- Objective:: - EquipmentDocument3 pagesObjective:: - EquipmentUtkarsh AryaNo ratings yet

- Kitless Fountain Pen Tutorial: A Tutorial By: Shawn NewtonDocument7 pagesKitless Fountain Pen Tutorial: A Tutorial By: Shawn NewtonRafael RogelNo ratings yet

- Solar Scorcher: An Innovation ProjectionDocument43 pagesSolar Scorcher: An Innovation ProjectionShane Catherine BesaresNo ratings yet

- MP LabDocument14 pagesMP LabJagan RmdNo ratings yet

- m.1 Me 15 - Machine Shop Manual Rev 0 Jun 17 2022Document4 pagesm.1 Me 15 - Machine Shop Manual Rev 0 Jun 17 2022Funa LovelymeNo ratings yet

- Daily DiaryDocument12 pagesDaily DiaryVireshNo ratings yet

- LathesDocument8 pagesLathesapi-513103092No ratings yet

- MFT Lab Manual 2017-18 Even UpdatedDocument63 pagesMFT Lab Manual 2017-18 Even UpdatedPrakash ThangavelNo ratings yet

- All Lab Reports of Manufacturing ProcessesDocument28 pagesAll Lab Reports of Manufacturing ProcessesZia JanNo ratings yet

- Shop-4-Cross Peen Hammer HeadDocument8 pagesShop-4-Cross Peen Hammer HeadJag MasterNo ratings yet

- To Complete This Task You Will Need The Following Items:: Roll CalculationDocument4 pagesTo Complete This Task You Will Need The Following Items:: Roll CalculationApollyonNo ratings yet

- Design and Fabrication Automatic Paper Cutter Using Geneva MechanismDocument10 pagesDesign and Fabrication Automatic Paper Cutter Using Geneva Mechanismgowrisankar32No ratings yet

- Lap Report TemplateDocument7 pagesLap Report TemplateMd Sajib SheikhNo ratings yet

- LathesDocument7 pagesLathesapi-478808705No ratings yet

- Drawing A Screw Solidworks PDFDocument11 pagesDrawing A Screw Solidworks PDFGeorge SaadehNo ratings yet

- Mapúa University: Shop Practice No. 8Document10 pagesMapúa University: Shop Practice No. 8marisonNo ratings yet

- Making Square Sticks Using A TablesawDocument5 pagesMaking Square Sticks Using A TablesawTisyam Noor FirmansyahNo ratings yet

- Ex No - 2 HOPPER MAKINGDocument4 pagesEx No - 2 HOPPER MAKINGANISH PATIL (RA2111029010064)No ratings yet

- ScreeningDocument13 pagesScreeningPARTHA SARATHI PANDANo ratings yet

- Assignment 2Document17 pagesAssignment 2AakarshNo ratings yet

- Rectangular Tray MakingDocument6 pagesRectangular Tray MakingHell YessNo ratings yet

- In Basic Wood Working The Requires Precision and Patience To Produce A Good Quality ProductDocument10 pagesIn Basic Wood Working The Requires Precision and Patience To Produce A Good Quality ProductAngeloLorenzoSalvadorTamayoNo ratings yet

- Mapúa University: Shop Practice No.7Document5 pagesMapúa University: Shop Practice No.7marisonNo ratings yet

- Manufacturing Processes Open Ended Lab ReportDocument15 pagesManufacturing Processes Open Ended Lab ReportDawood KhanNo ratings yet

- Fitting - Fabrication Manual 2020Document14 pagesFitting - Fabrication Manual 2020Malik AbubakerNo ratings yet

- Lab Manual - BWPDocument23 pagesLab Manual - BWPAneesh KumarNo ratings yet

- English Advanced Bamboo Furniture Making TechniquesDocument66 pagesEnglish Advanced Bamboo Furniture Making TechniquesJoe HanNo ratings yet

- W650 Owners ManualDocument24 pagesW650 Owners ManualOliver DaviesNo ratings yet

- AngleSettingJig 2Document5 pagesAngleSettingJig 2mikkelNo ratings yet

- Instructionsf16 6Document1 pageInstructionsf16 6Nicolas JamesNo ratings yet

- M-Jet ManualDocument17 pagesM-Jet Manualh2oo2hNo ratings yet

- Manual Model 180 XTEM Prep Kit 2007Document7 pagesManual Model 180 XTEM Prep Kit 2007iorga_alexandruNo ratings yet