Professional Documents

Culture Documents

CRI Installation FluidControl Case Study English

Uploaded by

AbdulSamiMinhas0 ratings0% found this document useful (0 votes)

2 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageCRI Installation FluidControl Case Study English

Uploaded by

AbdulSamiMinhasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

FluidControl Case Study

FluidControl Engineers Challenging CRI Installation in

Environmentally Sensitive Area Offshore Bahrain

Challenges

• Drilling in shallow water,

environmentally sensitive area

(Dugong feeding ground).

• Small rig that could position

itself in shallow water and avoid

damaging marine life was

required, which meant limited

deck space.

• Because of space restrictions,

CRI unit could not be pre

installed in the yard.

• Short term contract requiring

precise execution.

Well Information

• Shallow water (<30ft)

• Location: Offshore Bahrain

Solution & Results

• NOV FluidControl engineered a Because of rig space constraints, an operator drilling any unscheduled maintenance to the CRI package.

cuttings containment system in shallow water offshore Bahrain required a cuttings Over the course of the project, the cuttings slurry

and a cuttings re-injection containment system and cuttings re-injection was re-injected without environmental incident.

package for a short term package that could be installed temporarily on Rig down of the CRI and skip & ship equipment was

injection program. Space

the rig and safely removed after use. The project completed in one day, and the well was successfully

required a service provider with the experience to drilled within the operator’s specified time

restraints on the small rig

preplan, engineer and install the equipment without parameters. A total of approximately of 7000 bbl. was

required that NOV welders

disrupting a tight drilling schedule. NOV FluidControl injected in a short time period.

create custom-made load engineers surveyed the rig and engineered a unit

bearing frames and other custom that was compatible with the rig’s compact footprint. The equipment package consisted of:

parts for the containment and The initial operation required the rig to conduct a • 1 x 12mtr, 12” screw conveyor (length of shale

re-injection system. skip and ship operation to collect cuttings from top shakers)

• Equipment quickly mobilized hole drilling until the injection zone was reached. • 1 x 6mtr, 12” screw conveyor from primary auger to

between contract award and skip & ship and CRI package

installation.

Upon reaching casing point the rig conducted • 1 x CRI slurrification unit, consisting of a course and

offline activities that allowed FluidControl a 96 hour a fines tank.

• Cuttings re-injection completed

window to install the cuttings re-injection package • 1 x Twin low pressure injection pump

successfully with no

in order to drill the remainder of the well. It was

environmental impact. important that the operation could switch between Contact a NOV FluidControl representative to learn

• Installation and removal of skip & ship (for collecting drilled out shoe and more about Cuttings Re-injection and other waste

CRI unit completed with no cement) and CRI with no interruption to drilling. This transfer and containment needs.

interruption to drilling schedule. also provided a contingency back up in the case of

4310 N Sam Houston Pkwy East

Houston, Texas 77032

United States

Phone: 713 482 0500

Fax: 713 482 0699

©National Oilwell Varco - All rights reserved - D8C1004593-MKT-001 Rev. 01

FluidControl@nov.com nov.com

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 09 - Experience Macculloch Lwi CampaignDocument13 pages09 - Experience Macculloch Lwi CampaignAliNo ratings yet

- Decommissioning & Well AbandonmentDocument14 pagesDecommissioning & Well AbandonmentAMIAN DidierNo ratings yet

- Maersk Innovator AdvantagesDocument2 pagesMaersk Innovator AdvantagesHesham FandyNo ratings yet

- CS_PWT_NORTHSEA_13102015_SCREENDocument2 pagesCS_PWT_NORTHSEA_13102015_SCREENherbster28No ratings yet

- Method of StatementDocument9 pagesMethod of StatementSunil Anto100% (2)

- Integrated Operations in Oil and Gas DrillingDocument25 pagesIntegrated Operations in Oil and Gas DrillingKaoru AmaneNo ratings yet

- Innovation Case Study: (JUNE 2009 - 2011 (CURRENT) ) Kanoo P&IP - Corrosion SBU TeamDocument26 pagesInnovation Case Study: (JUNE 2009 - 2011 (CURRENT) ) Kanoo P&IP - Corrosion SBU TeamRaghavanNo ratings yet

- Nacap HDD Brochure DefDocument8 pagesNacap HDD Brochure DefxheurtauxNo ratings yet

- Two Pipeline Shore Appraoches-Berri and Qatif PDFDocument4 pagesTwo Pipeline Shore Appraoches-Berri and Qatif PDFdndudcNo ratings yet

- A1F6W9 - Keystone HDD Execution Plan Shannon CreekDocument19 pagesA1F6W9 - Keystone HDD Execution Plan Shannon CreekAsad KhawajaNo ratings yet

- Division Street Outfall: Environmental Dredging and Capping ProjectDocument30 pagesDivision Street Outfall: Environmental Dredging and Capping Projectzyrrel perey hoNo ratings yet

- Scope of Work Location Prepration For Wafa Drilling Well A61Document7 pagesScope of Work Location Prepration For Wafa Drilling Well A61ابرار عمرNo ratings yet

- Frac Rig Up North SeaDocument2 pagesFrac Rig Up North SeaLeonNo ratings yet

- Apache Callater Project: Offshore Oil and GasDocument5 pagesApache Callater Project: Offshore Oil and Gasegy pureNo ratings yet

- H012057 RapidStartCT LADocument2 pagesH012057 RapidStartCT LAJose Marval RodriguezNo ratings yet

- Procedure - Tie-In To Existing FacilitiesDocument8 pagesProcedure - Tie-In To Existing FacilitiesjabpunNo ratings yet

- Pile dredging and cutting servicesDocument15 pagesPile dredging and cutting servicesUddipan KunduNo ratings yet

- Jack-Up and Platform Drilling and Completion Systems - UKDocument28 pagesJack-Up and Platform Drilling and Completion Systems - UKenrique ojedaNo ratings yet

- Construction Site Layout and Logistics PDFDocument42 pagesConstruction Site Layout and Logistics PDFAKSHAYNo ratings yet

- Webinar On Health, Safety & Environment For DSF Operators: Best Practices On HSE: With Rig OperationsDocument25 pagesWebinar On Health, Safety & Environment For DSF Operators: Best Practices On HSE: With Rig Operationsshehryar khanNo ratings yet

- A1F9V8 - CP Rail and Cargill HDD Execution PlanDocument17 pagesA1F9V8 - CP Rail and Cargill HDD Execution PlanSbitNo ratings yet

- Stormwater Attenuation Design Guide Dec 2019Document11 pagesStormwater Attenuation Design Guide Dec 2019Kwadwo Siaw-MarfoNo ratings yet

- SPE 134586 Casing Drilling Application WDocument17 pagesSPE 134586 Casing Drilling Application WAmine MimoNo ratings yet

- Epa 40 CFR 112Document32 pagesEpa 40 CFR 112Vlad420No ratings yet

- API RP 8B Drilling Equipment CAT IV InspectionsDocument1 pageAPI RP 8B Drilling Equipment CAT IV InspectionsEdgar MejiasNo ratings yet

- LDD Gwynt y Môr OWFDocument2 pagesLDD Gwynt y Môr OWFmasih.jr.1401No ratings yet

- Grouting Method StatementDocument12 pagesGrouting Method StatementRajarajan RajaNo ratings yet

- PPVC lifting best practices for volumetric constructionDocument31 pagesPPVC lifting best practices for volumetric constructionPyae PhyoNo ratings yet

- Burns Noah Project Proposal Presentation 2023Document13 pagesBurns Noah Project Proposal Presentation 2023noah burnsNo ratings yet

- SOW_KTCFloatationMachinesRepairs_Rev01 REVISED SCOPEDocument23 pagesSOW_KTCFloatationMachinesRepairs_Rev01 REVISED SCOPEm_muchakaziNo ratings yet

- Project Safety ChecklistDocument4 pagesProject Safety ChecklistAejaz Mujawar100% (1)

- Bridge Load TestDocument4 pagesBridge Load TestvivekNo ratings yet

- Prensentation Slides For Industry BriefingDocument40 pagesPrensentation Slides For Industry BriefingkunalkhubaniNo ratings yet

- Aguas Subterraneas, en Mina de Tajo AbiertoDocument35 pagesAguas Subterraneas, en Mina de Tajo AbiertoLeonor Patricia0% (1)

- Design exploratory wells safely within budgetDocument55 pagesDesign exploratory wells safely within budgetKolawole AdisaNo ratings yet

- Short Radius PDFDocument10 pagesShort Radius PDFCHEKOUFI SaidNo ratings yet

- Compro TrirekonDocument14 pagesCompro Trirekonhadipurnomoputra100% (1)

- Multilateral AsiaDocument2 pagesMultilateral AsiaNazer CorleoneNo ratings yet

- JFO 2020 Overview Brochure - Digital EditionDocument7 pagesJFO 2020 Overview Brochure - Digital Editionjogioscarsinaga9679No ratings yet

- Hydrocyclones and Crudesep: Case History: Brownfield ImprovementDocument1 pageHydrocyclones and Crudesep: Case History: Brownfield ImprovementSun NanNo ratings yet

- Norshore Drill Ship Presentation 1113Document34 pagesNorshore Drill Ship Presentation 1113Grand PappyNo ratings yet

- Subsea Innovation Pipeline Repair PDFDocument7 pagesSubsea Innovation Pipeline Repair PDFamalhaj2013No ratings yet

- IADC/SPE 59209 A New Selective Lateral Re-Entry SystemDocument6 pagesIADC/SPE 59209 A New Selective Lateral Re-Entry SystemJorge FernandoNo ratings yet

- 22 - Di - 1302985 - CS - Digital ERA Saudi - WEBDocument2 pages22 - Di - 1302985 - CS - Digital ERA Saudi - WEBNew Auto TVNo ratings yet

- Corrib Field P6 Flexible Flowline Installation: Method Statement Revision 02 November 2020Document7 pagesCorrib Field P6 Flexible Flowline Installation: Method Statement Revision 02 November 2020sunday austineNo ratings yet

- DNV Maritime - New Tanker Rules SummaryDocument8 pagesDNV Maritime - New Tanker Rules Summaryy_596688032No ratings yet

- Well Intervention - First CoilHose Operation in Malaysia CS A4 ProofDocument1 pageWell Intervention - First CoilHose Operation in Malaysia CS A4 ProofdanielNo ratings yet

- Everything You Wanted To Know About Tanks But - ASTs - RevisionsDocument75 pagesEverything You Wanted To Know About Tanks But - ASTs - Revisionsoscar100% (2)

- MS For Core Walls Dowels Location Repair (Towers)Document5 pagesMS For Core Walls Dowels Location Repair (Towers)rayNo ratings yet

- Candidate Profile: CANDIDATE ID: SA-TRA-031 - Rev.01Document6 pagesCandidate Profile: CANDIDATE ID: SA-TRA-031 - Rev.01INGENIERA NNCHORTNo ratings yet

- Welltec Corporate Presentation - PDFDocument18 pagesWelltec Corporate Presentation - PDFzapspaz0% (1)

- Op-3-23. Supervision of Vertical Drains Installation: Work Instructions For EngineersDocument0 pagesOp-3-23. Supervision of Vertical Drains Installation: Work Instructions For EngineersdjgiumixNo ratings yet

- Preservationslidepkg 130316185342 Phpapp01Document29 pagesPreservationslidepkg 130316185342 Phpapp01Pitipong SunkhongNo ratings yet

- MASTER METHOD STATEMENT - WalsallDocument24 pagesMASTER METHOD STATEMENT - WalsallSaad AmerNo ratings yet

- Generator Room Ventilation SilencersDocument2 pagesGenerator Room Ventilation SilencersAhmed AzadNo ratings yet

- Marginal Field DevelopmentDocument56 pagesMarginal Field DevelopmentkurtbkNo ratings yet

- White Paper - DecomDocument12 pagesWhite Paper - DecomRavikumar mahadevNo ratings yet

- Contoh Aspek ImpactDocument22 pagesContoh Aspek ImpactNuny SantosNo ratings yet

- B.E. (Applied Chemistry) I YearDocument4 pagesB.E. (Applied Chemistry) I YearamirNo ratings yet

- The Advantages and Disadvantages of Hybrid CarsDocument6 pagesThe Advantages and Disadvantages of Hybrid CarsSaya PendakiNo ratings yet

- Edible Oil Industry Analysis SubmittedDocument26 pagesEdible Oil Industry Analysis SubmittedPradnesh Arun Deshmukh50% (2)

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocument4 pagesDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNo ratings yet

- Oil and Gas Sector in Myanmar: Warmly Welcome All Delegates From United State of AmericaDocument19 pagesOil and Gas Sector in Myanmar: Warmly Welcome All Delegates From United State of AmericaYe PhoneNo ratings yet

- Pipesys TutorialDocument62 pagesPipesys TutorialNatalia Prieto JimenezNo ratings yet

- Chevron Corrective Action OrderDocument8 pagesChevron Corrective Action OrderThe Salt Lake TribuneNo ratings yet

- Lummus Technology: Most Broad, Diversified Technology PortfolioDocument2 pagesLummus Technology: Most Broad, Diversified Technology PortfolioSARFRAZ ALINo ratings yet

- Use of Microwave and Ultra Sonic EnergyDocument29 pagesUse of Microwave and Ultra Sonic EnergyArpit SinghNo ratings yet

- Arokoyu Ogoro Amanoritsewo Petro Filling Stations Location 2015Document20 pagesArokoyu Ogoro Amanoritsewo Petro Filling Stations Location 2015Ahmed GhawiNo ratings yet

- Standard Oil Vs CasteloDocument2 pagesStandard Oil Vs Castelomelfabian100% (1)

- Dragon Oil Company Profile 2016Document44 pagesDragon Oil Company Profile 2016amir100% (1)

- NCD MB Handbook of Operational GuidelinesDocument228 pagesNCD MB Handbook of Operational GuidelinesChris Opuba100% (1)

- 01 - Introduction To Reservoir ManagementDocument23 pages01 - Introduction To Reservoir ManagementHosni Ben Mansour100% (1)

- Fpso Global Project Hotspots Caa 29 janTyfUin880NyIyy1q63hsNNE4CYqEmQGrT4X3iX5jDocument7 pagesFpso Global Project Hotspots Caa 29 janTyfUin880NyIyy1q63hsNNE4CYqEmQGrT4X3iX5jart_5No ratings yet

- 09.40 10.00 G. K. Acharya Deputy General Manager IOC Indian Oil Corporation 1Document36 pages09.40 10.00 G. K. Acharya Deputy General Manager IOC Indian Oil Corporation 1ra1958jaNo ratings yet

- Glossaire des termes maritimesDocument16 pagesGlossaire des termes maritimesbaryma100% (1)

- Petroleum Refinery: Soran University Petroleum Engineering DepartmentDocument31 pagesPetroleum Refinery: Soran University Petroleum Engineering DepartmentHemenMoNo ratings yet

- As 1767.1-1999 Insulating Liquids Specification For Unused Mineral Insulating Oils For Transformers and SwitcDocument10 pagesAs 1767.1-1999 Insulating Liquids Specification For Unused Mineral Insulating Oils For Transformers and SwitcSAI Global - APACNo ratings yet

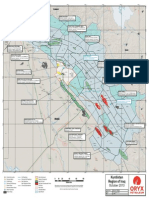

- Kurdistan Region of Iraq Investors MapDocument1 pageKurdistan Region of Iraq Investors Maphasan_676489616No ratings yet

- Choosing the Best Sand Control MethodDocument10 pagesChoosing the Best Sand Control MethodAnonymous Nb2o12WyQjNo ratings yet

- Satuan Kerja Khusus Pelaksana Kegiatan Usaha Hulu Minyak Dan Gas Bumi (SKK Migas)Document2 pagesSatuan Kerja Khusus Pelaksana Kegiatan Usaha Hulu Minyak Dan Gas Bumi (SKK Migas)puput wibowoNo ratings yet

- MBA Exam - Human Resource Management"TITLE"Evaluating Leadership Development Returns at BPDocument2 pagesMBA Exam - Human Resource Management"TITLE"Evaluating Leadership Development Returns at BPVinodh Kumar LNo ratings yet

- BS&W Thermo Measurement-DatasheetDocument4 pagesBS&W Thermo Measurement-DatasheetBEN ADEGBULUNo ratings yet

- HireDocument1 pageHireMohamed SONo ratings yet

- Condor Components and Systems ActualDocument164 pagesCondor Components and Systems ActualjpncorreiaNo ratings yet

- Natural GasDocument39 pagesNatural GasElvis NathanielNo ratings yet

- 1.1 Chemical Composition and Physical Property of Reservoir FluidDocument23 pages1.1 Chemical Composition and Physical Property of Reservoir FluidJames Freeman100% (1)