Professional Documents

Culture Documents

Rectangular Water Tank Design

Uploaded by

trsrajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rectangular Water Tank Design

Uploaded by

trsrajCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/332052267

Design of RCC Rectangular Water Tank: A Comparative Study Between

Approximate and IS Code Method

Article in SSRN Electronic Journal · January 2019

DOI: 10.2139/ssrn.3353083

CITATION READS

1 3,412

2 authors, including:

Ashish Nim

IPS Academy

3 PUBLICATIONS 2 CITATIONS

SEE PROFILE

All content following this page was uploaded by Ashish Nim on 13 June 2022.

The user has requested enhancement of the downloaded file.

Available online at http://ssrn.com

SSRN-ELSEVIER (2018-2019)

International conference on “Recent Advances in Interdisciplinary Trends in Engineering &

Applications”

Design of RCC Rectangular Water Tank: A Comparative

Study Between Approximate and IS Code Method.

a b

Vineet Kumar Saha , Ashish Nim

a

Undergraduate, Civil Engineering Department, 22 C Rajendra Nagar, Indore and 452012, India

b

Assistant Professor, Civil Engineering Department, 212-213 new Umariya colony, Indore and 453331, India

Abstract

Enormous research has been made to meet the water demand either on commercial or public level via RCC tank supply.

Meanwhile minimal researches are made on rectangular RCC water tanks. Tanks are significantly used as storage structure

which can be either below or above from ground level to store liquid petroleum, water, petroleum products and in-

distinguishable liquids. The paper emphasizes on analytical comparison to justify the effectiveness of rectangular water

tank for nominal capacity in terms of material feasibility design by approximate method and IS code method. When

compared, several parameters such as moment, direct tension & depth of vertical walls as well as slab got analysed in

which IS code method overwhelmed approximate method. IS code method have been proved economical & feasible

during design. The tanks resting on ground are directly supported on levelled ground and the walls of these tanks are

subjected to hydrostatic pressure while the base of the tank is subjected to weight of liquid with upward soil pressure. The

base performs no special structural function and can be designed with the minimum required steel. To have complete

construction overview including technical and financial estimation of rectangular RCC water tanks, our basic objective is

to create a good service with functional utility at an acceptable cost.

Keywords: Water tank, WSM (Working State Method), Economic, Feasible, Design moment, Depth, Suitability.

1. Introduction

Storage reservoirs or reservoir tanks are used to store liquid petroleum, water, petroleum products and alike

liquids. The design and force analysis of tank is same irrespective of chemical nature of the product and

designed as the crack free structures to abolish any leakage. Water or liquid petroleum retaining slab or walls

could be of reinforced concrete with sufficient cover to the reinforcement, adequate cover is necessary to

resist corrosion of reinforcement. To avoid any leakage and to supply ample strength, concrete of grade M25

and above is endorsed for liquid retaining structures. No special treatment to the surface is required as water

does not react with concrete. Tanks are significantly used as storage structure, which can be either below or

above from ground level. Reservoirs below the ground level are commonly built to store large quantities of

water while those of overhead types are built for direct distribution by gravity flow. For concrete it has to be

impervious higher density of concrete should be achieved and to achieve imperviousness, proper compaction

with adequate water cement (w/c) ratio using vibrators should be implemented (as w/c ratio is directly

proportional to permeability of concrete). Cement content varying from 330 Kg/m3 to 530 Kg/m3 is

considered in order to acquire low shrinkage. The higher head of liquid pertain more leakage; meanwhile it

has been observed that, no leakage problem occurred up to 15 m water head. For construction of liquid

retaining structures, high strength deformed bars of grade Fe415 are recommended however mild steel bars are

rarely took in consideration. Proper placing of reinforcement with high strength deformed bars leads to vanish

crack distribution, however crack width of 0.10 mm can be tolerated as permissible value for liquid retaining

structures while designing for liquid retaining structures “Code of Practice for the storage of Liquids- IS 3370

(Part I to IV)” are recommended. Flexural strength of concrete is evaluated as per clause 6.2.2 of IS 456 –

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

2000, using formula fcr=0.7√fck MPa. In order to minimize cracking due to shrinkage and temperature,

minimum reinforcement is recommended as:

• For thickness ≤ 100 mm = 0.3%

• For thickness ≥ 450 mm = 0.2%

• For thickness between 100 mm to 450 mm = varies linearly from 0.3% to 0.2%

For concrete thickness ≥ 225 mm, two layers of reinforcement to be placed, i.e. on both faces. Cover to

reinforcement should be;

• 25 mm,

• Diameter of main bar.

1.1 Introduction to Working State Method

In this method the concrete and steel are assumed to be elastic. At the worst combination of working loads, the

stresses in materials are not exceeded beyond permissible stresses. For different grades of concrete and steel,

permissible stresses given in Tables 21 and 22 of IS 456-2000. The modular ratio ‘m’ of composite material

i.e., the ratio of modulus of elasticity of steel to modulus of elasticity of concrete. But the code stipulates the

value of ‘m as m = 280/ σcbc’ in bending compression, where σcbc is the permissible stress in concrete.

!ℴ#$#

• K=

!ℴ#$#!ℴ"#

• j = [ 1 – K/3]

• Q = σcbc x j x K / 2

Table 1. Design constants

Concrete Steel σcbc m σst k j Q

Grade Grade

M20 Fe415 7 13.33 130 0.417 0.861 1.26

M25 Fe415 8.5 10.98 130 0.418 0.86 1.53

M30 Fe415 10 9.34 130 0.418 0.86 1.8

2. Literature review

G. Hemlatha, J. Tejaswi (2012)

This project entitled design of RCC overhead water tanks. This project gives in brief, the theory behind the

design of liquid retaining structure (Elevated circular water tank with domed roof and conical base) using

working stress method. Elements are design in limit state method.

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

Gurudutta Ajay Avinashe (2015)

The paper presents current practices of designing of RCC Overhead water tanks in India. Mostly Excel

Sheets are used for the design. But these can also be designed using VB.net giving it a Software Interface.

The designs are based in Indian Standard Codes. Visual Basic 2010 is used for programming. This is an

effort developing a powerful computer program for design of water tank which will be used by students and

professional structural designers. This program will give every reference and calculations in a single

interface. Standard examples were taken while writing the program and the results were cross checked and

found out to be correct.

Dr GS Suresh (2007)

This paper entitled the design of water tank. Storage tanks are built for storing water, liquid petroleum,

petroleum products and similar liquids. Analysis and design of such tanks are independent of chemical nature

of product. They are designed as crack free structures to eliminate any leakage. Adequate cover to

reinforcement is necessary to prevent corrosion. In order to avoid leakage and to provide higher strength

concrete of grade M20 and above is recommended for liquid retaining structures.

Nibedita Sahoo (2008)

This project gives in brief, the theory behind the design of liquid retaining structure (circular water tank with

flexible and rigid base and rectangular underground water tank) using working stress method. This report

also includes computer subroutines to analyze and design circular water tank with flexible and rigid base and

rectangular underground water tank. The program has been written as Macros in Microsoft Excel using

Visual Basic programming language. In the end, the programs are validated with the results of manual

calculation given in “Concrete Structure” book.

Dona Rose K J, Sreekumar M, Anumod A S (2015)

This project entitled response of the elevated circular type water tanks to dynamic forces. Overhead water

tanks consist of huge water mass at the top of a slender staging which are most critical consideration for the

failure of the tank.

3. Objective and Importance of project

• The main aspect of our project is to justify the effectiveness of rectangular water tank for nominal

capacity in terms of material feasibility as well as to fulfil water and fire demand.

• The whole design philosophy of the project will be studied deeply with all construction parameters and

executed as per codal provisions.

• To design Rectangular Overhead RCC water tank by analysing required parameters as per codal provision

including fire demand.

• Comparison of above designed RCC and Steel water tanks in terms of:

• Economy,

• Serviceability,

• Project’s main objective is to create a good service with functional utility at an acceptable cost and within

a reasonable time of construction

4. Analysis & design

4.1 Population of day scholars & hostelites (IES IPS Academy, Indore).

• Total number of day scholars (Engineering block & Pharmacy) = 5600*

• Total number of hostilities (Male & females) = 300*

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

• Water requirement in Litres Per Capita per Day(lpcd)

• Water demand for Day scholars = 45 lpcd

• Water demand for Hostels = 135 lpcd

*As per Ips academy website & manual survey.

4.2 Capacity of water tank

Capacity is evaluated by combination of two parameters:

Ø Water demand (including water losses)

Ø Fire demand.

Calculation of water demand:

Water demand = (Summation of products of water demand for day scholars & hostilities)

= (5600 X 45 + 300 X 135 + 10% water losses)

= 306000 lpcd.

Calculation of fire demand:

• Kuichling’s formula

Q = 3182√𝑃 = 7795 lpcd

where, Q = Quantity of water in lpcd

P = Population in thousand

• Buston’s formula

Q = 5662√𝑃 = 13872 lpcd

• Freeman’s formula

Q = 1136(P/5 + 10) = 12724 lpcd

• National board of fire underwriter’s formula

Q = 4637√(1-0.01√𝑃) = 11080 lpcd

Adopting maximum value of fire demand

Q = 13872 lpcd = 14000 lpcd

Net water demand = (water demand + fire demand)

= (306000 + 14000) lpcd

= 320000 lpcd

Hence, Capacity of water tank

Q = 320000 lpcd

Q = 320 cu. M

Size of rectangular water tank = 10m x 8m x 4m

Grade of cement concrete used is M30 (as per IS 3370 part 1, table no.- 1)

Grade of steel used is Fe415

Free board (F.B) taken = 250 mm

4.3 Design by approximate method

Design problem:

Design a rectangular water tank resting on ground for a capacity of 3,20,000 liters (Size 10m x 8m x 4m)

having flat bottom and top by using M 30 concrete and Fe 415 steel. Draw the suitable:

Ø Plan of tank.

Ø Central cross section of tank.

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

Solution

Step- 1: Given data

Size of tank = 10m x 8m x 4m

Fck = 30 MPa

Fy = 415 Mpa

σcbc = 10 MPa

γw = 10 KN/m3

Step 2: Design Constants & L/B ratio

• Modular ratio(m)

m = 280/ 3σcbc = 9.34

• K = mσcbc / (mσcbc + σst) = 0.418

• j = [ 1 – K/3] = 0.860

• Q = σcbc x j x K / 2 = 1.80

L/B Ratio = 10/8 =1.25< 2

• In this case both long wall & short wall will act like cantilever for the length upto H/4 or 1m from base

and,

• For length above H/4 or 1m, continuous frame action (i.e. direct tension) is there.

• H/4 = 1m

• Pressure at 1m (P) = γ (H-h) = 30 KN/m2

Step 3: Continuous frame action

Since P = 30 KN/m2

• Along short wall

B.M. at corner = P. B2/12 = 160 KN-m

• Along long wall

B.M. at corner = P. L2/12 = 250 KN-m

Distribution of moment using MDM (Moment Distribution Method).

Unbalanced moment is produced at the corners in short wall and long wall due to horizontal moments. This

unbalanced moment using moment distribution method has to be distributed to get balanced moment.

A B

250

Joints A

160

Members AD AB

D.F 0.55 0.45

F.E.M 160 -250

Distribution 49.5 40.5

Final Moment 209.5 209.5

D

Thus, maximum design moment = 209.50 KN-m

Overall Depth of walls:

Effective depth of wall (d)

!

d=√ = 350 mm

! .!

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

Overall depth, t =350 + Cover = 350 + 50

t = 400 mm

Step 4: Design of Long Wall (L.W)

Direct tension = γ (H-h) x B/2 = 120 KN

x = d – t/2 = 160 mm

Design moment at negative span

Md = 209.5 – 120 x 0.16

= 190.30 KN-m

Area of steel (Ast) for horizontal resistance

!! !

(Ast)req. = [ ] + [ ] = 5786.36 mm2

!!" ! ! ! ! !!"

Provide 25 mm φ @ 80 mm C/C at supports on inner face & curtailing half of the bars at distance 1 m from

supports.

Similarly

Design moment at mid-span

Md = 187.5 – 120 x 0.16

= 168.30 KN-m

Area of steel (Ast)for horizontal resistance

!! !

(Ast)req. = [ ] + [ ] = 5224.13 mm2

!!" ! ! ! ! !!"

Provide 25 mm φ @ 90 mm C/C at center of outer face & curtailing half of the bars at supports.

Step 4: Design of Short Wall (S.W)

Direct tension = γ (H-h) x B/2 = 150 KN

x = d – t/2 = 160 mm

Design moment at negative span

Md = 209.5 – 150 x 0.16

= 185.50 KN-m

Area of steel (Ast)for horizontal resistance

!! !

(Ast)req. = [ ] + [ ]= 5894.45 mm2

!!" ! ! ! ! !!"

Provide 25 mm φ @ 80 mm C/C at supports on inner face & curtailing half of the bars at distance 1 m from

supports.

Similarly,

Design moment at mid-span

Md = 120 – 150 x 0.16

= 96 KN-m

Area of steel (Ast) for horizontal resistance

!! !

(Ast)req. = [ ] + [ ]= 3529.16 mm2

!!" ! ! ! ! !!"

Provide 20 mm φ @ 90 mm C/C at center of outer face & curtailing half of the bars at supports.

Step 5: Design of Vertical Walls for Cantilever action

Note: Design will remain same for both long wall and short wall

Design moment

! .! ! ! ! !

Md = = 6.67 KN-m

!

!!

(Ast)req. = [ ]

!!" ! ! ! !

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

= 170.45 mm2

Minimum Ast = 0.35% of Cross Section

= 0.35 x 1000 x 400/100

= 1400 mm2

(Ast)req. = 1400/2 = 700 mm2

Provide 12 mm φ @ 160 mm C/C on both face of long wall & short wall as vertical reinforcement.

Step 6: Design of base slab

Adopting slab thickness as 180 mm

(Ast)min. = 0.35% of cross section area

= 0.0035 x 1000 x 180

= 630 mm2

Ast at one face = 630/2 = 315 mm2

Provide 8 mm φ @ 150 mm C/C in both faces both directions.

Step 7: Detailing

1. Plan

Fig.1. Plan of water tank

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

2. Sectional View

Fig.2. Sectional view of water tank at direction A-A

Fig.3. Sectional view of water tank at direction B-B

4.4 Design by IS code method

Design problem:

Design a rectangular water tank resting on ground for a capacity of 3,20,000 liters (Size 10m x 8m x 4m)

having flat bottom and top by using M 30 concrete and Fe 415 steel. Draw the suitable:

• Plan of tank.

• Central cross section of tank.

Solution

Step- 1: Given data

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

Size of tank = 10m x 8m x 4m

Fck = 30 MPa

Fy = 415 Mpa

σcbc = 10 MPa

γw = 10 KN/m3

Step 2: Design Constants

a) Modular ratio(m)

m = 280/ 3σcbc = 9.34

b) K = mσcbc / (mσcbc + σst) = 0.418

c) j = [ 1 – K/3] = 0.860

d) Q = σcbc x j x K / 2 = 1.80

Step 3: Analysis of Moment and Tensile forces

(a) Long Wall

L/a = 10/4 = 2.5

Max value of Mx for x/a = 1, y=0

From table 3 IS 3370 part 4

Mx = -0.108

At y = b/2 / x//a =0

My = -0.074

Max horizontal Mo = My x γw x a3

= 0.074 X 10 X 43 KN /m

Max Vertical Mo = Mx x γw x a3

= 0.108 x 10 x 4 3

= 69.12 KN-m

TL = Pb/2

p = γα ΚΝ/m2

p = 10 x 4 = 40 KN/ m2

TL = 40 KN X 8 / 2

TL = 160 KN

(b) Short Wall

B/a = 8/4 = 2

Applying boundary conditions, at x/a = ½, y = b/2

Mx = -0.100

at y = b/2, x/a = 0

My = -0.060

Max vertical Moment = Mx γw x a3

= 100 x 10 x 43

= 64 KN-m

Max horizontal moment = My x γw x a3

= 0.060 x 10 x 43 = 38.4 KN-m

Te = pl/2 = 40.875 x 10 /2 KN

Design of vertical moment

Max moment = 69.12 KN m

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

Depth required = √(M/Rb)

= √ (69.12 x 10 6)/ (1.806 x 10 3)

=195.63 mm

Provide t = 280 mm with 50 mm

Effective cover

d = 280 – 50 = 20 mm >195.63mm

Ast = m/σst = 69.12 x 106/130 x 0.86 x 240

Ast = 2576.03 mm 2

Use 16 mm φ @ 70 mm c/c as secondary reinforcement on both face

Ast min -= 0.24/100 x 1000 x 280 = 672 mm2

Provide 10mm φ 100 mm c/c as secondary reinforcement on both faces.

1. Design of Horizontal Moment

47.36

A C

38.4

8m

B 10m D

10m

Joint A

a) KAC = I/L = I/ 10 = 0.1 I Member AB AC

b) KAB = I/8 = I/8 = 0.125 I

DF 0.46 0.56

FEM -38.4 47.3

Distribution -5.02 -3.94

Final Moment -43.418 43.418

Tension in side walls is considered for section at height ‘h’ from base

a/4 = 1m

at 1m from base or H = 4-1 = 3m

(! .!!!.!"#)!

ThL = = 123.3 KN

!

(! .!!!.!"#)!

ThB = = 154.375 KN

!

x = d – t/2 = 100 mm

so, net bending moment = M – T. x

= 27.980 KN-m

Area of steel required

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

!! !

(Ast)req. = [ ]+[ ]= 2230.285 mm2

!!" ! ! ! ! !!"

Provide 10mm φ 130 mm C/C on horizontal direction at inner face

Step 4: Design of base slab

Adopting slab thickness as 180 mm

(Ast)min. = 0.35% of cross section area

= 0.0035 x 1000 x 180 = 630 mm2

Ast at one face = 630/2 = 315 mm2

Provide 8 mm φ @ 150 mm C/C in both faces both directions.

Step 7: Detailing

• Plan

Fig.4. R.C.C. detailing towards plan of water tank (IS Code Method)

• Sectional View

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

Fig.5. Sectional view of water tank (IS code method) at direction A-A

5. Result

The comparative study between IS code method and approximate method in terms of induced moment,

sectional and structural requirement are showing below in tabular form.

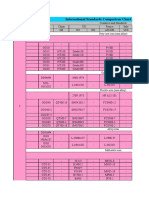

Table 2. Comparison between IS code method and approximate method:

IS Code Method Approximate Method

Moments and shear forces on side walls are Moments and shear forces on side walls are

lesser. more.

Maximum design moment = 43.418 KN-m Maximum design moment = 209.50 KN-m

Thickness of side walls is less. Thickness of side walls is more.

t = 280 mm t = 400 mm

It is economical as reinforcement is also It is comparatively costlier

less.

Provided 10 mm φ @ 130 mm C/C Provided 25mm φ @ 80 mm C/C.

Accordingly durable. Prolong durable.

Design of Base slab, top slab remains same. Design of Base slab, top slab remains same.

6. Conclusion

In this research work, analysis and design of R.C.C rectangular water tank were carried out by IS code

method and approximate method on the basis of material feasibility, economy, complexity and durability. It

has been observed that, the IS code method results more suitable for design of water tank as compared to

approximate method as per following parameters,

6.1 Economy

IS Code Method pertaining more economical than approximate method, as the area of reinforcement is less

than that of Approximate Method with the lesser thickness of walls.

Electronic copy available at: https://ssrn.com/abstract=3353083

Vineet Kumar Saha / SSRN-ELSEVIER (2018-19) 000–000

6.2 Material Feasibility

On the basis of material feasibility, IS Code Method is preferable because desired strength can be gained with

less amount of material consumption.

6.3 Complexity

In terms of complexity, we observed that approximate method is quite complex and lengthy procedure with

time consuming design.

6.4 Durability

If we consider durability, the results say that Approximate Method is more durable than IS Code Method. But

approximate method is uneconomical and with respect to IS Code Method, as IS Code method is sufficient

durable with adequate economy.

Hence considering above parameters, we conclude that IS Code Method is overall suitable than Approximate

Method.

References

Chirag N. Patel, H. S. Patel, "Optimum diameter of tapered elevated RC water tank staging", International Journal of Emerging

Technology and Advanced Engineering (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 2, Issue 12, December 2012), pp.

246-252.

George W. Housner, "The dynamic behavior of water tanks”, Bulletin of the Seismological Society of America. Vol. 53, No. 2, pp. 381-

387. February, 1963

Madhurar, G., and Madhuri, M., 2013. Comparison between Static and Dynamic Analysis of Elevated Water Tank. International

Journal of Scientific & Engineering Research, 4(6), ISSN 2229-5518, p. 2043 – 2052.

Nikhade, H., Dandge, A., and Nikhade, A., 2013. Dynamic analysis of circular water tank and study of relevant codal provision.

International Journal of Scientific & Engineering Research, 4(11), ISSN 2229-5518.

Gandhi, M.,, and Rajan., 2014. Necessity of Dynamic Analysis of Elevated Water Storage Structure Using Different Bracing in Staging.

International Journal of Research in Advent Technology, 2(2) , E-ISSN: 2321-9637.

Prasad, R., and Kamdi, B., 2012. Effect of revision of is 3370 on water storage tank. International Journal of Engineering Research and

Applications (IJERA), 2(5), ISSN: 2248-9622, p.664.

Raji, S.A., 2004. Window Based Computer Programs for Analysis and Design of Water Storage Tanks. Journal of Research Information

in Civil Engineering, 1(1).

Vazirani, V.N. and Ratwani, M..M., 1980. Concrete Structures. Khanna Publishers, Delhi.

Dayaratnam, P.,2000. Design of Reinforced Concrete Structures. Oxford & IBH publication, New Delhi.

IS 456-2000. Code of practice for plain and reinforced concrete.

IS 1370-1-1967. Code of practice for concrete structures for the storage of liquids- General requirements.

IS 1370-2-1967. Code of practice for concrete structures for the storage of liquids-Reinforced concrete structures.

IS 1370-4-1967. Code of practice for concrete structures for the storage of liquids- Design tables.

View publication stats Electronic copy available at: https://ssrn.com/abstract=3353083

You might also like

- Design and Analysis of Pre Stressed I Girders by Midas Civil SoftwareDocument7 pagesDesign and Analysis of Pre Stressed I Girders by Midas Civil SoftwareEditor IJTSRDNo ratings yet

- Hospital Building ProjectDocument58 pagesHospital Building ProjectAnonymous yM5XLR694% (18)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Design RCC Over Head TankDocument82 pagesDesign RCC Over Head TankVikram SinghNo ratings yet

- Structural Steel Design For Steel Intensive Quarantine CenterDocument35 pagesStructural Steel Design For Steel Intensive Quarantine CenterDnyaneshwar Gawai100% (1)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Analysis of Rectangular Water Tank Using Fem MethodDocument8 pagesAnalysis of Rectangular Water Tank Using Fem MethodIJRASETPublicationsNo ratings yet

- SilaneCouplingAgents eDocument28 pagesSilaneCouplingAgents emajidNo ratings yet

- Study The Behaviour of Box Type Bridge With Different Height and Same Width For The IRC LoadingsDocument6 pagesStudy The Behaviour of Box Type Bridge With Different Height and Same Width For The IRC LoadingsIJRASETPublicationsNo ratings yet

- A Study On Design and Analysis of Precast Box For Road Bridge Construction Using STAAD Pro ReviewDocument12 pagesA Study On Design and Analysis of Precast Box For Road Bridge Construction Using STAAD Pro ReviewEditor IJTSRDNo ratings yet

- Circular Water TankDocument7 pagesCircular Water Tanksimon maaaklaNo ratings yet

- Study The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadDocument4 pagesStudy The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadEditor IJTSRDNo ratings yet

- Chemistry Notes Gas LawsDocument5 pagesChemistry Notes Gas Lawsapi-263322904100% (1)

- Lab Report Experiment 3 4 and 5Document13 pagesLab Report Experiment 3 4 and 5Nurul Iman Che Awang90% (40)

- SSRN Id3353083Document13 pagesSSRN Id3353083Ehsanullah HarooniNo ratings yet

- Comparison of RCC and Prestressed Concrete Ciircular Water TanksDocument4 pagesComparison of RCC and Prestressed Concrete Ciircular Water TanksShivakumar PatilNo ratings yet

- Storage Tank Design - 5Document10 pagesStorage Tank Design - 5Riyan EsapermanaNo ratings yet

- Gurudatta Ajay Avinashe, Ranjan S. SonparoteDocument4 pagesGurudatta Ajay Avinashe, Ranjan S. SonparoteSudha JNo ratings yet

- Economics of RCC Water Tank Resting Over Firm Ground Vis-A-Vis Pre-Stressed Concrete Water Tank Resti PDFDocument15 pagesEconomics of RCC Water Tank Resting Over Firm Ground Vis-A-Vis Pre-Stressed Concrete Water Tank Resti PDFRahul KarnaNo ratings yet

- Analysis and Design of Slab Culvert With ManualDocument3 pagesAnalysis and Design of Slab Culvert With ManualChaitanya KumbharNo ratings yet

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankDocument5 pagesDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsNo ratings yet

- Design of Water TanksDocument15 pagesDesign of Water TankscherogonyaNo ratings yet

- (12-21) Water Tank Paper-FormatDocument10 pages(12-21) Water Tank Paper-Formatmohammed nafethNo ratings yet

- IJCRT2107046Document5 pagesIJCRT2107046المهندس: محمد محمود السوائيNo ratings yet

- ParametricAnalysisofElevatedServiceReservoirforVariousCapacities (1)Document10 pagesParametricAnalysisofElevatedServiceReservoirforVariousCapacities (1)Harwinder MattuNo ratings yet

- A Study On Design and Analysis of Precast Box For Road Bridge Construction Using STAAD ProDocument16 pagesA Study On Design and Analysis of Precast Box For Road Bridge Construction Using STAAD ProEditor IJTSRDNo ratings yet

- Analysis of Circular Elevated Service Reservoir Using STAAD Pro by Considering The Effect of ContinuityDocument14 pagesAnalysis of Circular Elevated Service Reservoir Using STAAD Pro by Considering The Effect of Continuitysameerdar465No ratings yet

- ProjectDocument20 pagesProjectRakesh Rosan SahooNo ratings yet

- Shreedhar T BeamDocument10 pagesShreedhar T BeamYazer ArafathNo ratings yet

- FEM_ docDocument8 pagesFEM_ docpandianNo ratings yet

- Irjet V5i3243 PDFDocument3 pagesIrjet V5i3243 PDFNiranjan YadavNo ratings yet

- 54 Jicr April 2605Document4 pages54 Jicr April 2605maddih gayeNo ratings yet

- Analysis and Design of Elevated Intze WaDocument13 pagesAnalysis and Design of Elevated Intze WaEntertainer PavalNo ratings yet

- Review Paper On Analysis and Design of Railway Box Bridge: Mr. Afzal Hanif SharifDocument4 pagesReview Paper On Analysis and Design of Railway Box Bridge: Mr. Afzal Hanif Sharifherupurwanto rustopoNo ratings yet

- Response of Intze Tank against Static and Earthquake Loads Using Staad ProDocument30 pagesResponse of Intze Tank against Static and Earthquake Loads Using Staad ProInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparative Analysis of Circular and Rectangular RDocument8 pagesComparative Analysis of Circular and Rectangular RJohn Michael Capulla CadienteNo ratings yet

- IJCRT2006368Document10 pagesIJCRT2006368oscarNo ratings yet

- Comparative Analysis of Circular and Rectangular R PDFDocument8 pagesComparative Analysis of Circular and Rectangular R PDFAditya SinghNo ratings yet

- Comparative Analysis of Circular and Rectangular R PDFDocument8 pagesComparative Analysis of Circular and Rectangular R PDFAditya SinghNo ratings yet

- Comparing Costs of Circular vs Rectangular Water TanksDocument8 pagesComparing Costs of Circular vs Rectangular Water TanksSaifAldeenAbdulmotaalSulimanNo ratings yet

- Stress Analysis of Mast Structure For Water-Well Drilling MachineDocument8 pagesStress Analysis of Mast Structure For Water-Well Drilling MachineBruno Santos100% (1)

- 22 HP-JRP-KBP Circular Water Tank 1-9!2!2014Document8 pages22 HP-JRP-KBP Circular Water Tank 1-9!2!2014Anjali AnjuNo ratings yet

- Design RCC TankDocument82 pagesDesign RCC TankBlitheNo ratings yet

- Irjet V2i6202 PDFDocument4 pagesIrjet V2i6202 PDFkovaryNo ratings yet

- ZE04-CAL-350KL-18M-100-R0Document60 pagesZE04-CAL-350KL-18M-100-R0PramodNo ratings yet

- Design The Circular Water Tank by Using The STAAD Pro SoftwareDocument17 pagesDesign The Circular Water Tank by Using The STAAD Pro SoftwareIJRASETPublicationsNo ratings yet

- Preheater DesignDocument6 pagesPreheater DesignAlejandroPáramoFandiñoNo ratings yet

- Comparative Study of Design of Water Tank With Reference To Is: 3370Document4 pagesComparative Study of Design of Water Tank With Reference To Is: 3370Moyukh DeNo ratings yet

- B.Tech UG Project Ideas 4Document11 pagesB.Tech UG Project Ideas 4nambimunnaNo ratings yet

- Makarov 2020 IOP Conf. Ser. Mater. Sci. Eng. 962 022051Document7 pagesMakarov 2020 IOP Conf. Ser. Mater. Sci. Eng. 962 022051emberzojasonNo ratings yet

- A Review Paper On "Comparative Analysis & Design of RCC & PSC Girder & Feasibility"Document4 pagesA Review Paper On "Comparative Analysis & Design of RCC & PSC Girder & Feasibility"Abhishek nirmaleNo ratings yet

- Modeling Analysis and Design of Intz Water Tank Considering Different Wind Speed Using STAAD PRO V8I SoftwareDocument6 pagesModeling Analysis and Design of Intz Water Tank Considering Different Wind Speed Using STAAD PRO V8I SoftwareEditor IJTSRDNo ratings yet

- Review On Comparative Analysis of Water Tank Rest On GroundDocument6 pagesReview On Comparative Analysis of Water Tank Rest On GroundIJRASETPublicationsNo ratings yet

- Ijtsrd 46362Document9 pagesIjtsrd 46362Dhoni LokiNo ratings yet

- A Review On Study of Rehabilitation and Repair Techniques of R.C.C. BuildingDocument5 pagesA Review On Study of Rehabilitation and Repair Techniques of R.C.C. BuildingIJRASETPublicationsNo ratings yet

- Comparative Study of RCC T-Beam Bridge byDocument32 pagesComparative Study of RCC T-Beam Bridge byPranay Reddy100% (2)

- Performance Based Analysis of Bridges: (Peer-Reviewed, Open Access, Fully Refereed International Journal)Document9 pagesPerformance Based Analysis of Bridges: (Peer-Reviewed, Open Access, Fully Refereed International Journal)IRJMETS JOURNALNo ratings yet

- AnshumDocument83 pagesAnshumVikku TiwariNo ratings yet

- Circular vs Rectangular Concrete Tank Cost AnalysisDocument7 pagesCircular vs Rectangular Concrete Tank Cost Analysis1Bnesa3No ratings yet

- Design and Analysis of A Girder Bridge For Highway Structures Using SAP 2000Document6 pagesDesign and Analysis of A Girder Bridge For Highway Structures Using SAP 2000Editor IJTSRDNo ratings yet

- Construction Stage Analysis of Three-Dimensional Cable-Stayed BridgesDocument15 pagesConstruction Stage Analysis of Three-Dimensional Cable-Stayed BridgesOlivia OeyNo ratings yet

- Analysis of Tunnel For Different Subsoil Plaxis PDFDocument7 pagesAnalysis of Tunnel For Different Subsoil Plaxis PDFGuillermo MansillaNo ratings yet

- Michael FaradayDocument33 pagesMichael FaradayRezie Dampog DellavaNo ratings yet

- Climatic Phenomenon DLPDocument15 pagesClimatic Phenomenon DLPMaureen Torres CastelNo ratings yet

- Distillation LabDocument18 pagesDistillation LabWong XimeiNo ratings yet

- Armix Hyyecrete Sp200: - Forhighgradeandmicro-SilicaconcreteDocument3 pagesArmix Hyyecrete Sp200: - Forhighgradeandmicro-Silicaconcreteraviteja036No ratings yet

- Hypersperse MDC220Document1 pageHypersperse MDC220giahaoNo ratings yet

- Energy System Integration Business Plan by SlidesgoDocument58 pagesEnergy System Integration Business Plan by SlidesgoHelmi NugrohoNo ratings yet

- The Consep AcaciaDocument7 pagesThe Consep AcaciaPrincess Ruwarashe Courteney MunyoroNo ratings yet

- Explosive PenetrationDocument3 pagesExplosive PenetrationKaarthicNatarajanNo ratings yet

- Effective atomic numbers of organic compoundsDocument7 pagesEffective atomic numbers of organic compoundsHala SweetNo ratings yet

- Mc1091 Recrushed SlagDocument4 pagesMc1091 Recrushed Slagtoxicity23No ratings yet

- Rod End SeriesDocument14 pagesRod End SeriesNopNo ratings yet

- Cambridge IGCSE™: Chemistry 0620/62 May/June 2022Document7 pagesCambridge IGCSE™: Chemistry 0620/62 May/June 2022aayan rahmanNo ratings yet

- Final Yr Project ReportDocument23 pagesFinal Yr Project ReportLOKENDRA91No ratings yet

- GE Flogard MS 6209 LDocument1 pageGE Flogard MS 6209 LArunkumar ChandaranNo ratings yet

- FLT93 Complete Manual Surface Mount (06EN003401f)Document100 pagesFLT93 Complete Manual Surface Mount (06EN003401f)May Rodyn Cuba de la CruzNo ratings yet

- Al Salem 2017Document22 pagesAl Salem 2017Xing KaiNo ratings yet

- 10th Grade Mixture LabDocument2 pages10th Grade Mixture Labsebastianlara96No ratings yet

- ENERGY PRINCIPLES & VIRTUAL WORK METHODDocument7 pagesENERGY PRINCIPLES & VIRTUAL WORK METHODpratiksha nagargojeNo ratings yet

- CHEM1901 Model MCQ PDFDocument13 pagesCHEM1901 Model MCQ PDFMavia NaushadNo ratings yet

- Iron International StandardsDocument2 pagesIron International StandardsAmir MusaibNo ratings yet

- Rheological Behavior of Sewage Sludge With High Solid ContentDocument10 pagesRheological Behavior of Sewage Sludge With High Solid Contenttranhonghakd5533No ratings yet

- Descriptive Physical Oceanography An IntroductionDocument3 pagesDescriptive Physical Oceanography An IntroductionAnonymous xdDh30QONo ratings yet

- Company Profile Baoding Saiderui Machinery Manufacturing Co., LTDDocument30 pagesCompany Profile Baoding Saiderui Machinery Manufacturing Co., LTDFerry Triyana AnirunNo ratings yet

- Special Steels CB10FF: For Cold Deformation and BearingsDocument1 pageSpecial Steels CB10FF: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- 3 Flexural Analysis of BeamsDocument27 pages3 Flexural Analysis of BeamsAfrasiyab KhanNo ratings yet

- Answer Key: PhysicsDocument24 pagesAnswer Key: PhysicsvardeshNo ratings yet

- PhDthesis Nayak PDFDocument224 pagesPhDthesis Nayak PDFPrachi PandeNo ratings yet