Professional Documents

Culture Documents

0002 - 710 - Mechanical Completion and Performance Acceptance of Facilities

0002 - 710 - Mechanical Completion and Performance Acceptance of Facilities

Uploaded by

tariqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0002 - 710 - Mechanical Completion and Performance Acceptance of Facilities

0002 - 710 - Mechanical Completion and Performance Acceptance of Facilities

Uploaded by

tariqueCopyright:

Available Formats

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I.

Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 1 of 35

ACCEPTANCE OF FACILITIES

TABLE OF CONTENTS

1. OBJECTIVE

2. SUMMARY

3. DEFINITION OF TERMS

4. COMPLETING AND TURNING OVER THE WORK

4.1 Acceptance of a Facility

4.2 Steps to Achieve Mechanical Completion

4.3 Steps for Performance Acceptance

4.4 Performance Acceptance Certificate

* 5. CONSIDERATIONS DURING PROJECT CLOSE-OUT

6. REFERENCE

Supplement 1 Example; Mechanical Completion Certificate (MCC)

Supplement 2 Example; Performance Acceptance Certificate (PAC)

* Supplement 3 Division of Responsibilities for Turnover

1. OBJECTIVE:

G.I. 2.710 is intended to define the respective duties and obligations required of the Saudi Aramco Project

Management Team (SAPMT)/Construction Agency, Inspection Agency, Loss Prevention Department, Fire

* Protection Department, the Proponent and other organizations that are necessary to ensure a smooth and timely

transition from the construction phase through the start-up and operation of a facility. The Mechanical Completion

and Performance Acceptance Certificates document these duties and obligations.

* Reference to this Instruction and its attachments in a contract as a requirement for the contractor to follow and as

a sole means of defining the contractor’s pre- and post-MC responsibilities is not permitted. This Instruction and

its attachments define responsibilities within Saudi Aramco organizations only and are not a suitable means of

assigning responsibilities to the contractor. As applicable, a customized division of responsibility based on needs

should be included or referenced in contract.

2. SUMMARY:

This Instruction and its attachments are applicable to all Saudi Aramco capital and non-capital projects

* (engineered), for details see GI 20.031, GI 20.110 and GI 20.620. Steps are detailed herein for: (1) accepting new

facilities as mechanically complete, (2) commissioning and start-up, and (3) performance acceptance and financial

closeout.

The Construction Agency is responsible for delivering a completed facility as defined in the project scope of work.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 2 of 35

ACCEPTANCE OF FACILITIES

After the facility is accepted as Mechanically Complete, the Commissioning, Start-Up and Performance

Acceptance become the responsibility of the Proponent Organization with the Construction Agency providing

necessary design and construction personnel, technicians and vendor representatives to assist in these activities.

For all facilities, the Construction Agency, Proponent and other stakeholders (as applicable) are to assign

personnel and establish a Pre-Commissioning & Mechanical Completion Plan and a Commissioning & Start-Up

* Plan as per SAEP-12.

** Note: For Mechanical Completion Certificate (MCC) requirements of Budget Items (BIs) that are solely for Master

Appropriation/ Purchasing, refer to AIM 201 and GI 202.305.

3. ACRONYMS & DEFINITION OF TERMS:

ACRONYM DESCRIPTION

** AC Acceptance Committee

ACC Acceptance Committee Chairman

AIM Accounting Instruction Manual

BI Budget Item

CA Construction Agency

CMS Capital Management System

CPD Capital Programs Division (from Finance Organization)

FPD Facilities Planning Department

FrPD Fire Protection Department

EI Exception Item

EIS Equipment Inspection Schedules

IA Inspection Agency

IPT Integrated Project Team

ISSD Industrial Security Support Department

LPD Loss Prevention Department

MAR Master Appropriations Release

MC Mechanical Completion

MCC Mechanical Completion Certificate

- PMCC - Partial Mechanical Completion Certificate

- FMCC - Final Mechanical Completion Certificate

MPCS Mechanical & Performance Closeout System

MSAER Mandatory Saudi Aramco Engineering Requirements, Include:

- SAEP: Saudi Aramco Engineering Procedure

- SAES: Saudi Aramco Engineering Standard

- SAMSS: Saudi Aramco Materials System Specifications

- SASD: Saudi Aramco Standard Drawings

O&M Operation and Maintenance

PAC Performance Acceptance Certificate

PDI Performance Acceptance Deficiency Item

PCR Project Change Request

PFAAD Projects and Fixed Asset Accounting Division

POD Power Operations Department

PS Project Sponsor

PSSR Pre-startup Safety Review

SOW Scope of Work

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 3 of 35

ACCEPTANCE OF FACILITIES

3.1 ACCEPTANCE COMMITTEE:

A Committee chaired by a Proponent representative and comprised of Construction Agency, Inspection

* Agency, Loss Prevention, Fire Protection Department, and other representatives as appropriate,

depending upon the nature of the facility. For details, refer to section 4.1.2.3 & 4.2.3.

** 3.2 CONSTRUCTION AGENCY:

The organization assigned to execute the project. This could be the Saudi Aramco Project Management

administrative area or the Proponent’s assigned organization (for C1-type projects). The Construction

Agency’s team assigned to the project is called the Project Management Team (PMT).

3.3 COMMISSIONING:

*

Commissioning is the functional testing process to verify the equipment, system or facility is working in

accordance to its design conditions per the approved project scope of work. For additional details, see

Supplement 2.710-3.

* 3.4 EXCEPTION ITEMS:

Mechanical Completion (MC) Exception Items (EIs) are outstanding project scope of work (SOW) or non-

adherence to the applicable MSAER items. EIs are Punchlist items (defined in section 3.17) that are

consolidated by the Construction Agency (CA) and approved by the Acceptance Committee Chairman

(ACC) for resolution.

“Yes” EIs are items that are evident danger to personnel safety or Company property, and those that may

impact the safe commissioning, start up, and operation of the facility. ‘Yes’ items are required to be

completed before the Mechanical Completion Certificate (MCC) is approved by the Proponent.

“No” EIs are items that, if not completed prior to Mechanical Completion (MC), will not impact the safe

commissioning, start up, and operation of the facility.

3.5 FACILITY:

*

Facility means structures or items being designed and engineered, constructed, installed or repaired under

the project SOW (capital or non-capital).

3.6 INSPECT (WORK):

To determine conformity to specified or other prescribed requirements by examination, measurement,

testing, analysis or other methods of assessment.

** 3.7 INSPECTION AGENCY:

The Inspection Agency (IA) is the organization which provides inspection services throughout the life

cycle of the project. This is accomplished through direct inspection, monitoring and quality

assessments, as required (for details, see SAEP-1150 and SAEP-68).

* 3.8 MECHANICAL COMPLETION

Mechanical Completion (MC) is achieved when the facility defined in the approved project SOW has been

installed, pre-commissioned, and all “Yes” Exception Items have been completed and closed or changed

to NO item per section 4.2.9. (See also Supplement No. 2.710-3)

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 4 of 35

ACCEPTANCE OF FACILITIES

3.8.1 Partial Mechanical Completion Certificate:

*

Partial Mechanical Completion Certificate (PMCC) is approved when a separable system of a

plant/facility as defined in the Pre-commissioning and Mechanical Completion Plan (see SAEP-

12) has met the requirements for MC.

* 3.8.2 Final Mechanical Completion Certificate:

The Final Mechanical Completion Certificate (FMCC) shall be approved when the project has met

the requirements for MC and shall only be issued at the BI level. For a project with a series of

PMCCs, final MCC will only be achieved at the BI level when the last PMCC is approved to deem

the entire project mechanically complete.

3.9 MECHANICAL & PERFORMANCE CLOSEOUT SYSTEM:

*

Mechanical & Performance Closeout System (MPCS) is a web-based application that shall be used to

document & manage Punchlist Items, Exception Items, Performance Acceptance Deficiency Items, and

their resolution, and to generate & approve Mechanical Completion and Performance Acceptance

Certificates for projects.

3.10 ON-STREAM COMPLETION DATE:

* For on-stream completion date definition, please refer to GI 20 520.

* 3.11 PERFORMANCE ACCEPTANCE:

The process of demonstrating via performance tests (as applicable) that the facility can operate

successfully at the design conditions established by the approved Project SOW. The Performance

Acceptance Certificate (PAC) is approved when the facility has met the performance acceptance

requirements. For details refer to sections 4.3 & 4.4 and their sub-sections.

* 3.12 PERFORMANCE ACCEPTANCE DEFICIENCIES:

Performance Acceptance Deficiencies Items (PDIs) consider system or facility operational performance

deficiencies (failure to meet performance required by the design basis) only and shall not include items

similar in nature to the Mechanical Completion Exception Items. Normal Wear & Tear shall not constitute

as PDI (see, section 3.21).

3.13 PRE-COMMISSIONING:

*

Testing of system components for continuity, operability and in the case of process plants, their ability to

withstand operating pressures prior to the introduction of feedstock or other final products into the facility.

For details, see Supplement 2.710-3.

* 3.14 PROJECT SCOPE OF WORK:

Project Scope of Work (SOW) is defined as all and any work associated with accomplishing the

requirements of the Approved Project Proposal, applicable MSAERs (issued before the standard’s cut-off

date stipulated in SAEP-14), Expenditure Request, Master Appropriations Release(s) (MAR's) and/or

approved Project Change Requests (PCR's) or subsequent redefinition ER. Adding SOW after FMCC

approval is not permitted. For scope changes’ guidelines and thresholds, refer to GI-20.520 and GI-20.500.

3.15 PROJECT SPONSOR:

**

Project Sponsor (PS) is an executive or a member of Management, appointed by the Proponent

organization, who is accountable for meeting project objectives and steering the Integrated Project Team

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 5 of 35

ACCEPTANCE OF FACILITIES

(IPT) towards maximizing investment value. For details, refer to applicable PS Guides issued by Capital

Program Efficiency Department (CPED).

** 3.16 PROPONENT:

The organization who is responsible for approving the Mechanical Completion Certificate and will own,

operate and maintain the completed facility assets.

3.17 PUNCHLIST:

*

A punchlist is master list of outstanding project SOW for all systems that has been identified by any party

(e.g., Construction Agency, Inspection Agency, Loss Prevention Department, Fire Protection Department,

Power Operations Department, Proponent, etc.) and submitted through the MPCS. Punchlist items must

be specific and not general statements such as verify, inspect etc. and shall include as minimum following

information:

1) Description: A brief description of item including tag number, line number, etc.

2) Location: Specify location by package, subsystem, plant, building, unit, zone, column, room

identification code(s), etc.

3) Category (or System): Instrumentation, Mechanical, Electrical, etc.

4) Reference documents: All comments shall include relevant reference or justification.

3.18 MCC SERVICE DATE:

*

For definition and details of MCC service date, please refer to Accounting Instruction Manual No. 201.

3.19 START-UP:

*

Following commissioning, the start-up will commence, which is achieved by energization of system/facility

and/or introduction of feedstock into the facility to achieve normal operating conditions.

3.20 SYSTEM:

A group of components (piping, instrumentation, equipment, motors, vessels, etc.) related to a single

process or utility service such as sweet gas, sour gas, firewater, etc. Where components of the same

service are located in different geographical locations, they can be treated either as separate systems or

as subsystems.

A system can also be other components of a facility logically grouped together e.g.: buildings, roads,

structures, foundations, electrical power distribution, etc.

3.21 WARRANTY DEFECT (Material & Equipment):

*

Manufacturing defect or premature failure of material (e.g. paint), equipment (e.g. pumps), or component

(e.g. bearings), discovered or occurring during the warranty period stipulated in a contract or purchase

order where the contractor and/or vendor is responsible for the cost of repair or replacement as defined in

the contract. Normal wear and tear shall not be considered as a defect of the item if it did not complete its

entire projected life cycle.

3.22 WITNESS (EVENT):

*

To be present at the event and sign attendance and acceptance.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 6 of 35

ACCEPTANCE OF FACILITIES

** 3.23 WORKING DAYS:

The work days per Saudi Aramco’s operational calendar.

4. COMPLETING AND TURNING OVER THE WORK

The completion and turnover activities of a project represent the culmination of project activities which have been

directed toward providing the Proponent a facility that conforms to the project scope of work (SOW). The following

shall establish the structure, activities to be accomplished, and assignment of responsibilities during the process

of Mechanical Completion, commissioning, and start-up of the facility.

Note: Temporary installations implemented by the Construction Agency in support of achieving the project’s

* scope and objectives shall be subject to the Proponent Organization’s Management of Change process

as required by Saudi Aramco’s Safety Management System, Element 5, Asset Integrity. The temporary

installation shall not be considered as part of the MCC process unless these installations are formally

approved as project SOW and incorporated in the project’s drawings, as required.

4.1 ACCEPTANCE OF A FACILITY

4.1.1 Requirements for Mechanical Completion

A facility, or portion thereof, shall be certified as Mechanically Complete and safe to operate prior

to commissioning, start-up, or placement in service. This applies for all Budget Items (BIs)

regardless of value. Further, in the case of hydrocarbon storage, handling, transportation, or

processing plant type facilities, the hydrocarbon may not be brought into the Plant/Unit concerned

until the Mechanical Completion Certificate (MCC) has been approved by the relevant parties. For

a facility to be certified mechanically complete, the following work is required:

4.1.1.1 All Spare Parts Data Packages (SPDP) have been submitted to the Material Supply

* Organization in accordance with the requirements of SAEP-31.

4.1.1.2 All construction and pre-commissioning activities for the project have been completed. For

* additional details, refer to Supplement-3.

4.1.1.3 All agreed “Yes” items on the MCC Exception Item List shall have been completed and

* approved by the Acceptance Committee members or their representatives or the ACC.

* 4.1.1.4 All pending quality issues including non-conformance reports (issued by Saudi Aramco

and Contractors) and worksheets shall have been resolved to the satisfaction of the IA or

entered on the consolidated punchlist and submitted to the ACC in accordance with

section 4.2.6. For details, refer to SAEP-381.

* 4.1.1.5 All redlined as-built vendor manuals, redlined vendor drawings, and redlined as-built key

drawings shall have been transmitted to the Proponent. For additional details, refer to

SAES-A-202 and SAEP-334.

4.1.1.6 All equipment fabrication documents, inspection record books and Equipment Inspection

Schedules (EIS) shall be made available for review at the construction site. (Reference

SAEP-20, Equipment Inspection Schedule)

4.1.1.7 All Operation and Maintenance (O&M) manuals will have been submitted to the Proponent

* for review four (4) weeks prior to MC. For details, refer to SAEP-121 & -122.

Note: Process O&M manuals for facilities must be approved by the Proponent before MC.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 7 of 35

ACCEPTANCE OF FACILITIES

4.1.2 Parties to Mechanical Completion Process

4.1.2.1 Construction Agency (CA)

*

4.1.2.2 Proponent

*

4.1.2.3 Acceptance Committee (AC)– A committee appointed by the Proponent to inspect the

* facility and certify Mechanical Completion. The Acceptance Committee shall be comprised

of the following personnel or their designated representatives per section 4.2.4, who will

have full authority to act on their behalf:

• Acceptance Committee Chairman “ACC” (Proponent Division Head or higher)

• Construction Agency Project Manager

• Proponent Maintenance Superintendent or Proponent Division Head (if Maintenance

Division is not available within the organization)

• Proponent Commissioning Representative

• Inspection Agency Division/Section Head

• Area Loss Prevention Representative

• Area Fire Protection Representative

• Area Power Operations Department Representative*

• Area Communication Operations Representative*

• Industrial Security Support Department Representative*

• Marine Department Representative*

• Any additional members designated by the Proponent to facilitate proper evaluation

and acceptance of the facility(s)*

* As Applicable

4.2 STEPS TO ACHIEVE MECHANICAL COMPLETION – (Organization with primary responsibility in bold)

4.2.1 The designated Construction Agency shall use MPCS to establish and maintain a punchlist of

* the items submitted in the MPCS by all parties (e.g.: Construction Agency, Inspection Agency,

Proponent, Loss Prevention Dept, Fire Protection Dept, Power Operations Dept etc.) throughout

the construction phase.

4.2.2 The Construction Agency (in conjunction with the Proponent) will define the facility by process

* system/subsystem (additionally by geographical area where appropriate) and assign non-process

components such as buildings, structures, power, etc., a system identification to ensure that all

parts of the facility (including the safety elements) are covered and allow punchlisting to be

performed in an organized, systematic manner. This definition shall be required in the Pre-

commissioning and Mechanical Completion Plan which is developed per SAEP-12 and finalized

as soon as practical prior to the Acceptance Committee kick-off meeting to be held at the latest

by 60% of BI’s actual construction. Specific consideration shall be given to establishing a system

of partial MCCs where equipment and facilities need to be pre-commissioned and commissioned

to allow subsequent activities to be completed (e.g. piping tie-ins, utilities and related energization

systems including fire and safety systems).

4.2.2.1 Prior to signing the MCC for the hydrocarbons facility or portion thereof, all fire protection

** and life safety systems in the approved project scope of work shall be mechanically

completed and commissioned for that portion where the hydrocarbons will be present.

Alternatively, temporary measures acceptable to the ACC shall be provided prior to the

introduction of hydrocarbons. For additional details, see Supplement- 3, Section 6.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 8 of 35

ACCEPTANCE OF FACILITIES

** 4.2.2.2 Prior to signing the MCC for any manned building or infrastructure facility, all fire protection

and life safety systems in the approved project scope of work shall be mechanically

completed and commissioned. Alternatively, temporary measures acceptable to the ACC

shall be provided prior to occupancy. For additional details, see Supplement 3, Section 6.

4.2.3 The Proponent shall establish the Acceptance Committee (AC) and appoint its Chairman as soon

* as practical after the start of the facility’s construction but no later than the 60% stage of BI’s actual

construction completion. Establishing the AC is not a milestone for starting punchlisting which shall

be as per section 4.2.5.

4.2.4 The Construction Agency shall advise the Proponent (ACC) that the BI’s construction stage has

* reached 60% and request a formal kick-off meeting of the Acceptance Committee (AC) to agree

on the detailed pre-commissioning and mechanical completion plans and procedures to be

implemented and inform the committee of the schedule and scope of proposed Mechanical

Completions (Partial and Final).

** Note: Prior to AC kick-off meeting, the Construction Agency shall submit detailed pre-

commissioning and mechanical completion plan(s) for the AC review and concurrence.

Any revision to these plan(s) will require concurrence of AC Chairman and distribution to

the AC.

* At the first formal kick-off meeting of the Acceptance Committee (required for all projects), the

Proponent and the Construction Agency may jointly concur that further formal Acceptance

Committee (AC) meetings are not required. In such case, the AC members from the Construction

Agency, Inspection Agency, Loss Prevention Dept, Fire Protection Dept, and other organizations

(as applicable) and the Proponent may designate their representatives.

4.2.5 When all major components of a system have been installed and verified as ready for punchlisting

* by the Construction Agency (CA), the CA shall obtain written agreement from the ACC confirming

that punchlisting may begin. Upon agreement, the Construction Agency will request the

Acceptance Committee (AC) to commence system punchlisting. All AC representatives shall

submit their system punchlist items (in accordance with punchlist definition under section 3.17)

into the MPCS within seven (7) working days of this request. The commencement of punchlisting

shall not be unduly delayed. The CA will make required project documentation available for the

AC.

* 4.2.6 The Construction Agency (CA), within seven (7) working days upon conclusion of the

punchlisting, will consolidate all project scope punchlist items, make an initial “Yes/ No”

designation and submit to the Acceptance Committee Chairman (ACC). Non-project scope items

will be handled per section 4.2.8.

Note: Punchlist items with the same description but recorded in different locations shall not be

consolidated as duplicate items.

4.2.7 Within five (5) working days of receiving the consolidated punchlist, the Acceptance Committee

* Chairman (ACC) will make the final determination which of these punchlist items are “Yes” items

in accordance with EI definition under section 3.4, and appoint the responsible party in the case

of duplicated items. Notifying duplicated items’ initiator for information, the ACC shall close

duplicate items immediately leaving only one item open for the CA to complete. The ACC will

approve the finalized punchlist and return via MPCS to the CA to complete. This list will be the

MC Exception Item(s) List.

4.2.8 Within four (4) weeks of the respective MCC’s (partial or final) Exception Items (EIs) List approval

** (and enough time before PMCC/FMCC), the Construction Agency (CA) will consolidate non-

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 9 of 35

ACCEPTANCE OF FACILITIES

project scope items submitted during the systems/ facilities punchlisting and indicating CA reasons

for considering these items as non-scope. The CA will issue these items to the Acceptance

Committee Chairman (ACC) in a report and will call for a meeting with the ACC to obtain

agreement on these punchlist items. The items agreed during this meeting as project scope items

and identified as YES or NO items, will be added in the MC EIs List. With information to Project

Sponsor (PS), disputed items will be issued for final ruling to:

FPD Manager for scope compliance item(s).

Concerned organization(s) for MSAERs compliance item(s), per SAEP-301.

Other appropriate organizations such as Contracting, Law, etc. for contractual, legal, external

relationship items, etc. as applicable.

Escalated items shall be concluded by the responsible organization within 10 working days of

escalation and followed up by Construction Agency until resolved.

* 4.2.9 Once the MCC Exception Item List is established, deleting an item from the Exception Item (EI)

List or changing a “Yes” item to “No” is the role/authority of the Acceptance Committee Chairman

with notification provided to the originator(s) using MPCS. Any disputes regarding critical safety

items must be resolved prior to approval of the partial/final Mechanical Completion Certificate, as

applicable. For details regarding Project Quality Issues Escalation Process, refer to SAEP-381.

4.2.10 When all of the assigned "Yes" items have been completed and approved, the MCC (partial and

* final) will be generated and electronically routed for notifications and approvals using MPCS. No

portion of the concerned system/facility shall be commissioned and started-up or have

hydrocarbons introduced or building(s) occupied until the MCC has been approved.

4.2.10.1 The Construction Agency can route the MCC (partial and final) to any organization

listed in Supplement-1 (except IA and Proponent organizations) for approvals after all

of the “Yes” items submitted by that organization are completed. IA and Proponent

organizations shall be notified of these routing(s) using MPCS. The PMCC/MCC shall

not be routed to the IA unless all required approvals other than Proponent

organizations have been obtained.

4.2.10.2 Upon receipt of the MCC (partial and final) workflow for approval by the requisite AC

member (except IA and Proponent organizations), it shall be approved/rejected within

three (3) working days, otherwise AC member and relevant Department Manager

shall be notified (using MPCS), requesting the Manager’s intervention for MCC/PMCC

approval/rejection within five (5) additional working days.

4.2.11 Upon receipt of the PMCC/MCC workflow for approval:

*

4.2.11.1 IA’s AC member shall approve/reject the MCC or PMCC within one (1) working day,

otherwise AC member and Department Manager shall be notified (using MPCS),

requesting the Manager’s intervention for MCC/PMCC approval/rejection within one

(1) additional working day.

4.2.11.2 The Proponent shall approve the MCC (partial and final) within two (2) working days

or notify the Construction Agency with justification of his reason for not doing so. In

case of no timely action by the Proponent, Construction Agency shall escalate the

matter to the PS for CMS projects for resolution within five (5) additional working days

and then to the Proponent and Construction Agency Administrative Area Heads if no

resolution can be achieved.

4.2.12 The MCC (partial and final) approval signifies acceptance of custody for the system and facility by

* the Proponent. After this turnover, routine system and facility maintenance and equipment layup

is the Proponent’s responsibility. The remaining work to clear “No” Exception Items by the

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 10 of 35

ACCEPTANCE OF FACILITIES

Construction Agency can only be accomplished upon issuance of Work Permits by the Proponent

in accordance with GI 2.100.

* 4.2.13 Once the MCC, partial or final, is approved, no additional Mechanical Completion Exception Items

should be added to the Exception Item List. In the exceptional circumstance where an item would

create a hazardous condition to personnel or equipment is identified after the MCC is approved,

the identified Exception Items that are within the approved scope of work can be added with the

concurrence of the Proponent and Construction Agency Department Managers.

* 4.2.14 After approval of the Final MCC, the Construction Agency and the Proponent, will review any

outstanding “No” Exception Items and agree on the organization responsible for completion of

each Exception Item. A schedule to complete these item(s) shall be agreed. The Proponent is

responsible for approving completed Exception Items or making arrangement for the originator to

be available for approval. Upon EI completion, a notification to the originator and ACC will be sent

and an alert after five (5) working days will also be sent to respective originator(s), their Division

Head(s) and ACC. If completed items are not Closed or Rejected (with justification) by Proponent

or originator within 10 working days of completion, the items will be considered closed. CA will

issue a request to the System Administrator to close these items.

Exception: The Construction Agency shall complete all EIs inside the boundary wall of residential

unit(s) within 60 days of the MCC approval (partial & final). Any delay shall be reported by the CA

to their and the Proponent Administrative Area Heads, and to the PS (for CMS projects), explaining

the reason for non-completion of each item and the target completion date.

* 4.2.15 An Energization Form (Certificate) obtained per Supplement-3, section 3.g shall not be used in

lieu of a MCC (partial & final). For details about Energization Form, refer to GI 2.703.

4.2.16 After Mechanical Completion, the Construction Agency is responsible for providing an agreed

* number of contractor and vendor commissioning and start-up assistance personnel. These

personnel shall be released as soon as possible after the start-up of the facility. If the Proponent

requires to retain the services of the personnel beyond the 60-day Performance Acceptance

period to assist with Plant operations, maintenance, or provide training, the Construction Agency

will transfer the administrative and cost functions associated with these personnel to the

Proponent to allow the project to be closed out.

4.2.16.1 The Construction Agency and the Proponent are responsible for fulfilling the

requirements stipulated in SAEP-140 for any Vendor provided training requested by

the Proponent. The cost of such training shall be charged in accordance with GI

202.309, Allocation of Costs – New Facilities Start-Up.

4.2.16.2 The cost of materials and consumables for commissioning and start-up will be

charged in accordance with GI 202.309.

4.3 STEPS FOR PERFORMANCE ACCEPTANCE

* 4.3.1 Upon approval of the Mechanical Completion Certificate, commissioning and start-up shall begin.

The Proponent Organization is responsible for these activities with the Construction Agency

providing assistance as listed in Supplement No. 2.710-3. Commissioning and Startup Plan shall

be developed as per SAEP-12 and shall include the PSSR checklist. The Proponent is

responsible for the development and execution of facility start-up and performance test plans and

procedures with the assistance of the CA. The acceptance of the Mechanical Completion

Certificate constitutes the beginning of the commissioning, start-up and initial operating period

during which the facility performance should, where possible, be demonstrated to be in

accordance with the approved Project Scope.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 11 of 35

ACCEPTANCE OF FACILITIES

* 4.3.2 During the performance acceptance period the Proponent shall:

4.3.2.1 Review facility performance, relative to operating conditions, in accordance with the

approved Project Scope of Work after conducting the necessary performance tests in

the presence of qualified contractor personnel and, vendor representatives provided

by the Construction Agency per section 4.2.16 (if required), and the Construction

Agency.

4.3.2.2 Prepare a list of performance-related items requiring corrective action if the facility is

not up to performance specifications and assign responsibility (in agreement with

relevant organization per section 4.3.2.3) for completion in MPCS which will remain

open for 60 days from MCC approval or PAC approval, whichever occurs first.

Exception Items relating to Mechanical Completion (non-performance related items)

shall not be included in the Performance Acceptance Deficiency Item list.

4.3.2.3 The agreed Performance Acceptance Deficiency Items (PDIs) will form the basis of

the Performance Acceptance Certificate (PAC - Saudi Aramco Form 7214) deficiency

item list, which will be attached to the PAC at the time of approval. These items may

fall under the jurisdiction of the Construction Agency (within approved project scope

of work) or Proponent’s Operation and Maintenance Departments. The cost of

completion for those items deemed to be the responsibility of the Construction

Agency (within the approved project scope of work) shall be charged in accordance

with AIM 201 and GI 202.309.

* 4.3.3 If performance tests cannot be completed due to lack of capacity (either of input to the plant or of

supply to the users) within a time period not to exceed sixty (60) days from the date of the final

MCC or other time period achieved through a formal agreement by the Proponent and

Construction Agency Department Managers, these tests will either be omitted or performed at

a later date by the Proponent and the Performance Acceptance Certificate shall be approved by

the Proponent representative without such tests. For MSAERs’ waiver requirements, please refer

to SAEP-302.

4.4 PERFORMANCE ACCEPTANCE CERTIFICATE

4.4.1 A Performance Acceptance Certificate (PAC) shall be prepared by the Construction Agency for

* each facility after the final Mechanical Completion Certificate (MCC) for the facility has been

approved for subsequent approval by the Proponent upon completion of performance testing. The

PAC will be generated and electronically routed for approval using MPCS no later than forty five

(45) days after final MCC and may include the PDI list mentioned in section 4.3.2.3.

* 4.4.2 The date of the Proponent representative’s approval on the PAC for process and process-related

facilities shall constitute the completion of the initial operating period. Proponent Representative

will approve the Performance Acceptance Certificate no later than sixty (60) days after the final

MCC was approved by the Proponent Representative.

4.4.2.1 If the Proponent Representative does not accept that the requirements for approving

the Performance Acceptance Certificate (with or without a list of PDIs, attached) have

been satisfied within sixty (60) days after the final MCC was approved, this shall be

reported by the Proponent to the Proponent and the Construction Agency

Administrative Area Heads and to the PS (for projects following Capital Management

System (CMS)) by letter with a copy to PFAAD (Projects and Fixed Asset Accounting

Division) explaining the reason(s) and the actions being taken to achieve Performance

Acceptance.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 12 of 35

ACCEPTANCE OF FACILITIES

4.4.2.2 If the sixty (60) days have elapsed and no letter with a list of performance deficiencies

has been issued by the proponent, the facility shall be automatically deemed accepted

by means of a Performance Acceptance Certificate’s approval in MPCS with the

Construction Agency’s representative’s signature. The construction agency shall send a

letter with the PAC attached to PFAAD with a copy to their and the Proponent

Administrative Area Heads and to the PS (if applicable), indicating that the Construction

Agency’s Performance Acceptance obligations have been met.

4.4.2.3 For all intents and purposes, the Proponent Representative’s approval of the

Performance Acceptance Certificate for the overall facility, signifies completion of the

Construction Agency’s Performance Acceptance obligations unless the certificate lists

performance deficiencies requiring rectification.

4.4.2.4 Should performance or equipment warranty issues arise after approval of the

Performance Acceptance Certificate, the Proponent shall notify the Construction

Agency’s management of the details so that the Construction Agency’s contract

representative can officially notify the Contractor in accordance with the contract’s

terms and conditions.

4.4.3 The capability to meet “Performance Specifications” is established after the facility has been

commissioned. The failure of the facility or its associated equipment to meet its operational design

criteria is a Performance Warranty Issue. The issuing of a Performance Acceptance Certificate

shall not be delayed for deficiency items that have little or no bearing on the operable condition of

the facility or for delays in completing Mechanical Completion exception items.

4.4.4 Although all references in this GI refer to one final Performance Acceptance Certificate, the

Construction Agency and Proponent may agree to use Performance Acceptance Certificates

to document partial completion. In this situation the Performance Acceptance Certificate must

clearly indicate in the space provided that the facility is partially accepted and under the

description, note that the accepted work is part of an overall facility.

4.4.5 The Proponent will maintain a list of Performance Deficiency Items identified during the

commissioning and initial operating period in MPCS. Any performance deficiencies not addressed

and closed out during this period will be listed as a Performance Acceptance deficiency item and

attached to the PAC at the time of approval.

4.4.6 Where the Proponent cannot obtain resolution of the equipment or facilities performance

deficiencies through the Contract Warranty terms, the Construction Agency must assist in

resolving the performance warranty issues.

4.4.7 The Proponent may formally notify the Construction Agency and the Financial Accounting

Department’s CPD and PFAAD that a Performance Acceptance Certificate is not required by the

time the Mechanical completion has been achieved.

* 4.4.8 The Performance Acceptance Certificate is not required for:

4.4.8.1 All Maintain Potential (MP) Master Appropriation ERs covered in GI 20.720.

4.4.8.2 Third party secondary fuel gas projects per SAEP 50, Third Party Royalty/Custody

Metering Facilities Execution Guide.

** 4.4.9 Within four (4) weeks of PAC approval, for the completion of Performance Acceptance Deficiency

Items (PDIs) within project scope, the Construction Agency and Proponent shall agree on the

schedule (including shutdown requirements, if applicable) and shall forthwith commence

resolution of those items. Upon PDI completion, a notification to the originator and ACC will be

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 13 of 35

ACCEPTANCE OF FACILITIES

sent and an alert after five (5) working days will also be sent to respective originator(s) and their

Division Head(s), and the ACC. If completed items are not Closed or Rejected (with justification)

by the Proponent within 10 working days, the items will be considered Closed. CA will issue a

request to the System Administrator to close these items.

** 4.4.10 In case of dispute between the Construction Agency and the Proponent as to whether a particular

PDI is within the project scope of work, with information to Project Sponsor (PS), Construction

Agency project manager shall escalate dispute(s) for final ruling and resolution following process

described in section 4.2.8.

* 4.11 Construction Agency will provide As-Built Drawings including On-Stream Inspection “OSI”

drawings in the Saudi Aramco’s Engineering Drawing Management System in accordance with

SAES-A-202 and SAEP-334 prior to the final Performance Acceptance Certificate (PAC). For OSI

details, refer to SAES-A-135 and SAEP-1135.

5. CONSIDERATIONS DURING PROJECT CLOSE-OUT

5.1 For the financial close-out process of a project, refer to Accounting Instruction Manual (AIM) 201 “Projects

* Financial Close-Out Process”.

5.2 Any MCC Exception Items and/or Performance Acceptance Deficiency Items not completed ninety (90)

* days after the Performance Acceptance Certificate has been approved, shall be reported by the

Construction Agency to their and the Proponent Administrative Area heads, and to the PS (for projects

following Capital Management System “CMS”) by letter explaining the reason for non-completion of each

item and the target completion date.

5.3 The project scope of work, including all pending “No” Exception Items and Performance Acceptance

** Deficiencies’ Items and excluding items covered in Section 5.4, shall be completed by the Construction

Agency within project’s closeout period. For details about said period and its extension, see AIM-201.

5.4 Where MCC Exception Items (EIs) and or Performance Acceptance Deficiency Items (PDIs) cannot be

* completed by the Contractor and/or are out of the Contractor's Scope of Work, and with the agreement of

the Proponent, the approved project scope of work’s MC Exception Items defined as "No" items and PDIs

can be assigned to the Proponent Maintenance and Engineering organization to complete after MCC and

PAC. For financial aspects, please refer to AIM 201.

* 5.5 Any changes and modifications to the constructed facilities or any additional construction activities outside

the approved project’s scope of work shall not be executed by the Construction Agency of that project.

The execution of such modifications shall, whenever feasible, be carried out by the Proponent’s

Maintenance Department. Where this is impractical, because of size or technical complexity of the

change(s), a new Construction Agency may be designated to execute the work. Consult CPD for the proper

funding mechanism and for the capital vs. expense ruling of these modifications or new construction

activities.

* 5.6 Before Mechanical Completion (PMCCs and FMCC), the Construction Agency will provide PFAAD with a

corresponding list of capital assets. For details, refer to AIM 201 and GI 202.305.

** 5.7 For projects where company supplied materials are free issued to the Contractors, the Construction

Agency shall complete material reconciliation prior to Final Release Agreement (FRA).

* 5.8 Costs associated with the period following MCC approval are treated according to the procedures

established in GI 202.309.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 14 of 35

ACCEPTANCE OF FACILITIES

6. REFERENCE:

The following references should be reviewed carefully by all parties to this GI:

** GI 2.100 “Work Permit System”

GI 2.102, "Pressure Testing Safely"

GI 7.030 "Inspection and Testing Requirements for Elevating /Lifting Equipment"

** GI 2.703, "Electrical Load Planning and Connection/Disconnection"

** GI 202.305, “Capital Assets Record Creation and Tag Numbering”

GI 400.001, “Quality System Roles and Responsibilities”

GI 1781.001 "Inspection, Testing and Maintenance of Fire Protection Equipment"

SAEP-20, “Equipment Inspection Schedules (EIS)”

SAEP-50, “Third Party Royalty/Custody Metering Facilities Execution Guide”

** SAEP-68, Inspection Coverage on C1 Projects

SAEP-121 Operating Instructions for New Facilities

** SAEP-122 Project Records

** SAEP-148, “Mandatory Engineering Standards and Codes for Non-Industrial, Public and Government

Facilities”

SAEP-301, “Instructions for Establishing and Maintaining Mandatory Saudi Aramco Engineering

** Requirements”

** SAEP-302, “Waiver of a Mandatory Saudi Aramco Engineering Requirement”

** SAEP-319, “Pressure Relief Devices - Testing and Inspection Requirements”

SAEP-327, “Disposal of Wastewater from Cleaning, Flushing, and Hydrostatic Tests”

** SAEP-334, “Retrieval, Certification and Submittal of Saudi Aramco Engineering and Vendor Drawings”

** SAEP-381, “Project Quality Issues Escalation Process”

SAEP-385, “Preservation of Project Materials and Equipment”

** SAEP-1135, “On-Stream Inspection Administration”

** SAEP-1150, “Inspection Coverage on Projects”

**

* SAEP-31, “Corporate Equipment and Spare Parts Data Requirements and Responsibilities”

** SAES-A-202, “Saudi Aramco Engineering Drawing Preparation”

SAES-A-004, “General Requirements for Pressure Testing”

SAES-A-007, “Hydrostatic Testing Fluids and Lay-Up Procedures”

** SAES-A-135, “Establishment of On Stream Inspection (OSI) Program”

SAES-B-014, “Safety Requirements for Plant and Operations Support Buildings”SAES-B-017, “Fire Water

** System Design“

SAES-B-054, “Access, Egress, and Materials Handling For Plant Facilities”

SAES-G-116, “Cleanliness Standard for Lube/Seal Oil and Fluid Power Systems”

SAES-J-801, “Control Buildings”

SAES-J-600, “Pressure Relief Devices”

SAES-K-002, “Air Conditioning Systems for Essential Operating Facilities”

** SAES-L-133, “Corrosion Protection Requirements for Pipelines, Piping, and Process Equipment”

* SAES-L-150, “Pressure Testing of Plant Piping and Pipelines”

SAES-L-350, “Construction of Plant Piping”

** SAES-M-100, “Saudi Aramco Building Code”

** SAES-O-201 "General Requirements of Security Directives"

Other related reference materials:

Saudi Aramco Construction Safety Manual

Accounting Instruction Manual No. 201 (AIM 201), “Financial Close-Out of Capital/Non-Capital Projects”

** GI 20.031, "Capital Program and Budget”

** GI 20.110, "Public Support Program and Budget

GI 20.520, “Project Change Request”

** GI 20.620, “Miscellaneous Projects & Purchases Master Appropriation (BI-19)”

**

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 15 of 35

ACCEPTANCE OF FACILITIES

GI 20.720, “Maintain Potential Master Appropriations”

GI 202.309, “Allocation of Costs – New Facilities Start-Up”

SAEP-12, “Project Execution Plan”

** SAEP-14, “Project Proposal”

** SAEP-140, “Project Training Impact Assessment”

SAEP-329, “Project Close-Out Report”

* SAEP-367, “Value Improving Practices Requirements”

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 16 of 35

ACCEPTANCE OF FACILITIES

APPROVED BY: (for minor change)

Date: _________________________

Manager

Project Management Office Department

*

CONCURRED BY:

_______________________ Date: _________________________

Sr. Vice President

Upstream

_______________________ Date: _________________________

Sr. Vice President

Downstream

_______________________ Date: _________________________

Sr. Vice President

Operations and Business Services

_______________________ Date: _________________________

Sr. Vice President

Finance, Strategy & Development

APPROVED BY

_______________________ Date: _________________________

Vice President

Project Management

_______________________ Date: _________________________

Sr. Vice President

Technical Services

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 17 of 35

ACCEPTANCE OF FACILITIES

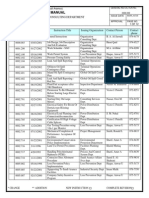

SUPPLEMENT NO. 2.710-1

MECHANICAL COMPLETION CERTIFICATE (Example) DATE

Saudi Aramco 7213

BI/JO NO. Partial/Final ID:

DESCRIPTION:

I hereby certify that this facility, or portion thereof has been completed in accordance with the approved expenditure

request, project drawings, and specifications except as noted below (if any):

CONSTRUCTION AGENCY PROJECT MANAGER: Date:

I hereby certify that the facility or portion thereof has been checked, pre-commissioned and that all electrical works

meet the relevant standards and can be energized without hazard to the power system.

POWER OPERATIONS DEPT. REPRESENTATIVE: Date:

* I hereby certify that this facility has been inspected and that it complies with all applicable safety and fire protection

requirements except as note below (if any):

LOSS PREVENTION REPRESENTATIVE: Date:

FIRE PROTECTION REPRESENTATIVE: Date:

I hereby certify that this facility or portion thereof, has been inspected and that all materials meet applicable Saudi

Aramco Standards, and that it is constructed in agreement with pertinent design and engineering specifications.

INSPECTION AGENCY REPRESENTATIVE: Date:

I hereby certify that tests have been conducted and witnessed demonstrating that this project is mechanically

complete and ready for commissioning and stat-up, that I have received adequate operating instructions including

* safety requirements have been received, and that this project conforms to the approved Expenditure Request,

project drawings and specifications except as noted below (if any):

PROPONENT MAINTENANCE SUPERINTENDENT: Date:

PROPONENT COMMISSIONING REPRESENTATIVE: Date:

PROPONENT REPRESENTATIVE (ACC): Service Date:

EXCEPTIONS:

*

Original to: Projects & Fixed Assets Accounting Division (PFAAD), Financial Accounting Department

Copy to:

1. Proponent Representatives (ACC,

2. Proponent Commissioning Representative,

* 3. Proponent Maintenance Superintendent)

4. Construction Agency Project Manager

5. Inspection Agency Division Head

6. Area Loss Prevention Division Head

7. Area Power Operations Department Representative

8. Area Fire Protection Division Head

9. Administrator, Material Standardization (MSO)

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 18 of 35

ACCEPTANCE OF FACILITIES

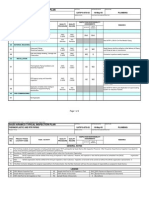

SUPPLEMENT NO. 2.710-2

PERFORMANCE ACCEPTANCE CERTIFICATE (Example) DATE

Saudi Aramco 7214

BI/JO NO. Partial/Final ID:

DESCRIPTION

I hereby certify that the equipment installed on this project has been demonstrated to perform within Saudi Aramco

Standards and project drawings and specifications.

CONSTRUCTION AGENCY PROJECT MANAGER: Date:

PROPONENT MAINTENANCE SUPERINTENDENT: Date:

PROPONENT OPERATIONS ENGINEERING SUPERVISOR: Date:

I hereby certify that I have witnessed or conducted operating tests demonstrating the operability of the facility and

that I have received adequate operating instructions including safety requirements, and that this project conforms

to the approved Expenditure Request and project drawings and specifications except as noted below.

PROPONENT COMMISSIONING REPRESENTATIVE: Date:

PROPONENT SUPERINTENDENT (ACC): Date:

* LIST OF OUTSTANDING PERFORMANCE DEFICIENCIES:

Original to: Projects & Fixed Assets Accounting Division (PFAAD), Financial Accounting Department

* Copy to:

1. Proponent Representative (ACC)

2. Proponent Commissioning Representative

3. Proponent Maintenance Superintendent

4. Construction Agency Project Manager

5. Area Loss Prevention Division Head

6. Area Power Operations Department Representative

7. Area Fire Protection Division Head

8. PFAAD - Immediately after Signature by Construction Agency

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 19 of 35

ACCEPTANCE OF FACILITIES

SUPPLEMENT NO. 2.710-3

*

DIVISION OF RESPONSIBILITIES FOR TURNOVER

The main purpose of this Supplement is to delineate those activities which are required

to be complete prior to Mechanical Completion and those activities which are performed

post-MCC, and to designate the responsible party for each activity.

INDEX: LEGEND:

1. General X - Perform Work

2. Civil/Structural R - Review and Approve

3. Electrical W - Witness (Event)

4. Piping I - Inspect (Work)

5. Mechanical Equipment O - Operate Process Equipment - By Operator

6. Fire & Safety E&I - Maintenance's Start-Up Electrical & Instrument Specialist

7. Communications M - Maintenance's Start-Up Machinist

8. Instrumentation P - Maintenance's Start-Up Fitter

9. Catalyst, Chemical and Desiccants

POD - Power Operations Department

FP - Fire Protection *

LP - Loss Prevention

P&CSD - Process & Control Systems Department

IT - Information Technology

NOTE 1: Construction Agency is responsible for performing all work prior to Mechanical Completion, unless

assigned otherwise as indicated with an X.

NOTE 2: Per paragraph 4.2.16 of G.I. 2.710, Construction Agency will provide an agreed number of Contractor

Commissioning Assistance Personnel to work under the direction of the Proponent Commissioning

Supervisor or his Nominee. Alternatively, and as directed by Proponent, Operations/Commissioning

will utilize E&I, P or POD personnel for Commissioning Assistance.

* NOTE 3: POD will inspect and sign-off for all Power Distribution Systems that are under its Operation and/or

Maintenance Responsibility as per GI 2.706, and other will be inspected by Inspection Agency and

witnessed by Operations and/or Maintenance Agency that will operate and maintain them.

NOTE 4: Minimum of 10% of Megger Testing to be witnessed, balance to be monitored.

* NOTE 5: Cleaning/flushing per SAES-A-004 to be witnessed by Inspection and reviewed by Proponent

Commissioning Team. All other specialty cleaning (lube oil systems, etc.) to be witnessed by

Proponent Commissioning Team. (See SAES-L-150).

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 20 of 35

ACCEPTANCE OF FACILITIES

CONSTRUCTION & PRE- COMMISSIONING &

COMMISSIONING STARTUP

(Pre-MCC) (Post-MCC)

Sr.

No. DESCRIPTION

(Note 1) * (Note 2) *

Commiss’g w/

Inspection Construction

Proponent Proponent

Agency Agency

1. GENERAL

a. Provide proper identification of all equipment. Identification I R

numbers shall be legible from 50 feet away for process

equipment.

b. Remove all rust preventatives, oil, grease, etc. used to I-R

preserve equipment during construction, and install proper

lubricants after review with Operations.

c. At time of turnover, all fire proofing and rough insulation shall I R

be complete. All equipment, piping, instruments, instruments

leads, etc. requiring insulation for heat conservation or proper

operation shall be covered so that startup operations will not

be delayed due to excessive heat loss. Insulation required for

personnel protection shall also be completed.

d. At time of turnover, painting shall be complete enough so that I R

an excessive amount of scaffolding is not left still standing in

the areas where the operators must work to start up the plant.

e. At the time of turnover, operating areas including platforms I

shall be free of debris, tools and extraneous materials which

would impede operation or cause an unsafe condition. All

access ways shall be open for emergency vehicles.

f. Make check of lighting intensities. I W

*

g. Make check of noise levels (after startup). X W

*

h. Complete all necessary paving, road marking, signs, fencing, I R

* and items of like nature.

i. All testing of lifting equipment shall be in compliance with GI W R

* 7.030 and witnessed by the Inspection Agency's Crane

Inspection Representative which can then be provided with a

current inspection sticker or the completion of the successful

tests.

j. Perform Leak test of all piping and equipment handling fluids in W R

* accordance with SAES-L-150 & SAES-A-004 and repair all

leaks. Check all nuts and bolts to see that threads are fully

engaged. All torque procedures for bolting and bolt pre-loads

should be verified on (ANSI 600# and above) piping and

equipment where applicable.

k. Verify all spare parts data packages have been submitted and X

accepted by Material Supply Organization (MSO).

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 21 of 35

ACCEPTANCE OF FACILITIES

CONSTRUCTION & PRE- COMMISSIONING &

COMMISSIONING STARTUP

(Pre-MCC) (Post-MCC)

Sr.

No. DESCRIPTION

(Note 1) * (Note 2) *

Commiss’g w/

Inspection Construction

Proponent Proponent

Agency Agency

l. All temporary fencing or barricades must be removed to allow I

free access to the operating units.

m. Verify all start up spare parts required by contract are available I X

* on site.

n. Verify all start up spare parts required by contract are available X

on site, if these are included in approved project SOW and/or

** relevant contract(s)/purchase orders(s).

2. CIVIL/STRUCTURAL

a. Inspect sewer lines and check all cleanouts manholes, and I W

service connections for proper installation and functioning.

Check manholes for leak tightness by filling and then

observing the water level for ten hours.

b. Test buildings for leak tightness and maintenance of required I W

* internal positive pressure. (Refer to SAES-K-002)

c. Access platforms, ladders, stairs, walkways and handrails. I W

d. Perform a "Flood Test" for verification of process area OWS I W

catch basins and a "Flow Test" of the floor drain for battery

rooms to the acid neutralization pits.

e. Check access around equipment at grade and at elevated I W

areas to ensure it is proper for normal operation and

maintenance as well as for emergency escape. Refer to

SAES-B-054 for more details.

f. Verify that all valves and instruments are provided with proper I W

access for normal operation and maintenance purposes as per

SAES-B-054.

g. Check heavy mobile cranes access roads and clearance/ I W

height from ground level to overhead pipe racks.

**

3. ELECTRICAL.

a. Perform dielectric strength tests on power transformer and I POD-W

disconnect switch insulating oil and install when satisfactory.

b. Check condition of grease in grease lubricated motor and I

generator bearings.

c. Perform all necessary prestart-up non-operating tests and Hi I POD

Pot checks on all power cables, generators, Switchgear, (Note 3)

MCCs, transformers and grounding resistors following

manufacturers' instructions and guidelines given in the

applicable Saudi Aramco Pre-Commissioning Forms Manual

available from Consulting Services Department.

d. Measure and record the insulation resistance (Megger Testing) I R

of all power (480V or less), instrument wiring (including (Note 4)

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 22 of 35

ACCEPTANCE OF FACILITIES

CONSTRUCTION & PRE- COMMISSIONING &

COMMISSIONING STARTUP

(Pre-MCC) (Post-MCC)

Sr.

No. DESCRIPTION

(Note 1) * (Note 2) *

Commiss’g w/

Inspection Construction

Proponent Proponent

Agency Agency

thermocouple leads) and lighting circuits from conductor to

conductor and from each conductor to ground.

e. Perform applicable checks, adjustments and field tests using, if I R

necessary in order to maintain schedule, temporary POD-W

construction power. (Note 2)

f. Calibrate and set substation relays on all circuit breakers. Set I POD-W

time delays. Set and test fault pressure relays and transformer

taps.

g. Energize substations and load centers by connection to R POD-W

* electrical distribution systems (Energized by authorized

electrical systems operator after obtaining approved

"Energization Authorization Certificate").

h Check operability of emergency and instrument power systems I W

as well as emergency lighting system.

i. Issue work permits to Contractor for carrying out checks on R X

* electrical equipment, after facilities are energized per item (g)

and/or partial MCC approved. For details, see GI 2.100.

j. Paint or tag all electrical apparatus (Push button boxes, I R

connection boxes, etc.) according to Saudi Aramco's color

code or regulations.

k. Construction Agency will use work permit procedure X

* (established per GI 2.100) for remaining construction period,

once electrical equipment is energized. (If the existing Tag and

Lock-Out Procedure needs to be revised, it shall be approved

by Loss Prevention and implemented as part of this effort).

l. Perform a final functional checkout for all equipment and I

systems. POD-W

m. Perform testing and Pre-commissioning of overhead I R

transmission line (OTHL), if OTHL is a Project SOW.

**

n. Confirm that all critical electrical systems (e.g. CP System, I W

Heat Tracing System etc.) not addressed elsewhere in this

** shall (where applicable) are tested for proper functioning.

4. PIPING

a. Flush, clean and hydro/pressure test, air/steam blowing per I R

* SAEP-327, SAES-A-004, SAES-L-150, SAES-L-350, and (Note 5)

SAES-G-116, all piping and piping systems as required by

drawings, standards and specifications prior to MCC. All orifice

plates, strainers, control valves, thermowells and other items,

which may be damaged during flushing and testing, are to be

removed from the system. With systems in LPG service, and

on completion of hydrotesting, system shall be fully drained

and dried.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 23 of 35

ACCEPTANCE OF FACILITIES

CONSTRUCTION & PRE- COMMISSIONING &

COMMISSIONING STARTUP

(Pre-MCC) (Post-MCC)

Sr.

No. DESCRIPTION

(Note 1) * (Note 2) *

Commiss’g w/

Inspection Construction

Proponent Proponent

Agency Agency

b. Provide and install all strainers, both temporary and X W/I

permanent, spec. blinds, and temporary blinds, called for on

drawings and specifications.

c. Check that all temporary blanks, plugs, caps, spectacle blinds I W

and temporary spools installed for the hydro/pressure test

have been removed and that all spectacle plates, blinds, etc.

that are to remain in the system are in their correct locations

as per the P&ID.

d. Provide and install other temporary blinds required for startup, X W/I

as specified by Proponent Operations.

e Check packing and packing materials and lubrication of valves, I R

repack and lubricate as necessary.

f. Supply and install line identification tags and signs. Stencil I R

lines for identification.

g. Provide list and location of all blinds installed for start-up and X R

not detailed on P&ID's.

h. Perform hot bolting of piping and equipment during initial plant X I

start up.

i. Commission spring hangers and supports after hydro test, I W

check spring hangers and pipe anchors and guides in hot

position, provide cold and hot setting data.

j. Check pipe anchors and guides. I R

k. Install corrosion probes. I W

l. Remove temporary strainers (Normally after start-up). X W

m. Confirm that bleeds and vents used during commissioning are X W

properly plugged.

n. Identify Insulation Inspection ports for OSI (On-Stream I R

Inspection).

**

5. MECHANICAL EQUIPMENT

5.1 AIR FIN COOLERS

a. Perform all hydro/pressure tests as required per SAES-A- W I

004.

b. Check levels and dimensions of substructure, machinery I R

mount, fan ring, Furnish record of measurements.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 24 of 35

ACCEPTANCE OF FACILITIES

CONSTRUCTION & PRE- COMMISSIONING &

COMMISSIONING STARTUP

(Pre-MCC) (Post-MCC)

Sr.

No. DESCRIPTION

(Note 1) * (Note 2) *

Commiss’g w/

Inspection Construction

Proponent Proponent

Agency Agency

c. Perform decoupled motor running test, (Min. 4 hours), I W

check vibration and perform necessary corrective work.

d. Set and align fan assembly, fan shaft, sheave and driver. I W

e. Demonstrate satisfactory operation of louvers; adjust as X O-W

necessary

f. Clean inside of the hood and remove all extraneous I W

articles around the air fin cooler.

g. Set and adjust V-Belts. W

h. Check and verify fan tip clearances. I W

5.2 BOILERS, DUCTWORK AND STACK

a. Perform hydrostatic tests per SAES-A-004. Empty water W I

completely after test and dry. Alternatively, can be laid up

with inhibitor added to test water.

b. Perform air leak test on completed casing. W I

c. Check to see if provision has been made for thermal I R

expansion of all boiler parts and attached piping

d. Clean out stack and duct, open manholes and other I W

opening for inspection. Check operation of dampers.

Close stack and duct after inspection.

e. Check mechanical operation of soot blowers. O-W

f. Prepare boiler dry-out procedure including manufacturer's R

recommendations and review with proponent 90 days in

advance of turnover.

g. Make check of boiler safety cutout. X I-R

h. Re-couple fans to drivers after successful run-in of driver. W R

i. Commission fans and drivers, and check vibration after X O-I

proponent run-in. Correct operability problems of fans and

drivers as required.

j. Inspect internal surfaces of drums, remove all debris and I W

provide supervised labor to open, clear and close boilers

after boil out and/or acid cleaning.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 25 of 35

ACCEPTANCE OF FACILITIES

CONSTRUCTION & PRE- COMMISSIONING &

COMMISSIONING STARTUP

(Pre-MCC) (Post-MCC)

Sr.

No. DESCRIPTION

(Note 1) * (Note 2) *

Commiss’g w/

Inspection Construction

Proponent Proponent

Agency Agency

k. Verify proper relief valve rating, certification, and I R

installation.

l. Purge, light off & put boilers and heaters in operation. X O-I

m. Dryout, boilout, and chemically clean according to X O-I

manufacturers' and contractor's procedures. Operations

will operate furnace and pumps.

n. Check out and fine tune instrumentation and controls X O-I

during start-up.

o. Determine boiler response under manually imposed load X O-I

changes and demonstrate operation of shutdown devices.

p. Repair damage to liners if it occurs during cureout. I W

q. Conduct guarantee performance test. W O-X

5.3 COMPRESSORS

a. Install compressor piping and make piping corrections as W I

required by manufacturer's tolerances. Set and cold align

compressor and driver. Furnish record of alignment to

Operations.

b. Clean suction piping of gas compressors, mechanically W I

* and/or chemically.

c. Ensure that compressor suction piping, suction and I W

interstage drums, lube and seal oil piping, are in clean

condition, free of mill scale, weld spatter and all loose and

foreign material. Disassemble piping for cleanliness

inspection as required.

d. Commission lube and seal oil systems, circulate oil, and X O-W

replace with clean oil, etc., as required to prepare system

for operation.

e. Run-in the uncoupled compressor drive motor (minimum 4 I W

hours).

f. Recouple compressor to driver after successful run-in of I W

driver. Complete cold alignment of train.

g. Check, Commission and run-in compressor. Operations X O-W

will operate equipment.

* CHANGE ** ADDITION NEW INSTRUCTION COMPLETE REVISION

SAUDI ARABIAN OIL COMPANY (Saudi Aramco) G. I. Number APPROVED

2.710

GENERAL INSTRUCTION MANUAL

ISSUE DATE REPLACES

ISSUING ORG. PROJECT MANAGEMENT 12/04/2018 03/15/2010

MECHANICAL COMPLETION AND PERFORMANCE APPROVAL PAGE NO.

SUBJECT AAS 26 of 35

ACCEPTANCE OF FACILITIES

CONSTRUCTION & PRE- COMMISSIONING &

COMMISSIONING STARTUP

(Pre-MCC) (Post-MCC)

Sr.

No. DESCRIPTION

(Note 1) * (Note 2) *

Commiss’g w/

Inspection Construction

Proponent Proponent

Agency Agency

h. Make comprehensive vibration check of rotating elements X O-W

and auxiliary equipment.

i. Check hot alignment of compressor and driver and do any X I

required doweling.

j. Correct any piping mis-alignment or deficiency which X W

results from run-in of the compressor after MCC.

5.4 COOLING TOWER

a. Clean inside and outside the tower. Remove all I W

extraneous articles around the tower.

b. Clean the cold water basin, water distribution deck and I R

ensure all spray nozzles are installed.

c. Couple fans to drivers. After the motor has been checked I W

for rotation, run-in 4 hours uncoupled, and check bearings.

d. Commission cooling tower. X O-W

e. After Commissioning, check vibration and perform X O-I

necessary correction work.