Professional Documents

Culture Documents

Valmet HP Cleaning System For Pulp Filters

Uploaded by

notengofff0 ratings0% found this document useful (0 votes)

15 views2 pagesValmet Service

Original Title

Valmet HP Cleaning System for Pulp Filters

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentValmet Service

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views2 pagesValmet HP Cleaning System For Pulp Filters

Uploaded by

notengofffValmet Service

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

A clean wire improves pulp filter

performance

Valmet HP Cleaning System for Pulp Filters

Effective high-pressure cleaning of the pulp filter wire is important if scaling is a

problem. HP Cleaning System cleans the wire of impurities before buildups start

clogging the wire. A clean wire ensures effective and uniform dewatering of the pulp.

Benefits

• Decreased production downtime

caused by scaling

• Improved pulp filter performance

• Production increase

• Better washing

• Reduced COD carryover

• Cleaning interval can be set to

match extent of scaling problems

• Manual cleaning not needed

HP Cleaning System for pulp filter is a high-pressure Easy rebuild

washing device for cleaning the wire on any type of HP Cleaning System is normally easy to install. It is

pulp filter. bolted to existing Pulp Filter gable and requires only a

few modifications in the main vat.

For demanding processes

HP Cleaning System is specially suitable for demand-

Runnability

ing processes where the standard low-pressure spray

pipe cleaning is not efficient enough.

HP Cleaning System cleans the wire with hot-high

pressure water during operation. A number of

nozzles move slowly in the longitudinal direction of Reduced washing efficiency HP Cleaning System

the rotating drum to cover the whole surface during Bad washing

the cleaning sequence. The cleaning is carried out at

intervals controlled by the DCS system. The interval is Serious runnability problems

set depending on the extent of scaling problems.

Time

Rebuild to HP Cleaning System significantly improves

the possibility of keeping the wire clean from scaling,

deposits and other dirt that plug it and consequently

reduce washing/dewatering efficiency.

HP Cleaning System consists of one high pressure pump unit and one separate wash unit mounted on the filter gable. The high

pressure wash unit has a number of spray nozzles.

© Valmet Corporation, CPDU_R_2080_197-02. 03/2018.

For more information, contact your local Valmet office. www.valmet.com

Specifications in this document are subject to change without notice.

Product names in this publication are all trademarks of Valmet Corporation.

You might also like

- HDBF - Filter UnderstandingDocument8 pagesHDBF - Filter UnderstandingroobiNo ratings yet

- Eaton TubularBackwashing Intro CleanableMedia Components PressureTactics USDocument8 pagesEaton TubularBackwashing Intro CleanableMedia Components PressureTactics USAllen de RichardNo ratings yet

- Eaton TubularBackwashing Intro CleanableMedia Components PressureTactics USDocument8 pagesEaton TubularBackwashing Intro CleanableMedia Components PressureTactics USMarco TaschiniNo ratings yet

- Detrashing SystemDocument6 pagesDetrashing Systemfrancesco.migliorucciNo ratings yet

- Pro Ue Rechengut enDocument6 pagesPro Ue Rechengut enDanilo MiranovicNo ratings yet

- Hi-Flo22 WS-090 W.MVPDocument4 pagesHi-Flo22 WS-090 W.MVPtachetNo ratings yet

- Eaton Fluid Purifier Systems and Oil Service Equipment Brochure en LowResDocument6 pagesEaton Fluid Purifier Systems and Oil Service Equipment Brochure en LowResVibenatNo ratings yet

- THE MOBILE"ONE" Self Cleaning Cartridge Filter Mobility Without LimitsDocument4 pagesTHE MOBILE"ONE" Self Cleaning Cartridge Filter Mobility Without LimitsBülent KabadayiNo ratings yet

- Girbau TBS-50 PDFDocument12 pagesGirbau TBS-50 PDFmairimsp2003100% (1)

- B Dispensing Us 01Document12 pagesB Dispensing Us 01Vruno Velasquez LNo ratings yet

- HOBART Warewashing Flight-Type Dishwasher GuideDocument32 pagesHOBART Warewashing Flight-Type Dishwasher GuideEric AllainNo ratings yet

- Torrential: High-Flow Filtration UnitDocument1 pageTorrential: High-Flow Filtration UnitBrahim BenabdallahNo ratings yet

- Binem DrumUnloaderDocument2 pagesBinem DrumUnloaderABC - Angela GomezNo ratings yet

- Admix Datasheet RotosolverDocument2 pagesAdmix Datasheet RotosolverYusuf DabhiyaNo ratings yet

- Sludge Dewatering.Document8 pagesSludge Dewatering.Musawenkosi NcubeNo ratings yet

- Ocean Us Web 2020Document12 pagesOcean Us Web 2020Alexandre OliveiraNo ratings yet

- B2B RO Systm 310134 Rev2-1Document4 pagesB2B RO Systm 310134 Rev2-1IanNo ratings yet

- Flottweg Ose Thickening Centrifuges: Optimizing The Digestion Process in Waste Water Treatment PlantsDocument4 pagesFlottweg Ose Thickening Centrifuges: Optimizing The Digestion Process in Waste Water Treatment PlantsAdolfo Chaves GoyenecheaNo ratings yet

- Total Water Management with Screw Press Sludge DewateringDocument13 pagesTotal Water Management with Screw Press Sludge Dewateringsachin pathakNo ratings yet

- Vial washing for parenteral drugsDocument2 pagesVial washing for parenteral drugsAnas Abandeh100% (1)

- Solder Pallet Cleaning Costs Reduced Over 50Document3 pagesSolder Pallet Cleaning Costs Reduced Over 50carlos finoNo ratings yet

- GEN Dual Multimedia Filtration Final0420Document1 pageGEN Dual Multimedia Filtration Final0420Ahamed IbrahimNo ratings yet

- C50 Brochure IND enDocument7 pagesC50 Brochure IND enArief AdiNo ratings yet

- Foam Generation & Application: Suprafoam ForDocument4 pagesFoam Generation & Application: Suprafoam ForchayanunNo ratings yet

- Huebsch Coin Galaxy 600 Sell Sheet Ah13 0011Document2 pagesHuebsch Coin Galaxy 600 Sell Sheet Ah13 0011NANA ADDONo ratings yet

- Pump-Clean Real Tech IncDocument2 pagesPump-Clean Real Tech IncQUONTROL SASNo ratings yet

- Reduce Waste and Increase Profits with Drum UnloadingDocument4 pagesReduce Waste and Increase Profits with Drum UnloadingABC - Angela GomezNo ratings yet

- 055 D 08Document6 pages055 D 08api-365035651No ratings yet

- High Pressure Parts Washer For Precision Cleaning: Quick and Efficient CleaningDocument2 pagesHigh Pressure Parts Washer For Precision Cleaning: Quick and Efficient CleaningAsadNo ratings yet

- Continuous cleaning and conditioning of paper machine fabrics and rolls using high pressure showersDocument20 pagesContinuous cleaning and conditioning of paper machine fabrics and rolls using high pressure showersSoma NathanNo ratings yet

- Equipment and Systems For Corn Wet MillingDocument8 pagesEquipment and Systems For Corn Wet MillingCarlos LinaresNo ratings yet

- Andritz Sidebar and Overhead Filter Presses DataDocument20 pagesAndritz Sidebar and Overhead Filter Presses DataTiago J C MachadoNo ratings yet

- Salsnes Fillter User ManualDocument10 pagesSalsnes Fillter User ManualMichael ElliottNo ratings yet

- ExchangerCleaning WebDocument8 pagesExchangerCleaning WebRPC_2404No ratings yet

- Belt Press Vs CentrifugeDocument7 pagesBelt Press Vs CentrifugeDavid ZamoraNo ratings yet

- Chamber Filter Press - Seperation of SludgesDocument4 pagesChamber Filter Press - Seperation of SludgesGREENLAB ECL TECHNo ratings yet

- Reduce Membrane Fouling With Good Cip Procedures inDocument3 pagesReduce Membrane Fouling With Good Cip Procedures indalton2003No ratings yet

- Gea Cip Star System Brewhouse 296991Document4 pagesGea Cip Star System Brewhouse 296991Hoàng Nguyễn VănNo ratings yet

- Hood Type Dishwasher with Guaranteed Rinse SystemDocument3 pagesHood Type Dishwasher with Guaranteed Rinse SystemHibatulAwwalUlfaNo ratings yet

- Hydraulic Filtration Essentials for Pump ProtectionDocument2 pagesHydraulic Filtration Essentials for Pump Protectionjacobian18No ratings yet

- Se Andritz KMPT Peeler Centrifuge HZ enDocument16 pagesSe Andritz KMPT Peeler Centrifuge HZ enlimim56582No ratings yet

- RMC Online Washing System Industrial Gas TurbineDocument3 pagesRMC Online Washing System Industrial Gas TurbinepayamzarNo ratings yet

- Artificial Lift Methods ComparisonsDocument12 pagesArtificial Lift Methods ComparisonsBassel EissaNo ratings yet

- ET Scavenger Plant DataSheetDocument2 pagesET Scavenger Plant DataSheetRaymundo AlarconNo ratings yet

- 40 - Suncombe CIP Overview PresentationDocument46 pages40 - Suncombe CIP Overview PresentationSantiago AguayoNo ratings yet

- Salsnes-Detailer 2016 LRDocument10 pagesSalsnes-Detailer 2016 LRLubrication´s RoomNo ratings yet

- Comenda AcrsDocument10 pagesComenda Acrso.m.martin81gmail.comNo ratings yet

- 11.2.2 Reverse OsmosisDocument2 pages11.2.2 Reverse OsmosisRISHI CHANDRANo ratings yet

- Stuffer 420 VDocument4 pagesStuffer 420 VAndrés ValdomezNo ratings yet

- AC2 Series: Rack Conveyor DishwashersDocument10 pagesAC2 Series: Rack Conveyor DishwashersBilal Hussein SousNo ratings yet

- Clean-In-Place (CIP) in Dairy IndustryDocument3 pagesClean-In-Place (CIP) in Dairy IndustryAnil KumarNo ratings yet

- Flyer Laab 8-Seiter en LQDocument8 pagesFlyer Laab 8-Seiter en LQAkash SharmaNo ratings yet

- Manual Columna de FlotaciónDocument40 pagesManual Columna de FlotaciónpaulinaNo ratings yet

- Glatt FBE Pro PDFDocument4 pagesGlatt FBE Pro PDFAmandaNo ratings yet

- TYPE CRP2000 - CRP30000: Description ApplicationsDocument2 pagesTYPE CRP2000 - CRP30000: Description ApplicationscindyNo ratings yet

- Project Execution PlanDocument20 pagesProject Execution Planprabhu rajendranNo ratings yet

- Hydraulic Filter CartDocument3 pagesHydraulic Filter CartyovannyNo ratings yet

- Aero WWTP2022Document8 pagesAero WWTP2022Kshitiz MittalNo ratings yet

- Harvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsFrom EverandHarvesting Rainwater for Your Home: Design, Install, and Maintain a Self-Sufficient Water Collection and Storage System in 5 Simple Steps for DIY beginner preppers, homesteaders, and environmentalistsNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Expertip Tips For Conditioning Your Press Fabrics 8 Common MistakesDocument6 pagesExpertip Tips For Conditioning Your Press Fabrics 8 Common MistakesnotengofffNo ratings yet

- WPP FabricsdryerDocument17 pagesWPP FabricsdryernotengofffNo ratings yet

- WPP FabricshistoryformingDocument16 pagesWPP FabricshistoryformingAkhil SinghNo ratings yet

- Expertip 6 Bowing Narrowing and DistortionDocument4 pagesExpertip 6 Bowing Narrowing and DistortionnotengofffNo ratings yet

- Expertip Tips For Reducing Forming Fabric Drive LoadDocument5 pagesExpertip Tips For Reducing Forming Fabric Drive LoadnotengofffNo ratings yet

- Lecture 7Document22 pagesLecture 7notengofffNo ratings yet

- Expertip Installing Seamed Press FabricDocument4 pagesExpertip Installing Seamed Press FabricnotengofffNo ratings yet

- Expertip 7 Paper Machine Water CalculationsDocument5 pagesExpertip 7 Paper Machine Water Calculationsnotengofff100% (1)

- Lecture 4 - Aalto University - HSE-2021-Tomi SarkalaDocument29 pagesLecture 4 - Aalto University - HSE-2021-Tomi SarkalanotengofffNo ratings yet

- Expertip Tension Part 2Document4 pagesExpertip Tension Part 2notengofffNo ratings yet

- Expertip 4 Tips On Forming Fabric GuidingDocument4 pagesExpertip 4 Tips On Forming Fabric GuidingnotengofffNo ratings yet

- Study of Black Liquor Evaporator Fouling at Södra Cell Värö: Emil Lagerberg NilssonDocument73 pagesStudy of Black Liquor Evaporator Fouling at Södra Cell Värö: Emil Lagerberg NilssonAmatari EbiNo ratings yet

- Lecture 4 - Aalto University Process Engineering - 07102021Document49 pagesLecture 4 - Aalto University Process Engineering - 07102021notengofffNo ratings yet

- Expertip Tension Part 1Document5 pagesExpertip Tension Part 1notengofffNo ratings yet

- Learning Assignment 8Document2 pagesLearning Assignment 8notengofffNo ratings yet

- Learning Assignment 6Document2 pagesLearning Assignment 6notengofffNo ratings yet

- Learning Assignment 3Document2 pagesLearning Assignment 3notengofffNo ratings yet

- Abb Process Hierrofundido Prestacionesestrandard3Document1 pageAbb Process Hierrofundido Prestacionesestrandard3notengofffNo ratings yet

- Learning Assignment 2Document2 pagesLearning Assignment 2notengofff0% (1)

- Learning Assignment 1Document3 pagesLearning Assignment 1notengofffNo ratings yet

- Hydrogen Regulation - Aleksandra SaarikoskiDocument20 pagesHydrogen Regulation - Aleksandra SaarikoskinotengofffNo ratings yet

- Thermal Spray Center FinlandDocument36 pagesThermal Spray Center FinlandnotengofffNo ratings yet

- Fuel Cells - Olli HimanenDocument37 pagesFuel Cells - Olli HimanennotengofffNo ratings yet

- Learning Assignment 5Document2 pagesLearning Assignment 5notengofffNo ratings yet

- Compact Press OverhaulDocument1 pageCompact Press OverhaulnotengofffNo ratings yet

- AAE-E3030 Lecture1Document60 pagesAAE-E3030 Lecture1notengofffNo ratings yet

- 21-MTT-4474 Catalog 2021 Cordless Catalog V13 WebDocument51 pages21-MTT-4474 Catalog 2021 Cordless Catalog V13 Webchris CruzNo ratings yet

- DW Uhp UsDocument9 pagesDW Uhp UsnotengofffNo ratings yet

- FLY ROLLS - Overhaul, Modernization, NewDocument5 pagesFLY ROLLS - Overhaul, Modernization, NewnotengofffNo ratings yet

- Vacuum Valve SVDocument1 pageVacuum Valve SVnotengofffNo ratings yet

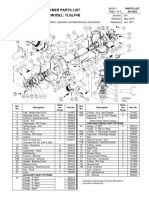

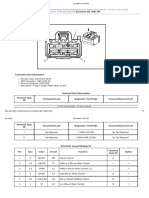

- Blackmer Parts List Pump Model: Tlglf4BDocument2 pagesBlackmer Parts List Pump Model: Tlglf4BRAUL ARMANDO PALOMO CAMPOSNo ratings yet

- 2005 c230 Factory Approved Service PamphletDocument30 pages2005 c230 Factory Approved Service Pamphletsrikarmallampati100% (2)

- Biotechnology 2018 Conference BrochureDocument6 pagesBiotechnology 2018 Conference BrochureJessica JordanNo ratings yet

- BSR330 Briefing IFP W1 - September 2019Document22 pagesBSR330 Briefing IFP W1 - September 2019Nur FatinahNo ratings yet

- SKODA ASN-ig enDocument14 pagesSKODA ASN-ig enqingpingleNo ratings yet

- 6 Shooting Tips From Bryan LitzDocument4 pages6 Shooting Tips From Bryan LitzMario Diez100% (1)

- Thawing Food Version 2.1Document3 pagesThawing Food Version 2.1Quy TranxuanNo ratings yet

- Ansys CrackingDocument1 pageAnsys CrackingPiranha TourniquetNo ratings yet

- Chapter10 Test BankDocument8 pagesChapter10 Test Bankapi-250771617No ratings yet

- Overview of IFIC Bank Limited's Products and ServicesDocument54 pagesOverview of IFIC Bank Limited's Products and ServicesTanvir Nayim0% (1)

- User 010613Document60 pagesUser 010613NurZul HealMeNo ratings yet

- Brymen BM 869s - User ManualDocument24 pagesBrymen BM 869s - User ManualSilver RoosterNo ratings yet

- Microsoft Word - FAQ-For Supervision ProjectsDocument16 pagesMicrosoft Word - FAQ-For Supervision ProjectsAman LawaniaNo ratings yet

- DUCTSD Duct Smoke Detector: Installation and Maintenance InstructionsDocument8 pagesDUCTSD Duct Smoke Detector: Installation and Maintenance InstructionsAnonymous tCin8XNo ratings yet

- Content/Development - 5 Points Organization (Neatness) - 5 Points Originality - 5 Points Total - 15 PointsDocument1 pageContent/Development - 5 Points Organization (Neatness) - 5 Points Originality - 5 Points Total - 15 PointsMJ LptNo ratings yet

- UmppDocument6 pagesUmppVIBHAVNo ratings yet

- Chap014 - JIT and Lean OperationsDocument31 pagesChap014 - JIT and Lean OperationsAgentSkySkyNo ratings yet

- Ac 1Document2 pagesAc 1Alfredo jose Medina revattaNo ratings yet

- Backdoors CT Case Negative - DDI 2015 SWSDocument304 pagesBackdoors CT Case Negative - DDI 2015 SWSseNo ratings yet

- Baker, BachourDocument178 pagesBaker, BachourHoward BrandonNo ratings yet

- Maruti Celerio ReviewDocument18 pagesMaruti Celerio ReviewKamal Yagami100% (1)

- Plant Layout and its Types in 40 CharactersDocument15 pagesPlant Layout and its Types in 40 CharactersRocks KiranNo ratings yet

- Dedan Kimathi University of Technolog: SemesterDocument17 pagesDedan Kimathi University of Technolog: SemesterGabriel KamauNo ratings yet

- WinCC V6 VBS Reference PDFDocument202 pagesWinCC V6 VBS Reference PDFVeljko MaricNo ratings yet

- Electronic Banking and Customer SatisfactionDocument55 pagesElectronic Banking and Customer SatisfactionNandini Mehrotra100% (1)

- 3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDSDocument7 pages3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDSRick OshayNo ratings yet

- RSView 32Document5 pagesRSView 32Josephus Ravanera100% (1)

- CC2640CC2650 Bluetooth Low Energy Software Developer's Guide PDFDocument249 pagesCC2640CC2650 Bluetooth Low Energy Software Developer's Guide PDFminhneoNo ratings yet

- Hitachi Inkjet Printer PB Model PDFDocument2 pagesHitachi Inkjet Printer PB Model PDFLeonard PeñaNo ratings yet

- Basundhara Wet Tisu MKT PlanDocument15 pagesBasundhara Wet Tisu MKT PlanNiaz FerdousNo ratings yet