Professional Documents

Culture Documents

Vffs Pneumatic Machine With Clutch Bracke Auger Filler

Uploaded by

Nancy Nadar0 ratings0% found this document useful (0 votes)

17 views3 pagesOriginal Title

Vffs Pneumatic Machine With Clutch Bracke Auger Filler (2)

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views3 pagesVffs Pneumatic Machine With Clutch Bracke Auger Filler

Uploaded by

Nancy NadarCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

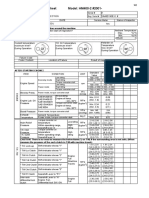

Technical Specification for VFFS Pneumatic Machine

SR. NO. DESCRIPTION

1. Machine VFFS Pneumatic Machine

2. Sealing Top Bottom Sealing Pneumatic Center Seal Sealing Pneumatic type

3. Pouch size As per your Requirement

4. Packaging material Laminated Film 2/3 ply Paper. Before order, please conform Packaging

Material

5. Electricals Heater’s cartridge type 350w x 8 noes’

6. Temperature SSR. 16 AMP 220 VOLTS.PID TEMPERATURE CONTROLLER

Controller

I-THERM MAKE DIGITAL TYPE TEMPERATURE

CONTROLLERS FOR UPPER AND LOWER JAWS WITH FEK

THERMOCOUPLE WASHER TYPE.EACH TWO.

0° c to 400°c

PID Temperature Controller

7. Machine Structure Body will be fabricated with M.S powder coting

8. Contact parts Product contact parts is Stainless Steel 304

9. Non-contact parts 1. Web roller Aluminum.

2. Chute frame MS

3. Camera unit MS

10. Speed & Accuracy (Depending upon the physical and flow characteristics of the product)

(output) ● 10 to 25 /min @ filling accuracy of +/- 3%)

The above stated speed can be met subject to: -

a) Uninterrupted product flow.

b) Uniformity of the machine to an effective air pressure system.

c) Connection of the machine to an effective air pressure system.

d) Strict Maintenance of the machine as per our Instruction Manual.

e) It’s fill weight, bulk density of the product, it’s flow properties

f) It also depends upon the kind, quality and thickness of laminate being used.

11. Filling Attachment Clutch Brake auger Filler

12. Contact parts 1. PRODUCT CONTACT PARTS SS 304

2. HOPPER S.S. 304

3. BODY MS FABRICATED WITH POWDER COTING.

13. Net wt. 300 Kg. approximately.

14. Mounting On wheels

15. NOTE: 1) COMPRESSOR IS NECESSARY FOR PNEUMATIC MACHINE

2) COMPRESSOR WILL NOT BE PROVIDED FROM OUR SIDE

16. Electricity Required 220 Volt Single Phase

Compressed Air

17. 7 Kg / sq. cm. (6 to 8 Bars) of non-condensing Air Supply (Continuous)

Required

TECHNICAL SPECIFICATION FOR CLUTCH BRAKE AUGER FILLER

SR.NO. DESCRIPTION DETAILS

1. Machine Auger filler (Screw dosing)

2. Speeds & Accuracies: (Depending upon the physical and flow characteristics of the

product) 15 to 25 /min @ filling accuracy of +/- 3%) The above

stated speed can be met subject to: -

A. Uninterrupted product flow.

B. Uniformity of the machine to an effective air pressure system.

C. Connection of the machine to an effective air pressure system.

D. Strict Maintenance of the machine as per our Instruction Manual.

E. It’s fill weight, bulk density of the product, it’s flow properties.

F. It also depends upon the kind, quality and thickness of laminate

being used.

3. Drive A/C Motor - 1HP 440 Volts / Three phase / 50 Hz.

Clutch Break unit 125 CBC, 24 DC and Maxi Torque model.

Controlled clutch break unit used Micro controller systems.

Reduction worm gear box 20:1 ratio.

4. Over all dimensions 2300 mm x 950 mm x 950 mm.

5. Machine Net wt. 200 KG APPROX

6. Micro Controller LOCAL MAKE

7. Hopper Capacity 58 Ltr. approximately.

8. Contact parts Product contact parts is stainless steel 304 and body will be covered

with M.S. Powder coated.

NOTE: -

1. Specification of Motors, Electrical Parts & Contact Part may be varied as per your

requirement and product properties.

AUGER FILLER ELECTRICAL PARTS

SR. NO. PART NAME MANUFACTURER

1 ELECTRICAL MOTOR HAVELLS/OTHER MAKE

2 GEAR BOX BEAFARED/ OTHER MAKE

3 CLUTCH BRAKE CRYOTRON MAGNADRIVES

4 U-SENSOR / PANNEL VEERAT

PNEUMATIC MACHINE ELECTRICAL PARTS

1 HMI FLEXEM OR DELTA MAKE OR SIMILER

2 TEMPERATURE CONTROLLER I-THERM

3 MCB SIEMENS

4 SMPS SHEVISON

5 SSR EMTECH

7 PLC SYSTEM SOFTWARE/OTHER MAKE

8 PROXY SENSOR OMRON OR OTHER MAKE

You might also like

- 120 BPM Bopp Labeling Machine & Shrink Wrapping MachineDocument6 pages120 BPM Bopp Labeling Machine & Shrink Wrapping MachineOMKAR JADHAVNo ratings yet

- Minerbolter Class NotesDocument10 pagesMinerbolter Class NotesSivalya SivaramanNo ratings yet

- DW115CNC Technical ParametersDocument11 pagesDW115CNC Technical ParametersProfCarlos GamaNo ratings yet

- Specifications of Vertical Milling Machine With D.R.O. PurposeDocument5 pagesSpecifications of Vertical Milling Machine With D.R.O. PurposeKhabirIslamNo ratings yet

- Techspec - PW MachineDocument5 pagesTechspec - PW MachineMariyappanNo ratings yet

- Hydraulic Press SpectsDocument11 pagesHydraulic Press SpectszNo ratings yet

- SXB-5000A Juice2 - NewDocument5 pagesSXB-5000A Juice2 - NewMahmoud EssamNo ratings yet

- Offer Specifications: BectochemDocument3 pagesOffer Specifications: Bectochemanita shindeNo ratings yet

- quotation of PVC wall panel production line 1条线 2set mouldDocument11 pagesquotation of PVC wall panel production line 1条线 2set mouldarg3112No ratings yet

- Manual 120726 Blow Moulding PDFDocument31 pagesManual 120726 Blow Moulding PDFrize1159No ratings yet

- Quatation 4Document11 pagesQuatation 4Swabir NalbandNo ratings yet

- NCC Nangsing HaisiDocument10 pagesNCC Nangsing HaisiLam NgoNo ratings yet

- JK-T5878-58B instruction book 操作手册英语Document22 pagesJK-T5878-58B instruction book 操作手册英语MG MaquinasNo ratings yet

- 4 - PPR63 Pipe Extrusion Line-160kgDocument15 pages4 - PPR63 Pipe Extrusion Line-160kgDennis machariaNo ratings yet

- MAintenance Manual Progressive Cavity Pumps 1Document24 pagesMAintenance Manual Progressive Cavity Pumps 1mtfrvtNo ratings yet

- Φ1250 Cantilever Single-twist Cabling MachineDocument3 pagesΦ1250 Cantilever Single-twist Cabling Machinetees220510No ratings yet

- Wave SolderDocument9 pagesWave SolderFredy HandokoNo ratings yet

- Specification of Vertical Milling Machine Emt-6751Document5 pagesSpecification of Vertical Milling Machine Emt-6751RAVI kayjayNo ratings yet

- ENG6445Document5 pagesENG6445Ajay TulpuleNo ratings yet

- User Requirement Specification OF 1000 L Working Capacity (WC) Liquid Manufacturing TankDocument8 pagesUser Requirement Specification OF 1000 L Working Capacity (WC) Liquid Manufacturing TankBlue VisionNo ratings yet

- Ern Halo - Electrical (26-08-2021)Document2 pagesErn Halo - Electrical (26-08-2021)santoshkumarNo ratings yet

- WC67-160 3200 Bending Machine From JIUYING LydiaDocument9 pagesWC67-160 3200 Bending Machine From JIUYING LydiaSantiago LeivaNo ratings yet

- Tube Filling and Sealing MachineDocument10 pagesTube Filling and Sealing Machinepeter mackey mamani mamanchuraNo ratings yet

- Maintenance of Stenter & Steamer 1Document27 pagesMaintenance of Stenter & Steamer 1Imtiaz Ahmed50% (8)

- Amorphous Alloy Cutting Machine 20072010Document5 pagesAmorphous Alloy Cutting Machine 20072010Electricalmechanical JagadeesanNo ratings yet

- N-Quotation of Hfqa-1800w 1 3Document13 pagesN-Quotation of Hfqa-1800w 1 3api-724687963No ratings yet

- Φ630 Cantilever frame Single-twist Cabling MachineDocument3 pagesΦ630 Cantilever frame Single-twist Cabling Machinetees220510No ratings yet

- 48 Inch Pipe Bedning (Nigeria)Document9 pages48 Inch Pipe Bedning (Nigeria)Robin SuNo ratings yet

- Tech Specification VSDDocument9 pagesTech Specification VSDDony SaputraNo ratings yet

- Intertec Maquinas para Su Empresa33Document2 pagesIntertec Maquinas para Su Empresa33Alberto VELOSA ROANo ratings yet

- 12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineDocument19 pages12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineImamul HaqueNo ratings yet

- 509ta Eng UmDocument138 pages509ta Eng UmBekzhanAliyevNo ratings yet

- Wilo-Datasheet International en 2537343 Siboost-Smart-3-Helix-Ve1003Document7 pagesWilo-Datasheet International en 2537343 Siboost-Smart-3-Helix-Ve1003sanaaNo ratings yet

- Plasma C MDocument9 pagesPlasma C Mhiren1206No ratings yet

- MX 500 User ManualDocument95 pagesMX 500 User Manualsettar06No ratings yet

- CAN TEC E01 GeneratorDocument22 pagesCAN TEC E01 GeneratorFionaNo ratings yet

- SF-2310S English Handbookv1.0Document51 pagesSF-2310S English Handbookv1.0Leo LiuNo ratings yet

- 1.0 en-US 2020-01 TS.3085Document32 pages1.0 en-US 2020-01 TS.3085FedeNo ratings yet

- Suzhou Industrial Park Mate Automation Tech. Co., LTD: Company Building & LocationDocument35 pagesSuzhou Industrial Park Mate Automation Tech. Co., LTD: Company Building & Locationgiahoang1992_4648201No ratings yet

- MR - Ranjeet Kumar Kurkure Process Line With PackingDocument12 pagesMR - Ranjeet Kumar Kurkure Process Line With PackingRanjeet BhaiNo ratings yet

- Brochure VARIPURE 20160519 EN PDFDocument8 pagesBrochure VARIPURE 20160519 EN PDFMhs EngineerNo ratings yet

- Tech Spec of Automatic Sugar Packaging MachineDocument3 pagesTech Spec of Automatic Sugar Packaging MachineLee MarcoNo ratings yet

- ICF - Control Panel - Manual (1999)Document27 pagesICF - Control Panel - Manual (1999)sangramjitNo ratings yet

- Simuwu Catalogo PDFDocument21 pagesSimuwu Catalogo PDFFBSBNo ratings yet

- Am - All.Round: ManualDocument40 pagesAm - All.Round: ManualRoberto VelascoNo ratings yet

- Specifications - Flow Meter For DP Transmitter CorrectionDocument2 pagesSpecifications - Flow Meter For DP Transmitter Correctiondon121don121No ratings yet

- Technical Specification of On Line Condition Monitoring System 1.0 SCOPEDocument15 pagesTechnical Specification of On Line Condition Monitoring System 1.0 SCOPEAnonymous KzJcjGCJbNo ratings yet

- 99002516B - Installation and Use Manual Heat Pump Mirai SMI EH0614DC-EH1014DC-EH1314DC-EH1614DC - GBDocument56 pages99002516B - Installation and Use Manual Heat Pump Mirai SMI EH0614DC-EH1014DC-EH1314DC-EH1614DC - GBSofoklis KyriazakosNo ratings yet

- Design and Manufacturing Semi-Automatic Machine For Battery Tray Riveting OperationDocument9 pagesDesign and Manufacturing Semi-Automatic Machine For Battery Tray Riveting OperationIJRASETPublicationsNo ratings yet

- 装盒机 23-0831 IntelliGent Cartoning Machine QuotationDocument5 pages装盒机 23-0831 IntelliGent Cartoning Machine QuotationDave BunquinNo ratings yet

- Part123carrierx PowerdcinverterminivrfgeneralinformationDocument100 pagesPart123carrierx PowerdcinverterminivrfgeneralinformationAdrian LopezNo ratings yet

- TPCK Series Immersible Pump: Instruction ManualDocument8 pagesTPCK Series Immersible Pump: Instruction ManualThiago Teixeira PiresNo ratings yet

- RXVRXHDCYPDocument31 pagesRXVRXHDCYPFARIDNo ratings yet

- Ahu - Wizard Mac W MFC W 201201Document10 pagesAhu - Wizard Mac W MFC W 201201Leed ENNo ratings yet

- Iris Valve Presentation - 6.12.23Document10 pagesIris Valve Presentation - 6.12.23Kamal KapaNo ratings yet

- Donper Technical SheetDocument35 pagesDonper Technical SheetDeniz Wu0% (1)

- LV Bulk Metering Sri LankaDocument15 pagesLV Bulk Metering Sri Lankaxeroix7039No ratings yet

- Maintenance of Stenter & SteamerDocument17 pagesMaintenance of Stenter & SteamerImtiaz Ahmed0% (2)

- Roll Forming Machine SpécificationDocument7 pagesRoll Forming Machine SpécificationIkram SarghiniNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Jet Propulsion QuestionsDocument1 pageJet Propulsion QuestionsanmolkaseraNo ratings yet

- Crankcase SuspensionDocument706 pagesCrankcase SuspensionSteve GaddisNo ratings yet

- Dynapac Ca250 t3 Service TrainingDocument197 pagesDynapac Ca250 t3 Service TrainingDushan Alwis100% (3)

- Alfa Laval Aalborg i-OC: Modular Composite BoilerDocument2 pagesAlfa Laval Aalborg i-OC: Modular Composite BoilerJohn Earl TejamoNo ratings yet

- Pm-Clinic Inspection Sheet Model: Hm400-2 #2001-: (Mmaq)Document2 pagesPm-Clinic Inspection Sheet Model: Hm400-2 #2001-: (Mmaq)Naughty VongNo ratings yet

- Catalogo Partes y Piezas GRAM HC 8100Document28 pagesCatalogo Partes y Piezas GRAM HC 8100yoye1968100% (3)

- Literature SurveyDocument6 pagesLiterature SurveytalhaNo ratings yet

- FZ FiDocument59 pagesFZ FiRIDERZ CHOICENo ratings yet

- Mono Ezstrip Technical ManualDocument65 pagesMono Ezstrip Technical ManualFelipe SalvatierraNo ratings yet

- TS Dryer-System Checklist 05517206Document1 pageTS Dryer-System Checklist 05517206Tanoj PatroNo ratings yet

- Service Station Manual: Typhoon 50Document160 pagesService Station Manual: Typhoon 50joseph mulenkaNo ratings yet

- Unit 2Document27 pagesUnit 2Ram SaaceNo ratings yet

- New E85 Flex Fuel Engine (Rpo) For Chevrolet HHR Panel and Passenger VanDocument3 pagesNew E85 Flex Fuel Engine (Rpo) For Chevrolet HHR Panel and Passenger VanakirafactorNo ratings yet

- Pump VLR-16Document2 pagesPump VLR-16Nguyễn Hoàng PhúcNo ratings yet

- Circuit Breaker Grade 9 PresentationDocument13 pagesCircuit Breaker Grade 9 PresentationJeffrey SawatiNo ratings yet

- SS15 CPGKDocument4 pagesSS15 CPGKDenzo RyugaNo ratings yet

- MAN Series EnginesDocument3 pagesMAN Series EnginesNico LomibaoNo ratings yet

- EEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Document5 pagesEEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Abkul KunniNo ratings yet

- Cat C 6.4 Fuel SystemDocument13 pagesCat C 6.4 Fuel Systemali83% (6)

- The Huck Bobtail System: Engineered For Ease of Installation, High Strength, and Vibration ResistanceDocument9 pagesThe Huck Bobtail System: Engineered For Ease of Installation, High Strength, and Vibration ResistanceGIRONHNo ratings yet

- Spare Parts Catalog: 4 WG 200 (555/5) (Current Date: 15.11.2012) Material Number: 4644.024.161Document92 pagesSpare Parts Catalog: 4 WG 200 (555/5) (Current Date: 15.11.2012) Material Number: 4644.024.161Mourad Chabchoub100% (1)

- CountershaftDocument1 pageCountershaftAlexandru NicolaNo ratings yet

- Thrust Bearing CatalogueDocument38 pagesThrust Bearing Cataloguemech_eng_indNo ratings yet

- Pneumatics Festo DidacticDocument218 pagesPneumatics Festo Didacticvab88100% (6)

- Volvo Penta Cylinder HeadsDocument1 pageVolvo Penta Cylinder HeadsMarine Parts ChinaNo ratings yet

- Hydraulic ExcavatorDocument22 pagesHydraulic ExcavatorUjjwal ShresthaNo ratings yet

- CHAPTER 7: Control Panels: Section I: Overview ControlsDocument19 pagesCHAPTER 7: Control Panels: Section I: Overview ControlsabilrajprNo ratings yet

- White Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Document20 pagesWhite Drive Products: Central Hydraulics, Inc. Stocking Distributor For White Hydraulic Motors 1 (800) 264-9571Central HydraulicsNo ratings yet

- Switch Guards & Shields Switch Guards MIL-G-7703 and Industrial GradeDocument5 pagesSwitch Guards & Shields Switch Guards MIL-G-7703 and Industrial Gradefayez zuwaidNo ratings yet