0% found this document useful (0 votes)

2K views10 pagesAutomotive Technology Module 1

This module contains lessons on performing shop maintenance. The first lesson instructs the reader to inspect and clean tools, equipment, and the work area. This includes removing dust, grease, and other substances and using cleaning solvents appropriately. Common cleaning solvents like water, gasoline, kerosene, thinner, and detergent soap are discussed. The reader should be able to inspect and clean the work area and tools at the end of the lesson.

Uploaded by

Jayson PalisocCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views10 pagesAutomotive Technology Module 1

This module contains lessons on performing shop maintenance. The first lesson instructs the reader to inspect and clean tools, equipment, and the work area. This includes removing dust, grease, and other substances and using cleaning solvents appropriately. Common cleaning solvents like water, gasoline, kerosene, thinner, and detergent soap are discussed. The reader should be able to inspect and clean the work area and tools at the end of the lesson.

Uploaded by

Jayson PalisocCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Automotive Servicing NC I Introduction: Introduction to Automotive Servicing NC I covering the course structure for Quarter 1, Module 1.

- Practicing Health, Safety, and Environment Procedures: Outlines health, safety, and environmental procedures essential for automotive servicing, including objectives and outcomes.

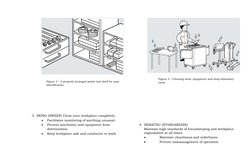

- Lesson 1: Inspect and Clean Tools, Equipment and Work Area: Focuses on the inspection and cleaning of tools and work areas in automotive servicing, providing definitions and expected outcomes.

- Organizational Principles: 5S Methodology: Describes the 5S principles for systematic organization and maintenance of workspaces in automotive servicing.