Professional Documents

Culture Documents

Att 2. Standard Risk Assessment

Uploaded by

RiskyMaulanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Att 2. Standard Risk Assessment

Uploaded by

RiskyMaulanaCopyright:

Available Formats

Standard

Risk Assessment

<Ship's Name>

[ Contents ]

1. Reviewed/Confirmed the Standard Risk Assessment by all crew onboard

2. Familiarization with Risk Assessment for new joining crew

3. Classification table of Work Process

4. Table of contents for Critical Risk Register

- 4.1 ~ 4.18 Critical Risk Register

(For reference) Items of Standard Risk Assessment

■ SHEQ-2.6 Ch.5.3 / File No. D-5

Revision Number 00

Standard Risk Assessment Revision Date 2022.06.30

1. Reviewed/Confirmed the Standard Risk Assessment by all crew onboard

▶ 본선 표준 위험성 평가 검토 및 서명

(검토 시 본선 고유 위험/고위험 식별하여 중대 위험 기록부에 반영)

▶ Review of the standard risk assessment and sign on below

(Identify the specific risks/critical risks to the ship when reviewed and

reflect to the critical risk register )

Ship's Name : Reviewed Date :

Rank / Name Signature Rank / Name Signature

C/E : / (Signature)

Master : / (Signature)

■ SHEQ-2.6 Ch.5.3 / File No. D-5

Revision Number 00

Standard Risk Assessment Revision Date 2022.06.30

2. Familiarization with Risk Assessment for new joining crew

▶ 신규 승선자는 본선 중대 위험 등록부를 숙지하고 하기에 서명해야 한다.

▶ The new joining crew shall be familiar with the Critical Risk Register and

sign the following.

Ship's Name :

Rank Name Date Signature

■ SHEQ-2.6 Ch.5.3 / File No. D-5

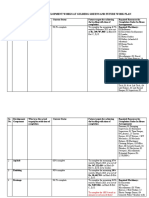

3. Classification table of Work Process (작업 공정 분류표)

Category Category Title Task Task Title No. of Step

Code Code Steps of Task

01 Air Compressor 01 Precautions

02 Ballast water exchange 01 Precautions

01 Discharging

03 Engine room bilge

02 Transporting

01 Precautions

04 Boiler 02 Blow down

03 Soot Blow

05 Bow Thruster 01 Precautions

01 Precautions

06 Bunker hose davit 02 During operation

03 After operation

07 Calorifier 01 Precautions

08 Compressed air & gas cylinder (Pressure gauge) 01 Precautions

01 Precautions

02 Deep fat frying

03 Hot plate

04 Refrigerated rooms

05 Oven & Microwave oven

09 Cooking

06 Knives, Saws, Choppers & Etc

07 Fry pan & Stew pot

08 Water purifier

09 Pressure cooker & Steamer

10 Food disposer

10 Cradles & Stages 01 Precautions

01 Precautions

11 Deck crane 02 During operation

03 After operation

01 Before deck washing

12 Deck washing 02 During deck washing

03 After deck washing

13 Disposal of Sludge 01 Precautions

01 Start & Stop

14 Economizer

02 Soot blow

15 Electronic appliances 01 Precautions

16 Exhaust Gas Cleaning System (EGCS) 01 Precautions

17 Fire detecting system 01 Precautions

18 Fresh water generator 01 Precautions

01 Precautions

02 Embarkation & Disembarkation

19 Gangway & Pilot ladder

03 Combination arrangement

04 Securing

01 Precautions

02 Start & Finish

20 Generator engine

03 Bunker change

04 Parallel operation

21 Hand tools 01 Precautions

01 Lifting & Carrying by crane

22 Heavy weight handling

02 Lifting & Carrying by manual

01 Precautions

23 Helicopter operation 02 Embarkation & disembarkation

03 After operation

01 Bilge operation

24 Hold bilge

02 Bilge sounding

A Operation 01 Precautions

25 Hydraulic equipment 02 During operation

03 After operation

01 Precautions

26 Hydraulic jacks

02 Transport & Sticking & Separation

27 Incinerator 01 Precautions

28 Inert Gas 01 Precautions

01 Precautions

29 Main engine 02 Start & Stop

03 Bunker change

30 MGPS 01 Start & Stop

01 Precautions

02 Approaching berth

03 Before line handling

31 Mooring & Unmooring

04 During line handling

05 After line handling

06 Adjusting line

32 Mooring & Unmooring by line boat 01 Precautions

01 F.O. Transferring

33 Oil transfer 02 L.O. Transferring

03 Waste oil transferring

34 Oily water seperator 01 Precautions

35 Overhead crance for engine room 01 Precautions

36 Propeller shaft & stern tube 01 Precautions

01 Precautions

37 Provision crane 02 During operation

37 Provision crane

03 After operation

01 Stanby & Finish

38 Purifler

02 During operation

39 Refrigerator & Air condition 01 Precautions

01 Precautions

40 Sand blaster 02 During operation

03 After operation

41 SBM & CBM mooring 01 Precautions

42 SCR system 01 Precautions

43 Seachest 01 Precautions

44 Sewage treatment 01 Precautions

45 Sounding of hold & tank 01 Precautions

01 Precautions

46 Suez canal light davit 02 During operation

03 After operation

01 Precautions

47 Suez canal mooring boat davit 02 During operation

03 After operation

01 Precautions

48 Treatment of harmful substance & liquid 02 Storage

03 Flammable combustible liquid

49 Verification of ship’s stability & strength 01 Verification

01 Setting & monitoring

50 Water ingress system

02 Familiarity

51 Work in Extremely Cold area 01 Precautions

01 Precautions

52 Workshop and bench machinery

02 Lathe Work

53 Rotor Sail 01 Precautions

01 ACC system 01 Precautions

01 Precautions

02 Air Compressor

02 Securing of major spare parts

03 Alarm Monitoring System (AMS) 01 Precautions

04 Auto Backwash Filter 01 Precautions

01 Precautions

02 During Inspection

05 Ballast water tank & Cargo hold/tank Inspection 03 After Inspection

04 Cargo Tank Inspection

05 Cargo Hold Inspection

01 Precautions

06 Bilge holding tank & well cleaning

02 Cleaning of bilge holding tank

01 Precautions

02 Boiler/Economizer Cleaning

07 Boiler 03 Boiler Safety Valve Popping Test

04 Burner system

05 Exhaust Gas Boiler

08 Bunker hose Davit 01 Precautions

09 Bunker tank cleaning 01 Precautions

01 Precautions

02 During working

10 Cargo hold/tank cleaning

03 After working

04 Cargo Tank Mopping

01 Precautions

02 Chipping

11 Chipping & Painting & Greasing

03 Painting

04 Greasing

12 Cleaning of Fresh water tank, Seawater tank & other tank 01 Precautions

01 Precautions

13 Communication Equipment

02 Antenna

14 Compressed air & gas cylinder (Pressure Gauge) 01 Precautions

15 Cooler (All kinds) 01 Precautions

01 Precautions

02 Wire Replacement

16 Deck crane 03 Sheave, Block repair and/or Replacement

04 Hyd. Motor Room Work

05 Oil Changing

17 Drilling & Cutter & Grinding 01 Precautions

01 Before dry dock

18 Dry docking

02 During dry dock

19 Duct keel inspection & maintenance 01 Precautions

20 Economizer 01 Precautions

21 Emergency battery 01 Precautions

22 Emergency fire pump 01 Running test of emergency fire pump

23 Emergency generator 01 Running test of emergency generator

24 Engine room Overhead crane 01 Precautions

25 Exhaust Gas Cleaning System (EGCS) 01 Precautions

26 Fan (All kinds) 01 Precautions

01 Precautions

27 Filter & Strainer (All kinds) 02 Auto Backwash Filter Maintenance

03 Centrifugal L.O Filter

01 Precautions

02 Fire detecting system

28 Fire fighting appliances inspection 03 Fixed CO2 extinguisher

04 Recharging BA air cylinder

05 Recharging potable extinguisher

29 Fresh water generator 01 Precautions

30 Fresh water tank cleaning 01 Precautions

31 Gangway & Pilot ladder 01 Precautions

32 General Maintenance 01 Narrow Space Work

01 Precautions

02 Bearing overhaul

03 Cyl. Head, Piston, Liner, T/C OVHL

04 Exchange & Maintenance cylinder head

05 Renew & Maintenance of exhaust valve

06 Exchange of F.O valve

07 Exchange of high pressure pipe for F.O & Exh.V/V

08 F.O Injecion Valve Maintenance

09 F.O pump overhaul

33 Generator engine

10 L.O Filter Cleaning

11 Overspeed Trip Test

12 Sump Tank Cleaning/Inspection

13 Tappet clearance

B Maintenance 14 Centrifugal L.O Filter

15 Turbo charger overhaul

16 Turning

17 Accessory Overhaul/Fit

18 Chamber inspection

01 Precautions

34 Hatch Cover

02 Watertightening Check

35 Heater (All kinds) 01 Precautions

36 Hull maintenance (other) 01 Steel, pipe work

37 Hydraulic equipment 01 Precautions

38 Inert Gas System 01 Inert Gas System maintenance

39 Installation of new equipment 01 Installation

01 Running test of Lifeboat engine

40 Life Boat Engine Test

02 Life Boat Check

41 Lighting fixtures 01 Precautions

01 Precautions

02 Bearing overhaul

03 Chamber & Chain case inspection

04 Cyl. Head & Piston & Liner & T/C overhaul

05 Renew & Maintenance of exhaust valve

06 Exchange & Maintenance cylinder head

07 Exchange of F.O valve

08 Exchange of high pressure pipe for F.O & Exh.V/V

42 Main engine

09 Exchange starting air valve

10 Scav. Air Drain Cleaning

11 Stuffing Box Maintenance

12 Turbo charger overhaul

13 Piston/Cyl. Liner Withdrawal/Carrying

14 Lifting Tool Carrying/Installation

15 Lubricating Oil Control

16 F.O pump overhaul

43 MGPS 01 Precautions

44 Motor (All kinds) 01 Precautions

01 Precautions

02 Antenna

03 GPS

04 Gyro & Auto Pilot

05 Magnetic Compass

45 Navigation equipment

06 Navigation Light Check & Renewal

07 RADAR

08 RADAR (Renewal)

09 ECHO Sounder

10 ECDIS

46 Oily water seperator 01 Precautions

47 Provision crane 01 Precautions

01 Precautions

02 Cargo Pump Maintenance

48 Pump (All kinds)

03 Cargo Pump Overhaul

04 Circulation Water Pump Maintenance

01 Precautions

49 Purifler

02 Vertical & Horizontal shaft overhaul

01 Precautions

50 Refrigerator & Air condition 02 Replenish refrigerants maintenance

03 Defrosting

51 Rope management 01 Precautions

52 Safety device test & alarm test 01 Precautions

01 Precautions

02 Lifa boat davit

03 Safety signs

04 Recharging BA Air Cylinder

53 Safety equipment inspection

05 Inspection of Fixed CO2 System in CO2 Room

06 Maintenance of Fixed CO2 System in CO2 Room

07 Inspection of Fire-Fighting Appliance

08 Chemical Fire Extinguisher Check

54 SCR system 01 Precautions

55 Seachest 01 Precautions

56 Steering gear 01 Precautions

57 Suez canal mooring boat davit 01 Precautions

58 Water ingress system 01 Precautions

59 Winch 01 Precautions

60 Windlass & Anchor & Anchor chain 01 Precautions

61 Wire renewal 01 Precautions

62 Rotor Sail 01 Precautions

63 BWMS 01 Precautions

01 Aloft work 01 Recognize & explain critical precautions

02 Electrical work 01 Recognize & explain critical precautions

03 Hot work 01 Recognize & explain critical precautions

04 Pipeline and pressure vessel work 01 Recognize & explain critical precautions

C Critical danger maintenance

05 Overboard work 01 Recognize & explain critical precautions

01 Recognize & explain critical precautions

06 Subcontractor control

02 Engine room working

07 Enclosed spaces work 01 Recognize & explain critical precautions

01 Precautions

02 Anchor Watch

03 Proceeding to anchorage

04 Heaving

01 Anchoring

05 After anchoring

06 Deep Water Anchoring

07 Emergency Anchoring

08 Large Vessel Anchoring

01 Preparation for arrival

02 Arrival

02 Arrival

03 Chart & Publication correction 01 Correction

04 Coastal navigation 01 Precautions

01 Onboard communication equipment

02 EPIRB & Two-way VHF & SART

05 Communication equipment

03 INMARSAT

04 MF/HF & VHF & NAVTEX

01 Preparation for departure

06 Departure

02 Departure

01 Precautions

02 Drifting

03 Shifting

07 Maneuvering in Harbor

04 Passing under Bridge

05 Take on/off Tug Line

06 STS Operation

01 AIS

02 Course recorder

03 ECDIS

04 GYRO & Auto pilot

05 Magnetic compass

D Navigation 06 Navigation light

08 Navigation equipment 07 RADAR

08 VDR

09 Weather fax

10 Whistle

11 ECHO Sounder

12 GPS

13 EM, Doppler Log

09 Navigation in cold area 01 Precautions

01 Sailing in Rough Sea

10 Navigation in heavy weather

02 Tropical depression response

01 Precautions

11 Navigation in narrow channel

02 Restricted water

12 Navigation in Piracy Area 01 Precautions

13 Navigation in restricted visibility 01 Precautions

14 Ocean navigation 01 Precautions

01 Appraisal & Planning & Execution & Monitoring

15 Passage planning

02 Other safety factors for deviation of voyage

01 Precautions

16 Pilot on board 02 Embarkation & disembarkation by boat

03 Embarkation & disembarkation by helicopter

01 Before shifting

17 Shifting by mooring rope 02 During shifting

03 After shifting

01 Precautions

02 Gangway watch

18 Watchkeeping during alongside berth

03 Cargo watch

04 Mooring line watch

01 Precautions

19 Watchkeeping during sailing

02 Changing over the watch

01 Precautions

02 Mooring & Unmooring of bunker barge

01 Bunkering 03 Bunker hose davit

04 Connection and Detaching of fuel hose

05 Duty on manifold

E Supply

01 Before taking

02 Fresh Water Supply 02 During taking

03 After taking

03 Provisions 01 Precautions

04 Ship's Store Supply 01 Precautions

01 Precautions

02 Drill

01 Boat launching & lowering 03 Davit operation

04 Davit preparation

05 Embarkation ladder

02 Drill of abandon Ship 01 Precautions

03 Drill of emergency steering 01 Precautions

01 Precautions

02 Fire fighting team

F Emergency Response 04 Drill of fire fighting

03 Commander team & duty team

04 Assist team

05 Drill of helicopter operation 01 Precautions

06 Drill of man overboard 01 Precautions

07 Drill of oil spill response 01 Precautions

08 Drill of rescue in enclosed space 01 Precautions

09 Drill of response for other emergency situations 01 Precautions

01 Discharging

10 Operation of fixed CO2 extinguisher

02 After discharging

01 Asbestos 01 Management

01 Management

02 Food Quality

02 Health & Hygiene

03 Hazardous Materials(Paint/Thinner)

04 Water Quality

01 Control of medicines

03 Medical treatment

02 Patients onboard

01 Indoor air and odor

02 Lightning

03 Noise

04 Vibration

05 Air Quality

06 Dust

04 Onboard environmental assessment

07 Food Waste

08 Garbage Management

09 Housekeeping

G Health & Sanitary

10 Humidity

11 Hygiene - Rat (or other animals which could harm crew)

12 Temperature

01 Drinking alcohol

02 Exercise

03 Health condition

05 Personal health & hygiene 04 Smoking

05 Fatigue, Stress

06 Personal hygiene

07 Venereal disease

06 Poisons 01 Management

01 At shore

02 Onboard

07 Prevention of infectious disease Communicable Diseases (Contamination of water/transmission by air/transmission

03 by mosquitoes/transmission by sexual contact)

04 Prevention of COVID-19

01 Before operation

01 Ballasting & De-ballasting 02 During operation

03 After operation

01 Cement clinker

02 Coal

03 Fertilizer

04 Hot Coil

02 Cargo (Bulk)

05 Iron Ore

06 Limestone

07 Sugar

08 Hazardous/Dangerous Cargo

01 Precautions

03 Cargo handling gear 02 During working

03 After working

01 Precautions

02 Cargo Loading/Discharging

03 Cargo Loading/Discharging (Tanker)

04 Cargo Management 04 Cargo Lashing/Unlashing

05 Manifold connection/Disconnection

06 Cargo Watch

07 Treatment of Cargo Residue

01 RF Container control

05 Container

H Cargo 02 DG Container control

01 Draft reading

06 Draft check

02 Draft survey

01 Precautions

07 Hatch cover 02 During operation

03 After operation

01 Heavy Cargo Care

08 Heavy Cargo 02 Load In

03 Load Out

09 Loading & Discharging plan 01 Precautions

10 Prevention of cargo heat damage by bunker heating 01 Precautions

11 Sinking 01 Precautions

01 Air Blow

02 Cargo Valve Operation

03 Dangerous Cargo Control(Incl. TDI/MDI)

04 Gas Free Inerting

05 N2 Purge / Tank Overpressure Prevention

12 Tanker

06 ODME

07 Phosphoric acid handling

08 Pigging after Veg. Oil Loaded

09 Squeezing Work

10 Toxic cargo handling

13 Woodship 01 Precautions

01 GDPR issues

02 Receiving e-Mail

03 Updating ECDIS

01 Cyber Security 04 Using critical equipment

05 Using IT system

I Security 06 Using mobile storage media

07 Using ship’s system by unauthorized person

01 Control in port

02 Drug

02 Control ship’s crew

03 Stowaway 01 Precautions

04 Visitor boarding 01 Management of visitor

01 Liability issues

02 Embarkation/Disembarkation of the PCASP

01 Deployment of Privately Contracted Armed Security Personnel 03 Compliance with international and national law

04 Ship and crew security, safety and protection

J Piracy

05 The potential for escalation of the situation at hand

01 Risk assessment

02 Piracy & armed thief & terrorism & striker & metal patient 02 Establishment of countermeasures

03 Implementation of countermeasures

4. Table of contents for Critical Risk Register

▶ 중대 위험 등록부를 검토하고 추가 또는 삭제 항목을 식별/반영한다.

▶ Review the Critical Risk Register and identify/reflect items to be added or deleted.

No. Doc No. Category Task Revision No. / Date Remark

1 RA-CRR-2022-001 A. Operation 19. Gangway & Pilot ladder 00 / 2022.06.30

2 RA-CRR-2022-002 B. Maintenance 05. Ballast water tank & Cargo hold/tank Inspection 00 / 2022.06.30

3 RA-CRR-2022-003 B. Maintenance 06. Bilge holding tank & well cleaning 00 / 2022.06.30

4 RA-CRR-2022-004 B. Maintenance 09. Bunker tank cleaning 00 / 2022.06.30

5 RA-CRR-2022-005 B. Maintenance 10. Cargo hold/tank cleaning 00 / 2022.06.30

6 RA-CRR-2022-006 B. Maintenance 12. Cleaning of Fresh water tank, Seawater tank & other tank 00 / 2022.06.30

7 RA-CRR-2022-007 B. Maintenance 16. Deck crane 00 / 2022.06.30

8 RA-CRR-2022-008 B. Maintenance 19. Duct keel inspection & maintenance 00 / 2022.06.30

9 RA-CRR-2022-009 B. Maintenance 30. Fresh water tank cleaning 00 / 2022.06.30

10 RA-CRR-2022-010 B. Maintenance 45. Navigation equipment 00 / 2022.06.30

11 RA-CRR-2022-011 B. Maintenance 47. Provision crane 00 / 2022.06.30

12 RA-CRR-2022-012 C. Critical danger maintenance 01. Aloft work 00 / 2022.06.30

13 RA-CRR-2022-013 C. Critical danger maintenance 02. Electrical work 00 / 2022.06.30

14 RA-CRR-2022-014 C. Critical danger maintenance 03. Hot work 00 / 2022.06.30

15 RA-CRR-2022-015 C. Critical danger maintenance 04. Pipeline and pressure vessel work 00 / 2022.06.30

16 RA-CRR-2022-016 C. Critical danger maintenance 05. Overboard work 00 / 2022.06.30

17 RA-CRR-2022-017 C. Critical danger maintenance 06. Subcontractor control 00 / 2022.06.30

18 RA-CRR-2022-018 C. Critical danger maintenance 07. Enclosed spaces work 00 / 2022.06.30

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-1. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-001 Revision No. / Date 00 / 2022.06.30

Category A. Operation Task 19. Gangway & Pilot ladder

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Fall overboard to death by

1 Precautions Early installation of ship's movement while Conduct a risk assessment for overboard work 2 5 3 Follow the work permit procedures 1 5 2

gangway before berthing attempting to install in 'Category C'

earlier before berthing

2 Precautions Failure to wear PPE (Life Injury Conduct a risk assessment for overboard work 2 5 3 Follow the work permit procedures 1 5 2

jacket, Safety belt, etc.) in 'Category C'

Failure to identify the risk Conduct a risk assessment for overboard work

3 Precautions of the overboard work Injury in 'Category C' 2 5 3 Follow the work permit procedures 1 5 2

Fall overboard to sea by

ship's movement while

performing removal of Conduct a risk assessment for overboard work

4 Securing Early Removal of Gangway gangway in early stage in 'Category C' 2 5 3 Follow the work permit procedures 1 5 2

during unberthing

operation

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-2. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-002 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 05. Ballast water tank & Cargo hold/tank Inspection

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Checked O2 & toxix gas contents, before

entering. Prepare breathing apparatus.

1 Precautions Insufficient ventilation Suffocation Reorting to watch man & bridge officer, 2 5 3 Follow the work permit procedures 1 5 2

durning inspection. Check Operational

condition of gas detector, before entry

Ventilate sufficiently before starting work and

Lack of Oxygen/Residual Injury by residual gas and enter after performing gas measurement.

2 Precautions lack of oxygen inside the The one entering must carry Gas Meter. When 2 5 3 Follow the work permit procedures 1 5 2

Gas tank gas alarm is actuated, stop work no matter

what the situation

Failure to identify the risk

3 Precautions of the enclosed space Injury Conduct a risk assessment for enclosed space 2 5 3 Follow the work permit procedures 1 5 2

work in 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-3. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-003 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 06. Bilge holding tank & well cleaning

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

1 Precautions Closed manhole although Injury Conduct a risk assessment for enclosed space 2 5 3 Follow the work permit procedures 1 5 2

crew remain in tank in 'Category C'

2 Precautions Improper ventilation Injury Conduct a risk assessment for enclosed space 2 5 3 Follow the work permit procedures 1 5 2

before entering of tank in 'Category C'

Failure to identify the risk Conduct a risk assessment for enclosed space

3 Precautions of the enclosed space Injury in 'Category C' 2 5 3 Follow the work permit procedures 1 5 2

work

Cleaning of bilge Low O2 rate or remained Check O2 regulary and before going into the

4 holding tank toxic gas in the tank Suffocation tank 2 5 3 Follow the work permit procedures 1 5 2

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-4. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-004 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 09. Bunker tank cleaning

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

1 Precautions No have enough time to Injury Make a gas free with enough time 2 5 3 Follow the work permit procedures 1 5 2

gas free

Failure to identify the risk Conduct a risk assessment for enclosed space

2 Precautions of the enclosed space Injury 2 5 3 Follow the work permit procedures 1 5 2

work in 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-5. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-005 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 10. Cargo hold/tank cleaning

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Atmosphere in cargo tank

1 Precautions are reach low explosive Exposion Conduct enough ventilation before work 2 5 3 Follow the work permit procedures 1 5 2

level

2 Precautions No have enough time to Exposion Make a gas free with enough time 2 5 3 Follow the work permit procedures 1 5 2

gas free

Failure to identify the risk Conduct a risk assessment for enclosed space

3 Precautions of the enclosed space Injury in 'Category C' 2 5 3 Follow the work permit procedures 1 5 2

work

Checked O2 & toxix gas contents, before

entering. Prepare breathing apparatus.

4 During working Insufficient ventilation Suffocation Reorting to watch man & bridge officer, 2 5 3 Follow the work permit procedures 1 5 2

durning inspection. Check Operational

condition of gas detector, before entry

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-6. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-006 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 12. Cleaning of Fresh water tank, Seawater tank & other tank

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Insufficient oxygen Ventilation before entrance

1 Precautions Suffocation Toxic gas concentration measuring 2 5 3 Follow the work permit procedures 1 5 2

consistence Forced ventilation while working

Failure to identify the risk Conduct a risk assessment for enclosed space

2 Precautions of the enclosed space Injury 2 5 3 Follow the work permit procedures 1 5 2

work in 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-7. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-007 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 16. Deck crane

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Injury and injury by fall Work Permit must be approved before starting

1 Precautions Works in High Position from work in high place Wear safety outfit. Work by a team of two. 2 5 3 work 1 5 2

2 Precautions Falling of heavy weight Injury When entering deck, wear safety helmet at all 2 5 3 Do not go near a place where heavy item may 1 5 2

times. be dropped

3 Precautions Failure to identify the risk Injury Conduct a risk assessment for aloft work in 2 5 3 Follow the work permit procedures 1 5 2

of the aloft work 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-8. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-008 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 19. Duct keel inspection & maintenance

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Ventilate sufficiently before starting work and

Lack of Oxygen/Residual Injury by residual gas and enter after performing gas measurement. The

1 Precautions Gas lack of oxygen inside the one entering must carry Gas Meter. When gas 2 5 3 Follow the work permit procedures 1 5 2

tank alarm is actuated, stop work no matter what

the situation

Failure to identify the risk Conduct a risk assessment for enclosed space

2 Precautions of the enclosed space Injury 2 5 3 Follow the work permit procedures 1 5 2

work in 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-9. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-009 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 30. Fresh water tank cleaning

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Ventilate sufficiently before starting work and

Lack of Oxygen/Residual Injury by residual gas and enter after performing gas measurement. The

1 Precautions Gas lack of oxygen inside the one entering must carry Gas Meter. When gas 2 5 3 Follow the work permit procedures 1 5 2

tank alarm is actuated, stop work no matter what

the situation

Failure to identify the risk Conduct a risk assessment for enclosed space

2 Precautions of the enclosed space Injury 2 5 3 Follow the work permit procedures 1 5 2

work in 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-10. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-010 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 45. Navigation equipment

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

1 Precautions Works in High Position Injury by fall from high Conduct a risk assessment for aloft work in 2 5 3 Follow the work permit procedures 1 5 2

place 'Category C'

2 Precautions Failure to identify the risk Injury Conduct a risk assessment for electrical work 2 5 3 Follow the work permit procedures 1 5 2

of the electrical work in 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-11. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-011 Revision No. / Date 00 / 2022.06.30

Category B. Maintenance Task 47. Provision crane

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

1 Precautions Failure to identify the risk Injury Conduct a risk assessment for aloft work in 2 5 3 Follow the work permit procedures 1 5 2

of the aloft work 'Category C'

2 Precautions Failure to identify the risk Injury Conduct a risk assessment for electrical work 2 5 3 Follow the work permit procedures 1 5 2

of the electrical work in 'Category C'

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-12. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-012 Revision No. / Date 00 / 2022.06.30

Category C. Critical danger maintenance Task 01. Aloft work

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Recognize & Failure to carry out permit Conduct safety measures the working &

1 explain critical Injury Conduct TBM before work & check risk factors 2 5 3 1 5 2

precautions to work system confirm the completion

Recognize & Failure to check

2 explain critical equipment & rope Injury Check equipment & rope condition before use 2 5 3 Follow the work permit procedures 1 5 2

precautions condition before use

Recognize & Failure to connect safety

3 explain critical Injury Check the connect condition before work 2 5 3 Check the condition always during work 1 5 2

precautions line to safety harness

Recognize &

4 explain critical Failure to wear PPE Injury Check the PPE when conduct the TBM before 2 5 3 Follow the work permit procedures 1 5 2

work

precautions

Recognize & Inadequate use of ladder Injury

5 explain critical Conduct TBM before work & check risk factors 2 5 3 Follow the work permit procedures 1 5 2

precautions & stage

Recognize &

6 explain critical Broken of using rope Crew injury by falling Carry out weight test before work 2 5 3 Follow the work permit procedures 1 5 2

precautions

Recognize & Solo work by unskilled Conduct the work in groups of at least two

7 explain critical crew Injury crews 2 5 3 Involve skilled crew to work 1 5 2

precautions

Recognize & Failure to identify the

Conduct safety measures the working &

8 explain critical specific risk of the Injury Conduct a risk assessment for the relevant task 2 5 3 confirm the completion 1 5 2

precautions relevant task

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-13. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-013 Revision No. / Date 00 / 2022.06.30

Category C. Critical danger maintenance Task 02. Electrical work

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Recognize & Failure to carry out permit Injury Conduct safety measures the working &

1 explain critical Follow the work permit procedures 2 5 3 1 5 2

precautions to work system confirm the completion

Recognize &

2 explain critical Failure to check voltage Injury Check voltage by using of tester before put in 2 5 3 Follow the work permit procedures 1 5 2

when put in plug plug

precautions

Recognize & Failure to confirm power

3 explain critical Injury Check to confirm power off before work 2 5 3 Follow the work permit procedures 1 5 2

precautions off

Recognize &

4 explain critical Failure to wear PPE Injury Check the PPE when conduct the TBM before 2 5 3 Follow the work permit procedures 1 5 2

work

precautions

Recognize & Wet working clothes & Electric shock by exposure Conduct safety measures the working &

5 explain critical Conduct TBM before work & check risk factors 2 5 3 1 5 2

precautions work place to high voltage confirm the completion

Recognize & Conduct safety measures the working &

6 explain critical Ungrounded Electric shock Conduct TBM before work & check risk factors 2 5 3 1 5 2

precautions confirm the completion

Recognize & Observe Permit to work. Carry out disconnect Post up a notice placard after intercept of elec.

7 explain critical Remaining voltage Electric shock of elec. Power. 2 5 3 Power. Keep on protection equipment 1 5 2

precautions

■ SHEQ-2.6 Ch.5.3 / File No. D-5

Recognize &

8 explain critical Inadequate use of electric Crew injury, Equipment Use proper electric equipment 2 5 3 Conduct safety measures the working & 1 5 2

equipment damage confirm the completion

precautions

Recognize &

9 explain critical Touch on body of elec. Electric shock Conduct TBM before work & check risk factors 2 5 3 Conduct safety measures the working & 1 5 2

precautions Power parts confirm the completion

Recognize & Working by unskilled Electric work shall be permitted to well-trained Conduct safety measures the working &

10 explain critical Crew Injury 2 5 3 1 5 2

precautions person crew only. confirm the completion

Recognize & Failure to identify the Conduct safety measures the working &

11 explain critical specific risk of the Injury Conduct a risk assessment for the relevant task 2 5 3 confirm the completion 1 5 2

precautions relevant task

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-14. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-014 Revision No. / Date 00 / 2022.06.30

Category C. Critical danger maintenance Task 03. Hot work

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Recognize & Damaged Hose for Crew injury and fire flame Check the condition of the hoes before work

1 explain critical 2 5 3 Follow the work permit procedures 1 5 2

precautions Acetylene damage

Recognize &

2 explain critical Failure to carry out permit Injury Follow the work permit procedures 2 5 3 Conduct safety measures the working & 1 5 2

to work system confirm the completion

precautions

Failure to certify as being

free of flammable gases

before any repair work is

Recognize & commenced at cargo Remove flammable material when before hot

3 explain critical tanks, fuel tanks, cargo Fire, Explosion wotk. Check risk factors & conduct safety 2 5 3 Follow the work permit procedures 1 5 2

precautions holds or other tank or measures the working of the day

spaces that have

contained flammable

substances

Failure to confirm

Recognize & dangerous goods

4 explain critical (Dangerous cargo, Fuel oil, Fire, Explosion Remove flammable material before hot work. 2 5 3 Conduct safety measures the working & 1 5 2

etc) at below or adjacent Conduct TBM before work & check risk factors. confirm the completion

precautions to the area of the work

before hot work

■ SHEQ-2.6 Ch.5.3 / File No. D-5

Recognize & Failure to observe the Familiar with the term of validity for work to

5 explain critical term of validity for work injury permit before work through TBM 2 5 3 Follow the work permit procedures 1 5 2

precautions to permit

Recognize & Check the PPE when conduct the TBM before

6 explain critical Failure to wear PPE Injury 2 5 3 Follow the work permit procedures 1 5 2

precautions work

Recognize & Flame back when using Install flameback arrestor to Oxygen/Acetylene

7 explain critical Gas welder/cutter Explosion supply system 2 5 3 Follow the work permit procedures 1 5 2

precautions

Recognize & Failure to identify the

8 explain critical specific risk of the Injury Conduct a risk assessment for the relevant task 2 5 3 Conduct safety measures the working & 1 5 2

confirm the completion

precautions relevant task

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-15. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-015 Revision No. / Date 00 / 2022.06.30

Category C. Critical danger maintenance Task 04. Pipeline and pressure vessel work

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Recognize & Failure to carry out permit Injury

1 explain critical Conduct TBM before work & check risk factors 2 5 3 Follow the work permit procedures 1 5 2

precautions to work system

Recognize &

2 explain critical Failure to wear PPE Injury Check the PPE when conduct the TBM before 2 5 3 Follow the work permit procedures 1 5 2

work

precautions

Recognize & Inadequate isolation of

3 explain critical pipelines & pressure (Line Injury, Pollution Conduct TBM before work & check risk factors 2 5 3 Follow the work permit procedures 1 5 2

blank, line disconnection,

precautions V/V close)

Recognize & Leave gas inside pipe

4 explain critical during open the high Injury Conduct TBM before work & check risk factors 2 5 3 Follow the work permit procedures 1 5 2

precautions pipe , valve

Recognize & Leave steam inside pipe

5 explain critical during open the steam Injury Conduct TBM before work & check risk factors 2 5 3 Follow the work permit procedures 1 5 2

precautions pipe, valve

Recognize & Failure to identify the

6 explain critical specific risk of the Injury Conduct a risk assessment for the relevant task 2 5 3 Conduct safety measures the working & 1 5 2

confirm the completion

precautions relevant task

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-16. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-016 Revision No. / Date 00 / 2022.06.30

Category C. Critical danger maintenance Task 05. Overboard work

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Recognize & Failure to carry out permit Injury Conduct safety measures the working &

1 explain critical Follow the work permit procedures 2 5 3 1 5 2

precautions to work system confirm the completion

Recognize & When working aloft or outboard, all

2 explain critical Failure to check Injury equipments must be checked by responsible 2 5 3 Conduct safety measures the working & 1 5 2

equipment to be use officer for the work himself before starting the confirm the completion

precautions work

Recognize & Failure to secure a safety The hook of Safety harness and safety belt

3 explain critical belt/harness at hull fixing Falling down should be secured proper location like a pad 2 5 3 Follow the work permit procedures 1 5 2

precautions part eye

Recognize & Failure to wear PPE (Life Check the PPE when conduct the TBM before

4 explain critical jacket, Safety harness, Injury work 2 5 3 Follow the work permit procedures 1 5 2

precautions etc.)

Recognize &

5 explain critical Sole work by unskilled Injury No allowed solely work, Following company 2 5 3 Follow the work permit procedures, Conduct 1 5 2

precautions crew procedure the work in groups of at least two crews

Recognize & Failure to identify the Conduct safety measures the working &

6 explain critical specific risk of the Injury Conduct a risk assessment for the relevant task 2 5 3 confirm the completion 1 5 2

precautions relevant task

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-17. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-017 Revision No. / Date 00 / 2022.06.30

Category C. Critical danger maintenance Task 06. Subcontractor control

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Recognize & Failure to check density of

1 explain critical flammable, explosive gas Fire, Explosion, Injury Conduct TBM before work & check risk factors 2 5 3 Conduct safety measures the working & 1 5 2

where is doubtful before confirm the completion

precautions working

Recognize &

2 explain critical Failure to discuss working Injury Conduct TBM before work & check risk factors 2 5 3 Conduct safety measures the working & 1 5 2

precautions time & contents confirm the completion

Recognize & Non-compliance with

3 explain critical working procedure or Injury Conduct TBM before work & check risk factors 2 5 3 Conduct safety measures the working & 1 5 2

confirm the completion

precautions safety regulations

Recognize & Failure to identify the

4 explain critical specific risk of the Injury Conduct a risk assessment for the relevant task 2 5 3 Conduct safety measures the working & 1 5 2

confirm the completion

precautions relevant task

Failure to power off

starting system or close

Engine room v/v while working on Conduct safety measures the working &

5 working overhaul, check, repair for Injury, Equipment damage Conduct TBM before work & check risk factors 2 5 3 confirm the completion 1 5 2

machines, v/v, pipes &

failure to post warning

notice

■ SHEQ-2.6 Ch.5.3 / File No. D-5

4-18. Critical Risk Register (중대 위험 등록부)

1. General

Doc No. RA-CRR-2022-018 Revision No. / Date 00 / 2022.06.30

Category C. Critical danger maintenance Task 07. Enclosed spaces work

2. Risk Assessment

No Steps of Task Hazard Probable Risk Existing Control Measures F C R Additional Control Measures F C R

Recognize & Defect of ventilating Check oxygen concentration and stop work if

1 explain critical Suffocation oxygen is found deficient. Worker shall carry 2 5 3 Follow the work permit procedures 1 5 2

precautions system Gas Detector

Recognize &

2 explain critical Failure to carry out permit Injury Follow the work permit procedures 2 5 3 Conduct safety measures the working & 1 5 2

to work system confirm the completion

precautions

Recognize & Failure to check gas Check the gas to bottom thoroughly enclosed

3 explain critical density (O₂,H₂S, Injury spaces. Check risk factors & conduct safety 2 5 3 Follow the work permit procedures 1 5 2

precautions combustible gas, CO) measures the working of the day

Recognize & Conduct safety measures the working &

4 explain critical Failure to wear PPE Injury Follow the work permit procedures 2 5 3 confirm the completion 1 5 2

precautions

Gas free during permit valid

Recognize &

5 explain critical Flammable gas presence Fire & Explosion - Forced Ventilation, Gas check, less than 1% 2 5 3 Follow the work permit procedures 1 5 2

precautions LEL(LFL), Personal gas meter provide to entry

personnel

Recognize & Suffocation by lack of Provide sufficient ventilation before working Follow the work permit procedures, Conduct

6 explain critical Insufficient ventilation oxygen during work and check oxygen concentration before 2 5 3 safety measures the working & confirm the 1 5 2

precautions entering completion

Recognize & Follow the work permit procedures, Conduct

7 explain critical One man Entry Risk of suffocation due to Work by more than two. Ensure of 2 5 3 safety measures the working & confirm the 1 5 2

precautions delayed rescue communication means completion

■ SHEQ-2.6 Ch.5.3 / File No. D-5

Gas free during permit valid

Recognize & - Forced Ventilation, Gas check, less than 50% Follow the work permit procedures, Conduct

8 explain critical Toxic gas presence Poisoning 2 5 3 safety measures the working & confirm the 1 5 2

precautions TLV, Personal gas meter provide to entry completion

personnel

Recognize & Failure to identify the

9 explain critical specific risk of the Injury Conduct a risk assessment for the relevant task 2 5 3 Conduct safety measures the working & 1 5 2

confirm the completion

precautions relevant task

■ SHEQ-2.6 Ch.5.3 / File No. D-5

You might also like

- WBS Maximo Folder StructureDocument1 pageWBS Maximo Folder StructureAashish Murali100% (1)

- Current Status of Development GreensDocument6 pagesCurrent Status of Development Greensshehzad Ul HassanNo ratings yet

- Mandatory Requirement For ISO 9001 & 14001 Certification: ServicesDocument5 pagesMandatory Requirement For ISO 9001 & 14001 Certification: Servicesmuhamadrafie1975No ratings yet

- SFO SyllabusDocument5 pagesSFO SyllabusAshok ChelikaNo ratings yet

- 03 Training PlanDocument1 page03 Training PlanHezaber ElaminNo ratings yet

- User Guide: Please Read This Handbook Carefully Before UseDocument12 pagesUser Guide: Please Read This Handbook Carefully Before UseravellNo ratings yet

- How Will The 5900 Meet My Needs?: Application-Based Testing SolutionsDocument1 pageHow Will The 5900 Meet My Needs?: Application-Based Testing SolutionsAnkit ChaurasiaNo ratings yet

- Steam Drum CalulationDocument85 pagesSteam Drum Calulationsibi_s_rajNo ratings yet

- Apco Infratech Pvt. LTD: Request For New Item-Code GenerationDocument13 pagesApco Infratech Pvt. LTD: Request For New Item-Code GenerationVenkat Raghav VasireddyNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument3 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Service InformationDocument6 pagesService InformationMarcelo GiussaniNo ratings yet

- D20x22II Vermeer Parts BookDocument410 pagesD20x22II Vermeer Parts BookJavierNo ratings yet

- Inspection Report: Sub-Station Details SR - No. Details Observations REM A 01Document6 pagesInspection Report: Sub-Station Details SR - No. Details Observations REM A 01p m yadavNo ratings yet

- Daily Reports: DC QC Form No. QI-04 (Version-2, 20/10/10)Document1 pageDaily Reports: DC QC Form No. QI-04 (Version-2, 20/10/10)burereyNo ratings yet

- Kater Turbo Povyshennay Moshnost 2kontura 103730Document43 pagesKater Turbo Povyshennay Moshnost 2kontura 103730TRNo ratings yet

- Cargo Operations Non Tanker ManualDocument226 pagesCargo Operations Non Tanker ManualAnonymous 1l8njob100% (4)

- Skidloader Monthly Inspection Checklist: Operator Signature: طختسـد رٹـیرپآDocument2 pagesSkidloader Monthly Inspection Checklist: Operator Signature: طختسـد رٹـیرپآUsman RajputNo ratings yet

- Fire Extinguisher Inspection ChecklistDocument9 pagesFire Extinguisher Inspection ChecklistWaqas SaeedNo ratings yet

- Att 3. Items of Standard Risk AssessmentDocument77 pagesAtt 3. Items of Standard Risk AssessmentRiskyMaulanaNo ratings yet

- Returnable Tools List - Sti TopazDocument1 pageReturnable Tools List - Sti Topazhareshphabiyani1996No ratings yet

- Daily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)Document1 pageDaily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)burereyNo ratings yet

- Standard Operating Procedure: Title: Sop For Cooling Water Pump/Tower Section No.: 13Document2 pagesStandard Operating Procedure: Title: Sop For Cooling Water Pump/Tower Section No.: 13KUSH SHARMANo ratings yet

- Form Inspeksi CraneDocument2 pagesForm Inspeksi CraneDaengkulle Firmansyah PuteraNo ratings yet

- QHM 2017-18Document16 pagesQHM 2017-18Ravi Kiran MNo ratings yet

- DAR Daily Report BUT SSM 15 February 2021Document4 pagesDAR Daily Report BUT SSM 15 February 2021NiraNo ratings yet

- Quality Manual SampleDocument51 pagesQuality Manual SampleFaizy NohNo ratings yet

- Depreciation Mar 2020Document20 pagesDepreciation Mar 2020JDE AdminNo ratings yet

- Cleaning and Inspection Works in Abu Dhabi Sewer LinesDocument1 pageCleaning and Inspection Works in Abu Dhabi Sewer LinesburereyNo ratings yet

- Morning Shift Logbook: Continuous Converter (CC) DowntimeDocument3 pagesMorning Shift Logbook: Continuous Converter (CC) DowntimeMoosa NaseerNo ratings yet

- Calb 1Document1 pageCalb 1ranjt53100% (2)

- Daily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)Document1 pageDaily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)burereyNo ratings yet

- IQ347-000-V1A-MEA0-00005 - C - Equipment ListDocument3 pagesIQ347-000-V1A-MEA0-00005 - C - Equipment ListarasNo ratings yet

- Generator SOP ChecklistDocument2 pagesGenerator SOP ChecklistGhure Berai -ঘুরে বেড়াইNo ratings yet

- Distribution list for quality manual revisionsDocument1 pageDistribution list for quality manual revisionsMohammad ArnoldNo ratings yet

- Workshop MachineryDocument5 pagesWorkshop MachinerytareqNo ratings yet

- Box Project Folder Structure - Overview - 02112018Document1 pageBox Project Folder Structure - Overview - 02112018ismaNo ratings yet

- Lub Oil Report IDocument15 pagesLub Oil Report Ishipdesigner088No ratings yet

- WI-02 Thermal CuttingDocument16 pagesWI-02 Thermal CuttingPrakash RajNo ratings yet

- Fan Coil Catalogue - EPCEN08-401 - Catalogues - EnglishDocument12 pagesFan Coil Catalogue - EPCEN08-401 - Catalogues - EnglishmariaNo ratings yet

- Mining Equipment Process Flow DiagramDocument1 pageMining Equipment Process Flow DiagramMuhammad Hussain BilalNo ratings yet

- 10.01.2012 - E16, E16-2 (Reh)Document1 page10.01.2012 - E16, E16-2 (Reh)burereyNo ratings yet

- Vitalis Indústria de Alimentos Ltda: P P R ADocument13 pagesVitalis Indústria de Alimentos Ltda: P P R ALucas TorresNo ratings yet

- 4.D-017C Oil Spill Drill Report Rev 0Document3 pages4.D-017C Oil Spill Drill Report Rev 0Bataklanden MusicNo ratings yet

- Span Calibration Guide: Client Document NumberDocument28 pagesSpan Calibration Guide: Client Document NumberEinjel TenaNo ratings yet

- HR 01 TNI AssociatesDocument1 pageHR 01 TNI AssociatesDeepakNo ratings yet

- CT DCT - Maintenance 3808Document6 pagesCT DCT - Maintenance 3808Andrew LiebermannNo ratings yet

- Wi MR 16Document1 pageWi MR 16Jaydeep PoteNo ratings yet

- Abandon Ship Drill ReportDocument6 pagesAbandon Ship Drill Reportmonica matualageNo ratings yet

- Inventaris Lsa & FfaDocument8 pagesInventaris Lsa & FfaRoby AditamaNo ratings yet

- Quality Control Check ScheduleDocument2 pagesQuality Control Check ScheduleMechtek LabNo ratings yet

- AVP-MM-WH-QF-013 - Dispensed Material Label (Tempelate) - 01Document1 pageAVP-MM-WH-QF-013 - Dispensed Material Label (Tempelate) - 01shahidniazi7860No ratings yet

- MPE 750 Turbo Marine Closed LoopDocument42 pagesMPE 750 Turbo Marine Closed LoopAleksandar Sasa SeferovicNo ratings yet

- JURNAL HARIAN REFRIGERASIDocument1 pageJURNAL HARIAN REFRIGERASIAgus WibowoNo ratings yet

- Daily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)Document2 pagesDaily Programme: DC QC Form No. QI-04 (Version-2, 20/10/10)burereyNo ratings yet

- Gop-Uty-08 (DMW 1)Document67 pagesGop-Uty-08 (DMW 1)Warda YousafNo ratings yet

- Program Transmission ID and Calibrate ClutchesDocument4 pagesProgram Transmission ID and Calibrate ClutchesUrielNo ratings yet

- EuRoC CompetitionRules RequirementsDocument54 pagesEuRoC CompetitionRules RequirementsAlexandr ProkopNo ratings yet

- Drive Solutions For Cranes.Document3 pagesDrive Solutions For Cranes.dhaNo ratings yet

- MV Cables Data Sheet - SampleDocument5 pagesMV Cables Data Sheet - SampleAvoor KhanNo ratings yet

- Smooth Masonry PaintDocument1 pageSmooth Masonry Paintvanhung88No ratings yet

- AAD Lab ManualDocument85 pagesAAD Lab ManualSwastik SinghNo ratings yet

- 1,6l Simos (AEH+AKL) 1Document10 pages1,6l Simos (AEH+AKL) 1Tremalone SemionelaNo ratings yet

- Lesson 1 - Position and Position Lines Learning OutcomesDocument23 pagesLesson 1 - Position and Position Lines Learning OutcomesMico SantosNo ratings yet

- PMM Shipyard DirectoryDocument9 pagesPMM Shipyard DirectoryHarisNo ratings yet

- Checklist For Const Building Supervisors PDFDocument84 pagesChecklist For Const Building Supervisors PDFMiky Tema100% (4)

- Pif 12 Vo Sta. Rosa II 1Document23 pagesPif 12 Vo Sta. Rosa II 1Elmer HerreraNo ratings yet

- Rick Thompson ResumeDocument2 pagesRick Thompson ResumeJohn AndersonNo ratings yet

- DM 103vaDocument2 pagesDM 103vaTanvon MalikNo ratings yet

- Iec Standards For Variable Speed Drives and Motor Winding InsulationDocument4 pagesIec Standards For Variable Speed Drives and Motor Winding Insulationmani_208eeNo ratings yet

- BS 5977 - 1 Lintels PDFDocument14 pagesBS 5977 - 1 Lintels PDFTom YeeNo ratings yet

- Perma Multipurpose Grease SF01 TDS enDocument2 pagesPerma Multipurpose Grease SF01 TDS enDwi April YantoNo ratings yet

- Turboplast Metric PDFDocument2 pagesTurboplast Metric PDFdeli34No ratings yet

- Code For Cost Estimation by COCOMO ModelDocument7 pagesCode For Cost Estimation by COCOMO ModelMukta DebnathNo ratings yet

- Lecture (05) Boolean Algebra and Logic Gates: By: Dr. Ahmed ElshafeeDocument12 pagesLecture (05) Boolean Algebra and Logic Gates: By: Dr. Ahmed ElshafeevenkateshNo ratings yet

- DVG CatalogDocument7 pagesDVG CatalogDinesh ChouguleNo ratings yet

- 09c01 Fuel Injection Pump (Rotor)Document6 pages09c01 Fuel Injection Pump (Rotor)hbpate3No ratings yet

- Engineering For Steel ConstructionDocument2 pagesEngineering For Steel ConstructionBiju Muttathukatil0% (1)

- Wedge Anchor BZplus A4Document4 pagesWedge Anchor BZplus A4francisbautistaNo ratings yet

- UIU EC-II Lecture#9Document18 pagesUIU EC-II Lecture#9Montosh RoyNo ratings yet

- Paper and PulpDocument13 pagesPaper and PulpSanjaya NaralNo ratings yet

- Segment Brochure Elotex BermocollDocument16 pagesSegment Brochure Elotex BermocollVictor ZuñigaNo ratings yet

- Sample Assignment For Harvard Referencing SystemDocument18 pagesSample Assignment For Harvard Referencing SystemShamsul Alam SajibNo ratings yet

- Andoverinfineti 2 Seriescontrollertechnicalreference 35081Document190 pagesAndoverinfineti 2 Seriescontrollertechnicalreference 35081Aaron SperaNo ratings yet

- Engine Familiarization 4-39: Number 1 and 2 Bearing Support SubDocument6 pagesEngine Familiarization 4-39: Number 1 and 2 Bearing Support SubKishan MalhotraNo ratings yet

- Half and Full Adder Circuit ReportDocument19 pagesHalf and Full Adder Circuit ReportNatasha Parti50% (8)

- User Manual: Opening Using The Opening Code Generally StructureDocument1 pageUser Manual: Opening Using The Opening Code Generally StructurePetre LeahNo ratings yet

- RC Datasheet ISCOM2600G 20160128 PDFDocument5 pagesRC Datasheet ISCOM2600G 20160128 PDFJhovanny PasaranNo ratings yet