Professional Documents

Culture Documents

5183 - Eng 1

Uploaded by

Manoranjan MohapatraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5183 - Eng 1

Uploaded by

Manoranjan MohapatraCopyright:

Available Formats

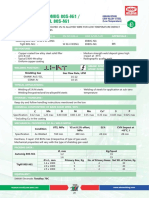

Al SAFRA

Mg4,5Mn/5183

DESCRIPTION AWS A5.10/A5.10M

ER 5183,R5183

Welding wires and rods to be used when very high seawater corrosion

resistance is needed. Applications in the construction of ships, offshore, EN ISO 18273

cryogenic plants, railway and in the automotive industry. S Al 5183 / AlMg4,5Mn0,7(A)

CHEMICAL COMPOSITION

MATERIALS TO BE WELDED in%(m/m)(a)

Al Mg 4,5 Mn / Al Mg 5 / Al Mg 2 Mn 0,8 / Al Zn Mg 1 / Al Zn Mg Cu 0,5 /

Al remainder

Al Mg Si 0,5 / Al Mg Si 1 / G-Al Mg 10 / G-Al Mg 5 / G-Al Mg 3 Si /

G-Al Mg 5 Si

Si 0,40

SHIELDING GASES MINIMAL VALUES OF THE MECHANICAL Fe 0,40

FOR GMAW/GTAW PROPERTIES (welded metal)

I1, I2, I3 Tensile strenght Rm: 275 N/mm2 Cu 0,10

Yeld strenght Rp 0,2: 130 N/mm2

Elongation L=5d: 18 % Mn 0,50 - 1,0

Mg 4,3 - 5,2

AVAILABLE SIZES* Cr 0,05 - 0,25

MIG: 5-6-7 Kg D300 or K300/KS300 spools

Diameter of the wire Zn 0,25

0,8 mm - 0,9 mm - 1,0 mm - 1,2 mm - 1,6 mm - 2,0 mm - 2,4 mm

Ti 0,15

TIG carton box of 10 Kg (x 1000 mm length)

Diameter of the rods

1,6 mm-2,0 mm-2,4 mm-3,2 mm-4,0 mm-5,0 mm

Be 0,0003

others each

MINI-MIG: 0,5 Kg D100 spools / 2 Kg D200 spools < 0,05

Diameter of the wire

others total

0,8 mm - 0,9 mm - 1,0 mm - 1,2 mm - 1,6 mm 0,15

(a) Single values shown in the table

* More diameters and packaging upon request are maximum values, unless

otherwise noted.

You might also like

- Aluminium Electrode With 12%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonDocument1 pageAluminium Electrode With 12%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonAdel AbduoNo ratings yet

- Aluminium Electrode With 5%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonDocument1 pageAluminium Electrode With 5%si: Size (MM) 2,5x350 3,2x350 4,0x350 Packets/Carton Kg/Packet Kg/CartonAdel AbduoNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- CWC-BookletF1 24Document1 pageCWC-BookletF1 24Jagannath SahuNo ratings yet

- CWC-BookletF1 36 PDFDocument1 pageCWC-BookletF1 36 PDFJagannath SahuNo ratings yet

- 25 35 4CNbDocument1 page25 35 4CNbRomy MiftachNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Automig 80s G Tigfil 80s GDocument1 pageAutomig 80s G Tigfil 80s Gvijaysvm999No ratings yet

- Miginox 307: Classification: en Iso 14343-ADocument1 pageMiginox 307: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Contacts M39029 and Glenair Signature Solutions: MIL-DTL-38999 Series III TypeDocument5 pagesContacts M39029 and Glenair Signature Solutions: MIL-DTL-38999 Series III TypeYounes AlzyoudNo ratings yet

- Automig 70S A1 - Tigfil 70S A1Document1 pageAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNo ratings yet

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Document1 pageAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraqueNo ratings yet

- 308 - Dogal LAD PDFDocument2 pages308 - Dogal LAD PDFchristos032No ratings yet

- Dogal LAD High Strength Low Alloy Steels For Cold Forming: GeneralDocument2 pagesDogal LAD High Strength Low Alloy Steels For Cold Forming: Generalchristos032No ratings yet

- Nextel Ceramic Fiber Typical Properties: 3M Property Units Nextel™ 312 Nextel™ 440 Nextel™ 550Document2 pagesNextel Ceramic Fiber Typical Properties: 3M Property Units Nextel™ 312 Nextel™ 440 Nextel™ 550ninatenaNo ratings yet

- RMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - SignedDocument3 pagesRMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - SignedNirmal WiresNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- 2024 Aluminium SheetDocument1 page2024 Aluminium SheetGeorge ChachlakisNo ratings yet

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 pageBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelNo ratings yet

- 1.4435 - C Stainless Steel DetailsDocument3 pages1.4435 - C Stainless Steel DetailsmeenakshiNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- JST - Automotive - Connectors - JSTM S A0001226634 1 1746827Document4 pagesJST - Automotive - Connectors - JSTM S A0001226634 1 1746827Araceli OrtizNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- .Au-Aluminium Alloy 3003Document5 pages.Au-Aluminium Alloy 3003ali alhamilNo ratings yet

- Nedal Alloy Datasheet EN AW 7108ADocument1 pageNedal Alloy Datasheet EN AW 7108ANico VazquezNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Flat Steel SpecsDocument8 pagesFlat Steel SpecscuongdcNo ratings yet

- Er100s GDocument1 pageEr100s GAhmed Abdel NabiNo ratings yet

- Selectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResaleDocument3 pagesSelectrode: Chromium Carbide Manufacturers of Custom Welding Lines For ResalesareddytejaaeNo ratings yet

- 1 s2.0 S0040609005025459 MainDocument4 pages1 s2.0 S0040609005025459 Mainrautsubhajit89No ratings yet

- Aisi H10Document6 pagesAisi H10Diego ParedesNo ratings yet

- 7.5 Kva BomDocument2 pages7.5 Kva BomDinesh MNo ratings yet

- VTA Al99,5Document1 pageVTA Al99,5dmcosta99No ratings yet

- h2066-HASTELLOY C-22 Welding DataDocument4 pagesh2066-HASTELLOY C-22 Welding DataGovindarajalu PadmanabhanNo ratings yet

- Rod - Union I Crmo 910Document1 pageRod - Union I Crmo 910Rushita SolankiNo ratings yet

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- AlMg 4.5Mn Product-SheetDocument1 pageAlMg 4.5Mn Product-SheetLuca MemoliNo ratings yet

- Doclib 4677 Autocraft 316lsi DatasheetDocument1 pageDoclib 4677 Autocraft 316lsi Datasheetamir moniriNo ratings yet

- CM900Document1 pageCM900ElMacheteDelHuesoNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- Aisi 431 Stainless SteelDocument3 pagesAisi 431 Stainless SteelAbdul MuizzNo ratings yet

- Aisi 431 Stainless SteelDocument3 pagesAisi 431 Stainless SteeldhaneshquilonNo ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Alu MN: Description and ApplicationDocument1 pageAlu MN: Description and Applicationmohamed AdelNo ratings yet

- WEB - Duplex UNS S31803 UNS S32205 Duplex Stainless SteelDocument4 pagesWEB - Duplex UNS S31803 UNS S32205 Duplex Stainless SteelHector MejiaNo ratings yet

- Welding ProcessesDocument28 pagesWelding ProcessesAnaswarpsNo ratings yet

- CWC-BookletF1 29 PDFDocument1 pageCWC-BookletF1 29 PDFJagannath SahuNo ratings yet

- 410 NiMo MigDocument2 pages410 NiMo MigAnonymous skBAwexNo ratings yet

- E 9018-B9 Product-SheetDocument1 pageE 9018-B9 Product-SheetjuanNo ratings yet

- Aluminium 5083Document2 pagesAluminium 5083Septiana WibowoNo ratings yet

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocument1 pageAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNo ratings yet

- Hydro en Aw 1050aDocument1 pageHydro en Aw 1050aManoranjan MohapatraNo ratings yet

- Astm StandardsDocument15 pagesAstm StandardsAbdouHemmalNo ratings yet

- Rates of Affixation of High Security RegistrationDocument4 pagesRates of Affixation of High Security RegistrationManoranjan MohapatraNo ratings yet

- Mechanical Properties PDFDocument57 pagesMechanical Properties PDFvardhaNo ratings yet

- Vashi Creek Water Quality NaviMumbaiDocument27 pagesVashi Creek Water Quality NaviMumbairanucNo ratings yet

- 6 - Designing Manufacturing Processes - Hill - Product ProfilingDocument20 pages6 - Designing Manufacturing Processes - Hill - Product ProfilingLalit S KathpaliaNo ratings yet

- Carreño Araujo Cesar - Capturas Calculadora Sesion 02Document17 pagesCarreño Araujo Cesar - Capturas Calculadora Sesion 02CESAR JHORCHS EDUARDO CARREÑO ARAUJONo ratings yet

- PH and ORP Systems: Reliable in Pure Water Treatment ApplicationsDocument10 pagesPH and ORP Systems: Reliable in Pure Water Treatment ApplicationsmateusT850No ratings yet

- Inhuman Exclusive PreviewDocument12 pagesInhuman Exclusive PreviewUSA TODAY Comics100% (1)

- LFT - Development Status and Perspectives: Prof. DR Michael SchemmeDocument7 pagesLFT - Development Status and Perspectives: Prof. DR Michael SchemmeabiliovieiraNo ratings yet

- Kaizenvest Education Report IndiaDocument62 pagesKaizenvest Education Report IndiaSakshi SodhiNo ratings yet

- List of Circulating Currencies by CountryDocument8 pagesList of Circulating Currencies by CountryVivek SinghNo ratings yet

- ACI-20 S2 Indonesia - en PDFDocument3 pagesACI-20 S2 Indonesia - en PDFOktaNo ratings yet

- Tablet BMR Ampsar 5 by 160Document31 pagesTablet BMR Ampsar 5 by 160Muhammad ImranNo ratings yet

- TechRef SoftstarterDocument11 pagesTechRef SoftstarterCesarNo ratings yet

- Enidine Wire Rope IsolatorsDocument52 pagesEnidine Wire Rope IsolatorsJocaNo ratings yet

- 01 04 2018Document55 pages01 04 2018sagarNo ratings yet

- PCAR Part 1 ReviewerDocument75 pagesPCAR Part 1 ReviewerMaybelyn ConsignadoNo ratings yet

- Pasreform Hatchery GuideDocument182 pagesPasreform Hatchery Guidemasud farahad100% (5)

- Oil and Gas CompaniesDocument4 pagesOil and Gas CompaniesB.r. SridharReddy0% (1)

- Student Counseling Management System Project DocumentationDocument4 pagesStudent Counseling Management System Project DocumentationShylandra BhanuNo ratings yet

- Income Tax Law & Practice Code: BBA-301 Unit - 2: Ms. Manisha Sharma Asst. ProfessorDocument32 pagesIncome Tax Law & Practice Code: BBA-301 Unit - 2: Ms. Manisha Sharma Asst. ProfessorVasu NarangNo ratings yet

- Computer Systems Servicing NC II CGDocument238 pagesComputer Systems Servicing NC II CGRickyJeciel100% (2)

- Technical Report Documentation PageDocument176 pagesTechnical Report Documentation Pagepacotao123No ratings yet

- Newcastle University Dissertation Cover PageDocument5 pagesNewcastle University Dissertation Cover PageThesisPaperHelpUK100% (1)

- Legend Sheet P&ID For As-Built - Drafting On 20210722-5Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-5Ludi D. LunarNo ratings yet

- Subgrade Preparation in Earth CutDocument3 pagesSubgrade Preparation in Earth Cutusama buttNo ratings yet

- Invoice: Buyer Information Delivery Information Transaction DetailsDocument1 pageInvoice: Buyer Information Delivery Information Transaction DetailsZarida SahdanNo ratings yet

- January 2017Document80 pagesJanuary 2017Alexandre AGNo ratings yet

- Valuation of Bonds and Stocks: Financial Management Prof. Deepa IyerDocument49 pagesValuation of Bonds and Stocks: Financial Management Prof. Deepa IyerAahaanaNo ratings yet

- Warm Mix Asphalt: "National Perspective"Document46 pagesWarm Mix Asphalt: "National Perspective"Royhan RizkyNo ratings yet

- Python Lab10 Report SummaryDocument8 pagesPython Lab10 Report SummaryVivekananda ParamahamsaNo ratings yet

- The Effect of Electronic Coupon Value To Perceived Usefulness and Perceived Ease-of-Use and Its Implication To Behavioral Intention To Use Server-Based Electronic MoneyDocument12 pagesThe Effect of Electronic Coupon Value To Perceived Usefulness and Perceived Ease-of-Use and Its Implication To Behavioral Intention To Use Server-Based Electronic MoneyInternational Journal of Innovative Science and Research TechnologyNo ratings yet