Professional Documents

Culture Documents

Filtro Hydac

Uploaded by

Wendel AndradeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filtro Hydac

Uploaded by

Wendel AndradeCopyright:

Available Formats

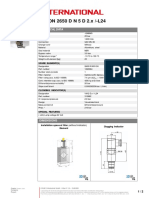

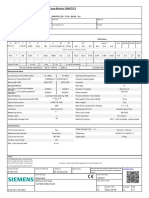

FLND BN/HC 400 DDF 10 A 1.

x

TECHNICAL DATA

Part number 1294584

Pmax * 25 bar

Qmax * 250 l/min

Connection G 1½

Change-over tap

Material Aluminium

Seal material NBR

Bypass valve Without bypass

Temperature range * -30 °C to 100 °C

Weight w ith element [kg] 12

SPARE ELEMENT(S)

Designation 0400 DN 010 BN4HC

Part number 1250530

Number elem.(s)/side 1

Filter material Betamicron®, Dpmax=20 bar

Filter rating (acc. to ISO 16889) 9.1 µm at βx(c) = 200

Cont. retention cap. (acc. to ISO 16889) 91.4 g at 5.0 bar

Differential pressure stability * 20 bar

Slope coefficient 0.001314 bar / (l/min)

CLOGGING INDICATOR(S)

Designation w ithout

Design With plug screw only

DIMENSIONS

Installation space of filter (without indicator)

Element

Creator: Guest User HYDAC Filtertechnik GmbH - Filter-IT² 1.0 – 20.06.2023

Company: *) Exceeding the mentioned and approved technical values can lead to malfunctions or destruction of the product.

Project: HYDAC dimensioning recommendations: We recommend a filter selection at a differential pressure of 20 % of the response pressu re of the clogging indicator. 1/2

T hat means a recommended differential pressure with clean element of: <br>· 1 - 1.5 bar for pressure filters <br>· 0.5 - 0.6 bar for return line filters <br>· 0.05

bar for suction filters

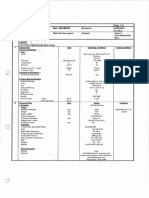

FLND BN/HC 400 DDF 10 A 1.x

CHARACTERISTICS

Pressure / Flow Pressure / Temperature

Total: Housing: Element(s):

OPERATING CONDITIONS FOR THE FILTER

Medium ISO VG 460 (mineral oil) Δp at 80 l/m in

Selecting temperature 45 °C Total 1.235 bar

Selecting viscosity 324.00 mm²/s Element(s) 1.135 bar

Cold Start Viscosity -

Flow 80 l/min

SPARE PARTS LIST

Part num- Num-

Pos. Spare Parts Designation

ber ber

1 Filter element(s) per side 1250530 0400 DN 010 BN4HC 1

2 Clogging indicator - w ithout 1

3 Repairing set 1294462 REPARATURSATZ-E FLND.160 W 1.2 1

Creator: Guest User HYDAC Filtertechnik GmbH - Filter-IT² 1.0 – 20.06.2023

Company: T he information in this brochure relates to the operating conditions and applications described. For applications or operatin g conditions not described, please

Project: contact the relevant technical department. Subject to technical modifications. 2/2

HYDAC dimensioning recommendations: We recommend a filter selection at a differential pressure of 20 % of the response pressu re of the clogging indicator.

T hat means a recommended differential pressure with clean element of: <br>· 1.0 - 1.5 bar for pressure filters <br>· 0.5 - 0.6 bar for return line filters <br>·

0.05 bar for suction filters

You might also like

- Spin OnDocument2 pagesSpin OntarobaclashNo ratings yet

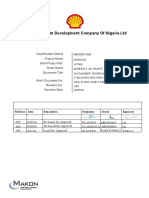

- NF ON 2650 D N 5 D 2.x /-L24: Technical DataDocument2 pagesNF ON 2650 D N 5 D 2.x /-L24: Technical DataGabriela - Vendas Amazon TecnologiaNo ratings yet

- Filtro RFM ON 185 V D 10 E 1.x (Hydac)Document2 pagesFiltro RFM ON 185 V D 10 E 1.x (Hydac)OARIASCONo ratings yet

- E) DSF1000 AlDocument5 pagesE) DSF1000 AlAgeng A. PooNo ratings yet

- BBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFDocument1 pageBBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFAdianto RahmanNo ratings yet

- Duplex Filter: 1. FeaturesDocument6 pagesDuplex Filter: 1. Featuresmostafa aliNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEnokarajuNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Work Instruction: Channel CoverDocument1 pageWork Instruction: Channel CoverPRAVEENKUMARNo ratings yet

- E) DSF1300 Al1Document5 pagesE) DSF1300 Al1Ageng A. PooNo ratings yet

- ANTAM Datasheet 10LAD21AA121 00Document1 pageANTAM Datasheet 10LAD21AA121 00heviNo ratings yet

- Sda s17893 Adic1 Ms 2105 00005 Data Sheet Instrument Air Compressor Filter A03Document3 pagesSda s17893 Adic1 Ms 2105 00005 Data Sheet Instrument Air Compressor Filter A03Oladiran AgbaraoluwaNo ratings yet

- Filter Regulator LFR-1/2-D-7-O-MIDI: Data SheetDocument1 pageFilter Regulator LFR-1/2-D-7-O-MIDI: Data SheetRichard Rodriguez GarciaNo ratings yet

- Intro PF en V4Document6 pagesIntro PF en V4plasticos_jfm6580No ratings yet

- Technical Details - Ecology UnitDocument9 pagesTechnical Details - Ecology Unitprashant.jadhavNo ratings yet

- Technical Details - MAHUDocument6 pagesTechnical Details - MAHUprashant.jadhavNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 Pravi kumarNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- OD92X77YZDocument4 pagesOD92X77YZpttNo ratings yet

- RF Return Line FilterDocument8 pagesRF Return Line Filterboobalan_shriNo ratings yet

- Service Unit FRC-1/2-D-MAXI-A: Data SheetDocument1 pageService Unit FRC-1/2-D-MAXI-A: Data SheetWahyu ArdiansyahNo ratings yet

- 1LE7503 2BB03 5AA4 Datasheet enDocument1 page1LE7503 2BB03 5AA4 Datasheet enhafidz.maxonNo ratings yet

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborNo ratings yet

- MC-001-DS-M-005-110 DS For Liquor Filter Rev ADocument4 pagesMC-001-DS-M-005-110 DS For Liquor Filter Rev AHeldiyan RamdhanNo ratings yet

- QAP Flexible Hose TemplateDocument2 pagesQAP Flexible Hose Templatesjk_akolNo ratings yet

- MC-001-DS-M-004-110 DS For Liquor Filter Rev ADocument4 pagesMC-001-DS-M-004-110 DS For Liquor Filter Rev AHeldiyan RamdhanNo ratings yet

- Wilo Datasheet - GB - en - 4215521 - Yonos Pico 30 1 8Document9 pagesWilo Datasheet - GB - en - 4215521 - Yonos Pico 30 1 8i7zook3No ratings yet

- Salt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDDocument3 pagesSalt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDkayaltharanNo ratings yet

- Cta 01 R2Document8 pagesCta 01 R2Constantin294No ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3073B Simotics SD - 71M - Im B3 - 4 PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3073B Simotics SD - 71M - Im B3 - 4 PSHYAM SHARMANo ratings yet

- Hydac Return Line Filter RFDDocument4 pagesHydac Return Line Filter RFDCarlos Andrés CuelloNo ratings yet

- HF 690 Series: in Line Medium Pressure FiltersDocument4 pagesHF 690 Series: in Line Medium Pressure FilterssitnikovsNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- Bomba KNF N035.1.2.18 E242Document3 pagesBomba KNF N035.1.2.18 E242Antonio FourcoNo ratings yet

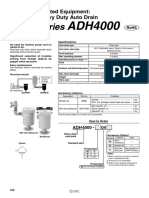

- Series: Related Equipment: Heavy Duty Auto DrainDocument3 pagesSeries: Related Equipment: Heavy Duty Auto Drainherysyam1980No ratings yet

- Pump Data Sheet - 3-ADocument1 pagePump Data Sheet - 3-Acruz romeroNo ratings yet

- Specifications: DaikinDocument17 pagesSpecifications: DaikinyoyokNo ratings yet

- 1LE7501 0DB22 3AA4 Datasheet enDocument1 page1LE7501 0DB22 3AA4 Datasheet enDNo ratings yet

- Folha de Dados MOTORESDocument1 pageFolha de Dados MOTORESpedro.inacioNo ratings yet

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- 1LE7603-0CB22-3FA4 Datasheet enDocument1 page1LE7603-0CB22-3FA4 Datasheet enrequirement.dcNo ratings yet

- 1LE7503-0CB32-3AA4 Datasheet enDocument1 page1LE7503-0CB32-3AA4 Datasheet enLuis RomeroNo ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- PRD Doc Pro 7699-00001 Sen Ain V1Document2 pagesPRD Doc Pro 7699-00001 Sen Ain V1rakhikishore143No ratings yet

- Air Trap RL1090 - RL1290Document2 pagesAir Trap RL1090 - RL1290satphoenixNo ratings yet

- Up To 100 L/min, Up To 280 Bar: Inline Filter MFMDocument4 pagesUp To 100 L/min, Up To 280 Bar: Inline Filter MFMSeyedAli TabatabaeeNo ratings yet

- Technical Data Compressor: Model 104G7550 115V/60Hz 1Document6 pagesTechnical Data Compressor: Model 104G7550 115V/60Hz 1Camilo CarreñoNo ratings yet

- Liquid Pipe Sizing: Group Technology SolutionsDocument1 pageLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNo ratings yet

- 1LE7501-1BB23-5AA4 Datasheet enDocument1 page1LE7501-1BB23-5AA4 Datasheet enVinit ShrivastavaNo ratings yet

- Proteccion de Aire 5 6Document2 pagesProteccion de Aire 5 6Abel BlNo ratings yet

- Juice Heater 1Document1 pageJuice Heater 1vijendrNo ratings yet

- Hze1ghze2gen - En617 - hze2g15gABDocument3 pagesHze1ghze2gen - En617 - hze2g15gABMohammad Adeel KhanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Eclipse Ring Planning Guide - Any To AnyDocument8 pagesEclipse Ring Planning Guide - Any To AnyAnsar ShafiiNo ratings yet

- PokeDex ChecklistDocument7 pagesPokeDex ChecklistJosh StrıkeNo ratings yet

- Reptilian Astral WarsDocument4 pagesReptilian Astral WarsAlienraces1No ratings yet

- Introduction To Discourse Analysis PDFDocument20 pagesIntroduction To Discourse Analysis PDFShobade Christianah Temitope100% (1)

- Ces511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)Document13 pagesCes511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)elhammeNo ratings yet

- Surface Vehicle Standard: Rev. AUG1997Document6 pagesSurface Vehicle Standard: Rev. AUG1997anupthattaNo ratings yet

- Rockmass Strength PropertiesDocument32 pagesRockmass Strength PropertieskannonzkNo ratings yet

- Bootstrap 3 All Classes List Cheat Sheet Reference PDF (2020) PDFDocument21 pagesBootstrap 3 All Classes List Cheat Sheet Reference PDF (2020) PDFHoney ShineNo ratings yet

- Qualitative Study On Stress Among Nurses Working at Private Sector, in Suburban KolkataDocument9 pagesQualitative Study On Stress Among Nurses Working at Private Sector, in Suburban KolkataSandra RNo ratings yet

- Lab Manual Fall 2017Document68 pagesLab Manual Fall 2017Nil SabbirNo ratings yet

- Gas Cutting - by KiranDocument40 pagesGas Cutting - by KiransridharchebroluNo ratings yet

- CompanyDocument7 pagesCompanylotchanNo ratings yet

- Four Gears ModelDocument13 pagesFour Gears ModelPratik PatilNo ratings yet

- Filipino ThinkingDocument2 pagesFilipino ThinkingRheyven JuanNo ratings yet

- Ascend P7: Huawei SchematicDocument51 pagesAscend P7: Huawei SchematicCarlos Andres EscamillaNo ratings yet

- Standard Operating Procedure For Clinical Biochemistry: R. K. Life Services Private LimitedDocument7 pagesStandard Operating Procedure For Clinical Biochemistry: R. K. Life Services Private LimitedAniruddha ChatterjeeNo ratings yet

- List of ROs Under VODocument74 pagesList of ROs Under VOvivek mishraNo ratings yet

- Contrastive Morphology The Morpheme Is The Smallest Unit of A Language That Has A Binary Nature (That CanDocument6 pagesContrastive Morphology The Morpheme Is The Smallest Unit of A Language That Has A Binary Nature (That CanIrynaNo ratings yet

- Add Math Project 2012 SabahDocument32 pagesAdd Math Project 2012 SabahIrsyadNo ratings yet

- Introduction To PFADocument7 pagesIntroduction To PFACHRISTINE KYLE CIPRIANONo ratings yet

- Republic of The Philippines Social Security System MemberDocument1 pageRepublic of The Philippines Social Security System MemberreyNo ratings yet

- Performance Evaluation of TDL Channels For Downlink 5G MIMO SystemsDocument4 pagesPerformance Evaluation of TDL Channels For Downlink 5G MIMO SystemspruxmanNo ratings yet

- Principles of Engineering Thermodynamics - SI Version 8th EditionDocument47 pagesPrinciples of Engineering Thermodynamics - SI Version 8th EditionanabNo ratings yet

- IHS Markit - The Global Ultrasound MarketDocument2 pagesIHS Markit - The Global Ultrasound MarketwwtqfgtpNo ratings yet

- WESCAM MX-15-0503AA-SpecDocument2 pagesWESCAM MX-15-0503AA-SpecAIT FARIDNo ratings yet

- Schoolwide Plan Worksheet: School Name: Pioneer Elementary Principal Name: Brenda Lopresto School Planning TeamDocument10 pagesSchoolwide Plan Worksheet: School Name: Pioneer Elementary Principal Name: Brenda Lopresto School Planning TeamChauncey Mae TanNo ratings yet

- Deber Modelación de AguasDocument2 pagesDeber Modelación de AguasLiz VillamarNo ratings yet

- Woldia University: The Role of Effective Communication in Resolving ConflictDocument17 pagesWoldia University: The Role of Effective Communication in Resolving ConflictMerry Hiyab100% (1)

- Geometry of Middle SurfaceDocument29 pagesGeometry of Middle SurfaceParth ShahNo ratings yet

- Industrial Mechanical Vapour Recompression 1Document2 pagesIndustrial Mechanical Vapour Recompression 1Gaurav UpaNo ratings yet