Professional Documents

Culture Documents

Zeiss Laser 532 Service Instructions

Uploaded by

Javier HdezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zeiss Laser 532 Service Instructions

Uploaded by

Javier HdezCopyright:

Available Formats

VISULAS 532s

(incl. VITE Option)

Service Instructions

Service Instructions VISULAS 532s incl. VITE Service

Service

SM-30-6021-A3-en Service

Service

Version 4: 2009-09-09

Replaces Version 3: 2005-02-23 Page 1 of 64 MAG-ST

Contents

Page

Contents ............................................................................................................................... 2

Update information .............................................................................................................. 5

Explanation of abbreviations used ..................................................................................... 6

System description .............................................................................................................. 7

"System test" mode ......................................................................................................... 7

"Eco" mode ...................................................................................................................... 7

"Info" mode ...................................................................................................................... 8

Main menu mode .............................................................................................................. 9

Slit lamp ........................................................................................................................ 10

"def" mode...................................................................................................................... 11

Therapy mode................................................................................................................. 12

STANDBY – READY ........................................................................................................ 14

STANDBY..................................................................................................................... 14

READY ......................................................................................................................... 14

Applicator ........................................................................................................................... 15

VISULINK 532/U ........................................................................................................... 15

LIO indirect ophthalmoscope ........................................................................................ 15

Endofiber ...................................................................................................................... 15

Aiming beam ...................................................................................................................... 16

Demo mode .................................................................................................................... 16

Service mode .................................................................................................................. 17

Service mode I ................................................................................................................ 17

Service mode II ............................................................................................................... 20

YAG combination mode ................................................................................................. 21

Remote YAG combination mode................................................................................... 21

Passive YAG combination mode................................................................................... 22

LPG mode ....................................................................................................................... 22

Software description ......................................................................................................... 22

Start program ................................................................................................................. 22

Boot procedure ............................................................................................................. 22

Software update using the PCMCIA card...................................................................... 23

Loading the dataset for the control panel ...................................................................... 23

System monitoring ......................................................................................................... 24

External safety logic...................................................................................................... 24

Monitoring of the "LD_ON" signal ................................................................................. 24

Monitoring of the "LD_DRIVE" signal ............................................................................ 24

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 2 of 64

Monitoring via a watchdog circuit ..................................................................................24

Monitoring of the laser power ........................................................................................25

External power monitoring .............................................................................................25

Monitoring of the shutter ...............................................................................................25

Monitoring of the physician's safety filter (PSF) ............................................................. 26

Controller test / current test ...........................................................................................26

Monitoring of the laser stop switch ................................................................................26

Monitoring of the door interlock .....................................................................................26

Monitoring of the aiming beam unit ...............................................................................26

Monitoring of the pulse duration ....................................................................................26

Current mode – Power mode.............................................................................................27

Temperature monitoring ....................................................................................................28

Heat sink temperature ....................................................................................................28

Temperature of the laser diode .....................................................................................28

Temperature of the LBO crystal ....................................................................................28

Problem monitoring ...........................................................................................................29

Error messages ..............................................................................................................29

CPU system errors ........................................................................................................29

General errors ...............................................................................................................29

Other CPU system errors ..............................................................................................31

Errors resulting in the system being switched off - EMERGENCY SHUT OFF ............. 31

Internal software errors .................................................................................................32

Power supply unit (PSU) errors .....................................................................................32

Warning ........................................................................................................................33

Warnings for the VITE option ........................................................................................33

System warnings ...........................................................................................................34

Warnings for YAG combination mode ........................................................................... 35

Notes on errors .............................................................................................................35

Notes displayed by the system ......................................................................................36

Combination mode using VISULAS YAG II plus, YAG III .................................................... 37

Control panel ......................................................................................................................38

DCU..................................................................................................................................38

Using the control panel ..................................................................................................38

Dismantling the unit ...........................................................................................................39

Removing the housing ...................................................................................................39

Removing the switches .................................................................................................40

Removing the CPU PCB .................................................................................................40

Removing the system control PCB ...............................................................................41

Removing the power supply unit ..................................................................................42

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 3 of 64

Removing the heat sink ................................................................................................. 42

Removing the electrical fan ........................................................................................... 43

Removing the resonator ................................................................................................ 43

Adjusting the touchscreen ............................................................................................ 44

Updating the software ....................................................................................................... 45

Replacing and adjusting components ............................................................................. 46

CPU ................................................................................................................................. 46

Replacing the NOVRAM ................................................................................................. 47

Replacing a flat battery ................................................................................................. 47

Replacing the battery before it has run down ................................................................ 48

System control PCB ....................................................................................................... 48

Adjusting the offset........................................................................................................ 49

Installing and aligning the P-detector PCB .................................................................. 49

Adjusting Pmon and Preal ................................................................................................. 50

Replacing and aligning the aiming beam PCB .............................................................. 52

Aiming beam module – old version ............................................................................... 53

Near field adjustment .................................................................................................... 55

Far field ........................................................................................................................ 56

Aiming beam module – new version ............................................................................. 57

Exchanging the aiming beam unit ................................................................................. 57

Aligning the aiming beam unit ....................................................................................... 57

Mounting the shutter PCB ............................................................................................. 60

Replacing the shutter PCB ............................................................................................ 61

Performing the technical safety check including electrical safety inspection .............. 63

Checking the electrical safety ....................................................................................... 63

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 4 of 64

Update information

Issue Comments

2002-01-07 Issue 1

2002-06-11 Issue 2 Completely updated

2005-02-23 Version 3 Adaptation to new software version 3.00

2009-09-09 Version 4 VITE Option added

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 5 of 64

Explanation of abbreviations used

The following abbreviations are used in these instructions:

Abbreviation

ASF Physician Safety Filter Arztschutzfilter

CPU Central Processing Unit Zentrale Recheneinheit

dc duty cycle Arbeitszyklus

DCU Display Controller Unit Recheneinheit in der Bedieneinheit

DFL Double Frequency Laser Doppel- Frequenz- Laser

H High Signal Signal Eins

HW Hardware Geräteausrüstung

IR Infrared Infrarot

L Low Signal Null - Signal

LBO Lithium Triborate (LiB3O5) Lithium Triborat (LiB3O5)

LD Laser Diode Laserdiode

Link VISULINK 532/U VISULINK 532/U

LIO Laser Indirect Ophthalmoscope Kopfophthalmoskop

LP Printed Circuit Board Leiterplatte

LSL 532s Laser slit lamp for VISULAS 532s Laserspaltlampe für VISULAS 532s

LSL Ar/532 Laser slit lamp for VISULAS 532 und Laserspaltlampe für VISULAS 532 und

VISULAS Ar II VISULAS Ar II

LPG Laser Position Generator Laser Positions Generator

MMI Man Machine Interface Person-Geräte-Schnittstelle (Bedienpult)

(control panel)

NAG Power Supply Unit Netzteil

NOVRAM Non-volatile RAM Nichtflüchtiger Speicher

Peltierelement Thermo Electrical Cooler (TEC) System zum Kühlen und Heizen (TEC)

PID Controlling unit (Power, Current, Regeleinrichtung (Leistung, Strom,

Differential Component) Differentialkomponente)

PSF Physician's Safety Filter Arztschutzfilter

PCB Printed Circuit Board Leiterplatte

PSU Power Supply Unit Netzanschlußgerät

PWM Pulse Width Modulation Pulsweitenmodulation

SHG Second Harmonic Generation Frequenzverdopplung

SPALA Slit Lamp Spaltlampe

Spaltlampe Ar Laser Slit Lamp for VISULAS Ar II Laserspaltlampe für VISULAS Ar II

SW Software Programm einer Geräteausrüstung

TEC Thermo Electrical Cooler System zum Heizen und Kühlen

TIntervall Time Interval Intervall (Pulspause)

Tpuls Time Pulse Duration Pulsdauer

TTL Transistor- Transistor- Logic Transistor- Transistor- Logik

VITE Option with Laser Position Generator Option mit Laser Positions Generator

(LPG )

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 6 of 64

System description

The system is controlled using menus.

The software is structured into different menus,

therapy modes and service modes.

"System test" mode

After the system has been switched on and the

booting procedure been completed, the

program control system switches to the

"System test“ mode. During the system test,

the user can directly switch to the Diagnosis

mode by pressing the ECO button.

A progress bar indicates the progress of the

system test and the setting of the operating parameters.

If an error occurs during the test, this error will be stored and displayed on the control panel.

After successful startup, it is possible to switch to the different application menus or to the

Service menu from the main menu.

"Eco" mode

The user can access this mode by pressing the

"Eco" button during the system test.

This mode allows the laser slit lamp to be used

as a diagnostic slit lamp.

In this case, the VISULAS 532s only serves as

the voltage source for the slit lamp.

The laser module and the associated

temperature control system remain

deactivated, i.e. the electrical fans are

operated at a minimum number of revolutions.

When the arrow button is pressed, the system

control switches to the system start.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 7 of 64

"Info" mode

The user can access the Info mode from the main

menu.

The following system information is displayed:

- Instrument name

- System date, system time

- Copyright

- Laser: service hours of the laser

- System: service hours of the overall

system

- Software version used by the laser console

- Control panel (MMI)

- Information on the last 10 errors

The following settings can be adjusted:

- System date, system time

Press the date area and adjust the time and date in the

window provided:

When the figure to be adjusted is pressed, this figure is

shown with a dark background and can be changed

using the encoder wheel.

Press the checkmark button to exit this function and save this data.

- Language selection

Press the relevant language button and turn the encoder wheel.

The following languages are supported in the Therapy mode: German, English, French and

Spanish.

The Service mode is in English.

- Contrast voltage for the LCD

Set by pressing the button and turning the encoder wheel.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 8 of 64

Main menu mode

The user can make all important system

settings in this mode.

These include:

- Selecting the applicator

Slit lamp, Link, LIO, ENDO,

YAG IIplus laser in combination system

- Setting the program required

The user can use three user-specific programs P1, P2, P3

or a permanently configured program P.

In the user-specific programs, the user can set the laser parameters: power, pulse

duration, pulse interval, aiming beam – as he would like to use them in the

Therapy mode after system startup.

After touching the P1, P2 or P3 button and the

- def button , the user can preset these values.

- Selecting hand / foot control

If a VISULAS YAG IIplus has been connected to VISULAS 532s and set as

the applicator, it is possible to select between hand and foot control.

Signal beep during treatment

ON / OFF

By pressing the appropriate buttons in the main menu you can access the

following modes:

- info information mode

- eco diagnosis mode

- def program definition

- therapy mode

- S1 - > S2 service mode

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 9 of 64

- "NEXT" button

After the buttons have been pressed, the software checks whether the application is ready for

operation.

Slit lamp - Physician's safety filter test

- Light guide connected?

- System monitoring active?

Link - Light guide connected?

- System monitoring active?

- Test of LINK_CONNECTED signal

- Note: LINK has been set!

LIO - Light guide connected?

- System monitoring active?

- Test of LIO_CONNECTED signal

ENDO - Physician's safety filter test

- Light guide connected?

- System monitoring active?

YAG - VISULAS YAG II plus ready for operation?

- System monitoring active?

S1/ S1 Service mode - Service mode possible (enable)?

- Applicator-dependent tests

- System monitoring active?

If no errors occur in this check, the software will switch to the Therapy mode or to the Service

mode if the service engineer has inserted a service connector or reset the relevant DIL switch.

If the selected applicator is not ready for operation, a

message to this effect will appear on the display.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 10 of 64

"def" mode

In this mode, three users can enter their

preferred start values in P 1, P 2 and P 3 for

the following parameters using the buttons and

the encoder wheel.

Pulse duration

Pulse interval

Power

Aiming beam brightness

These start values will be available for P 1 to P 3 at each restart of the system.

Thus, the software controls four different programs, of which three are configurable by the user

as required.

The fourth P program includes the lowest possible start values for pulse duration, pulse

intervals, power and aiming beam brightness.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 11 of 64

Therapy mode

All laser parameters relevant for the selected

applicator are displayed on the control panel and

can be changed using the relevant button and the

encoder wheel.

Display in the Therapy mode

Display in the Therapy mode for LIO and Endo as

of software version 3.0.

Display in the Therapy mode for

VISULAS 532s VITE Option

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 12 of 64

Note

In systems featuring the VITE option, a Laser Position Generator can be selected in

addition to the normal micromanipulator in order to apply specific treatment patterns.

Pulse duration (ms)

Selectable pulse duration 10 ... 2500

As of software version 3.0, cw with a

maximum pulse duration of 3 min is

possible up to 500 mW.

Pulse interval * [ms]

Selectable interval single shot (--), 100 ... 6000

* Limitation:

The shortest selectable interval is dependent on the power set:

If the selected interval is too short, the software will correct the interval.

Power at the cornea [mW]

50 ... 1500

Pulse counter

The pulse counter counts all pulses exiting from the laser.

The pulse counter is reset to zero when the "Reset“ button is pressed.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 13 of 64

STANDBY – READY

The Therapy mode is divided into the following functions:

STANDBY

In the "Standby“ mode, the therapy laser cannot be triggered.

In "Standby", the user can adjust the pulse duration, pulse interval, aiming beam

brightness and laser power using the encoder wheel.

The parameter to be set is selected by pressing the parameter on the touchscreen.

In addition, the "Laser power" parameter can be selected using the integrated key of the

encoder.

Pressing the RESET (<-0) button resets the pulse counter to 0.

The aiming beam laser can be switched on/off using its function button. As soon as the

aiming beam is on, the laser warning lamp on the control panel is lit.

The shutter is open.

However, the therapy laser cannot be triggered.

When the NEXT button is pressed:

the system switches to the READY mode after a transitional period of 3 seconds which

is visualized by a blinking STANDBY icon.

READY

In the "Ready" mode, the aiming beam and the laser warning lamp are always on, and

the aiming beam cannot be switched off, for safety reasons

The parameters are set in the same way as in the STANDBY mode.

When the actuator is pressed, a laser beam is emitted in accordance with the parameters set.

If a slit lamp or ENDO has been selected as the applicator, the physician's safety filter is also

activated and monitored.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 14 of 64

Applicator

The applicator currently selected is displayed in the header line of the control panel.

LSL laser slit lamp

VISULINK 532/U

LIO indirect ophthalmoscope

Endofiber

If the user opts for ENDO, the PSF type used Bi t t e wähl en Si e den benut zt en

must be confirmed. Ar zt schut zf i l t er und pr üf en Si e,

ob er ei ngebaut i st .

‘ saf et y f i l t er 532nm’

ei ngebaut

‘ saf et y f i l t er 532nm’

ei ngebaut

Passive PSF Active PSF

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 15 of 64

Aiming beam

The aiming beam is used as an orientation aid in laser therapy.

After pressure of the button and adjustment of the encoder, brightness can be varied in

5 steps, or 10 steps as of software version 3.0.

Demo mode

Pressing the blank space at the bottom for

about 5 s switches the system to the demo

mode.

This mode allows unrestricted use of the unit

for demonstrations without any activation of

laser beams.

This mode is deactivated by pressing the button

provided.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 16 of 64

Service mode

A special Service mode has been installed for instrument startup and service calls. You can

select this mode if you insert a service connector in the serial interface (RS232) on the back of

the unit or if you activate DIL switch no.3 on the system control PCB.

The service connector bridges the pins 1 and 5.

Service mode I

In Service mode I, you can set system

parameters.

In addition, internal readings are displayed.

Caution

If you activate the Service mode after selecting the LINK or LIO applicator, the system

will no longer recognize the light guide. All persons in the room have to wear laser

safety goggles or laser adjusting goggles.

The light guide will be recognized again after you have exited the Service mode.

Power (mW): Selectable power with preselected "power“ driver mode

50...2500

real (mW): Control signal for actual power provided by a sensor on the detector PCB.

mon (mW): Monitoring signal for actual power provided by a sensor on the detector PCB.

Duration (ms): Selectable pulse duration

10...2500; 999 (cw)

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 17 of 64

Interval (ms): Selectable intervals

Single shot (--); 100...6000

* Limitation:

The shortest selectable interval is dependent on the power set:

for powers 0 mW ... 500 mW ⇒ duty cycle < 75%

for powers 500 mW ... 1,000 mW ⇒ duty cycle < 50%

for powers 1,000 mW ... 1,500 mW ⇒ duty cycle < 30%

The minimum interval obtained is dependent on the pulse duration set.

Duty cycle (dc) is the ratio:

TPulse

TPulse + TInterval

If you select too short an interval, the software will correct the interval.

Aim [V]: 5 selectable aiming beam levels 0.5, 1.7, 4, 7, 10

10 selectable aiming beam levels (as of software version 3.0):

0.5, 0.7, 1.0, 1.3, 1.9, 2.6, 3.6, 5.1, 7.2, 10.0

real: Aiming beam value fed back by the diode,

corresponding to a specific voltage.

Current (A): 1; 1.5; 2; 2.5; ... 40

Selectable current for the pumping diode when the "current" driver mode has

been preset.

Threshold (A): 1; 1.5; 2; 2.5; ... 40

Pumping diode threshold depending on the diode used.

Must only be adjusted to the predetermined values when the laser module has

been changed.

Max. current (A): 1; 1.5; 2; 2.5; ... 40

Admissible pumping diode current depending on the diode used.

Only needs to be adjusted to the predetermined values when the laser module

has been changed.

Caution

An unnecessary change of this current will reduce the life of the

laser system!

Temp. LD (°C): 10 ... 60

Target temperature of the pumping diode required to achieve the necessary

wavelength

Caution

An unnecessary change of this temperature will reduce the power

of the overall system!

real (°C): Actual temperature achieved using Peltier elements (TEC) and electrical fans.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 18 of 64

Temp. SHG (°C): 10 ... 60

Target temperature of the crystal required for frequency doubling

(Second Harmonic Generation) LBO crystal (lithium triborate).

real (°C): Actual temperature achieved using Peltier elements (TEC) and electrical fans.

Temp. System

real (°C): 10 ... 60

Actual temperature of the overall system.

Driver mode: Selectable mode of action of the laser diode controller.

The laser can be operated in either the "Power" or "Current" driver mode.

Power: The pumping diode is light output-driven.

The laser diode controller uses a preset light output value.

The laser diode controller feeds the current corresponding to this light output

value to the pumping diode.

The laser power emitted at the exit of the laser system corresponds to the

laser power set at "Power“.

Transmission factors are not taken into account.

Current: The pumping diode is operated using a preset current.

It receives the current preset in "Current“ from the laser diode controller.

Use the arrow buttons to move to the position required.

Switching the aiming beam on and off

The aiming beam can always be switched on/off in the Service mode,

no matter whether the STANDBY or READY mode has been set.

Standby: The therapy laser cannot be triggered in the "Standby" mode.

When you press the button, the system switches from "Standby" to

"Ready".

Ready: The laser can only be triggered in the "Ready" mode.

When you press this button, a laser beam is emitted as preset.

The aiming beam and the laser warning lamp are on.

If "Slit lamp“ or ENDO has been selected as the applicator, the physician's

filter is also activated and monitored.

Back When you press this button, the display shows the main menu.

Troubleshooting Possibility of deactivating power monitoring by the software.

If the button is lit, the error monitor is active.

Service mode 2 When you press the "S2“ button, you access Service mode 2.

S2

I+ Integrator - internal software I-share of the PI controller.

I− Used by product development staff.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 19 of 64

Service mode II

This mode is used to check the transmission

factors or to enter newly determined factors

during system installation, maintenance or repair.

The software needs this data to compute the

power present at the applicator.

It is possible to test the shutter and the

physician's safety filter.

In this mode, the different levels of the internal

signals are displayed.

Use the arrow buttons to move to the positions required.

Transmission SL (%) Transmission of the LSL/ Ar or 532s slit lamp applicator.

Transmission LINK (%) Transmission of the Visulink 532/U applicator.

Transmission LIO (%) Transmission of the LIO indirect ophthalmoscope applicator.

Transmission ENDO (%) Transmission of the endofiber applicator.

Shutter test Tests proper functioning of the shutter in the console.

The shutter must have reached the selected position within 50 ms.

PSF test Tests proper functioning of the physician's safety filter in the

LSL/ Ar slit lamp or surgical microscope.

The PSF must have reached the selected position within 50 ms.

V PID Used by product development staff.

Default settings provided by the CPU to the PID controller of the

system PCB.

The PID controller presets factors for different power values. The

power values are computed from power, current and differential

components using a specific formula.

Caution

This data is entered during instrument production and

must not be changed under any circumstances!

RESET

Operating time Resets the number of service hours of the laser and system in the

Info mode.

Caution

Only needs to be reset after replacement of the laser

system!

RESET

Error list Resets the error list in the Info mode.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 20 of 64

Back to the main menu.

Back to Service mode I.

YAG combination mode

The YAG combination mode can only be

selected if the customer has a combined laser

system.

In this system, a VISULAS 532s laser and a

VISULAS YAG II (software 3.x),

VISULAS YAG II plus or YAG III laser are

operated together with the same slit lamp.

The two units are connected via an adapter

cable.

To ensure the downward compatibility of systems already installed, two different combination

versions have been implemented:

Remote YAG combination mode

Both systems are controlled using the

VISULAS 532s control panel.

The 532s user interface (operation via

touchscreen and incremental encoder) has

been adapted for YAG IIplus and YAG III.

The Remote YAG Combi mode is activated

using DIL switch S4 on the CPU PCB of

VISULAS 532s.

DIL switch S4 on the CPU PCB of VISULAS

532s must be in the ON position.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 21 of 64

Passive YAG combination mode

VISULAS YAG II (software 3.x), YAG II plus and YAG III are operated using their own control

panels.

In this mode, only the triggering signals are controlled using VISULAS 532s.

VISULAS YAG II is controlled via its own control panel.

The Passive YAG Combi mode is activated using DIL switch S4 on the CPU PCB of

VISULAS 532s.

The DIL switch must be in the "OFF" position.

LPG mode

Note

The LPG mode can only be selected if

VISULAS 532s features the VITE option

and if software version 4.x or higher is

used.

The option permits the Laser Position

Generator to be activated as a further

application and to apply preset treatment

patterns for retinal coagulation.

The use is described in the user manual.

The function test and calibration are part

of the LSL service manual (annex).

In devices featuring the VITE option, the Service mode includes an additional button

marked LPG. This button is used to activate a further service menu for the calibration of

the spot positions.

(see Service Instructions LSL SM-30-6023-A2 section 3.8.4)

Software description

Start program

Boot procedure

As part of the boot program, various internal tests and initialization routines are performed.

The following steps are executed:

- Power-up, initialization of the control panel

- Start of system monitoring

- Test of the watchdog circuit

- Activation of the thermo-electrical coolers and thermostat and setting of the preset

temperature values.

- Test of the shutter function.

- Firing of laser test shots.

Note

If an error occurs during the tests, this error will be displayed on the control panel.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 22 of 64

Time-out

If the time limit is exceeded during the boot process, a beep will be emitted and the system

must be restarted.

The heat-up phase may vary in the amount of time required. It typically takes 90 seconds

during which the TECs generate the preset working temperature of the pumping diode and

SHG crystal.

Software update using the PCMCIA card

If the electronic system of the CPU PCB identifies a PCMCIA card, the software will start the

boot program from the external EPROM.

This independent program includes functions which enable the contents of the PCMCIA card to

be transferred to the internal or external flash EPROM of the system control PCB.

Software versions

SW 1.x with BIOS V:01 – the update to a higher version requires the replacement of the CPU

board (with BIOS V:02).

SW 2.x can be updated to 3.01. A new user manual must be provided to the customer, and the

customer must be briefed on the new functions.

SW 3.0 must be updated to 3.01. SW 3.01 contains bug fixes and prevents the software-related

occurrence of error 23.

SW 4.x contains LPG functions which, however, are only enabled if the corresponding

hardware exists.

Loading the dataset for the control panel

Before the control panel display appears, the software queries the DCU version.

If the software detects a conflict between the CPU and DCU versions, the current DCU dataset

will be loaded from the CPU to the control panel.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 23 of 64

System monitoring

External safety logic

All control signals relevant to safety are monitored by a safety logic which is independent of the

software.

Monitoring of the "LD_ON" signal

The system control will only activate the "LD_ON" signal if the program is in the appropriate

system mode (Service mode, Therapy mode).

If an error occurs during monitoring, an error message will be displayed.

Monitoring of the "LD_DRIVE" signal

The "LD_DRIVE" activating signal for the laser diode driver is linked to a logic circuit.

This ensures that the failure of components or a processor or software error do not result in any

situations where safety is not guaranteed.

Monitoring via a watchdog circuit

Every time the program is started, the watchdog circuit is checked using the trigger frequency.

The laser enable signal (LD_ENABLE) will only be provided if the watchdog circuit is found to

be OK.

An software control error will result in the abortion of the program.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 24 of 64

Power monitoring

A comparator compares the

target value (P_NOM) provided by

the system control with the actual

power (P_MON).measured by the

sensor of the P detector PCB.

If the actual power measured

exceeds the target value, the

P_ERROR signal will be

generated and held by a flip-flop.

The error signal can only be reset

by switching off the system.

Monitoring of the laser power

The actual power of the laser is measured by

two independent light sensors using two

different reflections.

These laser powers are constantly monitored

by the system control.

If the difference between the target value

shown on the control panel and the actual

measured value is greater than ± 20 %, a

warning note will be displayed on the control

panel.

A difference of greater than ± 50 % will cause (Pmon)

the laser to be switched off.

An error message to this effect will be (Preal)

displayed.

External power monitoring

The light output of the laser must not exceed the target value provided by the computer. This is

monitored by external monitoring electronics and the sensors on the detector PCB.

If an error is detected, the laser diode will be switched off.

The monitoring unit reports the error to the system control by providing the P_ERROR signal.

The error message is shown on the display.

Monitoring of the shutter

The shutter is monitored using its switchover time and position.

− Switchover time: the shutter must have reached the position required within 50ms.

− Position: the shutter my only be open/closed in the appropriate system modes.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 25 of 64

Monitoring of the physician's safety filter (PSF)

When the laser is used in the Slit Lamp or ENDO applicator setting (with active PSF) , the

physician's safety filter is also monitored.

Monitoring covers:

− The switchover time: the PSF must have adopted the position required within 50 ms.

− LD_ON must only be active if the filter is in the beam path.

− The Therapy mode or Service mode can only be accessed if the PSF has been connected

and is functioning properly.

Passive physician’s safety filter

The passive PSF is not monitored.

If the user selects the passive PSF after the prompt, although an active PSF has been

connected, the filters in the connected active PSF module are swung in as long as the

ENDO applicator is used.

Controller test / current test

Before each laser pulse, the current of the laser diode is increased up to the threshold value.

If the actual, flowing current deviates from the target value by > 20 %, an error message will be

displayed.

Monitoring of the laser stop switch

The laser stop switch is constantly monitored.

Laser emission (aiming beam and therapy laser) is only possible when the laser stop switch has

not been activated.

When the laser stop is active, a note appears on the control panel.

Monitoring of the door interlock

The door interlock is constantly monitored.

Laser emission (aiming beam and therapy laser) is only possible when the door interlock has

not been activated.

When the door interlock is active, a note appears on the control panel.

Monitoring of the aiming beam unit

The aiming beam unit is constantly monitored.

A deviation from the target value by > 30 % causes an error message to be displayed.

Monitoring of the pulse duration

The pulse duration of the emitted laser pulses is monitored by an independent function.

If the actual pulse duration differs by more than 4 ms from the pulse duration set on the control

panel, an error message will be displayed.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 26 of 64

Current mode – Power mode

The laser diode can be operated in two different ways.

Current mode (I):

In the Current mode, the default for the laser diode current is set

by the system control

I_SET = I_NOM

Power mode (P):

I_SET is adjusted by the PID controller.

The gain of the PID controller is set by the system control via V_PID.

The two modes are distinguished using the system control’s I_P signal.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 27 of 64

Temperature monitoring

Heat sink temperature

− If the temperature exceeds 65° C, a warning will appear on the display and the laser will be

switched off.

− If the temperature exceeds 70° C, a warning will appear on the display and the laser and

the Peltier driver will be switched off.

− If the temperature exceeds 75° C, the whole system will be switched off.

Temperature of the laser diode

The temperature of the laser diode is stabilized using digital control.

− If there is a difference of > 1° C between the target and the actual values, a warning will be

displayed and the laser will be switched off.

The warning disappears as soon as the actual temperature is within ± 0.5° C of the target

temperature.

− If the temperature of the laser diode exceeds the limit value of 45° C, an error message will

be displayed and the laser / Peltier drivers will be switched off.

− If the laser diode temperature falls below 10° C, an error message will be displayed and the

laser / Peltier drivers will be switched off.

Temperature of the LBO crystal

The temperature of the LBO crystal is stabilized using digital control.

− If there is a difference of > 2° C between the target and actual values, a warning will be

displayed and the laser will be switched off.

The warning disappears as soon as the actual temperature is within ± 1° C of the target

temperature .

− If the temperature of the LBO crystal exceeds the limit value of 60° C, an error message will

be displayed and the laser / Peltier drivers will be switched off.

− If the LBO crystal temperature falls below 10° C, an error message will be displayed and the

laser / Peltier drivers will be switched off.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 28 of 64

Problem monitoring

The program generates error messages, warnings and notes.

Error messages

If the system detects an error, the shutter will

be closed and the laser and TEC (Peltier)

drivers deactivated.

This status can only be removed by a restart of

the system.

Exception: If the service connector has been

inserted, you can continue working in the

service mode by touching the arrow key.

Note

If an error occurs, five warning beeps

will be emitted.

CPU system errors

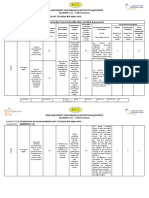

Error Description Error correction

0 Communication problems Check wiring between system control PCB and control panel connector

between control panel and

console

1 Error during NOVRAM test Replace NOVRAM (battery)

2

3

4 Error during memory test Replace CPU

5

6

7

8 HW error of processor

General errors

Error Description Error correction

12 Check cable and plugs

14 Control panel error Replace control panel

Replace CPU

Replace system control PCB

15 Touchscreen pressed for more Remove your fingers from touchscreen

than 5 seconds Replace control panel

20 Error in analog / digital Replace CPU

21 converters of CPU

23 Physician's safety filter error: Check PSF (mechanical and electrical parts), check cable to slit lamp/

too much time required for surgical microscope for defects

swinging in/out (> 50 ms)

24 Shutter error: too much time Check shutter (binding)

required for swinging in/out Unscrew Shutter PCB

(> 50 ms) Check shutter support

25 PSF not in beam path when Replace PSF

laser pulse is triggered

32 Interrupt error Replace CPU

33

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 29 of 64

Error Description Error correction

35 Actuator error Check/ replace footswitch

Replace system control PCB

36 Actuator assignment error Replace system control PCB (relays are defective)

(COMBI logic)

37 Signal monitoring error (YAG) Check YAG connecting cable

38 Wrong remote YAG II+ Check YAG connecting cable

39 message Replace CPU

40 Memory error Replace CPU (defective NOVRAM)

41 Memory error

42 Replace CPU

45 Test of shutter signal

46 Aiming beam monitoring Replace aiming beam assembly

47

48 DEMO mode error

52 External power monitoring error Replace system control PCB

53 Safety logic error

55 Processor error Replace CPU

56

57 Control panel error Replace control panel

58 Processor error

59

61 Clock frequency monitoring

error

64 Replace CPU

65

66 Watchdog error

67

68

69 Software error Load software , replace CPU

72 Temperature of laser diode too

high

73 Temperature of laser diode too

low

74 Temperature of LBO (SHG) Replace laser system

crystal too high

75 Temperature of LBO (SHG)

crystal too low

76 Temperature of heat sink too

high

81 Check cables

83 Power monitoring error Replace P- detector PCB

Replace CPU

84 AIM power monitoring error Replace aiming beam assembly

85 Power at Pmon too low

86 Power at Preal too low P-detector PCB:

87 Power at Pmon too high Adjust Pmon, Preal

88 Power at Preal too high

89 Laser light detected although Replace system control PCB

the laser was not activated Replace P- detector PCB

91 Laser is active, although the Replace CPU

display is not in the

corresponding menu

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 30 of 64

Error Description Error correction

93 Pulse duration monitoring error Replace system control PCB

Replace laser system

94 Pulse duration monitoring error Check threshold setting (SM 1)

Replace system control PCB

Replace laser system

96 No current Replace system control PCB

Replace laser system

Other CPU system errors

Error Description Error correction

100

101

102

103 CPU defective Replace CPU

104

105

106

107 Check PSU voltages

Power failure Replace PSU

Replace system control PCB

Errors resulting in the system being switched off - EMERGENCY SHUT OFF

Error Description Error correction

120 Laser diode temperature too

high: > 55 °C

Device switches off

121 Laser diode temperature too

low : < 5 °C

Device switches off

122 LBO (SHG) temperature much Replace laser system

too high

Device switches off

123 LBO (SHG) temperature much

too low

Device switches off

124 Heat sink temperature too high:

> 75°C

Device switches off

125 Laser light detected when laser Replace laser system

has not been activated

Device switches off

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 31 of 64

Internal software errors

Error Description Error correction

200 ... Software errors

400

222 Adjusted power plus transmission Replace CPU

exceed the permitted range

300 ... Software errors

308

400 Checksum error of I²C bus Replace CPU, replace LPG PCB

401 LPG position test error Defective manipulator drive, cable connection, LPG calibration

402 Zoom lens evaluation error Defective zoom lens feedback

403 Interruption of I²C connection Replace CPU, check cable connections

Power supply unit (PSU) errors

Error Description Error correction

Device cannot be Check fuses Replace fuses

switched on Check voltages using overview on page 5.7 Replace PSUt

Device switches off Check fuses Replace fuses

after intensive use Check voltages using overview on page 5.7 Replace PSU

Switch device back on after cooling (30 min) and check PSU for Replace fan

fan defect

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 32 of 64

Warning

If a critical condition is detected which can be

eliminated, the relevant error warning will be

shown on the control panel display for as long

as this error persists (but at least for 1.5

seconds).

The laser cannot be operated during this

period.

The control system switches to the STANDBY

status and 2 warning beeps are emitted.

If the critical error is no longer present, you can

quit this system status by pressing the READY

button.

Warnings for the VITE option

Since it is not possible to use all combinations of spot diameter – spot spacing – spot number,

appropriate warnings are displayed to the user in a yellow window. They disappear after the

uncorrected value has been corrected.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 33 of 64

System warnings

Note displayed Description

The doorlock is activated, please close the door. Door interlock warning

Der Türinterlock ist aktiv, bitte Tür schließen.

La porte est ouverte, fermez la porte !

Puerta esta abierta, cierrela

The Laser Stop is activated, to continue, please unlock. Laser stop

Der LASER STOP ist betätigt, bitte entriegeln.

La porte est ouverte, fermez la porte !

Laser Stop activo, cambielo.

The VISULAS YAG II plus is not available. YAG laser not ready for use

Der VISULAS YAG II plus ist nicht verfügbar.

VISULAS YAG II plus non disponible.

Error del VISULAS YAG II

No physician safety filter or slit lamp connected ! Physician's safety filter not detected

Spaltlampe oder Arztschutzfilter nicht angeschlossen !

Pas de filtre de protection ou de lampe à fente installé.

Filtro protector o lámpara de hendidura no conectado.

No fiber connected! Fiber interlock

Es ist keine Faser angeschlossen!

Verifier le faisceau!

Revise el enchufe de fibra

Foot switch not connected. Actuator not connected

Es ist kein Fußschalter angeschlossen.

Pédale de commande non connectée

El panel de mando pedal no está conectado

Temperature deviation, please wait! Temperature warning

Temperaturabweichung Bitte warten!

Divergence de température - Veuillez patienter

Alta temperatura del sistema dejele refrigerar

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 34 of 64

Warnings for YAG combination mode

Note displayed Description

Temperature VISULAS YAG II+ too high, please wait YAG temperature

VISULAS YAG II plus Temperaturalarm. Bitte warten

Temp. VISULAS YAG trop élevé. Attendez s'il

vous plait

Alta temperatura del VISULAS YAG II+ dejele

refrigerar

The doorlock is activated, please close the door. YAG door lock

Der Türinterlock ist aktiv, bitte Tür schließen.

La porte est ouverte, fermez la porte

Puerta esta abierta, cierrela.

Temperature VISULAS YAG II+ too high, please wait YAG laser head temperature

VISULAS YAG II plus Temperaturalarm. Bitte warten

Temp. VISULAS YAG trop élevé. Attendez s'il vous plait

Alta temperatura del VISULAS YAG II+ dejele refrigerar

The Laser Stop is activated, to continue, please unlock. YAG laser stop

Der LASER STOP ist betätigt, bitte entriegeln.

La porte est ouverte, fermez la porte!

Laser Stop activo, cambielo.

Please remove the prism Laser emission blocked

Bitte das Lampengehäuse ausschwenken

Déplacez la lampe s'il vous plait

Quitar lampara

An Error occured on the VISULAS YAG II plus YAG error

Beim VISULAS YAG II plus ist ein Fehler aufgetreten.

Erreur VISULAS YAG II plus.

Error en el VISULAS YAG II.

Notes on errors

If an uncritical and tolerable error is detected, a note will be displayed on the control panel.

The note will be displayed for as long as the problem persists (but at least for 1.5 seconds).

This does not affect the system control, and the user can continue working without any

restrictions.

When a problem occurs, two warning beeps are emitted.

When the note is deleted, one warning beep is emitted.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 35 of 64

Notes displayed by the system

Note displayed Description

Pulse interval matched. Pulse duration adapted to preset power

Pulsintervall wurde angepasst. See description of Service mode 1 !

Intervalle d'impulsion adapté.

El intervalo de pulso fue adaptado.

More than 20% power deviation! Power emitted differs by more than ± 20%

Mehr als 20% Leistungsabweichung! from target value.

Ecart de puissance supérieur à 20%! Check laser system or detector PCB.

Más del 20% desviación de la potencia.

The foot switch is activated. Foot switch pressed during use of the

Der Fußschalter ist betätigt. display, or foot switch does not switch.

Pédale de commande activée.

El panel de mandos pedal está activado.

Monitoring disabled, for service purpose only! System monitoring deactivated via DIL

Überwachung deaktiviert. Nur für Service-Zwecke! switch (see page 5.11) or touch panel (check

Contrôle désactivé aux seules fins d'entretien! 20%)

Vigilancia desactivada, sólo para fines de servicio!

Applicator LINK is selected, are you sure? Asks the user whether he wishes to use the

Applikator LINK selektiert, soll LINK verwendet werden? Link, as the PSF is not monitored in this

Applicateur LINK sélectionné, LINK doit-il être utilisé? case.

Aplicador LINK seleccionado, Desea utilizar LINK?

Applicator LIO is selected, are you sure? Asks the user whether he wishes to use the

Applikator LIO selektiert, soll LIO verwendet werden? indirect ophthalmoscope, as the PSF is not

Applicateur LIO sélectionné, LIO doit-il être utilisé? monitored in this case.

Aplicador LIO seleccionado, Desea utilizar LINK?

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 36 of 64

Combination mode using VISULAS YAG II plus, YAG III

In the combination mode using VISULAS YAG IIplus, YAG III, either the foot switch or the hand

switch of the slit lamp can be activated.

YAG

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 37 of 64

Control panel

DCU

The DCU controls the color display.

The DCU incorporates a Flash-Eprom in which the display data have been stored.

The laser parameters relevant to safety are refreshed on the control panel at specific intervals.

The blinking I dot indicates to the user that the control panel is functioning properly.

Buttons

The buttons are constantly monitored.

If a button is pressed for longer than 3 s, an

error message will be displayed.

Encoder

The integrated key of the encoder is constantly

monitored. If it is pressed for longer than 10

seconds, an error message will be displayed.

To prevent accidental changes from being

made to the laser parameters, a short beep will

be emitted within 3 seconds after each

parameter change.

To prevent the encoder from remaining in a prohibited intermediate position, the signals

provided by the encoder are constantly monitored.

Using the control panel

When you touch a sensitive area (button) with your finger, this area is enabled. This is indicated

by the change in the area's color (exceptions: Demo mode, date / time setting).

You can change values by turning the wheel of the encoder.

The encoder wheel can also be used as a pushbutton.

This is of importance in the Therapy mode:

When you press the encoder wheel in this mode, the power setting is always active.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 38 of 64

Dismantling the unit

Removing the housing

• Remove all connectors from the console.

• Unscrew 8 screws from the housing, pull

off the cover backward while lifting its rear

at the same time.

• Use a key for LEMO connectors to unscrew

the retaining ring for the connector of the

display cable.

• Lift the base plate at its rear and pull it

approx. 5 cm backward.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 39 of 64

• Unplug connector (1) for the EMERGENCY

OFF switch.

To do this, use a small screwdriver to press

the flap slightly away from the connector

3

1

Flap

• Remove the connector for key switch (2).

Note

Turn the connector through 45° while pulling it at the same time.

• Disconnect LIO voltage cable (3).

• Disconnect ground cable (4).

• Remove the complete base plate.

Removing the switches

• Perform the procedure “Dismantling the unit“.

• EMERGENCY OFF switch:

Use a slotted nut key to unscrew retaining ring

(5) by turning it counterclockwise.

• Key switch (6):

Use flat nose pliers to unscrew the retaining

ring by turning it counterclockwise. 5

Removing the CPU PCB

• Perform the procedure “Dismantling the unit“.

Note

The CPU PCB is directly plugged on to the

system PCB and secured in position with

four screws.

• Remove the 4 screws and remove the CPU

PCB upward.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 40 of 64

Removing the system control PCB

• Perform the procedure

“Dismantling the unit“.

• Perform the procedure

“Dismantling the unit“.

• Connect the two stay bolts for the voltage

1

supply of the laser diode using a wire

jumper (1) to prevent electrostatic charge

from building if you happen to touch the

two stay bolts, as this charge would

destroy the laser diode. Slightly loosen the

two nuts on the stay bolts.

• Remove the two screws from the ribbon-

type supply jumpers on the PCB and move

the jumpers outward until the system PCB

can be removed without any difficulty.

• Unplug all remaining connections from the

system PCB.

• Use the key for LEMO connectors to 4 4

remove the nuts of the 5 connector

sockets (2). (Note: colored rings).

Colors of the rings:

Red foot switch

Yellow interlock / doorlock

Blue service connector

• Loosen 5 screws (3) of the supporting bar.

Note

Loosen one screw after the other

by one turn at a time. 33

• Remove the supporting bar.

22

• Loosen the connection between system

control PCB and PSU by raising the PCB near connector (4).

• Remove the PCB.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 41 of 64

Removing the power supply unit

• Perform the procedure “Dismantling the unit“.

• Perform the procedure “Dismantling the unit“.

• Remove the connections concerned.

• Remove the four screws from the back of the

base plate.

• Remove the small bar.

• Pull out the supply unit sideward.

Note

The Lambda power supply exists in an old

and new version. Since the connectors for

the key switch differ in the two versions,

the delivery package of the VEGA lambda

PSU spare part 000000-1356-888 includes a complete switch-in unit consisting of a

housing, laser stop switch, key switch and connecting cable. This permits the new

power supply to be also used as replacement for the old version.

Removing the heat sink

• Perform the procedure “Dismantling the unit“.

• Perform the procedure “Dismantling the unit“.

• Unscrew six screws and remove the heat sink.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 42 of 64

Removing the electrical fan

• Perform the procedure

“Dismantling the unit“.

• Perform the procedure

“Dismantling the unit“.

• Perform the procedure

“Dismantling the unit“.

• Remove the fan base and press out the fan

in an upward direction.

Removing the resonator

• Perform the procedure

“Dismantling the unit“.

• Perform the procedure

“Dismantling the unit“.

• Perform the procedure

“Dismantling the unit“.

• Unscrew six screws and remove the

resonator from the main frame.

Note

The resonator, the optics module and

the heat sink form one unit and must

not be separated.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 43 of 64

Adjusting the touchscreen

In this procedure, the resistance values of the touchscreen panel are adjusted:

• Switch off the unit.

• Set DIL switch 2 to a different position.

• Switch on the unit.

Note

A graphical display is visible against a

gray background.

• After you have touched the screen with your

finger, touch the symbols one after the other

as they become visible.

This completes the calibration and the screen

contents of the main menu appears.

• Set DIL switch 2 back to its original position.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 44 of 64

Updating the software

A PCMCIA card is used to update the software.

• Remove the cover for the slot behind the

control panel.

• Insert the PCMCIA card.

• Switch on the unit.

Note

The update is performed automatically.

The progress of the update is visible on

the display.

• After completion of the update, switch off

the unit and remove the PCMCIA card.

• Switch the unit back on again.

Note

The software checks whether the

software status of the control panel

corresponds to the current release.

If not, the control panel's software

will be updated.

Then the software restarts the

system.

This MMI software upload can also

be forced using DIL switch 1.

• Check whether the unit is in the DEMO MODE. To switch off the Demo mode, press the

DEMO MODE button for a few seconds.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 45 of 64

Replacing and adjusting components

CPU

Note

In devices featuring the VITE option, the

CPU can only be replaced together with

the LPG PCB!

The two PCBs are paired and enabled at

CZM AG.

• Switch on the unit.

• Set Service mode I:

Note down the readings for

− Threshold

− Max. current

− Temp. LD

− Temp. SHG.

• Set Service mode II:

Note down the readings for

− Transmission SL

− Transmission LINK

− Transmission LIO

− Transmission ENDO

− V PID (0-110 mW)

− V PID (120-320 mW)

− V PID (330-750 mW)

− V PID (760-1600 mW)

− V PID (1700-2500 mW).

• Unscrew 8 housing screws, pull off the cover

backward while lifting its rear at the same time

(Dismantling the unit).

• Perform the procedure “Dismantling the unit“.

• Insert the new PCB and secure it in position

using 4 screws.

• Load the software.

• Call Service modes I and II and enter the

readings you noted down.

• Switch off the DEMO mode.

• Re-attach the cover.

Note

In devices featuring the VITE option, the

replacement of the CPU must be followed by a calibration of the Laser Position

Generator.

(see Service Instructions LSL SM-30-6023-A2 section 3.8.4)

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 46 of 64

Replacing the NOVRAM

The NOVRAM saves the following data:

From Service mode I:

− Threshold

− Max.current

− Temp.LD

− Temp.SHG

From Service mode II:

− Transmission SL

− Transmission LINK

− Transmission LIO

− Transmission ENDO

− V PID (0-110mW)

− V PID (120-320mW)

− V PID (330-750mW)

− V PID (1700-2500mW)

− System time

−

Note

If error no.1 is displayed, the NOVRAM

contains incorrect values. In this case,

replace the NOVRAM battery.

Replacing a flat battery

If still possible, use the unit in the Service mode and note down the above readings.

• Switch off the unit and pull the battery off upward.

• Insert the new battery.

• Switch on the unit and enter the readings

for:

− Treshold

− Max.current

− Temp.LD

− Temp.SHG

− Transmission SL

− Transmission LINK

− Transmission LIO

− Transmission ENDO

− V PID (0-110mW)

− V PID (120-320mW)

− V PID (330-750mW)

− V PID (1700-2500mW).

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 47 of 64

If data has been lost:

• Take the readings for:

− Threshold

− Max. current

− Temp. LD

− Temp. SHG

from the product literature and enter them.

• Perform calibration for Preal and Pmon.

• Determine the transmission values for the application units provided.

• Leave the readings entered for the controlling unit as they are:

− V PID (0-110mW)

− V PID (120-320mW)

− V PID (330-750mW)

− V PID (1700-2500mW)

Note

In devices featuring the VITE option, the Laser Position Generator needs to be

recalibrated.

Replacing the battery before it has run down

If the NOVRAM battery can be changed before it has run down, you can replace the battery

with the unit switched on.

In this way, the saved data can be retained.

System control PCB

• Perform the procedure “Dismantling the unit“.

• Install the new system control PCB in reverse

order.

• Before you can screw on the outer nuts of the

5 connector sockets, you must slightly screw

on the counternuts on the inside.

• These nuts are used to correctly position the

vertical panel of the unit.

• Place the unit on a horizontal surface and put

an angled bracket against the vertical panel of

the housing.

• Align the panel using the counternuts and

tighten the outer nuts.

Caution

The system control PCB is extremely ESD-sensitive!

Make sure to provide adequate ESD protection.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 48 of 64

Adjusting the offset

This adjustment is necessary to eliminate any voltages produced by residual light striking the

Preal sensor and any other voltages present at the operational amplifiers.

• Remove the CPU.

• Reposition the jumper from 1-2 to 2-3.

• Switch on the unit.

• Turn the potentiometer until the LED

lights yellow.

• Switch off the unit.

• Reset the jumper to the 1-2 position.

• Plug in the CPU and secure it in

position using 4 screws.

• Perform the system test.

Installing and aligning the P-detector PCB

• Secure the P-detector PCB with two

screws (1).

• Plug in the connector.

• Switch on the unit.

• Perform the following adjustments:

Service mode 1

Aim 10

Aim on

The values for real

and for mon

should be zero (0).

Tolerance: 4

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 49 of 64

• If the Pmon and / or Preal values are not within

tolerance, then the deviation caused by the

aiming beam must be eliminated by careful

rotation of polarization filter (1).

• Adjust Pmon and Preal.

1

Adjusting Pmon and Preal

The R6 potentiometer for Pmon and the R16

potentiometer for Preal on the detector PCB are

used to adjust the laser light control system (real)

and the independent monitoring system (mon) via

two sensors on the P-detector PCB.

To reduce the sensitivity of the potentiometers, additional resistors have been built in which can

be activated using the S2 (real) and S1 (mon) step switches.

Position 0 and prohibited intermediate positions are the most sensitive positions.

Sensitivity is reduced by turning the switches clockwise to position 4.

Caution

There are 2 different versions of the PCB!

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 50 of 64

Adjusting procedure:

• Perform the procedure

“Dismantling the unit“.

• Remove the cover from the laser optics

module.

• Position the power meter sensor (LM10) in

front of the laser exit port of the console.

• Switch DIL switch 5

on the CPU to the

ON position.

• Switch on the unit

• Set Service mode I.

• Set the aiming beam to level 4 and position

the power sensor in such a way that the

beam covers 2/3 of the sensor area.

− Presetting:

• Adjust the following on the display:

− Service mode I

− Duration 999 (CW)

− Driver mode current

− Set the current to approx.

10.5 A to 12.5 A.

• Press the foot switch.

• Turn both potentiometers (R6, R16)

clockwise back to the original position.

Watch the P_mon and P_real values in the

display.

Note

The lowest possible value should

be set.

• The power meter should display 1 W.

If the reading deviates by more than 0.1 W:

• Release the foot switch and correct the “Current” setting until approx. 1 W is displayed.

− Initial adjustment:

• Press the foot switch.

• Slowly turn S2 step switch (real) clockwise until the "real“ display on the laser module is

between 400 mW and 1000 mW.

• Using the R16 potentiometer, adjust the reading shown on the display of the laser module

to the same value as shown on the display of the power meter.

• Slowly turn S1 step switch (mon) clockwise until the "mon“ display on the laser module is

between 400 mW and 1000 mW.

• Using the R6 potentiometer, adjust the reading shown on the display of the laser module to

the same value as shown on the power meter.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 51 of 64

− Final adjustment:

• Make the following adjustments:

• Service mode I

- Power 1000 mW

- Duration 999 (CW)

- Driver mode power

• Press the foot switch.

• Using the R16 potentiometer, adjust the output power until the power meter reads exactly

1000 mW.

• Using the R6 potentiometer, adjust the P_mon value shown on the display of the laser

module to the same value as P_real.

• Set DIL switch 5 on the CPU back to the OFF position.

Replacing and aligning the aiming beam PCB

• Perform the procedure “Dismantling the unit“.

• Connect the control panel,

foot switch,

power switch,

laser stop switch,

power cord,

interlock connector,

service connector.

• Remove the cover from the optical system.

• Remove the shutter PCB and shutter shaft.

• Connect the dummy shutter PCB instead of

the shutter PCB.

Service Instructions VISULAS 532s (incl. VITE) Version 4: 2009-09-09

SM-30-6021-A3-en Replaces Version 3: 2005-02-23 Page 52 of 64

• Unplug connector (1) from the aiming

beam PCB.

1