Professional Documents

Culture Documents

5W2H

Uploaded by

alfredo.martinezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5W2H

Uploaded by

alfredo.martinezCopyright:

Available Formats

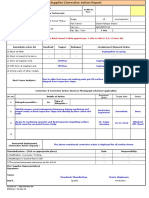

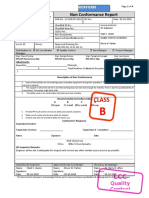

8D report

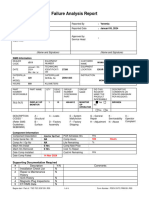

Customer plant CK3 Internal claim # Date of claim 17-Ago-23

Customer contact Cynthia cabello Nidec Site Date of QR

Customer reference Author Benito Sanchez Update of QR

QUICK RESPONSE (D1-D3)

This document must be issued within 24 hours after claim notification

D 1. Description of the problem

1.a What is the problem ? Use 5W+2H to describe what is the current situation.

What happened? No cumple con la espesificacion

Problem description Flecha sin maquinado

Why is it a problem? No se puede hacer las pruebas en EOL

Incident type Internal claim

Part number M0027029 When did it happen? 17-Ago-23

Part description Flecha Who detected it? Línea de producción CK3-L1

Traceability of nok parts D08Z202308151 Where was it detected? RT010

Recurrence non reccurent How was it detected? Area de rotor

Previous QN if recurrence non reccurent How many parts ? 1

Defect S/R no

picture / sketch

picture / sketch

nok part

ok part

1.b Problem solving team

Name Position Location Telephone Email

1.c Tools to use

FTA 5why's LLC Audit Other

1.d First analyse of problem / potential root causes

Falta de ajuste en el porceso

Samples of nok parts required in plant for analyse NG part ETA and Tracking number

D 2. Risk on similar products and processes

Walk the process with Process FMEA & Process Control Plan. Was the risk considered?

Can this defect happen on similar parts ? Comments (compulsory if yes)

Other family product

Other line

Other tools/work station

Other

D 3. Containment

Actions to detect all non-conforming parts in the process flow (add additional sheets if neded)

Sorting criterias (add additional sheets if neded)

Location in the supply chain Nb to be sorted Nb parts sorted Nb nok parts ppm Date Resp.

Parts at customer (Car maker)

Parts at customer (Tier 1)

Parts in Nidec plant

Parts at Nidec logistics platform

Parts in transport / transit

Parts at supplier / supplier platform

How are the ok parts identified ?

How are the ok paletts identified ?

First contained shipment information

Immediate actions to prevent production and delivery of nok parts ?

Actions Resp. Date plan. Date clos.

Ref. P102.01X F102.01E

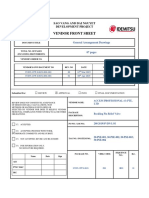

ASSIGNMENT / BREAKDOWN

WHAT ? WHO? [8] Due date [9] Done date [10]

Confirm actual situation (Quick Response PDCA) [1]

Make Factor Tree Analysis for Occurrence [2]

Make Factor Tree Analysis for Non detection [3]

Confirm root cause with 5 Why's [4]

Implement action plan [5]

Confirm efficiency of Action plan [6]

Standardize and Generalize [7]

N° ASSIGNMENT [11] RESULTS [12] WHO [13] Due date [9] Done date [10]

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Ref. P102.01X F102.01E

Ishikawa Diagram

Customer plant #VALUE! Internal claim # #VALUE! Date of claim #VALUE!

Customer contact #VALUE! Nidec Site #VALUE! Date of Ishikawa

Customer reference #VALUE! Author #VALUE! Update of Ishikawa

Material Environment Method

Machine Measurement Manpower

Ref. P102.01X F102.01E

Factor Tree Analysis Occurrence

Customer plant Internal claim # 0 Date of claim #VALUE!

Customer contact Nidec site 0 Date of FTA

Customer reference Author Benito Sanchez Update of FTA

Problem description: #VALUE!

Factor Direct

4M Factors Control point Standard OK parts NOK parts Std meet Std OK

Nb link ? Potential Root Cause

OCCURENCE

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

1 Yes No Yes

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

2

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

3

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

4

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

5

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

6

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

7

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

8

STD number and revision level ?

All validated causes (direct link or doubt) must lead to a 5 Why's analysis

Ref. P102.01X F102.01E

Factor Tree Analysis Non Detection

Customer plant Internal claim # 0 Date of claim #VALUE!

Customer contact Nidec site 0 Date of FTA

Customer reference Author Benito Sanchez Update of FTA

Problem description: #VALUE!

Factor Direct

4M Factors Control point Standard OK parts NOK parts Std meet Std OK

Nb link ? Potential Root Cause

OCCURENCE

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

1 Yes No Yes

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

2

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

3

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

4

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

5

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

6

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

7

STD number and revision level ?

WHAT is the STANDARD method/value? GOOD part taken as reference / GOOD BAD part taken as reference / BAD situation

situation taken as reference: taken as reference:

WHO is trained to the STANDARD?

WHERE is the standard available? Measurement on Real Parts / Condition of Real Measurement on Real Parts / Condition of Real

Situation: Situation:

8

STD number and revision level ?

All validated causes (direct link or doubt) must lead to a 5 Why's analysis

Ref. P102.01X F102.01E

5 Why's

Customer plant CK3 Internal claim # 0 Date of claim 17-Ago-23

Customer contact Cynthia cabello Nidec site 0 Date of 5 why's

Customer reference 0 Author Benito Sanchez Update of 5 why's

Problem description : Flecha sin maquinado

Potential Root Cause Nb. 1st WHY? How was verified? 2nd WHY ? How was verified? 3rd WHY ? How was verified? 4th WHY ? How was verified? 5th WHY ? How was verified?

OCCURENCE

NON DETECTION

SYSTEMIC

Ref. P102.01X F102.01E

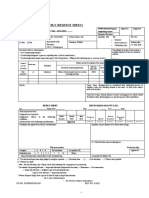

8D report

Customer plant CK3 Internal claim # 0 Date of claim 17-Ago-23

Customer contact Cynthia cabello Nidec site 0 Date of D4-D8

Customer reference 0 Author Benito Sanchez Update of D4-D8

PLAN - DO (D4-D6)

Commitment date to present D4-D5-D6 (to be filled in with the quick response) : dd/mm/yy

D 4. Root cause of occurrence FTA 5 why's

Work out the root causes using FTA and 5 why's

Root cause of occurrence :

How was the defect reproduced ?

D 5. Root cause of non detection FTA 5 why's

Work out the root causes using FTA and 5 why's

Root cause of non detection :

D 6. Countermeasure occurrence and non detection

Actions Resp. Date plan. Date clos.

CHEK - ACT (D7-D8)

Commitment date to present D7-D8 (to be filled in with the check act) : dd/mm/yy

D 7. Effectiveness of action plan

Actions to check effectiveness (to plan with part D6) Resp. Date plan. Date clos.

D 8. Lessons learned

8.1 Do following documents require an update ? 8.2 Generalization of countermeasures to similar lines/ products

Resp. Date plan. Date clos.

PFMEA

Control Plan

Work instruction

Control instruction 8.3 Internal audit (if required)

Procedure Date Results

Control gage Comments

Maintenance instruction

Lesson Learned Card

Other

Other 8.4 Validation of 8D closure by client (if requested)

Other Name / Position Date

CLOSURE OF 8D BY NIDEC MANAGEMENT

Calculated cost of

Efficiency of 8D proven Nok stocks at zero Name Cynthia cabello Date

incident

Validation by NIDEC management Decision Name Date

Management comments:

Ref. P102.01X F102.01E

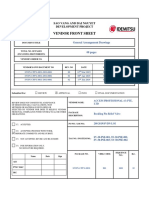

Lesson Learned Card

Customer plant Nidec Site Detection Logistics

Internal claim # Author LLC Type Occurrence Process

Date of incident Date of LLC Management Product

1. WHAT WAS THE PROBLEM? (5W + 2H) 2. WHAT IS THE CAUSE?

What happened ?

No cumple con la espesificacion

Why it is a problem ?

No se puede hacer las pruebas en EOL

When did it happen ?

17-Ago-23

Who has detected it ?

Línea de producción CK3-L1

Where has been detected ?

RT010

How has it been detected ?

Area de rotor

How many ?

0

3. DESCRIPTION OF THE APPLIED MODIFICATION

BEFORE AFTER

4) WHAT WE LEARNED?

ERADICATION CHECKING

SIGNALING

What is the countermeasure that was put in place to avoid What is the countermeasure supposed to do or make or hightlight

What is the method (who, what, how) for the countermeasures?

recurrence ? when detecting a non conformity ?

5. WHAT HAS BEEN MODIFIED ?

d. Control Plan and PFMEA

b. All documents have been

e. Maintenance instructions

validated with the operators

describe what they must do

checklists, reaction sheets,

preventive maintenance...)

according to Before/ After

j. Operators can correctly

g. Visual aids are posted

c. Procedures and work

h. Operators and other

updated and has been

a. Proces is modified

avalaible (records,5 '

functions are trained

i. Proof of training is

f. Records (start-up

instructions

meeting)

k. Other:

l. Other:

sheet

6. POTENTIAL APPLICABILITY

Product :

Line / process :

Share LLC with other sites :

Nidec approval (if required):

Quality Manager Site Director R&D Director Purchasing Director Productline Director Operations Director

Ref. P102.01X F102.01E

You might also like

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- CAPA FormDocument1 pageCAPA Formprabhat suma100% (1)

- 8D Report: Problem Solving TeamDocument2 pages8D Report: Problem Solving TeamAshok Kumar A100% (4)

- Ok Part NG: (Vendor Non-Conformance Report)Document2 pagesOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- 8M5Y Root Cause Worksheet 5Document1 page8M5Y Root Cause Worksheet 5Masood KhanNo ratings yet

- Process Failure Modes and Effects AnalysisDocument20 pagesProcess Failure Modes and Effects AnalysisHemantNo ratings yet

- Deviation Approval FORMDocument4 pagesDeviation Approval FORMFatimahAhmatNo ratings yet

- Supplier Incident Analysis: Claim NoDocument10 pagesSupplier Incident Analysis: Claim Nonitin pendharkarNo ratings yet

- en 30 Inspection ReportDocument3 pagesen 30 Inspection ReportJoaquinNo ratings yet

- A Guide To Fact Based Problem SolvingDocument56 pagesA Guide To Fact Based Problem SolvingAli AlsaadeeNo ratings yet

- 8D - One Page 8-D Report Rev 007 Duplicate PKG ID-UNITDocument7 pages8D - One Page 8-D Report Rev 007 Duplicate PKG ID-UNITEdgar LopezNo ratings yet

- Deviation PresentationDocument14 pagesDeviation PresentationyogendraNo ratings yet

- Corrective and Preventive Actıons ProcedureDocument4 pagesCorrective and Preventive Actıons Procedureevrim korı100% (1)

- Supplier 8D Report: D 1. Description of The ProblemDocument7 pagesSupplier 8D Report: D 1. Description of The ProblemDearRed FrankNo ratings yet

- VD 1233 330 Dig 001 1Document12 pagesVD 1233 330 Dig 001 1Reza AranNo ratings yet

- SOP For Handling of Out of Specification Results-1Document54 pagesSOP For Handling of Out of Specification Results-1osamatqm9No ratings yet

- Class: Non Conformance ReportDocument4 pagesClass: Non Conformance ReportStephenNo ratings yet

- RCA Training 6apr20Document84 pagesRCA Training 6apr20Ryan PertezNo ratings yet

- Root Cause Analysis Presentation (RCA)Document21 pagesRoot Cause Analysis Presentation (RCA)beriNo ratings yet

- Interested Parties List: Interested Party Int / ExtDocument81 pagesInterested Parties List: Interested Party Int / ExtAngeloNo ratings yet

- Sample Report AudioDocument33 pagesSample Report AudioraulNo ratings yet

- QRQC / 8D Form: D 1. Description of The ProblemDocument5 pagesQRQC / 8D Form: D 1. Description of The ProblemDearRed FrankNo ratings yet

- Problem Management Process Guide - Reduce Incidents & Improve IT ServiceDocument10 pagesProblem Management Process Guide - Reduce Incidents & Improve IT ServiceSandhiyan RaviNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- SVDN CPP I 0031 D01 0001 Rev.01 General Arrangement DrawingsDocument7 pagesSVDN CPP I 0031 D01 0001 Rev.01 General Arrangement DrawingsjfdlksaNo ratings yet

- 8D Report: D 1. Description of The ProblemDocument8 pages8D Report: D 1. Description of The Problemalfredo.martinezNo ratings yet

- Defect Analysis and Corrective ActionDocument3 pagesDefect Analysis and Corrective ActionHariprasanth ChandranNo ratings yet

- FORM 08 - Intervention Report - Cold SHEAR ClutchDocument2 pagesFORM 08 - Intervention Report - Cold SHEAR ClutchRamy Hassan EmaraNo ratings yet

- Package Cover Sheet Line Maintenance: Certificate of Release To ServiceDocument6 pagesPackage Cover Sheet Line Maintenance: Certificate of Release To ServiceFemi AgbanaNo ratings yet

- Protocol of failures report for lung ventilatorDocument2 pagesProtocol of failures report for lung ventilatorGalilea GalileaNo ratings yet

- Compaction Inspection Report for Emily-1 ProjectDocument9 pagesCompaction Inspection Report for Emily-1 Projectmuhammad sauqiNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument2 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- 8D Material Mal EtiquetadoDocument1 page8D Material Mal EtiquetadoantonioNo ratings yet

- Punch List: Project Name: Job No. Subcontractor's Name: Report NoDocument1 pagePunch List: Project Name: Job No. Subcontractor's Name: Report NoRjeb mohamedNo ratings yet

- FORM 08 - Intervention Report - Cold SHEARDocument3 pagesFORM 08 - Intervention Report - Cold SHEARRamy Hassan EmaraNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- 2023.01.15 Intervention Report Lance Cooling ValveDocument1 page2023.01.15 Intervention Report Lance Cooling ValveRamy Hassan EmaraNo ratings yet

- Maintenance Process Traceability CardDocument1 pageMaintenance Process Traceability Cardmohamed hamedNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument3 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- SVDN CPP I 0031 D01 0001 Rev.02 General Arrangement DrawingsDocument8 pagesSVDN CPP I 0031 D01 0001 Rev.02 General Arrangement DrawingsjfdlksaNo ratings yet

- M007-CCC-STR-MES-00005 Rev. 2.0Document102 pagesM007-CCC-STR-MES-00005 Rev. 2.0Mikku KattaNo ratings yet

- Yoseph 535 119779Document6 pagesYoseph 535 119779Heni HasanahNo ratings yet

- Waiver Request Format Rev 3Document2 pagesWaiver Request Format Rev 3manjunatha gNo ratings yet

- FAR_ZBN41205Document4 pagesFAR_ZBN41205yeremia kristianNo ratings yet

- Mahindra Bolt Loosening Issue 3.10.2017Document24 pagesMahindra Bolt Loosening Issue 3.10.2017Sridharan VenkatNo ratings yet

- IRS For AgitatorDocument3 pagesIRS For AgitatorMonaNo ratings yet

- MDR FMP 15-086Document51 pagesMDR FMP 15-086miorNo ratings yet

- SIMRA Maroc First Article Inspection ReportDocument6 pagesSIMRA Maroc First Article Inspection ReportAhmed AlmalehNo ratings yet

- Trouble Report: I. Definition of Problem / TroubleDocument2 pagesTrouble Report: I. Definition of Problem / TroubleChabilita AgquizNo ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj KhanNo ratings yet

- Hydraulic Filter 1Document2 pagesHydraulic Filter 1OUC-SECBNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- Itr-Pug (Ug Piping)Document12 pagesItr-Pug (Ug Piping)mahmoudNo ratings yet

- Painting of Pipes & Fittings-Fire Fighting SystemDocument22 pagesPainting of Pipes & Fittings-Fire Fighting SystemkiranramNo ratings yet

- Casing Cap O.D OversizeDocument2 pagesCasing Cap O.D OversizeAbhishek DahiyaNo ratings yet

- 51Q-BU-0010 - Rev.1 Plaster Works ChecklistDocument1 page51Q-BU-0010 - Rev.1 Plaster Works Checklistnazim7No ratings yet

- Non-Conformance Report IssuesDocument4 pagesNon-Conformance Report IssuesStephenNo ratings yet

- Design Organization Manual Inspection ProceduresDocument7 pagesDesign Organization Manual Inspection ProceduresDavid SiahaanNo ratings yet

- 8 DsDocument2 pages8 DsAlejandro LunaNo ratings yet

- GMR RH Tyre DefectDocument1 pageGMR RH Tyre DefectMinhal RizviNo ratings yet

- Process Traveler: Originator Cognizant Engineer Ext./Phone# Project Account NumberDocument2 pagesProcess Traveler: Originator Cognizant Engineer Ext./Phone# Project Account NumberShoaib TariqNo ratings yet

- PDE-EQS-3100-EC-00006 - 00 Technical Specification of Safety VesselDocument9 pagesPDE-EQS-3100-EC-00006 - 00 Technical Specification of Safety Vesselhgag selimNo ratings yet

- C Rail 104 Py KTC 047 1Document2 pagesC Rail 104 Py KTC 047 1sharanNo ratings yet

- 51Q-BU-0003 - Rev.1 Check List For Door, Window, Hardware, ClazingDocument2 pages51Q-BU-0003 - Rev.1 Check List For Door, Window, Hardware, Clazingnazim7No ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- Eo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofDocument7 pagesEo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofVince Renier RamosNo ratings yet

- 2924-B200-13C67-DWG-0003 - R1.0 Electrical Cable Routing and Cable Tray Layout LYE Storage AreaDocument2 pages2924-B200-13C67-DWG-0003 - R1.0 Electrical Cable Routing and Cable Tray Layout LYE Storage AreaRonti ChanyangNo ratings yet

- RMASSDocument7 pagesRMASSGabrielle Angelo PereñaNo ratings yet

- Root Cause Analysis Training PresentationDocument40 pagesRoot Cause Analysis Training PresentationGaby GNo ratings yet

- Pillar 3 UpdatedDocument118 pagesPillar 3 UpdatedmmblakoshaNo ratings yet

- $RIBX5HADocument5 pages$RIBX5HApubgsayan2021No ratings yet

- Application of 8D Methodology For ProducDocument3 pagesApplication of 8D Methodology For ProducLaura RSNo ratings yet

- 5 Why 1 How Analysis (RCA)Document4 pages5 Why 1 How Analysis (RCA)Max VioNo ratings yet

- DOE Workbook 1999Document224 pagesDOE Workbook 1999ricardoNo ratings yet

- Lahiru Anjana Kandelekamge HND-COM 002: Assignment Brief BTEC Level 4-5 HNC/HND Diploma (QCF)Document68 pagesLahiru Anjana Kandelekamge HND-COM 002: Assignment Brief BTEC Level 4-5 HNC/HND Diploma (QCF)shashinNo ratings yet

- Comparative ACRootDocument204 pagesComparative ACRootEnrique Lopez De ArroyabeNo ratings yet

- 7 Steps in Creating A Reading ProgramDocument20 pages7 Steps in Creating A Reading ProgramAnne Bacnat GabionNo ratings yet

- Lean Management ImplementationDocument34 pagesLean Management ImplementationFusi MokoenaNo ratings yet

- Problem Solving & Root Cause AnalysisDocument8 pagesProblem Solving & Root Cause AnalysisPermanapurba100% (1)

- Preteshbiswas Com 2019 05 06 Iso 450012018 Clause 10 ImproveDocument28 pagesPreteshbiswas Com 2019 05 06 Iso 450012018 Clause 10 Improvedija100% (1)

- Lean Six Sigma Green Belt Certification Course Root Cause AnalysisDocument29 pagesLean Six Sigma Green Belt Certification Course Root Cause Analysisطلال المطيريNo ratings yet

- Azure Status History - Microsoft AzureDocument6 pagesAzure Status History - Microsoft Azurebruno.miguelscribd1No ratings yet

- A Systems Approach To Root Cause Analysis and CAPA InvestigationsDocument76 pagesA Systems Approach To Root Cause Analysis and CAPA InvestigationsmadhubiochemNo ratings yet

- Information Security Governance - ManagementDocument2 pagesInformation Security Governance - ManagementMohamed ToubeneNo ratings yet

- Year ReviewDocument4 pagesYear ReviewNourNo ratings yet

- Materi Workshop CAPA BPOMDocument53 pagesMateri Workshop CAPA BPOMRidwan ArifandiNo ratings yet

- Sooksai, T.Document7 pagesSooksai, T.Katherine Diana Michue AbarcaNo ratings yet

- Analysis of Unintended Events in Hospitals: Inter-Rater Reliability of Constructing Causal Trees and Classifying Root CausesDocument9 pagesAnalysis of Unintended Events in Hospitals: Inter-Rater Reliability of Constructing Causal Trees and Classifying Root CausesMATEJ MAMICNo ratings yet