Professional Documents

Culture Documents

P&id Symobl

Uploaded by

kunallpatill95Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P&id Symobl

Uploaded by

kunallpatill95Copyright:

Available Formats

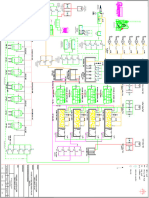

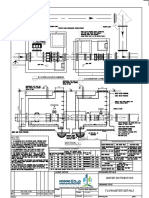

PIPING SYMBOLS PIPING SEGMENT BREAKS & LABELS FIRE AND SAFETY ITEMS MISC SYMBOLS & SPECIALTY

FIRE AND SAFETY ITEMS MISC SYMBOLS & SPECIALTY ITEMS GENERAL NOTES

GROUP BREAK HYDRANT

PRIMARY PIPING

BREAKS SERVICE CODE, LINE NUMBER

LINE CLASS. TRIANGLE PRESSURE RELIEF VALVE SWING ELBOW

SECONDARY PIPING POINTS TO LINE CHANGED.

HYDRAULIC PIPING A RESTRICTION ORIFICE

B FIRE MONITOR VACUUM RELIEF VALVE

A

A B M

UNDERGROUND PIPING MOTORIZED VALVE

SC SAMPLE CONNECTION

LINE CLASS BREAK PRESSURE / VACUUM RELIEF VALVE

XXX

FUTURE PIPING POST INDICATOR VALVE

INDICATES CHANGE IN LINE CLASS

NOTES

EXISTING PIPING P

AF183N AR183N SAMPLE COOLER

1. STEAM TRAP PROVIDED WITH INTEGRATED FILTER.

SS-EW SAFETY SHOWER AND EYEWASH

HEAT TRACED PIPING PILOT OPERATED RELIEF VALVE 2. STEAM TRAP INLET AND OUTLET NOZZLE SIZE IS INDICATED ON APPLICABLE P&IDs.

OUTSIDE BUILDINGS

PROPER REDUCER AND EXPANDER TO BE SELECTED BASED ON INLET / OUTLET

INSULATION BREAK LINE SIZE AND STREAM TRAP NOZZLES SIZE.

JACKETED OR DOUBLE

CONTAINMENT PIPING INDICATES CHANGE IN INSULATION 3. ITEM IDENTIFICATION CODE. 2

EW SAFETY EYEWASH OUTSIDE BUILDINGS

PULSATION DAMPENER 4. DELETED.

FREE DRAINING ATMOSPHERIC PRESSURE RELIEF VALVE TCMPL-X-R-0086

FREE DRAINING 5. BYPASS SIZE SAME AS STEAM LINE SIZE.

0.2 % HC NO

SS-EW SAFETY SHOWER AND EYEWASH 2

SLOPE RUPTURE DISC

INSIDE BUILDINGS

D DETONATION ARRESTOR

NO POCKET

NO POCKET TRACING BREAK EW EYEWASH INSIDE BUILDINGS

25-WS-XXXX-AF183N-HW

25-MC-XXXX-AF193S-HW

25-MS-XXXX-AF192S-HW

25-PA-XXXX-AF183N-NN

AUTO RECIRCULATION VALVE

25-LI-XXXX-AF182S-NN

AF183N

AF192S

BATTERY LIMIT INDICATES CHANGE IN TRACING TYPE

F FLAME ARRESTOR X-FA-YYY

123

111

RESERVE

116

PACKAGE LIMIT

109

ST RESERVE AIR SUPPLY ANGLE BLOWDOWN VALVE

113

AIR SUPPLY

PIPING CONNECTORS MANUAL AIR RELEASE VALVE

M S IN-LINE SILENCER

PID CONTINUATION ARROW LIMIT OF SUPPLY SLIDE VALVE

MIN.

WITHIN UNIT MS

INDICATES A CHANGE IN RESPONSIBILITY SPK SPRINKLER SYSTEM

SERVICE DESCRIPTION 4-WAY PLUG VALVE DN

CONNECTOR NUMBER XXXX DWG. NUMBER

XXX MFR S VENT SILENCER 25

TO/FROM REMARKS WCS WET CHEMICAL SYSTEM STEAM

DIVERTER VALVE-WYE TRAP

SINGLE FLOW

EQUIPMENT NOZZLE CONNECTIONS T1

P9 9KG DRY POWDER EXTINGUISHER HOSE HOSE HOSE HOSE

SERVICE DESCRIPTION COUPLING COUPLING COUPLING COUPLING

CONNECTOR NUMBER FLANGED NOZZLE ATMOSPHERIC VENT

XXXX DWG. NUMBER

XXX SIGHT GLASS

6KG CO2 EXTINGUISHER UTILITY STATION ARRANGEMENT

TO/FROM REMARKS C6

FLANGED NOZZLE ON SIDE OF VESSEL

3

DUAL FLOW WELDED NOZZLE EXHAUST / STEAM HEAD X-STH-YYYY

DETAIL A

HR WATER HOSE REEL VENT COVER

STEAM TRAP FOR DRIP LEG

PID CONTINUATION ARROW INSTRUMENT CONNECTION

BETWEEN UNITS

P&ID REPRESENTATION EXPANDED REPRESENTATION

SERVICE DESCRIPTION SPRAY NOZZLE (FULL CONE TYPE)

CONNECTOR NUMBER XXXX DWG. NUMBER

MW MANWAY

INJECTION NOZZLE S SEPARATOR

TO/FROM REMARKS SPRAY NOZZLE (BLADE TYPE) T1

ST

SINGLE FLOW

MW MANWAY 20 20

DUPLEX STRAINER

SERVICE DESCRIPTION 1

BREATHER

CONNECTOR NUMBER XXX DWG. NUMBER

XXXX

TO/FROM REMARKS HH

HANDHOLE

DUAL FLOW T-TYPE STRAINER

UL UNLOAD CONNECTION

PID - UFD CONTINUATION EXPANSION JOINT

2

CONNECTOR NUMBER XXX DWG. NUMBER

XXXX

INSPECTION OR FITTINGS

SAFETY HATCH Y-TYPE STRAINER DETAIL B

TO/FROM REMARKS FLANGE STEAM TRAP FOR PROCESS ITEMS 2

ON UFD CALIBRATION BOTTLE

BLIND FLANGE P&ID REPRESENTATION EXPANDED REPRESENTATION

XXXX

VALVES

CONNECTOR NUMBER

LINE SERVICE CODE YY CONE STRAINER

ON PID DWG.NO. GATE VALVE FLANGE SET T2

SOCKET FILTER ST

CHECK VALVE

DRAIN CONNECTORS UNION

20 20

INLINE BASKET STRAINER (TEMPORARY)

STOP CHECK VALVE

5

CLOSED DRAIN

CAP

GLOBE VALVE BLEED RING

CONNECTOR NUMBER XXXX

BUTTERFLY VALVE

LINE SERVICE CODE YY BASKET FILTER

CONCENTRIC REDUCER

DWG.NO. NEEDLE VALVE VORTEX BREAKER 2 25.11.2019 ISSUED FOR CONSTRUCTION- FINAL A. Waykole

B. Hivet / H. Al

Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. Al

1 13.05.2019 ISSUE FOR CONSTRUCTION 2 A. Waykole Jarrah / A. Lo Verso D. Ballardini

OPEN DRAIN BALL VALVE PSV B. Hivet / H. Al

ECCENTRIC REDUCER ILO 0 21.12.2018 ISSUE FOR CONSTRUCTION 1 A. Waykole Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. AI

DRAIN 3-WAY BALL VALVE FILTER B 21.09.2018 ISSUE FOR DESIGN A. Waykole Jarrah A. Lo Verso

3 INTERLOCKED VALVES (MECHANICAL LINK)

LINE SERVICE CODE FUNNEL A 10.05.2018 ISSUE FOR APPROVAL A. Waykole

B. Hivet / H. AI

A. Lo Verso

D2 3 ILO

Jarrah

EX:OILY WATER SEWER X-ILK-XXXX Issue Date Prepared By Checked By Approved By

PLUG VALVE HOSE CONNECTION 3 Ред. Дата Purpose Of Issue Цель выпуска Разраб.

X-HSC-YYYY KEY MECHANICAL

Проверил Утв.

INTERLOCK

DIAPHRAGM VALVE QUICK COUPLING SWAGELOK-TYPE OR EQUIVALENT T STEAM TRAP X-STT-YYYY

TECNIMONT IDENTIFICATION CODE

MULTIPORT VALVES 3-WAY VALVE

SEE DETAIL A/B ISOLATION KIT X-ISK-YYY JSC Gazpromneft - Omsk Refinery Идентификационный код Текнимонт

Job-EC-Type-N°

Omsk - Russian Federation

FULL PRESS. CLASS BLANK & SPACER 4019-XZ-DM-000011TE

АО "Газпромнефть - ОНПЗ"

(NORM OPEN) PERMANENTLY INSTALLED FLEXIBLE HOSE CHEMICAL SEAL / DIAPHRAGM SHEET Лист DOC. CLASS. ISSUE

4-WAY VALVE Омск - Российская Федерация 1 of 1 A 2

Согласовано

FLOW THRU

CLIENT IDENTIFICATION CODE

MAIN Delayed Coking Unit (DCU) Идентификационный код Заказчика

PINCH VALVE FULL PRESS. CLASS BLANK & SPACER REVISION CLOUD

(NORM CLOSED) PERMANENTLY INSTALLED REMOVABLE SPOOL Установка замедленного коксования ONPZ-ORU-RD-7821-000

RS

-TX-0002

ANGLE VALVE ОАО "Газnромнефmь - ОНПЗ"

Взам. инв. N

TITLE

FLOW THRU

FIGURE 8 (NORMALLY OPEN) XX REVISION INDEX Наименование PIPING AND INSTRUMENTATION DIAGRAM

BRANCH ROTARY VALVE

PERMANENTLY INSTALLED RS ELBOW TYPE REMOVABLE SPOOL SYMBOLOGY LEGEND SHEET

INDICATE NORMAL FLOW PATH

WITH DIRECTIONAL ARROW SCALE ORIG. SIZE

Y ANGLE GLOBE VALVE Масштаб 1:1 Исх. размер А1

(TYP FOR ALL MULTIPORT VALVES) R DRIP / FLUSH RING

Подп. и дата

GENERIC DAMPER / LOUVER

FIGURE 8 (NORMALLY CLOSED)

PERMANENTLY INSTALLED

X-SP-YYYY SP ITEM LABEL ONPZ-ORU-RD-7821-000-TX

2 4 Зам 112-19 25.11.2019 АО "Газпромнефmь - ОНПЗ"

ROTARY GLOBE / PLUG VALVE WELDED CONNECTION NOTE REFERENCE SYMBOL Изм. Кол.уч. Лист N док. Подп. Дата

SEAL VESSEL WITH

XX (XX = NOTE NUMBER, HAND OPERATED PUMP Разраб. A. Waykole 25.11.2019 Установка замедленного коксования Стадия Лист Листов

2 ROTATE ARROW AS REQUIRED) B. Hivet / H. Al Jarrah /

Проверил ОАО "Газпромнефmь - ОНПЗ"

подл.

25.11.2019

PLUG

A. Lo Verso

Р 2

Гл.спец. D. Ballardini 25.11.2019

EARTHING

CONNECTION PIPING AND INSTRUMENTATION DIAGRAM

Инв. N

TRANSITION PIECE X-SP-3XX Н. контр. D. Ballardini 25.11.2019

SYMBOLOGY LEGEND SHEET

ГИП V. Petrovich 25.11.2019 Текнимонт

Формат A1

GENERAL NOTES

3

1 1

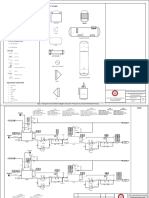

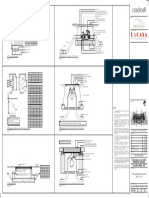

PUMPS COMPRESSORS & BLOWERS HEAT EXCHANGERS 4

HORIZONTAL

CENTRIFUGAL PUMP

POSITIVE TEMA TYPE BEM

DISPLACEMENT BLOWER

TEMA TYPE BEU

POSITIVE

DISPLACEMENT PUMP

TEMA TYPE AEM

CENTRIFUGAL BLOWER

NOTES

1. MOTORS ARE SHOWN HERE TO ILLUSTRATE DRIVER ORIENTATION.

TEMA TYPE AEL

2. LENGTH VARIES DEPENDING UPON DEPTH OF SUMP.

3. REFER TO TEMA FOR TYPES OTHER THAN THOSE SHOWN.

VERTICAL 4. EXCHANGERS SHOWN HERE REPRESENT SINGLE PASS SHELL AND EVEN NUMBER OF TUBE PASSES.

INLINE PUMP

CENTRIFUGAL COMPRESSOR

TEMA TYPE NEN

TEMA TYPE AES

LIQUID RING

VACUUM PUMP

TEMA TYPE BKU

AIR COOLER

(WITH LOOVERS AND

RECIPROCATING COMPRESSOR STEAM COIL OPTIONAL)

CENTRIFUGAL

2 SUMP PUMP

M M

SCREW COMPRESSOR

PLATE AND FRAME EXCHANGER

VERTICAL CAN PUMP

DRIVERS

HAIRPIN

MULTI TUBE TYPE

ELECTRIC MOTOR

PROGRESSIVE CAVITY PUMP

HAIRPIN

DOUBLE PIPE TYPE

TURBINE DRIVER

SCREW PUMP

B. Hivet / H. Al

2 25.11.2019 ISSUED FOR CONSTRUCTION- FINAL A. Waykole Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. Al

DIESEL ENGINE 1 13.05.2019 ISSUE FOR CONSTRUCTION 2 A. Waykole D. Ballardini

SPIRAL EXCHANGER Jarrah / A. Lo Verso

B. Hivet / H. Al

0 21.12.2018 ISSUE FOR CONSTRUCTION 1 A. Waykole Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. AI

B 21.09.2018 ISSUE FOR DESIGN A. Waykole Jarrah A. Lo Verso

B. Hivet / H. AI

PROPORTIONING PUMP AND MOTOR A 10.05.2018 ISSUE FOR APPROVAL A. Waykole Jarrah A. Lo Verso

Issue Date Prepared By Checked By Approved By

Ред. Дата Purpose Of Issue Цель выпуска Разраб. Проверил Утв.

EXCHANGER

AIR PREHEATERS (GENERIC) JSC Gazpromneft - Omsk Refinery

TECNIMONT IDENTIFICATION CODE

Идентификационный код Текнимонт

Job-EC-Type-N°

Omsk - Russian Federation

4019-XZ-DM-000021TE

АО "Газпромнефть - ОНПЗ"

SHEET Лист DOC. CLASS. ISSUE

Омск - Российская Федерация 1 of 1 A 2

Согласовано

EXCHANGER CLIENT IDENTIFICATION CODE

A DIAPHRAGM PUMP AND AIR DRIER (GENERIC) Delayed Coking Unit (DCU) Идентификационный код Заказчика

Установка замедленного коксования ONPZ-ORU-RD-7821-000

-TX-0003

ОАО "Газnромнефmь - ОНПЗ"

Взам. инв. N

TITLE

AIR PREHEATER AIR PREHEATER 2 ELECTRICAL EXCHANGER Наименование PIPING AND INSTRUMENTATION DIAGRAM

SYMBOLOGY EQUIPMENT

SCALE ORIG. SIZE

Масштаб 1:1 Исх. размер А1

Подп. и дата

ONPZ-ORU-RD-7821-000-TX

2 0 Зам 112-19 25.11.2019 АО "Газпромнефmь - ОНПЗ"

Изм. Кол.уч. Лист N док. Подп. Дата

Разраб. A. Waykole 25.11.2019 Установка замедленного коксования Стадия Лист Листов

B. Hivet / H. Al Jarrah /

Проверил ОАО "Газпромнефmь - ОНПЗ"

подл.

25.11.2019

A. Lo Verso

Р 3

Гл.спец. D. Ballardini 25.11.2019

PIPING AND INSTRUMENTATION DIAGRAM

Инв. N

Н. контр. D. Ballardini 25.11.2019

SYMBOLOGY EQUIPMENT

ГИП V. Petrovich 25.11.2019 Текнимонт

Формат A1

GENERAL NOTES

HEATERS COLUMNS & VESSELS

M

COOLING TOWER

HORIZONTAL VESSEL HORIZONTAL VESSEL WITH BOOT

COVERED BASIN

NOTES

SUMP

COOLING TOWER

FLAT TOP VESSEL

COLUMNS DETAILS

DEMISTER

SINGLE PASS

FURNACE

SPARY NOZZEL

PACKED SECTION

COKE VESSEL

CHIMNEY

TWO PASS

BURNER LEAD

DUCT WITH

AIR DOOR

DRAW OFF

AIR COOLER

MANWAY

GENERIC TRAY

VORTEX BREAKER 2 25.11.2019 ISSUED FOR CONSTRUCTION- FINAL A. Waykole

B. Hivet / H. Al

Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. Al

1 13.05.2019 ISSUE FOR CONSTRUCTION 2 A. Waykole Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. Al

0 21.12.2018 ISSUE FOR CONSTRUCTION 1 A. Waykole Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. AI

B 21.09.2018 ISSUE FOR DESIGN A. Waykole Jarrah A. Lo Verso

VERTICAL VESSEL COLUMN REACTOR COLUMN

B. Hivet / H. AI

A 10.05.2018 ISSUE FOR APPROVAL A. Waykole Jarrah A. Lo Verso

Issue Date Prepared By Checked By Approved By

Ред. Дата Purpose Of Issue Цель выпуска Разраб. Проверил Утв.

TECNIMONT IDENTIFICATION CODE

TANKS MISCELLANEOUS JSC Gazpromneft - Omsk Refinery Идентификационный код Текнимонт

Job-EC-Type-N°

Omsk - Russian Federation

4019-XZ-DM-000031TE

АО "Газпромнефть - ОНПЗ"

SHEET Лист DOC. CLASS. ISSUE

Омск - Российская Федерация 1 of 1 A 2

Согласовано

CLIENT IDENTIFICATION CODE

Delayed Coking Unit (DCU) Идентификационный код Заказчика

Установка замедленного коксования ONPZ-ORU-RD-7821-000

-TX-0004

ОАО "Газnромнефmь - ОНПЗ"

Взам. инв. N

TITLE

Наименование PIPING AND INSTRUMENTATION DIAGRAM

AGITATOR / MIXER DESUPERHEATER SYMBOLOGY EQUIPMENT

SCALE ORIG. SIZE

Масштаб 1:1 Исх. размер А1

Подп. и дата

ONPZ-ORU-RD-7821-000-TX

FILTER

2 0 Зам 112-19 25.11.2019 АО "Газпромнефmь - ОНПЗ"

Изм. Кол.уч. Лист N док. Подп. Дата

Разраб. A. Waykole 25.11.2019 Установка замедленного коксования Стадия Лист Листов

B. Hivet / H. Al Jarrah /

Проверил ОАО "Газпромнефmь - ОНПЗ"

подл.

25.11.2019

A. Lo Verso

Р 4

Гл.спец. D. Ballardini 25.11.2019

INTERNAL FLOATING ROOF TANK EXTERNAL FLOATING ROOF TANK CONE ROOF TANK LAUNCHER / RECEIVER EJECTOR / EDUCTOR STATIC MIXER PIPING AND INSTRUMENTATION DIAGRAM

Инв. N

Н. контр. D. Ballardini 25.11.2019

SYMBOLOGY EQUIPMENT

ГИП V. Petrovich 25.11.2019 Текнимонт

Формат A1

GENERAL NOTES

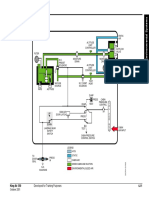

INSTRUMENT LINE SYMBOLS INSTRUMENT IDENTIFICATION LETTERS GENERAL INSTRUMENT SYMBOLS

1. ALL TEMPERATURE ELEMENTS SHALL BE FLANGED IN ACCORDANCE WITH THE JOB DESIGN SPECIFICATION FOR

INSTRUMENT (DOC. NO. 2491-7821-JSD-1540-01) AND WITH THE FEED TECHNICAL DESIGN ASSIGNMENT.

FIRST-LETTER SUCCEEDING-LETTERS DISCRETE SHARED DISPLAY AND COMPUTER SYSTEM AND

INSTRUMENT SUPPLY LOCATION/ ACCESSIBILITY ESD PLC

INSTRUMENTS CONTROL (DCS) SOFTWARE 2. DELETED.

OR CONNECTION PROCESS

MEASURED OR READOUT OR OUTPUT FIELD MOUNTED

MODIFIER MODIFIER

INITIATING VARIABLE PASSIVE FUNCTION FUNCTION 1. FIELD OR LOCALLY MOUNTED.

PNEUMATIC SIGNAL A ANALYSIS NOT TO BE USED ALARM NOT TO BE USED NOT TO BE USED 2. ACCESSIBLE TO AN OPERATOR AT DEVICE.

B BURNER, FLAME, COMBUSTION NOT TO BE USED NOT TO BE USED NOT TO BE USED NOT TO BE USED 3. LOCALLY INSTALLED COMPUTER.

C NOT TO BE USED NOT TO BE USED NOT TO BE USED CONTROLLER NOT TO BE USED

ELECTRIC SIGNAL PRIMARY LOCATION NORMALLY ACCESSIBLE TO AN OPERATOR

D DENSITY DIFFERENTIAL NOT TO BE USED NOT TO BE USED NOT TO BE USED

E VOLTAGE, ELECTRIC VALVE NOT TO BE USED SENSOR (PRIMARY ELEMENT) NOT TO BE USED NOT TO BE USED 1. CENTRAL OR MAIN CONTROL ROOM.

CAPILLARY TUBING 2. FRONT OF MAIN PANEL OR CONSOLE MOUNTED.

F FLOW RATIO (FRACTION) NOT TO BE USED NOT TO BE USED NOT TO BE USED

(FILLED SYSTEM) 3. VISIBLE ON VIDEO DISPLAY.

GLASS, GAUGE, 4. ACCESSIBLE TO AN OPERATOR AT DEVICE OR CONSOLE.

G GROUND OR EARTH NOT TO BE USED NOT TO BE USED NOT TO BE USED

VIEWING DEVICE 5. COMPUTER ACCESS FROM MAIN PANEL.

SOFTWARE OR DATA LINK H HAND NOT TO BE USED NOT TO BE USED HIGH HIGH HIGH (TRIP FUNC.)

I CURRENT (ELECTRICAL) NOT TO BE USED INDICATE NOT TO BE USED NOT TO BE USED PRIMARY LOCATION NORMALLY INACCESSIBLE TO

AN OPERATOR

J POWER MULTIPLEXED SCANNING NOT TO BE USED NOT TO BE USED NOT TO BE USED

SERIAL LINK K TIME, TIME SCHEDULE TIME RATE OF CHANGE 1. CENTRAL OR MAIN CONTROL ROOM.

NOT TO BE USED NOT TO BE USED NOT TO BE USED

2. REAR OF PANEL OR CABINET MOUNTED.

L LEVEL NOT TO BE USED LIGHT LOW LOW LOW (TRIP FUNC.)

3. ESD INTERLOCK.

M MOTOR MOMENTARY/PULSED NOT TO BE USED NOT TO BE USED NOT TO BE USED 4. NOT NORMALLY ACCESSIBLE TO AN OPERATOR AT

FOUNDATION FIELDBUS

N TORQUE NOT TO BE USED NOT TO BE USED NOT TO BE USED NOT TO BE USED DEVICE OR CONSOLE.

WIRELESS, NUCLEAR OR O PHASE ANGLE NOT TO BE USED RESTRICTION NOT TO BE USED NOT TO BE USED

AUXILIARY LOCATION NORMALLY ACCESSIBLE TO AN OPERATOR

UNGUIDED ELECTROMAGNETIC P PRESSURE, VACCUM NOT TO BE USED POINT (TEST) CONNECTION NOT TO BE USED NOT TO BE USED

Q QUANITY, COMPOSITION, 1. SECONDARY OR LOCAL CONTROL ROOM.

SIGNAL INTEGRATE, TOTALIZE NOT TO BE USED NOT TO BE USED NOT TO BE USED 2. FIELD OR LOCAL CONTROL PANEL.

CONCENTRATION

3. FRONT OF SECONDARY OR LOCAL PANEL MOUNTED.

HYDRAULIC SIGNAL R RADIATION NOT TO BE USED RECORD NOT TO BE USED NOT TO BE USED 4. VISIBLE ON VIDEO DISPLAY.

S SPEED, FREQUENCY SAFETY SWITCH SWITCH NOT TO BE USED 5. COMPUTER ACCESS FROM AUXILIARY PANEL.

ELECTROMAGNETIC T TEMPERATURE NOT TO BE USED NOT TO BE USED REMOTE TRANSMIT NOT TO BE USED

AUXILIARY LOCATION NORMALLY INACCESSIBLE TO

SONIC, OPTICAL U MULTIVARIABLE, SHUTOFF VALVE NOT TO BE USED MULTIFUNCTION MULTIFUNCTION MULTIFUNCTION NOTES

AN OPERATOR

V VIBRATION, VISCOSITY VALVE, DAMPER, VALVE (SELF ACTUTED

NOT TO BE USED NOT TO BE USED 1. SECONDARY OR LOCAL CONTROL ROOM.

LOUVER CONTROL VALVE OR SOLENOID)

2. FIELD OR LOCAL CONTROL PANEL.

W WEIGHT, FORCE NOT TO BE USED WELL/PROBE NOT TO BE USED NOT TO BE USED 3. REAR OF SECONDARY OR LOCAL PANEL OR CABINET

X STATE, ON/OFF VALVE X AXIS STATE UN CLASSIFIED UN CLASSIFIED NOT TO BE USED MOUNTED. EXAMPLES OF CONTROL VALVES ARRANGEMENT TO BE APPLIED BY EPSCM CONTRACTOR IN THE NEXT ISSUE OF PIDS,

RELAY, COMPUTE 4. NOT VISIBLE ON VIDEO DISPLAY. TO ALL CONTROL VALVES.

Y MECHANISM DRIVE Y AXIS DCS FUNCTION NOT TO BE USED NOT TO BE USED 5. NOT NORMALLY ACCESSIBLE TO AN OPERATOR AT DEVICE

CONVERT, SOLENOID

Z POSITION, DIMENSION Z AXIS NOT TO BE USED MULTIFUNCTION NOT TO BE USED OR CONTROL.

PRIMARY ELEMENT SYMBOLS (FLOW) SYMBOLS AND FUNCTION IDENTIFICATIONS INSTRUMENT VALVE CONTROL VALVE FAILURE INSTRUMENT CONNECTORS

S PID CONTINUATION ARROW BETWEEN UNITS

XX

GENERAL SYMBOL IN-LINE

TWO-WAY ON-OFF SOLENOID VALVE

ELEMENT XX=FS, FG, FE, FT

CONNECTOR NUMBER XXXX DWG. NUMBER

MAGNETIC S TO/FROM REMARKS FOR ELECTRIC PNEUMATIC ACTUATOR

XXX

REFER TO LIST BELOW FOR IDENIFICATION ANGLE ON-OFF SOLENOID VALVE

TURBINE OR PROPELLER XXX: FO FAIL TO OPEN POSITION

SUM HIGH LIMITER HIGH SELECTOR

S

ULTRASONIC FC FAIL TO CLOSED POSITION

FOUR-WAY PLUG OR BALL ON-OFF SOLENOID VALVE PID CONTINUATION ARROW WITHIN UNITS

DIVIDE LOW LIMITER LOW SELECTOR ARROWS INDICATES DE-ENERGIZED FLOW PATHS

FL FAIL LOCKED IN LAST POSITION

VORTEX EXTRACT DIFFERENCE MULTIPLY

X

SQ. RT. S FLO FAIL LOCKED AT LAST POSITION DRIFT OPEN CONNECTOR NUMBER XXXX DWG. NUMBER

THREE-WAY ON-OFF SOLENOID VALVE

PITOT TUBE d/dt DERIVATIVE f(x) GENERIC FUNCTION USER DEFINED ARROWS INDICATES DE-ENERGIZED FLOW PATH TO/FROM REMARKS FOR FOUNDATION FIELD BUS PNEUMATIC ACTUATOR

FLC FAIL LOCKED AT LAST POSITION DRIFT CLOSED

n

EXPONENTIAL

CORIOLIS n AVERAGE BIAS X

DEO DE-ENERGIZED TO OPEN

Mo3 MIDDLE OF 3 DEV DEVIATION 2oo3 2 OUT OF 3 VOTING DEC DE-ENERGIZED TO CLOSED

FLOW NOZZLE PRESSURE REDUCING REGULATOR

SET POINT MEDIAN (SELF-CONTAINED)

SP MED 2oo2 2 OUT OF 2 VOTING

VENTURI

PV PROCESS VARIABLE 1oo2 1 OUT OF 2 VOTING

WEDGE METER BACK PRESSURE REGULATOR

RSP REMOTE SET POINT COMP COMPENSATION

(SELF-CONTAINED)

WEIR */* CONVERSION INPUT/ OUTPUT

TD TIME DELAY FUNCTION

ACTUATOR PRESSURE SAFETY VALVE REFERENCE

L LL H HH SOFTWARE ALARM

POSITIVE DISPLACEMENT LOW/LOW LOW / HIGH / HIGH HIGH BACK PRESSURE REGULATOR INLET NOZZLE DIA

SOFTWARE CONTROL THRESHOLDS W/EXTERNAL TAP (mm)

CL CH

ORIFICE IN QUICK LOW/ HIGH GENERIC ACTUATOR ORIFICE

CHANGE FITTING SPRING-DIAPHRAGM ACTUATOR

*/* A ANALOG H HYDRAULIC OUTLET NOZZLE DIA

TARGET (mm)

B BINARY I CURRENT PRESSURE REDUCING REGULATOR

W/EXTERNAL TAP SPRING-DIAPHRAGM ACTUATOR SAFETY VALVE

D DIGITAL O ELECTROMAGENETIC WITH POSITIONER 80K100

FI TAG Pset @ Mpag

ROTAMETER

E VOLTAGE P PNEUMATIC

LINEAR PISTON ACTUATOR

F FIBER OPTIC R RESISTANCE (ELECTRICAL)

FG DIFFERENTIAL PRESSURE SINGLE ACTING SPRING OPPOSED

FLOW GLASS REDUCING REGULATOR DOUBLE ACTING

FLOW CONDITIONING DEVICES

(e.g STRAIGHTENING VANES) LINEAR PISTON ACTUATOR

WITH POSITIONER

V-CONE OR AND TEMPERATURE REGULATOR

LOGIC "OR" FUNCTION LOGIC "AND" FUNCTION FILLED SYSTEM TYPE

THERMAL M

ROTARY MOTOR OPERATED ACTUATOR 2 25.11.2019 ISSUED FOR CONSTRUCTION- FINAL A. Waykole

B. Hivet / H. Al

Jarrah / A. Lo Verso D. Ballardini

B. Hivet / H. Al

RESTRICTION ORIFICE, 1 13.05.2019 ISSUE FOR CONSTRUCTION 2 A. Waykole Jarrah / A. Lo Verso D. Ballardini

ORIFICE PLATE ON-OFF VALVE 0 21.12.2018 ISSUE FOR CONSTRUCTION 1 A. Waykole

B. Hivet / H. Al

Jarrah / A. Lo Verso D. Ballardini

WITH SIDE HAND WHEEL E/H

OTHER FUNCTIONS AS PER ISA-S5.1 ELECTRO/HYDRAULIC ACTUATOR B 21.09.2018 ISSUE FOR DESIGN A. Waykole

B. Hivet / H. AI

Jarrah A. Lo Verso

B. Hivet / H. AI

MULTISTAGE RESTRICTION A 10.05.2018 ISSUE FOR APPROVAL A. Waykole Jarrah A. Lo Verso

ORIFICE Issue Date

Purpose Of Issue Цель выпуска Prepared By Checked By Approved By

MODULATING SOLENOID ACTUATOR Ред. Дата Разраб. Проверил Утв.

S

SOLENOID ACTUATOR FOR

PROCESS ON-OFF VALVE

SWITCH VALVE TECNIMONT IDENTIFICATION CODE

JSC Gazpromneft - Omsk Refinery Идентификационный код Текнимонт

Job-EC-Type-N°

Omsk - Russian Federation

ACTUATOR WITH SIDE-MOUNTED HANDWHEEL 4019-XZ-DM-000041TE

АО "Газпромнефть - ОНПЗ"

SHEET Лист DOC. CLASS. ISSUE

Омск - Российская Федерация 1 of 1 A 2

Согласовано

CLIENT IDENTIFICATION CODE

ACTUATOR WITH TOP-MOUNTED HANDWHEEL Delayed Coking Unit (DCU) Идентификационный код Заказчика

Установка замедленного коксования ONPZ-ORU-RD-7821-000

MISCELLANEOUS SYMBOLS CORROSION MONITORING MANUAL ACTUATOR ОАО "Газnромнефmь - ОНПЗ"

-TX-0005

Взам. инв. N

HAND ACTUATOR

TITLE

Наименование PIPING AND INSTRUMENTATION DIAGRAM

0 R

RESET

INSTRUMENT SYMBOLOGY

CX

SCALE ORIG. SIZE

PILOT LIGHT OR GAUGE GLASS ILLUMINATOR X: Масштаб 1:1 Исх. размер А1

C: CORROSION COUPON

Подп. и дата

M: CORROSION PROBE

PRESSURE BALANCED DIAPHRAGM

ONPZ-ORU-RD-7821-000-TX

2 0 Зам 112-19 25.11.2019 АО "Газпромнефmь - ОНПЗ"

Изм. Кол.уч. Лист N док. Подп. Дата

DUAL FUNCTION OR INSTRUMENTS

SHARING COMMON HOUSING Разраб. A. Waykole 25.11.2019 Установка замедленного коксования Стадия Лист Листов

B. Hivet / H. Al Jarrah /

Проверил ОАО "Газпромнефmь - ОНПЗ"

подл.

25.11.2019

A. Lo Verso

Р 5

Гл.спец. D. Ballardini 25.11.2019

PIPING AND INSTRUMENTATION DIAGRAM

Инв. N

Н. контр. D. Ballardini 25.11.2019

INSTRUMENT SYMBOLOGY

ГИП V. Petrovich 25.11.2019 Текнимонт

Формат A1

GENERAL NOTES

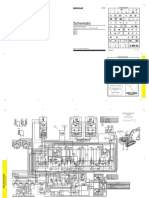

DETAIL 16 DETAIL 17 DETAIL 25 - FOR LEGEND SHEETS (PIPING NOTES & SYMBOLS, INSTRUMENT NOTES & SYMBOLS AND

SWITCH VALVE LOCAL PANEL AND INSTRUMENTATION. EQUIPMENT SYMBOLS) SEE P&ID 000011 AND FOLLOWING.

SP-3 INSTRUMENTATION AND LOCAL ALARMS. TYPICAL FOR ON-OFF VALVE WITH REDUNDANT

LIMIT S/W AND SINGLE SOV - FOR TRIPS AND ALARMS ON PUMP BEARINGS AND SEALS REFER TO TYPICAL 8 ON PID 000082.

- INSTRUMENTS AND DEAD LEGS SHALL BE ELECTRICALLY TRACED FOR WINTERIZATION PURPOSE.

1 SWITCH VALVE ME-101 LOCAL PANEL FOR MORE DETAILS REFER DOCUMENT ONPZ-ORU-RD-7821-000-AK.DDD-0005

2

SWITCH VALVE - NECESSARY BLINDS FOR POSITIVE ISOLATION FOR HYDRAULIC TESTING WILL BE DEFINED

POWER ME-101 LAMP TEST

OUTPUT SIGNALS FROM ESD TO SWITCH VALVE BY GCC IN THE TEST PACK PREPARED BY GCC ITSELF.

2

1 1 ME-101 LOCAL PANEL

EJL EHS

7821-1-EJL-9001 POWER SIGNALS FROM 7821-1-LP-6103 TO ESD - AS REGARDS FIRE SAFE REQUIREMENT FOR ON-OFF VALVES BODY AND FIRE PROOFING REQUIREMENT

9001 9001 A FOR ON-OFF VALVES ACTUATORS AND CABLES, REFER TO DOC. 4019-SZ-SG-000004-TE.

7821-1-EZL-9001A AT BYPASS 7821-1-EHSC-6103A JOG CLOSE

"FIRE PROOFING SPECIFICATION" AND TO ON-OFF VALVES DATA SHEETS.

DRUM D-(A) 7821-1-EZL-9001B AT DRUM R-101 7821-1-EHS-6103B LAMP TEST

ENABLE DRUM D-(B) ZAH ZAL ZAH ZAL

TO BYPASS STOPPED 7821-1-EZL-9001C AT DRUM R-102 7821-1-EHSO-6103 JOG OPEN - IN THE PRESENT ISSUE OF P&ID's, PIPING CLASSES HAVE BEEN MODIFIED ON ALL LINES, SHOWING

TO BYPASS TO BYPASS THE CODES OF PIPING CLASSES DEVELOPED ACCORDING TO ASME / ASTM. BEING THIS A GENERAL

1 7821-1-EZL-9001D AT MIDPOINT 7821-1-EZSH-6103 VALVE OPEN LIMIT SWITCH

1 ON 1 EHS OFF 1 EZL REVISION APPLICABLE TO ALL LINES ON ALL P&ID's.

EHS EHS 7821-1-EZSL-6103 VALVE CLOSE LIMIT SWITCH

7821-1-EZL-9001E PERMISSIVE TO DRUM R-102

9001 B 9001 C 9001 D 9001 K

7821-1-EZL-9001F PERMISSIVE TO BYPASS - TURN OF ON/OFF VALVES TO HOME POSITION SHALL BE PERFORMED REMOTELY FROM DCS PANEL

I (LOCAL RETURN TO NORMAL POSITION IS NOT PROVIDED).

7821-1-EZL-9001G PERMISSIVE TO DRUM R-101

BYPASS TO BYPASS TO PERMISSIVE

AT BYPASS 7821-1-EZL-9001K STOPPED

DRUM D-(A) DRUM D-(B) TO DRUM D-(A)

1 EHS

1

EZL 1 EHS 1 7821-1-EXS-9001A MOTOR ENABLE SIGNALS FROM ESD TO 7821-1-LP-6103

EZL 7821-1-EXS-9001B VALVE CLOSE COMMAND -CW UYV

9001 E 9001 A 9001 F 7821-1-EYC-6103 VALVE CLOSE - CW + S

9001 G 7821-1-EXS-9001C VALVE OPEN COMMAND -CCW 7821-1-EYS-6103 STOP COMMAND

7821-1-EXS-9001D CLOSE INTERLOCK 7821-1-EYO-6103 VALVE OPEN - CCW IA

7821-1-EXS-9001E OPEN INTERLOCK 7821-1-EXO-6103A OPEN INTERLOCK VENT

PERMISSIVE DE

AT DRUM D-(A) AT MIDPOINT AT DRUM D-(B) TO BYPASS 7821-1-EXS-9001F POSITION INDEX 7821-1-EXC-6103A CLOSE INTERLOCK ZSL ZSH

7821-1-EYS-9001A MOV READY A A NOTES

1 7821-1-EZAL-6103L VALVE CLOSED - LAMP /B /B

1 EZL 1 EZL 1 EZL EZL

1 7821-1-EZAH-6103L VALVE OPENED - LAMP

9001 B 9001 D 9001 C 9001 F I

007 UV 1. FOR DETAILS REFER TO VELAN DOCUMENT N. X-879788-ILD (ONPZ-ORU-PR-7821-1543.01-EUV.ESV-HV-A3303-0001).

+

2. LOCAL ACTUATOR OPEN / CLOSE PUSH BUTTONS ENABLED ONLY IF INTERLOCK IS SATISFIED.

PERMISSIVE 5 3. REDUNDANT LIMIT SWITCHES FOR EUV's MARKED WITH (*)

DRUM D-(A) TO MID-POINT MID-POINT DRUM D-(B) TO

TO DRUM D-(B)

MID-POINT TO D-(A) TO D-(B) MID-POINT 4. ALL VALVES LISTED HERE AND TAGGED LIKE 7821-N-EUV-XXXX (WHERE N IS THE UNIT AND XXXX IS A 4 DIGIT NUMBER

1 1 1

1 EHS 1 EHS

0

EHS EHS

1

EZL INPUT SIGNALS TO ESD FROM SWITCH VALVE ME-101 e.g. 7821-1-EUV-6101) HAVE LOCAL PANEL TAGGED ACCORDINGLY 7821-N-LP-XXXX (e.g. 7821-1-LP-6101)

EZAL EZAH

9001 G 9001 H 9001 I 9001 J 9001 E LOCAL PANEL CLOSED OPEN 5. FOR TYPE OF VALVE REFER RESPECTIVE P&ID.

6103 L LAMP TEST 6103 L

7821-1-EZS-9001A MAKE AT BYPASS PROXIMITY SWITCH 6. POSITION FEEDBACK REQUIRED ONLY FOR VALVES 1-EUV-6118 & 1-EUV-6218. INCHING FOR VALVES 1-EUV-6118/6218

1 EHS 1 SHALL BE PERFORMED USING OPEN/STOP/CLOSE PUSHBUTTONS ON LOCAL PANEL.

7821-1-EZS-9001B MAKE AT DRUM R-101 PROXIMITY SWITCH 1

STOP RESTART EHSO

LOC 1 REM 7821-1-EZS-9001C MAKE AT DRUM R-102 PROXIMITY SWITCH EHSC 6103 B

1 1 JOG OPEN

EHS EHS EHS JOG CLOSE 6103 O

7821-1-EZS-9001D MAKE AT MIDPOINT PROXIMITY SWITCH 6103 A

9001 K 9001 L 9001 M

DETAIL 28

7821-1-EHS-9001A LAMP TEST TYPICAL FOR ON-OFF VALVE

RED GREEN CONTROLLED BY ESD AND

7821-1-EHS-9001B DRUM R-101 TO BYPASS

REDUNDANT LIMIT SWITCH

7821-1-EHS-9001C ENABLE TO BYPASS ON OFF SIGNAL CONNECTED TO DCS.

7821-1-EHS-9001D DRUM R-102 TO BYPASS 7821-1-LP-6103

1

7821-1-EHS-9001E BYPASS TO DRUM R-101

BYPASS DRUM (A) DRUM (B) 7821-1-EHS-9001F BYPASS TO DRUM R-102

1 1 1 1 MID POINT 7821-1-EHS-9001G DRUM R-101 TO MIDPOINT

EZS EZS EZS EZS

SIGNALS FROM 7821-1-LP-6103 TO

7821-1-EHS-9001H MIDPOINT TO DRUM R-101

ACTUATOR

BYPASS

9001 A 9001 B 9001 C 9001 D 7821-1-EHS-9001I MIDPOINT TO DRUM R-102 I ZAH ZAL

7821-1-EHS-9001J DRUM R-102 TO MIDPOINT 1 1 7821-1-EYC-6103 VALVE CLOSE - CW

B B

7821-1-EHS-9001K STOP EZSH EZSL 7821-1-EYS-6103 STOP COMMAND

7821-1-EHS-9001L CONTROL LOCAL REMOTE 6103 6103 7821-1-EYO-6103 VALVE OPEN - CCW

7821-1-EHS-9001M RESTART 7821-1-EXO-6103A OPEN INTERLOCK

1 UYV

7821-1-EXC-6103A CLOSE INTERLOCK + ZAH ZAL

M EUV S

4-20 mA POSITION SIGNAL 7821-1-EZT-9001

+

A A

M 6103

COKE DRUM OVHD IA

TO FRACTIONATOR

R-101 R-102 FROM COKE DRUM SP-3A DE HOLDS

D-(A) D-(B) SIGNALS TO ACTUATOR FROM SWITCH VALVE D-(A) OR D-(B)

ME-101 LOCAL PANEL ZSH ZSL

1 VENT

A /B A /B

ESV 7821-1-EXS-9001A MOTOR ENABLE 2

+

9001 7821-1-EXS-9001B VALVE CLOSE COMMAND -CW UV

+

7821-1-EXS-9001C VALVE OPEN COMMAND -CCW

7821-1-EXS-9001D CLOSE INTERLOCK

7821-1-EXS-9001E OPEN INTERLOCK

EFFLUENT

5

7821-1-EXS-9001F POSITION INDEX

HEATER

7821-1-EYS-9001A MOV READY

DETAIL 18 DETAIL 18A

TYPICAL MOTORIZED VALVE TYPICAL MOTORIZED VALVE

LOCAL PANEL.

LOCAL PANEL 7821-1-LP-XXXX

4

EA

GENERAL

UNIT 100 - VENDOR VELAN 1

FAULT

PID-100-TX-0002 PID-100-TX-0004 EZAL EHS EZAH

EUV-6104 EUV-6108 EUV-6204 EUV-6208 L L L

EHL

PID-100-TX-0003 CLOSED LAMP OPEN 6 B. Hivet / H. Al

LOCAL/REMOTE 2 25.11.2019 ISSUED FOR CONSTRUCTION- FINAL A. Waykole Jarrah / A. Lo Verso D. Ballardini

TEST 1 6

EUV-6101 EUV-6102 EUV-6106 EUV-6107 1 1 13.05.2019 ISSUE FOR CONSTRUCTION 2 A. Waykole

B. Hivet / H. Al

Jarrah / A. Lo Verso D. Ballardini

EZI EZI I B. Hivet / H. Al

EUV-6201 EUV-6202 EUV-6206 EUV-6207 EZAH 0 21.12.2018 ISSUE FOR CONSTRUCTION 1 A. Waykole Jarrah / A. Lo Verso D. Ballardini

L

B. Hivet / H. AI

A 21.09.2018 ISSUE FOR DESIGN A. Waykole A. Lo Verso

CLOSE STOP OPEN Jarrah

Issue Date Prepared By Checked By Approved By

Цель выпуска

UNIT 100 EHSC EHSS EHSO Ред. Дата Purpose Of Issue Разраб. Проверил Утв.

PID100-TX-0002 PID100-TX-0003 PID100-TX-0004 PID100-TX-0042 L L L EZAH EXA

EZAL I

EUV-6109 EUV-6110 EUV-6209 EUV-6009 A * /B TECNIMONT IDENTIFICATION CODE

A JSC Gazpromneft - Omsk Refinery Идентификационный код Текнимонт

Job-EC-Type-N°

EUV-6117 EUV-6111 EUV-6217 EUV-6009 B * Omsk - Russian Federation

4019-XZ-DM-000042TE

EUV-6118 6 EUV-6112 6 EUV-6218 EUV-6013 A * EHS АО "Газпромнефть - ОНПЗ"

SHEET Лист DOC. CLASS. ISSUE

I EZAL Омск - Российская Федерация 1 of 1 A 2

Согласовано

EUV-6119 EUV-6113 EUV-6219 EUV-6013 B *

A /B EZSH EZSL

EUV-6120 EUV-6114 EUV-6220 - 1 6 CLIENT IDENTIFICATION CODE

EUV Delayed Coking Unit (DCU) Идентификационный код Заказчика

EZT EYC: CLOSE COMMAND 2 M +

EUV-6121 EUV-6115 EUV-6221 - Установка замедленного коксования ONPZ-ORU-RD-7821-000

EYS: STOP COMMAND

EUV-6122 EUV-6116 EUV-6222 - EYO: OPEN COMMAND -TX-0030

ОАО "Газnромнефmь - ОНПЗ"

Взам. инв. N

EUV-6123 EUV-6210 EUV-6223 - EXC: CLOSE INTERLOCK

TITLE

EUV-6124 EUV-6211 EUV-6224 -

EZSH EZSL EXO: OPEN INTERLOCK Наименование PIPING AND INSTRUMENTATION DIAGRAM

A /B A /B UNIT 100

PID-101411 EUV-6212 PID-101471 PID-101501 M EUV

+

AUTOMATIC VALVES DETAILS

3 EUV-6011 AA EUV-6011 BA -

EUV-6010 * EUV-6213 EUV-6002 A * EUV-6004 * SCALE ORIG. SIZE

PID-100-TX-0074 Масштаб 1:1 Исх. размер А1

EUV-6011 AB EUV-6011 BB -

EUV-6014 * EUV-6214 EUV-6002 B * EUV-6005 * 5

Подп. и дата

- EUV-6215 EUV-6003 A * EUV-6006 * UNIT 500

ONPZ-ORU-RD-7821-000-TX

- EUV-6216 EUV-6003 B * EUV-6007 * EUV-6001 AA EUV-6001 BA -

PID-500-TX-0012 2 3 Зам 112-19 25.11.2019 АО "Газпромнефmь - ОНПЗ"

EUV-6001 AB EUV-6001 BB - Изм. Кол.уч. Лист N док. Подп. Дата

UNIT 200 Разраб. A. Waykole 25.11.2019 Установка замедленного коксования Стадия Лист Листов

B. Hivet / H. Al Jarrah /

Проверил ОАО "Газпромнефmь - ОНПЗ"

подл.

EUV-6057 * EUV-6067 * - 25.11.2019

PID-200-TX-0002 / A. Lo Verso

Р 30

200-TX-0003 Гл.спец. D. Ballardini 25.11.2019

EUV-6065 * EUV-6068 * -

PIPING AND INSTRUMENTATION DIAGRAM

Инв. N

Н. контр. D. Ballardini 25.11.2019

AUTOMATIC VALVES DETAILS

ГИП V. Petrovich 25.11.2019 Текнимонт

Формат A1

You might also like

- RENR7439 - 320D Excavators Hydraulic System - Attachment - SysDocument2 pagesRENR7439 - 320D Excavators Hydraulic System - Attachment - SysMarcelo ItoNo ratings yet

- Domestic and Industrial Wastewater Treatment Plant Design SchemeDocument1 pageDomestic and Industrial Wastewater Treatment Plant Design SchemeReza MuhammadNo ratings yet

- Line Symbols Service Code Work Breakdown Structure Valve Symbols Line SymbolsDocument346 pagesLine Symbols Service Code Work Breakdown Structure Valve Symbols Line SymbolsEnrique100% (1)

- 560-000-Pi-T-001 - 1 - Simbologia PDFDocument1 page560-000-Pi-T-001 - 1 - Simbologia PDFismylive100% (1)

- 330D & 336D Hyd System Without Heavy Lift & Fine SwingDocument2 pages330D & 336D Hyd System Without Heavy Lift & Fine SwingmahmudiNo ratings yet

- Sistema Hidraulico 312BL - 3Document2 pagesSistema Hidraulico 312BL - 3tallerNo ratings yet

- 320D & 320D L Excavator Hydraulic System Schematic PDFDocument2 pages320D & 320D L Excavator Hydraulic System Schematic PDFchanlin100% (5)

- B A C E D F H G I K J L L M: Line Identification Fire and Safety Process PipelinesDocument3 pagesB A C E D F H G I K J L L M: Line Identification Fire and Safety Process PipelinesJoséMiguelSánchezGNo ratings yet

- 215 D Schema Hydraulique - cssiSImageServletDocument2 pages215 D Schema Hydraulique - cssiSImageServletSieda SiedaNo ratings yet

- Plumbing GRP 2Document5 pagesPlumbing GRP 2Jezreel PatawaranNo ratings yet

- R13-013B01-IDM-00IC-YMAXX-DWG-MD-00010 - 02 - P&ID SYMBOLOGY符号示意Document6 pagesR13-013B01-IDM-00IC-YMAXX-DWG-MD-00010 - 02 - P&ID SYMBOLOGY符号示意Chaudhary TALHANo ratings yet

- PIPING & INSTRUMENT DIAGRAM SYMBOLS & LEGENDS (PIPING)Document1 pagePIPING & INSTRUMENT DIAGRAM SYMBOLS & LEGENDS (PIPING)zalabiNo ratings yet

- P&ID-500 CMR-R1 (Original)Document1 pageP&ID-500 CMR-R1 (Original)Ahmed WagihNo ratings yet

- Cat - Dcs.sis - controller.CSSISImageServlet 2Document2 pagesCat - Dcs.sis - controller.CSSISImageServlet 2Miguel Jorge Chavez ChavezNo ratings yet

- E307C Hydraulic Circuit Diagram SimpleDocument2 pagesE307C Hydraulic Circuit Diagram Simplekhun shwe htoo100% (1)

- 318B HydDocument2 pages318B Hydkelmal KELMALLNo ratings yet

- Diagrama Hidráulico 320d SISDocument2 pagesDiagrama Hidráulico 320d SISFranklin BeaumontNo ratings yet

- Power Plant P& ID SymbolsDocument1 pagePower Plant P& ID SymbolsAmit BalotNo ratings yet

- 87ae5500 Cyr - Gen P 01 0001Document1 page87ae5500 Cyr - Gen P 01 0001Raksha KMNo ratings yet

- Pid P Xylene2Document17 pagesPid P Xylene2ภูมิรพี ศรีโวทานัยNo ratings yet

- Sheet1 140217213621 Phpapp02Document1 pageSheet1 140217213621 Phpapp02Mark Anthony Baes EnoyNo ratings yet

- 320 D Esquema HidrahulicoDocument2 pages320 D Esquema Hidrahulicosebastian velasquezNo ratings yet

- 320 D Esquema HidrahulicoDocument2 pages320 D Esquema Hidrahulicosebastian velasquez100% (1)

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerRamon MontesNo ratings yet

- 035 Pnevmoraspredeliteli Namur PDFDocument37 pages035 Pnevmoraspredeliteli Namur PDFbrij singhNo ratings yet

- M4E-PR-FRM-PWD-00555-B-Form 2 - Scope of Work Appendix 5Document15 pagesM4E-PR-FRM-PWD-00555-B-Form 2 - Scope of Work Appendix 5Chakib AutomationNo ratings yet

- Material Caterpillar 793c Mining Truck Off Highway Steering Components PartsDocument21 pagesMaterial Caterpillar 793c Mining Truck Off Highway Steering Components PartsИгорь ИвановNo ratings yet

- M320 Excavator Hydraulic System - Attachment: Item Component NoDocument2 pagesM320 Excavator Hydraulic System - Attachment: Item Component NoLhsan Rajawi100% (1)

- Piping SystemDocument1 pagePiping SystemJephthah Jude Tadeo GaleosNo ratings yet

- Environmental Systems PressurizationDocument14 pagesEnvironmental Systems PressurizationJuan Garcia SanchezNo ratings yet

- 385B Excavators Hydraulic System - Attachment: Mya1-Up Rcd1-Up Bkf1-Up Ans1-Up Cls1-Up Bkx1-Up Bly1-UpDocument2 pages385B Excavators Hydraulic System - Attachment: Mya1-Up Rcd1-Up Bkf1-Up Ans1-Up Cls1-Up Bkx1-Up Bly1-UpFlorencio MaximilianoNo ratings yet

- Plano Hidraulico M313CDocument2 pagesPlano Hidraulico M313CKrippy KushNo ratings yet

- 330D Excavator Hydraulic System - Attachment: Nbd1-Up B6H1-UP Mwp1-Up Edx1-Up Mey1-UpDocument2 pages330D Excavator Hydraulic System - Attachment: Nbd1-Up B6H1-UP Mwp1-Up Edx1-Up Mey1-UpYoungmi Franchesca Vladimir LizbetNo ratings yet

- Sav - Klinger Inspection: Tags Basic Valve DataDocument1 pageSav - Klinger Inspection: Tags Basic Valve DataMartin Augusto Torrau CayoNo ratings yet

- Schematic Caterpillar 312c Excavator Hydraulic SystemDocument2 pagesSchematic Caterpillar 312c Excavator Hydraulic SystemJPJF100% (5)

- 312CL Hyd SchematicDocument2 pages312CL Hyd SchematicEmmanuel solomon100% (1)

- SENR89080001Document2 pagesSENR89080001Ηρακλης ΤσαπραζηςNo ratings yet

- M318 Wheeled Excavators Hydraulic System: 8AL1-1019 6ES1-228Document2 pagesM318 Wheeled Excavators Hydraulic System: 8AL1-1019 6ES1-228lahcen boudaoudNo ratings yet

- Plano Hidraulico PDFDocument2 pagesPlano Hidraulico PDFYefry LBNo ratings yet

- V VS A HZ: Ug LV Cable Refer To Note 12Document1 pageV VS A HZ: Ug LV Cable Refer To Note 12Bhavanishankar ShettyNo ratings yet

- Wat STD 0009Document1 pageWat STD 0009SaeidKHOKHANo ratings yet

- Sh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Document1 pageSh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Thanh SonNo ratings yet

- Piping SymbolsDocument1 pagePiping SymbolsLalit MohanNo ratings yet

- Symbols Description Symbols VSD VariableDocument24 pagesSymbols Description Symbols VSD VariableRifqi IsbillyNo ratings yet

- Basic Hydraulics System: - Presentation - Student HandoutDocument1 pageBasic Hydraulics System: - Presentation - Student HandoutGrahaauto DarisNo ratings yet

- Pipe and installation design diagram for Lombok Menara Energygas LPG facilityDocument1 pagePipe and installation design diagram for Lombok Menara Energygas LPG facilityRANU LMENo ratings yet

- Aircon & Heating Electrical SystemDocument2 pagesAircon & Heating Electrical SystemFajrin niswatinNo ratings yet

- Untitled-11 1 PDFDocument1 pageUntitled-11 1 PDFsyaikulNo ratings yet

- Cat 318Document2 pagesCat 318Roman100% (4)

- Central waste water treatment facility cleaningDocument1 pageCentral waste water treatment facility cleaningPaolo Cobrado67% (3)

- 320D HidraulicoDocument2 pages320D Hidraulicosilvanioqueiroz100% (1)

- D6M Track-Type Tractor Hydraulic System: 9ZM1-UP 2RN1-UP 3WN1-UP 4JN1-UP 5NR1-UP 5WR1-UP 6LR1-UP 2YS1-UP 4GS1-UP 4HS1-UPDocument2 pagesD6M Track-Type Tractor Hydraulic System: 9ZM1-UP 2RN1-UP 3WN1-UP 4JN1-UP 5NR1-UP 5WR1-UP 6LR1-UP 2YS1-UP 4GS1-UP 4HS1-UPElectronica Mecatronica RasmusNo ratings yet

- 12147.001 CLL Irr DWG P103 SW 00 7301Document1 page12147.001 CLL Irr DWG P103 SW 00 7301Jacob CapistranoNo ratings yet

- 320D, 324D, and 325D Excavators Hydraulic System - AttachmentDocument2 pages320D, 324D, and 325D Excavators Hydraulic System - Attachmentmirbek mairykovNo ratings yet

- The Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeFrom EverandThe Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeDonald M. WallerRating: 4 out of 5 stars4/5 (1)

- 1623917396609-Model Qsns On Comp - GroundDocument10 pages1623917396609-Model Qsns On Comp - Groundrupakdutta158No ratings yet

- Kalibrr Brochure 2020 PDFDocument12 pagesKalibrr Brochure 2020 PDFSuryadi YadiNo ratings yet

- Installation of ESRS Virtual Edition (ESRSVE) On VMwareDocument58 pagesInstallation of ESRS Virtual Edition (ESRSVE) On VMwaremummy206No ratings yet

- Control Valves PDFDocument21 pagesControl Valves PDFRiyadh DaoudiNo ratings yet

- Build Java REST APIs Step-by-StepDocument2 pagesBuild Java REST APIs Step-by-StepAthar RiazNo ratings yet

- AIRPORTS AUTHORITY OF INDIA I CardDocument2 pagesAIRPORTS AUTHORITY OF INDIA I Cardkallul5551350100% (1)

- How To Reset Canon MP198Document4 pagesHow To Reset Canon MP198Eko NoegNo ratings yet

- Heart Clinical Case by SlidesgoDocument53 pagesHeart Clinical Case by SlidesgoUlfa Sari Al-BahmiNo ratings yet

- The National Artificial Intelligence Research and Development Strategic Plan: 2019 UpdateDocument50 pagesThe National Artificial Intelligence Research and Development Strategic Plan: 2019 UpdateDarth VaderNo ratings yet

- S&T Achievements from Marcos to PresentDocument9 pagesS&T Achievements from Marcos to PresentNICOLE IRISH CABUNILASNo ratings yet

- Technical Report NowDocument27 pagesTechnical Report NowKadiri Ibrahim100% (1)

- Eduwork: Free Class Web ProgrammingDocument53 pagesEduwork: Free Class Web ProgrammingAgnesNo ratings yet

- APSC 177 Lab 2Document2 pagesAPSC 177 Lab 2Nusaiba NaimNo ratings yet

- E-mail Encryption Project ReportDocument15 pagesE-mail Encryption Project Reportishant7890No ratings yet

- What is a 50/50 in minesweeperDocument7 pagesWhat is a 50/50 in minesweeperGannon GageNo ratings yet

- Fault Codes HyundaiDocument12 pagesFault Codes HyundaiAnonymous j7LBFXO50% (2)

- Sharepoint Job ProfileDocument2 pagesSharepoint Job ProfilePrasad KshirsagarNo ratings yet

- umati@EMO Hannover 2019Document8 pagesumati@EMO Hannover 2019frasorNo ratings yet

- PD2-PaperGang John Wick A4Document2 pagesPD2-PaperGang John Wick A4Bot 2No ratings yet

- Cgo San Jose Nueva Ecija-Administrative Aide III Utility Worker IIDocument1 pageCgo San Jose Nueva Ecija-Administrative Aide III Utility Worker IIWarren Del RosarioNo ratings yet

- BTECDocument11 pagesBTECRini SandeepNo ratings yet

- Energy Saving HRC Fuse-Links: Blade Type HN 63 A - 800 A Cylindrical Type HF 2 A - 63 ADocument8 pagesEnergy Saving HRC Fuse-Links: Blade Type HN 63 A - 800 A Cylindrical Type HF 2 A - 63 AprekNo ratings yet

- Artificial Intelligence Big Data 01 Research PaperDocument32 pagesArtificial Intelligence Big Data 01 Research PapermadhuraNo ratings yet

- Entrepreneurship Pre-Test: Kyle's Typing Business ExpandsDocument3 pagesEntrepreneurship Pre-Test: Kyle's Typing Business ExpandsMutya Neri Cruz100% (1)

- Scania 5-Series Engine Inspection ManualDocument275 pagesScania 5-Series Engine Inspection Manualgiovani martinsNo ratings yet

- C-Zone SDN BHD: WWW - Czone.myDocument2 pagesC-Zone SDN BHD: WWW - Czone.myFirman SyahNo ratings yet

- 華語輔導系統使用說明 Mandarin Tutorial System GuidelineDocument11 pages華語輔導系統使用說明 Mandarin Tutorial System GuidelineAsnidar SiahaanNo ratings yet

- Movetronix - Product Catalog 2023Document17 pagesMovetronix - Product Catalog 2023infoNo ratings yet

- Final Report For Research PaperDocument55 pagesFinal Report For Research PaperAnshu PandeyNo ratings yet

- Check-Lists D'inspectionDocument43 pagesCheck-Lists D'inspectionElisee93% (29)