0% found this document useful (0 votes)

940 views3 pagesFormwork Fabrication Operation Sheet

The document provides instructions for fabricating formworks, including required tools, materials, safety practices and procedures. It lists the tools, supplies and personal protective equipment needed and gives step-by-step instructions for fabricating formworks that include preparing materials, laying out and cutting sheeting, assembling form panels and checking for compliance.

Uploaded by

Nhatz Gallosa MarticioCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

0% found this document useful (0 votes)

940 views3 pagesFormwork Fabrication Operation Sheet

The document provides instructions for fabricating formworks, including required tools, materials, safety practices and procedures. It lists the tools, supplies and personal protective equipment needed and gives step-by-step instructions for fabricating formworks that include preparing materials, laying out and cutting sheeting, assembling form panels and checking for compliance.

Uploaded by

Nhatz Gallosa MarticioCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

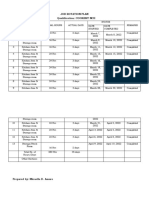

- Operation Sheet: Outlines the operation including tools, equipment, safety practices, and assessment checklist required for fabricating formworks.

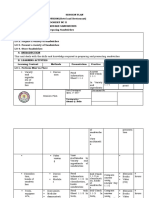

- Learning Objective and Fabrication Details: Covers learning objectives and detailed descriptions of formwork construction components and types.

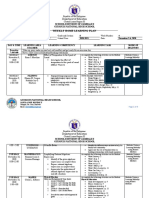

- Steps and Procedures: Describes the step-by-step process to prepare and perform the formwork operation effectively.