0 ratings0% found this document useful (0 votes)

299 views92 pagesMarine Bridge

Reference Methods for Marine Bridge

Uploaded by

william pasamonteCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

299 views92 pagesMarine Bridge

Reference Methods for Marine Bridge

Uploaded by

william pasamonteCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

@%Redco International DAEWOO E&C

14

aaa

14.2

113

14

12

13

14

24

22

23

24

244

24.2

25

26

27

274

272

273

28

29

2.10

2.11

212

213

2.14

2.15

2.16

2.17

MEMORANDUM OF PROCEDURE

CHAPTER 1 - GENERAL DESCRIPTION.

PROJECT INTRODUCTION. ns 1

General 1

Project Site 1

Geology. 1

Weather and Climate Condition$....1:nmnnnnnnnnnnnininnensinnt aoe

SCOPE OF WORKS (SIGNATURE BRIDGES 8 & 9). ea

‘TRANSPORT TOAND FROM DOHA... 6

MATERIAL SUPPLY... f see

CHAPTER 2 ~ GENERAL CONSTRUCTION ARRANGEMENT. 7

SETTING OUT & SURVEY... es 7

SITE INVESTIGATION FOR UTILITIES SERVICES. = See

CONSTRUCTION LAND. vanes 8

PRINCIPLE OF GENERAL CONSTRUCTION ARRANGEMENT, 8

Construction site Conditions. 8

Construction Arrangement Principle 9

CONSTRUCTION CAMP ARRANGEMENT 0

‘SHARED FACILITIES... 10

ENGINEER'S SITE FACILITIES 10

General requirement 10

Computers and Printers.

Measuring and Recording Equipment... 2

ACCESS ROAD ARRANGEMENT 2

LIGHTING FOR CONSTRUCTION fon 2

CONSTRUCTION COMMUNICATION. 3 2

ASPHALT CONCRETE ARRANGEMENT 13

FILLING MATERIAL ARRANGEMENT. ad eel)

‘COMPRESSED AIR SUPPLY. 3

Water SUPPLY. 13

POWER SUPPLY snes eat . a3

DESIGN Works, 3

PROCUREMENT. 4

@% Redco International DAEWOO E&C

2.18 SUBCONTRACTING......... 15

2.19 INFORMATION HANDLING SysTEW 16

2.20. MATERIAL SUBMITTALS. mrss 16

2.21 DRAWINGS SUBMITTALS.. a7

CHAPTER 3- GENERAL CONSTRUCTION SCHEDULE...

34 (GENERAL 18

3.2. PREPARATION PRINCIPLE OF GENERAL CONSTRUCTION SCHEDULE: 18

3.3 (CONSTRUCTION SCHEDULE OF MAJOR WORKS. 1.20

33:1 Preparation Stage 120

3.3.2 Construction tage. 2a

3.3.3 Completion / Handing over 21

3.4 CONSTRUCTION SCHEDULE REFERENCE. a2

35 OPTIMIZATION. san 2D

CHAPTER 4 ~ ORGANIZATION AND RESOURCE ALLOCATION..

44 RESOURCE ARRANGEMENT. 23

4.2. MOBILIZATION OF PERSONNEL AND EQUIPMENT 2

4.3. METHOD OF MOBILIZATION OF EQUIPMENT AND MATERIAL, 23

43.1 Method of equipment mobilization. 23

43.2. Method of main material mobilization 23

44 CONSTRUCTION ORGANIZATION 24

4.5 CONSTRUCTION ORGANIZATION CHART 24

4.3.1 Major responsibilities of key personnel/departments.... 24

46 Work Force 27

4.7 MOBILIZATION PLAN OF MAN EQUIPMENT . a

4.8 MATERIAL TESTING AND QUALITY INSPECTION INSTRUMENTS 28

4.9 MATERIAL SUPPLY PLAN.. 28

(CHAPTER 5 ~ OVER ALL CONSTRUCTION STRATEGY AND TRAFFIC DIVERSION.

5.1 GENERAL 29

5.2 CONTRACT (CONSTRUCTION OF MARINE SIGNATURE BRIDGE 8 & 9) 29

5.3 PHASING OF CONSTRUCTION AND TRAFFIC DIVERSION 30

53.1 General 30

53.2 Conformance 30

5.3.3 Safety and Site Protection.

CHAPTER 6 ~ CONSTRUCTION METHOD OF MAJOR ITEMS ..

@%Redco International DAEWOO E&C

64 GENERAL...

6.2 CONSTRUCTION SURVEY. nasennmnninininnnn eo : 32

6.2.1 Reference points, Lines and Levels

6.2.2 _ Establishment of baseline for calibration of EDM Equipment onsnssnninnnsinnnnnn 38

6.2.3 Survey Procedure. 2

6.3 EXCAVATION PROGRAM 38

64 BACKFILLING. 5

6.5 BRIDGE CONSTRUCTION WORKS... 35

65.1 Genera...

65.2 Excavation

65.3 Concrete works...

654 Mie deSigM cn cnnnnnnsnn a 36

65.5 Supply of Concrete. 36

65.6 Concrete construction ”

65.7 Concrete Work Procediure.. a7

6.5.8 Concrete Workmanship .

66 DEWATERING OF PILING SITE. . sn

6.7 POURING OF BoRED PILE .

68 _ INSTALLATION OF BORED-PILE STEEL CASING. a

69 — PLECAPs. pelted ac Se et eM

6.10 _PIERS/AUXILIARY SUPPORT/ABUTMENT/ANCHOR BLOCK/PYLON RSB a

6.11 BRIDGE Deck SLAB (PRECAST). ee eee

6.12 BRIDGE DECK SLAB JOINTS ANO SIDE BEAMS (FOR CAST-IN-SITU). 43

6.13 PosT-TENSION sysTEM

6.14 BRIDGE BEARING...

6.15 BRIDGE EXPANSION JOINT SYSTEM...

6.16 BRIDGE CONSTRUCTION PROCEDURE (ACTIVITY CHARTS) .waonsnnsnnninnenenene dS

6.17 PIPEWoRKS ~ ees

6.18 PERMANENT ELECTRICAL WORKS .s-sun-nsestunnsnnnnsnuina 49

6.42.1 General a ne)

6.12.2 Street Lighting 49

6.12.3. Cable Laying 49

6.12.4 Duct works for Electrical... 50

6.19 ASPHALT WORKS. 50

4% Redco International DAEWOOE&C

6.20

6.21

6.22

6.23

94

9a.

92

9.24

922

923

924

925

INSTALLATION OF MISCELLANEOUS METAL WORKS. 51

TRAFFIC SIGNS & SURFACE MARKINGS! ...seunnsnmnnninennnnnn fereeni Y

Key POINT OF PROPOSED CONSTRUCTION SEQUENCE... 2 51

HANDING OVER AND DEMOBILIZATION: -anssearnvn i ' ea)

CHAPTER 7 ~ QUALITY ASSURANCE PLAN.

CHAPTER 8 ~ SAFETY PLAN.

CHAPTER 9 - ENVIRONMENT PROTECTION PLAN ..

GENERAL 5 82

Environmental Protection Objective..

ENVIRONMENTAL POLLUTION CONTROL MEASURES. 33

Dust CONtFO! svn

Noise control,

Water pollution control 3

Exhausted gas and odor pollution control... 84

Reinstatement of affected areas. 84

@%Redco International DAEWOO E&C

14

14

141.2

1.1.3

1.4.4

CHAPTER 1 - GENERAL DESCRIPTION

Project introduction

General

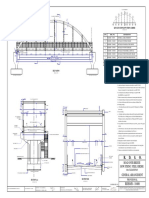

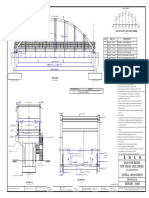

The Construction Package 3A Phase 2 consists of the Construction

of Marine Bridges 3, 4, 5, 7, 8 & 9 of which bridges 3, 4, 5 and 7 will

inter-connect the isolated Qetaifan Islands whilst bridges 8 & 9 will

connect the Qetaifan Islands to the mainland.

This Method Statement will focus only for the Construction of

Marine Bridges 8 & 9, a suspension 2-lane dual carriageway

signature bridges with bearing-to-bearing spans of 204m and 186m

respectively.

Project Site

Bridge construction worksite is located at Lusail Development City

in Doha Qatar.

Geology

Depending on the regional geology of the Arabian Peninsula area,

the Qatar peninsula geologically represents a part of the Arabian

Gulf Basin. The site for the said bridges has been backfilled by

Earth bridges forming as temporary access for Qetaifan Islands and

mainland by the other contractors, owners and authorities. These

earth bridges may need to be widened and maintained by the

Contractor during the entire execution of Contract.

Weather and Climate Condi

ns

Qatar belongs to desert climatic characterized by not summer and

mild winter.

Maximum ambient temperature 50° Celsius

Minimum ambient temperature 5° Celsius

Maximum metal temperature under the sun 85° Celsius

Maximum ambient humidity 100%

Minimum ambient humidity 20%

Yearly rainfall 80-150 mm

@%Redco International DAEWOO E&C

1.2

« The temperature is relatively mild from October to May and hot

from June to September.

* The relative ambient humidity is generally low from October to

May and generally high from June to September.

* Under certain climatic conditions, considerable condensation can

take place.

* A considerable amount of salt is contained in the atmosphere

which together with the relatively high ambient humidity can

produce severe corrosion problem.

* Distribution and occurrence of rainfall events are very erratic.

Rainfall events are generally of a high intensity with a short

duration and usually occur between December and March

+ The prevailing wind directions are from the north and west.

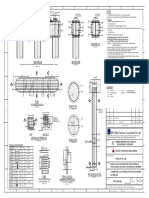

Scope of works (Signature Bridges 8 & 9)

The ambit of work is the construction of 2 nos. suspension bridges

namely the Bridges 8 & 9 with built-up pylon (RC concrete piers,

bottom ring segment, hammer head and structural steel ring

segments RSM, RSS & RST) towering within the middle third of

span. Both bridges 8 & 9 are 2-lane dual carriageways with spans of

204m and 186m respectively measured from centerline’s start to

end. The bridges are designed to be 2-lane dual carriageways at

the opening with hard shoulder and Cycle track/Footpath separated

by crash barriers and railings at the edges of the carriageways and

will be transformed into 3-lane dual carriageways utilizing the hard

shoulder and Cycle track/Footpath as the third lane by dismantling

the crash barriers in the future.

In addition, the work scope may include the following

* Bored piles under pylon pilecaps, auxiliary support pilecaps,

anchor block & abutment (Dia 1000mm)

* Pilecaps, Anchor block and Abutment

* Built-up Pylon (RC concrete Piers, RSB, Hammer Head & Steel

RSM, RSS & RST)

* Post tensioning

«Structural Steel Main Girders

* Precast RC concrete bridge deck

* Cast in-situ bridge deck and edge beams

@%Redco International

DAEWOO E&C

* Suspension cables and hangers

Flexible pavements

+ Road markings & Traffic signage

‘+ Damp proofing work includes laying of water proofing membrane

for the substructure work and sprayed water proofing for the

exposed top surface of the bri

* Miscellaneous metal works include installation of Movement

idge

joints, Railing, Crash barriers as per drawings and specifications

* Storm water drainage from the bridge decks

* Pumped TSE irrigation pipelines

+ Pumped potable water pipelines

* Foul water rising mains

* Gas main

* Signboards for Marine Traffic

* Electrical works

* Dehumidification system of the suspension cable

© Street lightings and lightning protection

* Metal doors

Approximate Quantities of Major Works (Bridges 8 & 9)

1. Earthwork

Remarks

Item Unit | Quantity

1. Foundation excavation m 13,262

2. Backfilling m 7,694

2. __Conerete (Bored Plies)

Item Unit | Quantity Remarks

1. 1000 mm dia B/Pile C40 concrete | m? 803

3.___Conerete (Bridge Structure)

Item Unit | Quantity Remarks

4. C30 blinding concrete m? 218

2. C50 RCC bridge structural conc. | m? 5,658

3. Prestressed concrete & 7 4,138

non-prestressed concrete

2% Redco International DAEWOO E&C

tem Unit | Quantity Remarks,

(Pylon, Anchor Block, beams &

deck) C60

4, Precast concrete (deck slab) area

exceeding 15m’ but less than No. 208

50m?

5, Precast concrete (Base pad) area

exceeding 0.1m? but not No. 294

exceeding 0.5m”

4. Formwork

Item Unit | Quantity Remarks

1. Formwork (Bridge structure) m? 8,646

5. Reinforcement

Item Unit | Quantity | Remarks

1. Deformed grade 460 = bare

(in various diameter)

6. Structural Metal works

Item Unit | — Quantity Remarks

1. Bridge main members (ring

segment, base plate, tube ring & | ton 4,953

etc.)

2. Main Cables & Hangers m 3,264

7.__Water Proofing works

Item, Unit | Quantity Remarks.

1, Water proofing membrane m? 5,339

2. Sprayed water proofing m 8,628

Pipework

tem Unit | Quantity Remarks

1, 400mm dia Potable water line um 406

2. 300mm dia Potable water line LM 406

3. 200mm dia TSE sewer line Lm 406

4, 400mm dia Foul sewer line LM 212

5. 200mm dia Gas pipe line Lm. 406

@%Redco International DAEWOOE&C

9. Railing and safety barriers

Item Unit | Quantity Remarks

1. Railing LM 788

2. Crash Barrier LM 1,576

40. Roads & Pavement

Item Unit | Quantity | Remarks i]

1. Road base Course m? 8,628

2. wearing course m? 8,628

3. Bond coat m? 8,628

14. Other works

tem Unit_| Quantity Remarks

1, Dehumidification systems item 2

2. Electrical works item 2

3. Street lighting item 2

4, Lightning protection item 2

In general, the Contractor's Scope of works includes:

- The provision of all labor, material, construction equipment,

supervisory and administrative personnel and other facilities

required for the construction, installation, testing and

commissioning of the project in accordance with Engineer's

design and Contractor's detailed or amended approved design,

and project specifications

- The provision of all assistance to the Engineer in supervision of

the work,

- Temporary traffic diversion, including Maintenarce of Traffic flow

and Management of Traffic flow as per traffic department

regulations.

- Widening and maintenance of earth bridge.

- Environmental protection and Clearance of site.

- Communication and Control works.

- Construction of Electrical and Mechanical works.

- The provision of As-built Drawings, and Operation and

maintenance Manuals.

- Co-operation with other contractors working on the project, and

with all relevant authorities and agencies so as to ensure

@%Redco International DAEWOO E&C

1.3

1.4

co-ordination of Contract interfaces and minimize disruption of

existing services and infrastructures within the local area

- Submittal items, such as Pre-Construction Photographs, Monthly

Photographs, work procedures, As-Built Record Drawings, data

Delivery etc.

Transport to and from Doha

Qatar is a peninsula country in the Gulf Region, and Doha, the

capital city, is an important port in the region. Therefore, marine

transport conditions are favorable for the Work.

Imported plants, equipment and material, which are necessary for

the execution of the works shall be unloaded in Doha Port or Doha

International Airport, then transported to project site.

All materials and equipments necessary for the execution of the

works which are domestically produced or are cf national origin

which comply in all respects with the requirements of the

Specification shall be given purchase priority than that of the

overseas origin and shall be transported by road to construction site.

Material supply

Subject to tender documents and site investigation, main material

such as steel, cement crushed aggregate and spacial fill material

shall be locally purchased. Purchased material snall be provided

with quality certificates, ex-factory qualification certificate and shall

be tested by field laboratory as qualified materials. Material to be

purchased shall be transported by truck to construction site.

Suitable filling material from excavation and Imported fill material

shall be transported from the source approved by the Engineer.

Main materials for the suspension bridge, i.e. suspension cable,

accessories and structural steel, shall be sourced out with first

priority from approved local suppliers or otherwise from the

recognized international supplier from abroad as alternative

2% Redco Intemational DAEWOO E&C

CHAPTER 2 — GENERAL CONSTRUCTION ARRANGEMENT

24

22

Setting out & Survey

Before the commencement date of the Works in the Contract,

Engineer will be requested in writing to intimate the location and

values of the permanent survey monuments that shall be used for

the execution of the works.

Upon receipt of the monument data, Contractor will physically

identify the survey points and protect them with guardrails.

Contractor will be responsible for protection and maintenance of

these survey points and shall ensure that all his personnel and

subcontractors are aware of these monuments and that no persons,

with the exception of his survey staff, shall enter the boundaries of

the guard rail.

Contractor shall be responsible for the setting out of the works and

the positions, levels, dimensions and alignments of all parts of the

works reckoning from the permanent survey monuments.

Engineer will, if necessary, provide Contractor with supplementary

information to that shown on the Drawings, which are sufficient for

Contractor to commence the works. Such supplementary

information may be provided on drawing sketches, in writing or

indicated on the site.

Based on project control monuments provided by the Engineer,

Contractor shall establish control monuments (CM), and additional

survey control monuments (ACM) to control measurement, and all

required setting out points and temporary benchmarks propagated

around the project site for the execution of the works by utilizing

Total Station Survey Equipment.

Site Investigation for Utilities Services

For the utility services along or crossing the Project area at different

locations such as power cable, lighting works, gas line, water supply

pipe, sewerage line etc., shall be dealt with in accordance to the

accepted manner and procedure during construction period

Prior to any commencement of earth excavation, the related

@% Redco International DAEWOO E&C

2.3

24

2.4.1

underground condition shall be investigated clearly and accurately.

The site investigation procedure shall be executed as following:

- All concemed authorities will be contacted and all record and

information will be acquired about underground services within

project area.

- According to layout provided to construction, the related location

of the facilities shall be set out accordingly.

- To liaise with the Engineer, certain trial pil locations shall

be made.

- Trial pit shall be made by using appropriate equipment.

- Protection of services keeping the trial hole free of water

- Backfill and compaction of surfaces

- Preparation of records

Construction land

The following land areas will be made available to Contractor by the

Employer for the sole purpose of the construction activities of the

works:

- The area within the line of ROW shown on the Drawings

- The residential camp and construction facilities areas

- Easements of adequate width for temporary access roads to

spoil disposal area, borrow areas and residential camp

- The disposal area shall be selected and got approved by the

Engineer in consultation with local municipal authorities.

Before the commencement date of the works, Engineer shall

approve and provide, as per Contractor's submittals, the proposed

locations of all residential camps, construction facilities temporary

access roads and a statement of the easement required for these

roads and for the construction of the permanent works which lie

outside the ROW.

Contractor shall ensure that it will make good any damage to lands

caused by him or his sub-contractors outside the areas made

available to him by the Employer.

Principle of General Construction Arrangement

Construction Site Conditions

@%Redco International DAEWOO ESC

2.4.2

- Existing traffic network for the areas along the construction line

provides means for transportation.

- The construction site starts at Lusail Development City Doha

with convenient transportation and where temporary

accommodation and construction yards can be leased from

Authorities.

- Should the Contractor require using adjacent areas of land for

camps, planting site etc., he shall arrange for the right to use the

said land himself.

Construction Arrangement Principle

In accordance with the construction site conditions and project

specification, construction arrangement shall be subject to the

principles as shown below:

- Principle of construction period guarantee: In order to fully

comply with the requirement

- s of construction period with no delay permitted, mechanized

construction shall be maximized and manpower input shall be

proportionally reduced so as to reduce the time required for

various construction activities.

- Principle for adaptation to actual situation: Taking advantage

of civilian houses scattered near the project area,

accommodation and offices can be arranged by renting the local

civilian houses at the preliminary stage. Temporary facilities

shall be located in areas where construction management and

safety can be ensured. For site facilities moveable

accommodation will be provided through Porta cabin.

- Principle for adaptation to weather condition: Project

construction shall experience hot weather condition (extreme)

especially during summer season and temporary facilities shall

be located in areas as close to water source as possible.

- Principle of convenience for construction, living and

management: Arrangements shall follow the principle of a

combination of concentration and decentralization. Construction

camp, warehouses and equipment parking yards shall be

scattered along the construction line according to the demand of

actual construction activities at site.

- Principle of safety: Storage for hazardous materials shall be

located in areas away from construction site, living camp and

traffic roads and safety protection shall be strengthened around

these areas.

¢%Redco International DAEWOO E&C

2.5

26

27

274

- Principle of environmental protection: General construction

arrangement shall be such that minimum harm to the

surrounding environment is done and proper environmental

protection measures are taken promptly.

For the purpose of execution of the works, site management will be

set up, and all construction resources, such as labor, materials,

construction equipment, supervisory and administrative personnel

and other facilities required for the construction, installation, testing

and commissioning of the Project in accordance with Engineer's

design and Contractor's detailed or amended approved design,

specification and Engineer's instruction, will then be provided on

site accordingly and expeditiously.

Construction Camp Arrangement

A construction camp is planned for smooth execution of the

Contract and will be arranged in accordance with actual site and

geographical conditions, construction procedures, and to the

satisfaction of construction schedule and requirements of the works.

Contractor's office shall be set up adjacent to Engineer's site office

for the convenience of work.

A housing facility shall be arranged to fulfill the requirements of the

project near the construction site of the project,

Shared fat

S

Emergency Medical Facilities shall be shared by Engineer and

Contractor.

Emergency medical facility shall be comprised of, as a minimum,

single bedrooms, washrooms, dispensary and emergency room

Engineer's site facilities

General requirement

The Contractor shall provide, maintain and keep clean, temporary

site offices with all associated equipment and services for the

exclusive use of the Engineer's and his staff, from the

commencement of the Project. The offices shall remain, in whole or

in part as required by the Engineer in his possession, until the end

0

%Redco Intemational DAEWOO E&C

2.7.2

of the Project.

The temporary site offices shall be either prefabricated portable

unit/s or alternatively made of some other form of weatherproof

design and construction materials to the approval of the Engineer.

The offices shall have full partitions and room sizes shall be as per

contract requirements. All rooms shall have individual entrance door.

Corridors and entrance areas shall be additional to the office sizes.

The offices shall be air-conditioned with the exception of the Toilet,

Shower and Kitchen areas.

All rooms shall have glazed windows complete with fly screens

Adequate fitted hardware, electrical switches, sockets, lighting and

plumbing fittings, sanitary ware & fittings and fixtures etc., shall be

provided as necessary for the different areas.

The electrical installation shall provide for simultaneous use of all

electrical appliances.

All necessary furniture and consumables for the use of Engineer's

office shall be provided as specified in the Contract

Computers and Printers

The Contractor shall supply the Engineer with computing facilities in

compliance with the Contract.

The contractor shall be responsible for installing legal copies of

operating system and software, trouble shooting, supplying of

required consumables and maintenance of the system.

Operating System and Software Requirements shall be as specified

by the Engineer, with the following as a minimum:

- MS Windows XP Professional with all required drivers

- MS Office Professional

- MS Project

- Primavera P6.2

- AutoCAD

The contractor shall provide a A4/A3 colour photocopier, Minolta

@%Redco International DAEWOO E&C

273

28

29

2.10

BIZHUB C355 for the exclusive use of the Engineer together with

servicing, accessories and materials for the contract period.

Measuring and Recording Equipment

The Contractor shall supply and maintain all measuring and

recording equipments for the duration of the Contract. Surveying

instruments shall be new or in as good as new condition, of an

approved make with a current certificate of adjustment.

Access road arrangement

The Contractor will maintain and provide satisfactory temporary

access and traffic flow to, from and within the areas of the works.

Temporary traffic signs and lighting for temporary roads and

diversions are to be in strict accordance with the requirements of

the Qatar Traffic Manual and any additional requirements instructed

by the Traffic Police or the Engineer.

Pursuant to construction demand, temporary access roads shall be

constructed in some area where bridge shall be constructed and

transportation access shall be constructed to borrow pit.

To facilitate the flow of traffic to and fro and the construction of

Bridges 8 & 9 on the earth bridges, the Contractor shall widen and

maintain the roadway as much as possible in accordance to what is

required in the specification or as instructed by the Engineer.

Lighting for construction

For the construction of bridge, high lighting tower with sunlamp

(3X3.5kw) shall be installed to provide long-range illumination, and

iodine-tungsten lamp and water-proof dysprosium lamp shall be

adopted to provide short-range illumination.

Other working area and equipment parking lot shall be provided with

flood lamps for lighting. For construction areas without power

source available, mobile lighting towers shall be installed,

Construction communication

For construction communication during the whole construction

period, Contractor ensures that he shall provide sufficient telephone

@% Redco International DAEWOO E&C

2.11

2.12

2.13

2.14

2.15

2.16

service. The supervisory staff shall be provided with mobile phones

or other mean of communication.

Asphalt Concrete Arrangement

Asphalt concrete will be purchased locally after making necessary

test to ensure the specification requirements and approval from

the Engineer.

Filling Material Arrangement

The imported fill material shall be arranged from the designated

borrow area and shall be used for filling after laboratory tests and

approval of the Engineer.

Compressed Air Supply

Diesel air compressors of sufficient capacity each supplemented

with stand by small air compressor shall be arranged to fullfill the

compressed air requirements for the various bridge construction

activities at site

Water Supply

The suitable arrangements shall be made for the smooth and

continuous supply of water at construction site. The water shall be

tested for the suitability of usage in labour camp, concrete work and

earthwork etc. The water storage at site shall be arranged for the

peak usage and for the emergency usage of water for firefighting

Water storage tanks of adequate capacity shall be arranged and

installed at suitable locations.

Power Supply

Power for construction shall be generated mainy by the diesel

generators.

Design Works

The Design of the permanent Work is generally Engineer/Client's

responsibility, however, the Contractor may need to undertake

design of some works which may be needed to fully execute the

entire Work as required in the Contract subject to the approval of

@% Redco International DAEWOO E&C

217

the Engineer.

The Design under Contractor's responsibilities and all temporary

construction facilities shall be subcontracted to a specialized Design

firm / subcontractor subject to the approval of the Engineer.

The design stages shall be coordinated by an Engineering Manager

who will coordinate between proposed Design Engineering Firm,

Project Manager and the Engineer till obtaining the approved

drawings for construction.

The drawings contained in the tender document shall be checked,

reviewed, verified and endorsed in order to confirm their adequacy

for the preparation of the Detailed Engineering Documents.

Procurement

REDCO - DAEWOO JV has a dedicated and experienced

Procurement Team based in Doha head office. This is led by the

Head of Procurement Department and supported by Procurement

Engineers, Quantity Surveyors and Purchasers.

a) Our procurement team with many years of experience in

project procurement is enabled to identify the project

requirements in terms of domestic/international sourcing and

prioritise the Long Lead Items. Processing and follow up of

international orders, tracking of material deliveries etc are

done by the procurement team, according to the Company's

procedure for procurement. This enables the Company to

expedite the delivery of critical items by coordinating with the

supplier (if needed), in order to comply with Project

programme requirements.

b) The following items have been identified as Long Lead Items:

- Suspension cables & accessories

- Steel segments of Pylon

- Post tensioning tendons

- Structural steel girders

- Bridge bearings

- Steel pipes & fittings and accessories

- Metal Works ( Expansion Joints, Railing, Crash Barriers)

- Electrical and Mechanical Material.

@%Redco International DAEWOO E&C

c)

d)

The Procurement & Delivery Schedule shall form the base for

timely submittals, approvals and delivery to site of all

materials; special attention shall be focused on long lead

manufacturing and delivery items.

REDCO - DAEWOO JV procurement procedure which

involves all types of inquiries to manufacturers & suppliers

and on site follow up and visits, technical comparison sheets

and evaluations, banking procedures (LC’s, LG's etc...) shall

be utilized to secure deliveries to site on time.

2.18 Subcontracting

a)

b)

d)

We intend to subcontract the following works in accordance

with project scope of work and schedule:

- Waterproofing Work

- Bored Pile Work

- Post Tensioning Work

- Suspension Cable Work

- Road marking & Traffic signs works

- Structural and Miscellaneous Metal Works

All subcontract agreements shall include the procedures for

time scheduling & planning, procurement, technical and site

activities, which shall be in full compliance with the REDCO -

DAEWOO JV procedures, the agreements shall also include

contractual issues such as time milestones, performance

bonds, liquidated damages etc as provided in contract

between client and M/s REDCO - DAEWOO JV.

The planning for each subcontract shall be extracted from the

detailed project programme to ensure that the progress of

works is in accordance with the overall project schedule,

Subcontractors’ procurement activities shall be monitored by

REDCO - DAEWOO JV to ensure timely purchase orders and

adherence to the project specifications

All technical issues such as shop drawings and materials

submittals shall be presented to the Engineer only after

reviewing and ensuring their compliance with the project

@%Redco International DAEWOO E&C

2.19

2.20

specifications.

f) The above shall be closely monitored by REDCO - DAEWOO.

JV utilizing various construction management techniques

such as:

- Weekly progress reviews and coordination meetings to

evaluate the progress of the subcontractor, review

schedules, evaluate past, current, and potential

problems, and resolve interfaces and restraints.

- Manpower requirements at site.

- Assessment of completed and remaining works.

- Shop drawings and materials submittals progress.

- Equipment and materials deliveries to ste.

Information Handling System

All project documentations will be recorded on database systems to

ensure efficient tracking of information and it will be reported on a

weekly basis, flow of information transmitted within the project will

be controlled via document transmittal, which will also be recorded

on a database for traceability.

Material Submittals

Schedule of material/Equipment to be utilized in the project shall be

developed and submitted to the Engineer for approval.

The approved list of material/equipment shall be developed to

material submission, Procurement & Delivery Schedule indicating

the following

- Submittal Number

- Material/Equipment description

- Manufacturer and local agent.

- Date of submission for review by the Engineer.

- Date of approval.

- Date of placing the order/Order No.

- Mode of Delivery (air, land or sea)

- Approval status as on date of report.

In the attached project execution programme, we have allowed for a

turn around for the review and approval of the materials by the

4% Redco International DAEWOO E&C

2.21

Engineer.

A detailed procurement and delivery schedule will be produced

every week to ensure that when materials arrive at site it shall be

unloaded immediately

Planning Engineer shall issue a weekly schedule for material

required on site. Site Management team shall make the necessary

arrangements to comply with this schedule.

Drawings Submittals

Coordinated shop drawings / installation drawings for the civil works,

Electrical/Mechanical Works shall be prepared and submitted to the

Engineer for approval.

1) Shop drawings for the civil works shall be prepared in the

main office in coordination with the Project Engineer.

2) For Mechanical, Electrical and Plumbing Works proposed

Subcontractor shall prepare and submit their detailed

shop/installation drawings which will, be submitted to the

Engineer for his approval

3) All shop drawings shall be reviewed prior to submission to the

Engineer for comments, and if any shall be incorporated and

resubmitted for approval with a new revision. The approved

drawings shall be forwarded to the Construction Team

[Concerned Subcontractor thereafter.

4) The drawings submittal & approval register status shall be

developed for the Design Drawings and shop drawings status

indicating the following

- Submittal Number

- Drawing Number

- Drawing Revision

- Drawing Title

~ _ Date of submission for review by the Engineer.

- Date of approval.

- Approval status as on date of report.

@%Redco International DAEWOO E&C

3.1

3.2

CHAPTER 3 - GENERAL CONSTRUCTION SCHEDULE

General

As per the requirements of the tender documents, we have

analyzed and planned the major construction activities for the

project. The schedule is prepared based on a computerized network

analysis, on Primavera Project Planner (P6) software using the

latest version of the programme software.

As per the tender documents, the allowable construction duration is

730 days from the commencement date to the date of preliminary

acceptance of the complete system. We will submit a detailed

construction progress schedule with in specified time period based

on the schedule prepared at the bidding stage and pursuant to the

requirements and specifications of the contract, to the Engineer for

review and approval.

Preparation principle of general construction schedule

(1) General construction schedule shall be strictly prepared

according to the requirements specified in the tender

document.

(2) It shall highlight the importance of the project and critical path

of the construction. It shows the sequence of the construction

activities and the high priority of the construction activities

which are difficult, or need long time to be completed, or

interfere with the other activities, in order to ensure the

completion of critical construction path. Coordinate the

construction of every structure according to the rationalization

of each structure's construction period in order to minimize

the interference between activities.

(3) Optimize construction method, allocate sufficient equipment,

enhance the construction arrangement and coordination, so

that we can meet the requirements specified in the tender

documents on quality and progress with proper management

and utilization of sufficient construction equipments.

(4) Balanced construction with assurance of construction safety

and quality shall be achieved to the maximum degree by fully

familiarizing with basic project data and by adopting advanced

construction technology and equipment. In case of change of

construction condition adjustment shall be made to ensure the

@%Redco International DAEWOO E&C

implementation of construction program.

(5) Before the start of main structure construction all relevant

preparatory work shall be completed so as to create

conditions for smooth starting of main structure construction.

(6) Construction program shall be properly prepared and

construction efficiency shall be improved by making full use of

construction experience and deployment of advanced heavy-

duty construction equipment so as to meet with each

construction milestones.

Progress Control for the project shall include the preparation of a

detailed schedule identifying all the activities (including Engineering,

Procurement, delivery of long lead items and subcontract works and

Construction works) and regular monitoring of the schedule shall be

done by utilizing Primavera P6 software. A preliminary work

program bar chart is included in ‘CONTRACT EXECUTION PLAN —

EXECUTION PROGRAM’

A comprehensive planning package based on a contract execution

plan shall be submitted to the Engineer for approval. This program,

once approved, shall become the project Base Line Program.

Planning Engineer shall operate the planning, control and reporting

system for this project from the main office.

Planning documents shall be prepared in different levels. These are

Level-1, Level-2 and Level-3.

- Level - 1 Bar Chart shall cover all the works packages

- Level - 2 Bar Chart shall be at the work group level.

- Level - 3 Bar Chart shall reflect all the work elements.

Level-3 activities can be rolled into Level-2 and Level-2 can be

rolled into Level-1. Alll the activities in the Level 3 schedule shall be

assigned weightage based on estimated man-hours and when

approved, this shall be the basis for the detailed progress reporting

system

Progress S-Curve and Manpower Histogram shall be prepared

based on the resource loading in Level 3 schedule.

The schedule shall be updated with progress on a regular basis.

Actual progress shall be measured based on physical achievement

@% Redco International DAEWOO E&C

3.3

3.3.1

only. Look ahead bar charts (90 days, 60 days, 30 days and etc.)

as required shall be extracted from the updated schedule.

Daily, weekly and monthly reports shall be submitted on a regular

basis throughout the project duration on an approved format by the

Engineer

Construction schedule of major works

Based on the successful experience gained in other similar projects

and taking into account the other factors to the construction of the

project (such as bad weather, local holidays, contingency etc.), the

general construction schedule is prepared in a reasonably-

optimized way by deploying sufficient manpower and mechanical

equipment.

Upon award of the Contract, the mobilization process will be started

including possession of site/handing over site by the employer,

followed by the commencement of the preparation work for

construction, such as the Camp Construction, access roads

construction, excavation for fill materials, and erection of auxiliary

facilities. Possession of site and land acquisition in timely

manner is critical for the successful completion of the bridge

structure as per construction schedule attached.

As per the construction features of the present Project, we have

strictly arranged the Construction schedules of major unit works

under the Contract. All of construction activities shall be completed

within 714 days subject to complete handing over of the cleared &

unobstructed site, not including demobilization. Each construction

process shall be conducted alternately or one after another to

achieve the objective of the general construction schedule.

The Work is divided into three stages i.e Preparation, Construction

and Completion/Handing over.

Preparation Stage

Upon receipt of Notice to Proceed and/or construction site is

handed over in timely manner, the project adjacent civilian houses

shall be rented for use at the early stage of construction and mobile

equipment such as diesel generators, air compressors, excavators

and dump trucks shall be used for the construction of temporary

20

@%Redco International DAEWOO E&C

3.3.2

3.3.3

3.4

access road so as to ensure the transportation of heavy duty

equipment as well as for the construction site preparation.

Meanwhile Engineer's site office, contractor's site office and camp

shall be established. The construction equipment shall be ordered/

purchased and delivered to site during this stage. The stake out

survey shall be completed and control points shall be established

Construction Stage

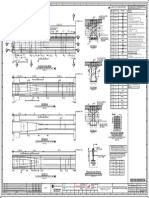

Bridge Construction Work includes excavation, pouring of bored

piles under piers, anchor block, abutment and hammer heads,

construction of pile caps under piers and auxiliary support,

construction of anchor block, abutment and pylon ring segment

bottom and hammer heads concrete, construction of steel falsework

for bridge steel girder, installation of bridge steel girders, installation

and post tensioning of piers tendons, installation and completion of

steel ring segment of pylon, construction of top deck slab,

installation of bridge suspension cable and hangers, installation of

piping and services, removal of steel falsework, laying of bituminous

road base course and wearing surface, installation of railings and

crash barriers, marking of bridge's roadways and traffic signs,

installation of bridge street lightings, electrical cables and lights,

installation of signboards for marine traffic, installation of lightning

protection and dehumidification system.

The arrangement of construction fronts and the organization of flow

process shall be reasonable so as to ensure the full use of

resources and smooth link-up of construction procedures and

sequences. Please refer to sequence drawings for construction

stages.

Completion / Handing over

Before the end of 714 days, all the major and minor works will be

completed. The last 16 days shall be reserved for the site clearance

and demobilization. The temporary construction facilities shall be

demolished or removed and the site shall be reinstated to the

original condition as far as possible.

Construction Schedule Reference.

For details of general construction schedule please refer to

4 Redco International DAEWOOE&C

3.5

‘CONTRACT EXECUTION PLAN — EXECUTION PROGRAM’.

Optimization.

Upon the award of Contract, we will further optimize our technical

proposal including general construction schedule to be submitted to

Engineer for approval, and the proposed construction equipment

and proposed personnel and other construction resources will be

adjusted to the best quantity accordingly.

@Redco International DAEWOO E&C

41

42

43

4.3.1

4.3.2

CHAPTER 4 — ORGANIZATION AND RESOURCE

ALLOCATION

Resource arrangement

Upon award of Contract, project management personnel shall be

deputed immediately to site and a team made up of project manager

and key construction personnel shall make further investigation of

the site and prepare a practical construction organization design

loaded with resource requirements. Mobilization of personnel and

equipment shall be carried out immediately and purchase contracts

with qualified manufacturers concerning plant and equipment to be

purchased shall be signed. Key temporary facilities including

construction camp and auxiliary facilities shall be set up and early

preparation shall be completed in a shortest time to ensure the

‘commencement of project as required.

Mobilization of personnel and equipment

Mobilization of personnel is initially planned to be carried out in

stages. At the initial stage, 30 personnel shall be deployed at site

after the signing of the Contract and at the second stage, more 100

persons shall arrive at site after the commencement of the Contract

depending on approved manpower schedule. On the succeeding

stage, deployment shall be in accordance with the work requirement.

Most of the construction equipment shall be company owned, and

some of them will be rented locally.

Method of mobilization of equipment and material

Method of equipment mobilization

New equipment shall be shipped to Doha seaport oy Sea and then

drive on to the site by themselves or transported to the site by flat-

bed trailer.

Method of main material mobilization

Material including concrete, asphalt, and steel bars etc; shall be

purchased from the local supplier and transported to the site by

road, Excavation material or borrowed material shall be transported

through temporary access roads from borrow/quarry area up to

€% Redco International DAEWOO E&C

44

45

4.3.1. Major responsi

existing Asphalt road than up to construction site.

Construction organization

Once the Construction Contract is awarded to REDCO - DAEWOO

JV, we will organize a Project Management office immediately. The

head of organization will consist of Project Manager, one

Construction Manager for alll of the construction activities under the

leadership, there will be functional departments such as Sub-

contractor Coordinator, Accountant, Contract Manager, Planning

Manager, Engineering Manager, Quality Assurance/Quality Control

Manager, Plant Manager, Health Safety Manager and

Admin Officer

The construction Manager will have with his team of senior surveyor,

site engineers, supervisors/foremen for earth work and bridge

structural works.

Construction organization Chart

The whole project is managed layer by layer and run according to

specialty as shown in the detailed Construction Organization Chart

attached. See Technical Proposal Schedule 5.0

ies of key personnel/departments

- Project Manager

4) Project manager, who is the official representative of

REDCO - DAEWOO JV on the site, is the core of

administrative organization and responsible for the project

management and for dealings with the Employer and/or its

Engineer and local authorities. The project manager is

responsible for executing and maintaining the works

according to the contract, implementing quality policies of

the corporation, achieving construction objectives of the

project and various economical and technical targets.

2) Project manager is also responsible for the

implementation of regulations established by the JV and

various decisions made by the JV, the setting-up of site

management organization, allocation of personnel and

other resources, clarification of the responsibilities of

concerned persons.

3) Project manager shall make appropriate decisions on

4

@%Redco International DAEWOO E&C

project management timely, appoint and remove

personnel, make decisions on critical construction

methods, financial works, resources allocation, plan and

progress, contract agreement, variations, and cost control.

- Construction Manager

1) Construction Manager shall be responsible for project

construction activities, methodology, quality of work and

safety of construction operation, make decisions for major

technical methods of the works at the project construction

stage.

2) Construction Manager is responsible for Progress of work

while meeting the targets for major construction milestone

as per construction schedule or as per revised plan by

planning engineer.

3) Construction Manager shall coordinate and arrange

quality/technical matters between various departments.

4) Construction Manager is responsible for the progress of

various teams deputed for construction such as survey,

earthwork and structural activities involved in the

construction of the bridge

5) Construction Manager shall carry out the direction from

the Project Manager and Engineering Manager.

- Engineering Manager

1) Engineering Manager shall be responsible for all the

design works at the various stages of construction of the

Project.

2) Engineering Manager shall coordinate with all concerned

departments for the implementation of technical designs.

3) Engineering Manager shall coordinate all work related to

design detailing and shop drawings.

- Quality Assurance / Quality Control Manager

1) Prepare and revise the quality assurance plan and the

assurance procedures which shall conform to the

specified requirements,

2) Ensure that all site personnel know and implement the

quality assurance plan by distributing quality assurance

plan documents and by carrying out internal quality audit,

3) _ Ensure that the corrective actions are put into operation,

4) Plan and carry out internal quality audits to verify

whether quality of activities comply with planned

@% Redco International DAEWOO E&C

5)

6)

arrangements and to determine the effectiveness of the

quality assurance plan,

Maintain records of the internal quality audits,

Make the plan and program conceming the quality

activities.

- Health, Safety and Environment Manager

1)

2)

3)

4)

5)

Carry out the health & safety education, check the

status of safety, ensure good safety management to

achieve the safety objectives.

Carry out the regulations and policies on safely, assist

construction staff to set up safety management

evaluation standards.

Check and inspect the construction activities regularly,

find out problems timely and correct them. If some

safety problems happen, the safety manager has the

right to ask them to stop the construction, rectify the

problems first.

Carry out relative safety and labor protection laws, make

statistics, analysis and reports on accidents, participate

in the investigation and treatment on accident

Dealing with the environmental issues regarding the

potable water pollution, waste oil, exhaust gas, powder,

noise pollution and ensure their prevention

- Contracts Manager

1)

The Contract Manager is responsible for all Contractual

matters, in charge of claim, quantity survey, subcontract,

cost control, quantity certification, preparation of running

bills and archives of contract documents.

- Planning Manager

1)

2)

The Planning Manager is responsible for monitoring the

progress and revision of activity schedule.

Preparation of daily, weekly and monthly progress

reports,

- Administration Officer

1)

The Administration officer is responsible for all

administrative matters including local coordination,

general service, accounting, and management of

personnel, for the procurement and storekeeping of all

materials and equipment local or imported as well as for

6

@%Redco International DAEWOO E&C

46

47

custom clearance of imported materials and equipment

- Sub Contractor Coordinator

1) The subcontractor coordinator is responsible for

coordination with the specialized subcontractors

assigned for bridge structure, post tensioning,

suspension cables and hangers, electrical works,

asphalt works, road marking and road signage works etc.

- Plant Manager

1) Plant Manager is responsible for all mechanical &

electrical matters & in charge of construction equipment

management, mobilization/transferring of machinery and

equipment, maintenance & repair, metal structure

fabrication and installation, electrical installation, power

supply, water treatment, and other supporting service.

Work Force

The work force assigned for this project shall be mobilized to the

site as per the construction progress requirements and will be

accommodated in our proposed staff camp. Daily transport from and

to the site shall be arranged by means of buses.

Work will be executed in 10 hour shift six (6) days a week. If we

found that working on Night shift and/ or Friday/Holidays are

required due to the magnitude of the project works, or for any

unforeseen reasons Engineer shall be advised for it and the timing

to be coordinated accordingly. All manpower shall be provided with

uniform carrying REDCO - DAEWOO JV identification Logo. The

construction manpower shall be readjusted according to actual

construction progress.

Mobilization plan of main equipment

Equipment arrangement shall be made subject to construction

program and intensity of each construction item. Number of

equipment arranged for excavation, piling works, compaction,

loading and transportation shall be 15% more than the required

strength. Priority shall be given to imported equipment with

excellent performance and operation records.

For complete list of equipment which REDCO - DAEWOO JV has at

n

@% Redco International DAEWOO E&C

48

49

present and is attached in Technical Proposal Schedule 7.0.

Material testing and quality inspection instruments

Instruments for material testing, survey and quality inspection shall

be in sufficient numbers in order to satisfy the project requirements.

Approved independent laboratory shall be arranged for the testing

of the major materials.

Material supply plan

Subject to information provided in tender documents and site

investigation, main material including Ready mix concrete, crushed

stone, sand, cement, stee! and asphalt for this project shall be

purchased locally from approved suppliers.

28

@% Redco International DAEWOO E&C

5.1

5.2

CHAPTER 5 — OVER ALL CONSTRUCTION STRATEGY

AND TRAFFIC DIVERSION

General

General Schedule of Construction has been made in a reasonably-

optimized way by providing sufficient manpower and mechanical

equipment with the consideration of similar successful practical

experiences as well as the normal negative factors to construction

such as bad weather, local holidays, and emergency incident on site

etc. Once the Contract is awarded, we shall immediately start the

preparation works for construction, such as equipment and personal

mobilization, control survey, access roads, utility survey, contact the

material suppliers, erection of auxiliary facilities.

As per the construction characteristic of the said Project, we have

strictly arranged the Construction Schedules of each major

individual work item under the Contract. The total Construction

activities shall be completed within 714 days. Each working

procedure shall be conducted concurrently or one after another so

as to achieve the objective of the General Schedule.

After the signing of Contract Agreement, a construction team will be

established for execution of the Contract. This team will be headed

by a Construction Manager at site who will work under the Project

Manager residing in the main site office. In the following paragraph

a brief description of Bridges works along with general sequence of

operation for Contract is given.

CONTRACT (Construction of Marine Signature Bridge 8 & 9)

The Contract is the construction of 2 nos. suspension bridges, the

Marine Signature Bridges 8 & 9 with built-up pylon towering within

the middle third of span. Both bridges 8 & 9 are 2-lane dual

carriageways with spans of 204m and 186m respectively measured

from the centerline’s start to end. The bridges are designed to be 2-

lane dual carriageways at the opening and will be transformed into

3-lane dual carriageways in the future located at Lusail City Doha

Qatar.

»

@%Redco International DAEWOO E&C

5.3

5.3.1

5.3.2

5.3.3

Phasing of Construction and Traffic diversion

General

We shall construct and maintain a temporary and efficient site traffic

diversion system to permit all existing traffic movements during the

construction period of Signature Bridges 8 & 9. Traffic diversion

shall comprise traffic management and the provision of adequate

drainage, lighting, sign posting and traffic control devices.

The main layout for site traffic diversion shall be adopted as per

requirement of tender drawings.

We shall widen and maintain the existing earth bridge to facilitate

the existing and future traffic during the entire construction of

Bridges 8 & 9 in accordance to the requirement mentioned in ITB.

These earth bridges will be demolished once its services are not

needed anymore prior to demobilization

Conformance

Traffic Signs and control devices associated with traffic diversion

shall conform to the relevant provisions of Qatar Traffic Manual

“Traffic Control at Roadworks and Bridges” produced by the Ministry

of Public Works and shall be to the approval of the Lusail safety

team and/ or local authorities.

Safety and Site Protection

We confirm that all safety issues associated with the installation

operation, maintenance and removal of traffic diversions shall be

implemented.

The construction site is located near the coastal line at Lusail, and

to ensure the safety of personnel and vehicles around the

construction site, pedestrians safety net, Traffic barriers, etc. shall

be set up to isolate site from outside.

Before the commencement of work, necessary traffic investigation

and contactinegotiation with local traffic administration shall be

carried out with reference to tender drawing for typical phasing of

construction, we shall prepare detailed plans showing any proposed

traffic diversions to the Engineer for review and shall be approved

0

@%Redco International DAEWOO E&C

by the Lusail Authorities/Traffic Police. The plans shall fully detail

the diversion in all respects and shalll include construction details if

necessary. The plans shall show the position of ramps, traffic signs,

cones, barriers, demarcation posts and tape, flashing lights and any

other traffic control devices. Traffic diversion apparatus shall not be

erected until the Lusail Authorities/Traffic Police have reviewed and

approved the traffic diversion plans. According to the site traffic

conditions, we shall undertake and manage Site traffic diversion in

three stages

If it is necessary or required by the Engineer, we shall arrange

exclusive persons to manage traffic at required location during

required times. Such persons acting as flagmen shall be physically

and mentally qualified and trained in their duties and courteous.

Each flagman on duty shall be identified with appropriate and

distinctive apparel approved by the engineer and equipped with

bilingual stop/go signs. Reflective apparel shall be used for flagging

duties during darkness.

Where upgrading/non-upgrading alternative route for right turning

traffic, carriageways or ramps are required, they shall be provided

and maintained to a standard suitable in all respects from the class

or classes of traffic or pedestrians.

On completion, all traffic diversion works and apparatus shall be

removed and land affected by them reinstated to its original

condition

at

@%Redco International DAEWOO E&C

CHAPTER 6 — CONSTRUCTION METHOD OF MAJOR ITEMS.

6.1

6.2

6.2.1

General

Detailed method statement for the major parts of the work shall be

submitted to the Engineer for approval prior to starting of any work.

Subcontractors’ works shall be coordinated and controlled by the

project programmed and the activities therein.

The sequence of operations shall be as outlined in the project

execution program.

Upon commencement of the Works and site possession, site layout

shall be submitted for the Engineer's approval including but not

limited to all temporary facilities, storage area and labour camp in

order to finish the mobilization.

It is envisaged that all construction will utilize tried and trusted

methods, using conventional plant and equipment, working to give a

quality finished product which meets the specifications in all

respects. The nature of the work, and the close tolerance laid out in

the specification, routine operations to be carried cut to the highest

standards of quality and accuracy.

The specified standard will be achieved by close control of materials

and workmanship. The key is to organize operations such that they

run smoothly and consistently.

Construction Survey

Reference points, Lines and Levels

All setting out shall be executed within a quality control system

implemented by the approved survey company.

The Engineer will provide reference survey control stations in the

field wherein the survey company can refer and establish the survey

control stations for construction.

Slope stakes, reference lines and points will be set out by the

survey company before the commencement of excavation and

layout of structures and would be re-established as required during

4% Redco International DAEWOO E&C

6.2.2

6.2.3

the progress of Works.

Establishment of baseline for calibration of EDM Equipment

The survey company shall be responsible for establishment and

maintenance of a baseline to calibrate EDM (Electronic Distance

Measuring) equipment at an appropriate location. The baseline shall

be established to conform to the Royal Institution of Chartered

Surveyors London publication "Guide for the Calibration and Testing

of EDM Instruments". It will also take into account the US Army

Corps of Engineer Publication No. ETL-0190 "The use and

calibration of distance measuring equipment for precise

measurement of dams (Revised)".

The Contractor shall be responsible for maintaining all survey

markers/monuments, and property corners. ‘If any

markers/monuments are destroyed or damaged, the Contractor shall

arrange to replace them to the entire satisfaction of the Engineer. If

a monument cannot be replaced in its original position, the

Contractor shall install a witness corner. The Contractor shall

complete and file monument reference cards on all monuments as

instructed by the Engineer.

The Contractor will employ experienced survey company with

adequate experience in the construction surveys similar in nature to

that required by this Contract.

Survey Procedure

For Survey procedure see the following flow chart.

3B

@% Redco International DAEWOO E&C

Flow Chart for Survey Work

Handing-over of primary control

point by the Engineer

|

Recheck of control point by the

Contractor

|

Establishment of control network

by the Contractor

+

Original topography survey Pad

Construction drawing

submission by design office

¥

Drawing checking

¥

Checking and filing by the Preparation of draft drawing and

Contractor ical data for field setting out

{ |

Recording of setting out |_| Fiold setting out

resulls

Insoection and approval by the

Field crosscheck Engineer

¥

Handing over of setting out points

to construction team

+

‘Commencement of field

Construction

“

@% Redco International DAEWOO E&C

6.3

6.4

6.5

6.5.1

Excavation program

General excavation will be carried out by either Excavators or

Bulldozers and the material will be loaded into trucks by front

shovels, or by direct loading using large backhoe. If and when rock

is encountered, it will be ripped as far as possible by Ripper-Dozer

until the rock becomes too hard. From this point, drilling will be done

by jack hammer mounted excavators.

All excavated surplus material will be disposed of at approved

locations adjacent to the works all in accordance with local

regulations. All dump trucks shall be covered during the transport of

excavated material. Haul roads will be continuously watered to

minimize dust.

Borrow pits will be arranged in such a manner as to minimize

haulage and disruption to the local population. All borrow pit and tip

sites will be reinstated to the Engineer's satisfaction as they

becomes redundant.

Backfilling

The material for back filling shall meet the requirement of the

specification. The back filling shall be carried out layer by layer. The

material shall be placed and leveled by excavator/loader. Manpower

shall be used where excavator is not suitable for placing and

leveling. Backfilled material shall be compacted to designed density

by the portable flat-plate compactors/small roller. Water shall be

sprayed to the backfilling material timely to prevent the dust

generating. Test will be carried out after the completion of the

compaction of the subject layer. Test result shall be submitted to the

Engineer for approval prior to start of the next layer.

The backfilling shall be a continuous process and shall not be

stopped until the layering is completed unless otherwise instructed

by the Engineer.

Bridge Construction Works

General

The scope of work includes the excavation, pouring of blinding

concrete, pouring of bored piles with permanent steel casing,

3s

@% Redco International DAEWOO E&C

6.5.2

65.3

6.5.4

6.5.5

construction of pile caps followed by piers, anchor block and

abutment, composite pylon, earth retaining walls, wing walls, bridge

deck steel girder, bridge deck top slab, post tensioning, suspension

cables and hangers, bridge accessories (crash barrier, signboards

and railing), paintings, lightings, electricals and etc.

Excavation

The site shall be investigated to be satisfied wth the situation

Resurvey shall be carried out to confirm the quality and level before

commencement of the excavation. Temporary drainage system shall

be in function during the excavation in case of any underground

water or raining. The excavation shall be carried out by excavator

and shall be disposed off with dumpers. The material shall be

dumped to the place as designated by the engineer. After

completing the excavation the contractor shall carry out survey and

report to the engineer for next procedures.

Concrete works

The concrete works shall be carried out according the specifications

or as instructed by the engineer.

Mix design

All concrete grades shall be designed according to the specification

and be verified by trial mix. The results of selected concrete trial mix

which meets all of the specification requirements will be submitted

to the Engineer for Approval. The blinding concrete shall be grade

30Mpa, for piling is grade 40Mpa underwater concrete. Concrete for

bridge deck slab, pylon piers, hammer heads and pylon ring is grade

60Mpa and grade 50Mpa concrete is to be used for the rest of the

structure. Concrete grout is C80 for top joint in hammer head & C60

for side joints of hammer head. Grade of concrete is defined in

accordance with BS EN 206-1 wherein the strength of concrete is

the 28 days characteristic. The mean strength shall meet the

requirement of specifications accordingly.

Supply of Concrete

We intend to use ready mix concrete for all concrete works. The

concrete will be transported from batching plant to construction site

for placement by concrete transit mixers/agitators. The pre-cast

36

@%Redco International DAEWOO E&C

concrete members will be transported to the desired place by any

truck or trailer.

6.5.6 Concrete construction

a. Construction Joint

Alll joints at the concrete structure should be according to the

design or according to the approved construction shop drawing.

Construction joints shall be located and the sequence of placing

arranged as approved, or as shown on the Drawings, to

minimize shrinkage and thermal strains in the concrete.

Horizontal construction joints in walls shall be formed along

straight lines which may coincide with the full height of the

formwork. Construction joints shall be formed normal to the

surface of the retained concrete.

Under the approval of the Engineer, a retarding agent may be

used on the construction joints and the laitance removed prior

to the next concrete pour using appropriate methods. Alll traces

of retarding agent shall be removed prior to subsequent pours.

The use of construction joints shall be avoided when possible

where they are in addition to the approved pour sequence

design.

b. Lift Height of Concrete

Unless otherwise shown on the Drawings or directed by the

Engineer, the permissible depth of concrete placed in one lift

shall be as follows:

- The permissible depth of concrete placed in one lift is 1.50 m

where the concrete is cast on bedrock and / or the thickness

of base slab and wall exceeds 3.00 m.

- The concrete directed dropped height should be not greater

than 1.00 meter.

- The details of concrete lifts should be according to the

approved concrete lift drawing or the instruction of the

Engineer.

6.5.7 Concrete Work Procedure

3”

@%Redco International DAEWOO E&C

The procedure for pouring of concrete shall be as following:

- Survey and marking of structural member,

- fix the reinforcements,

- install the embed parts,

install the formwork,

- Pouring the concrete.

Before pouring the concrete the pouring fronts, i.e, plumbness and

adequacy of the formwork, diameters and numbers of steel bars

installed, concrete spacers for coverings and chairs, cleanliness,

pouring guides and levels, shall be checked and approved by the

Engineer.

6.5.8 Concrete Workmanship

a. Formworks

The formworks shall meet the requirement of the specification

The surfaces of formwork should meet the approved finishes of

concrete on the drawings after stripping and the requirements

as stipulated in the Technical Specifications. Formwork

manufacturing and installation shall meet the requirements as

stipulated in the Technical Specifications of Special Provisions

strictly

All formwork and supports shall be strong and firm enough to

withstand all the loads and restrained from movement during

and after pouring of concrete. Joints shall be mortar-tight and

sufficiently strong to withstand weight of concrete and

equipment.

The ties or anchors for fixing formwork shall be not bent and

could easily be installed and rubber cones and nuts can easily

be removed. Connection of ties and anchorage shall be firmed

and have enough anchorage in enduring loads.

The periods of time elapsing between the placing of the

concrete for removal of formworks shall be according to

requirements as specified in the Technical Provisions.

b. Reinforcement

All reinforcement shall be purchased in batches according to

reinforcement detail drawings, design documents and

3

@%Redco International DAEWOO E&C

construction time plan. All steel reinforcing bars shall be stored

after testing in lots and approval, mark the batches according to

different grade, trademark, type and manufacturers, Each batch

of steel bar shall meet the requirement of Technical

Specifications in Special Provisions. Unqualified products shall

not be allowed to be delivered to site.

Reinforcement cutting and bending in workshop shall be

according to shop drawings and specifications in Special

Provisions. Cut, bent and fabricated reinforcing bars ready for

site installation shall be transported to site by trucks. Lifting to

working front shall be done by mobile crane or manpower and

fixed manually.

The reinforcement steel should be fixed on place by providing

enough ties using approved steel wires according to the

reinforcement detailed drawings. The cover to the reinforcement

should be maintained by concrete spacer blocks. The concrete

blocks should be approved by the Engineer. Prior to concrete

placement and / or during concrete placement, the positions of

reinforcement should be kept to the correct positions. It is not

allowed to shift or cut the reinforcement steel for convenience of

concrete placement.

c. Embedded Parts

Embedded parts include bridge expansion joints, items of post

tensioning system dead end anchorages, suspension cable

strands, pylon ring segment base plates and anchorages, joint

filler approved by Engineer and embedded according to the

drawings. Pay attention to concrete around embedded parts

during concrete placement. Correct promptly when there

appears distortion or moving

d. Joints Treatment

When the concrete is placed on base face, the foundation