Professional Documents

Culture Documents

Work Method Statement For Site Cabin Mobilization, Temporary Storage & Fabrication Area

Uploaded by

Mohd Hafizi AzlanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Method Statement For Site Cabin Mobilization, Temporary Storage & Fabrication Area

Uploaded by

Mohd Hafizi AzlanCopyright:

Available Formats

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 1 of 10

Method Statement Title:

Site Cabin Mobilization, Temporary Storage and Fabrication Area

Reviewed by Kinetics Approved by KSM

Submitted by Project Manager

Contractor Construction

QA/QC EHS

Manager

Signature:

Name:

Date:

Time:

Table of Content

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 2 of 10

Section Description

1.0 Introduction

2.0 Resources

2.1 Material

2.2 Machinery & Equipment

2.3 Manpower Involved/Plan

2.4 Contractor Involved

2.5 Qualification

3.0 Primary Requirement

3.1 Coordination Requirement

3.2 Others Operation Requirement

3.3 Receiving

3.4 Handling

3.5 Storage

3.6 Parking

4.0 Work Activity Methodology/ Arrangement

4.1 Site Preparation

4.2 Mobilization & Installation

5.0 Inspection, Testing, and Commissioning Proposal

6.0 List of Attachment / Appendices / References / Drawing

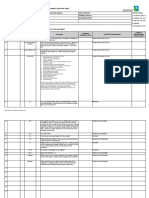

7.0 Safety Hirarc

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 3 of 10

1.0 Introduction

This document shall address the typical works of settings up for the office cabins and equipment,

temporary storage, fabrication area, general offloading and lifting operations of construction

materials/equipment.

2.0 Resources

2.1 Materials

All materials used on site must be approved type and they are as follows: -

No Type / Brand Name Description of Materials

1 Cabin 20FT x 8FT Lay down site office

2 Cabin 20FT x 8FT Storage cabin

3 Uni strut and accessories For storage rack

4 Floor protection Plywood/plastic sheet/Heavy

Duty Canvas

2.2 Machinery and Equipment

No Type / Model Quantity

1 Cutting Machine Various

2 Hand Tools Various

3 Ladder Various

4 Office Table Various

5 Printer Various

6 Office Chair Various

7 Lorry (Transportation) Various

8 Partition Board Various

9 Office Cabinet Various

10 Plotter Machine Various

11 Extension Wire Various

12 TIG Welding Set Various

13 Work Bench Various

14 Orbital Welding Set Various

15 Temporary DB Various

16 Spotlight Various

17 Genset Various

18 Vacuum set Various

19 Tent Various

20 Power Tools Various

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 4 of 10

2.3 Manpower Involved / Plan

Designation / Name (Kinetics) Key Person Quantity

Manager: / 1

Engineer: / 1

Supervisor: / 1

EHS: / 1

QA/QC: / 1

Designation / Name (DPV) Key Person Quantity

Manager: / 1

Engineer: / 1

Supervisor: / 1

EHS: / 1

QA/QC: / 1

2.4 Contractor Involved

Company Type / Model Quantity

CSA Contractor 1 lot

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 5 of 10

3.0 Primary Requirement

3.1 Coordination Requirement

3.1.1 The mobilizing operation shall be led by an Engineer. The role & responsibilities of

the various parties involved in the operation and together with the line of

communication are shown in the organization chart.

3.1.2 Client shall be informed of the date and time of mobilization in advance. Lifting

procedures shall be submitted to the client for review and approval in advance.

3.1.3 The EHS Officer shall determine the condition permissive for the operation before

proceeding with the work.

3.1.4 All lifting activities shall be coordinated by authorized personnel. Steps taken shall

follow the approved lifting procedures and any change made prior to or during the

operation shall be agreed upon by all relevant parties.

3.1.5 The Lifting Coordinator shall maintain overall control. No unauthorized personnel

shall instruct the operators to commence or cease work without instruction from the

coordinator.

3.1.6 Checks shall be carried out on shackles and other lifting equipment and verified

prior to lifting.

3.1.7 Pre-lift meeting shall be conducted by the Engineer-in-charge and attended by all

parties concerned.

3.2 Other Operation Requirement

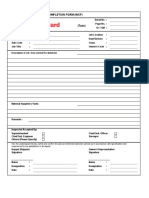

3.2.1 The following are to be prepared and performed during the mobilization of office

cabins, machineries and equipment presented to the client’s representative in

advance prior to the actual lifting.

i) Preparation of JHA and endorsement.

ii) List of equipment to be used for lifting such as cranes, sling, shackle, etc.,

complete with valid certificates.

iii) Identifying Engineer, Lifting Coordinator, and Supervisor Personnel in

charge for the lifting.

iv) Perform briefings to all personnel involved.

v) Lifting Plan.

vi) Permit to Work (PTW)/SIPP.

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 6 of 10

3.3 Receiving

3.3.1 All delivery materials to the site shall be informed to the site manager/ to have the

plan for unloading. Upon arrival of materials at the storage yard, the materials

controller will match delivery notes and shall verify the consignment.

3.3.2 Receiving/Handling/Storage for all materials must comply manufacturer’s

recommendation & IMCS

3.3.3 Upon arrival of the material, the consignment shall be verified by the supervisor to

match the packing list and inspected by Kinetics QAQC & Client.

3.3.4 All material received at site shall be visually inspected for any damages in order to

avoid of work.

3.3.5 Deliver each container with labeling intact which identifies manufacturer, type of

material, brand name, brand code, coverage, surface preparation, drying time,

cleanup, color designation, and instructions for mixing and reducing.

3.4 Handling

3.4.1 Proper methods & equipment, i.e., trolley or pallet jack to be used for transferring of

the materials or tools.

3.4.2 Supervisor shall monitor the work and ensure the work is complied with all safety

requirements.

3.5 Storage

3.5.1 Proper barricade & barrier ownership tag to be used for materials storage.

3.5.2 Proper containment tray to be used for materials storage.

3.5.3 Store materials in a sheltered dry place that is free from excessive moisture.

3.5.4 Daily housekeeping shall be carried out to ensure the cleanness of the area.

3.6 Parking

3.6.1 Site parking for Sub-Contractors are not provided in the compound of KMDP

WP10b. No reserved parking is available. Picking up and dropping off passengers

on the streets of KMDP WP10b is forbidden.

3.6.2 For vehicles that require regular access to Intel KMDPWP 10b, a gate pass

available at Intel Security. Vehicles of Sub-Contractors entering the compound of

KMDP WP10b will only be eligible to load/offload items required at work site.

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 7 of 10

3.7 Utilities

3.7.1 Power

a) Temporary power supply shall be provided at Fabrication area, Common areas

whichever required.

3.7.2 Water

a) Water supply shall be provided for sanitation with the installation of Hand-wash

Sink at selected areas. (if required).

3.8 Common Areas

3.8.1 List of common areas (below) to be concurrently established with the fabrication area:

a) Smoking Zone (if required)

b) Rest Area (if required)

c) Toilet Facility (Portable Toilet) (if required)

d) Eye-wash Station (if required)

e) Toolbox Meeting Area/Evacuation ground (if required)

f) Dumpster Area (if required)

g) Setup of these areas shall strictly follow the Standard Operating Procedure of

Covid-19 Prevention.

4.0 Work Activity Methodology / Arrangement

4.1 Site Preparation

No Activity Sequence

1 a) To inform related Project Manager, System Owner and KINETICS EHS

management before start work for the day.

b) To obtain the entire relevant valid EHS document before start work.

c) Identified the working area on site and potential obstructions/possible impact

on existing services before installation structures.

d) Get approval from Intel for the laydown area and mark on layout drawing.

e) Existing building and services shall be protected/relocated. (if any)

*To assign all the workers, stuff to attend safety induction before start work.

*

*Get the valid permit for the workers and machinery to enter the site.*

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 8 of 10

2 a) To Inform the Project Manager or person in charge before start work.

b) Detail of the activity to be performed shall be informed/briefed and explained

before starting work.

c) To ensure all gate passes, permits, tools & materials for safety precautions,

manpower and equipment are available and approved before commencement of

work. Precautions must be taken before and during activity in accordance to

DOSH standard.

d) To ensure access roads are always clear from any obstruction and site is

always accessible as approved by KINETICS & CLIENT.

e) To ensure all the materials used is approved before applied on site.

f) Provide safeguards, including related signages, barricades, temporary fences,

warning lights and other similar items that are required for protection of all

personnel during all activity involved.

4.2 Mobilization & Installation

No Activity Sequence

a) To inform related Project Manager, System Owner and EHS Management

1 before start work for the day.

b) Obtained the entire relevant valid EHS document before start work.

c) All Vehicles to comply the wheel stopper when loading material.

d) Shall be use manpower to mobilize the materials into the work location and

storage area. (Backhoe/Excavation & Lorry will be used for excavation)

2 To brief the workers on the job sequence and streamline their job for hazard

avoidance prior work starts.

3 Work Sequence

a) Fabricate and erect temporary fencing/hoarding: (if required)

- Unload material/Install surrounding fencing using manpower and hand/power

tools.

b) Offloading site cabin and material

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 9 of 10

- Cabin offloading & setup.

-To hoist down site office cabin, required material and facilities equipment from

trailer using a crane by the approved supplier.

- Critical lifting plan need to be prepared and approved by Intel EHS before

lifting.

c)Temporary DB setup:

- Wiring works and installation electric supply to site office.

- Spotlight, Lightning Arrestor & Earthing Installation

- Mobilize all the office facilities into the room, table, chair, computer, racks etc.

by using manpower.

d) Cable laying: (if required)

- Cable to be pulled and laid by discussed with KINETICS and seek approval from

KINETICS & INTEL.

- Connection of cable to be carried out under witnessed by KINETICS & CLIENT

REPRESENTATIVE.

e) Cable termination: (if required)

- Cable to be terminated under witnessed by KINETICS and INTEL

REPRESENTATIVE to the designated points by using the inspected termination

materials that include glands, lugs, and other accessories part of termination kit,

by using proper crimping tools.

- Meeting will be conducted prior termination work.

f) Energizing Temporary DB.

- Obtain a permit before a temporary DB can be set up.

- Inspection must be done by Authorized Personnel.

- Check power connection.

g) Fabrication Tent setup: (if required)

- Install at storage & fabrication area as overhead protection.

Rev. 0 Rev. date: 20210904

Work Method Statement for Site Cabin

Mobilization, Temporary Storage and

Fabrication Area

Prepared by: Ref. no:

(Signature)

Revision:

Name: Date:

Contact no.:

Company: Page 10 of 10

- Place 3mm Plywood for floor protection.

h) Common area setup: (if required)

- Smoking Area will be setup using manpower and hand/power tools.

- Barricade smoking area and provide ash-trays’ stands for proper dispose of

buds. Only 6 pax allowed at a time.

- Setup Rest area using manpower and hand/power tools.

- Rest area to follow social distancing of 2.0metre for the seats and table

arrangement.

- Mobilize materials and tools to the work location and store at temporary

storage

- Fabricate and erect storage rack using manpower, hand/power tools and

Unistrut.

4 COVID 19 Safety Measures to be follow strictly throughout the setup.

5 To do final housekeeping at works area and proper material arrangement.

5.0 Inspection, Testing and Commissioning Proposal

N/A

6.0 List of Attachments / Appendices / References/ Drawing

Attachment layout of the location of Site Cabin, Temporary Storage and Fabrication Area

Document Reference No. Document title

Rev. 0 Rev. date: 20210904

You might also like

- Work Method Statement For Painting Existing TrussDocument11 pagesWork Method Statement For Painting Existing TrussMohd Hafizi AzlanNo ratings yet

- Work Method Statement For DemolitionDocument9 pagesWork Method Statement For DemolitionMohd Hafizi AzlanNo ratings yet

- WMS of Plasterboard Ceiling Installation 1Document11 pagesWMS of Plasterboard Ceiling Installation 1Mohd Hafizi AzlanNo ratings yet

- Work Method Statement For Constructing New RC Plinth & Top Up SlabDocument9 pagesWork Method Statement For Constructing New RC Plinth & Top Up SlabMohd Hafizi Azlan100% (1)

- Work Method Statement For Painting Existing WallDocument11 pagesWork Method Statement For Painting Existing WallMohd Hafizi AzlanNo ratings yet

- Work Method Statement For Constructing RC FoundationDocument16 pagesWork Method Statement For Constructing RC FoundationMohd Hafizi AzlanNo ratings yet

- Boundary Wall Design Staad File PDFDocument6 pagesBoundary Wall Design Staad File PDFParwan Exceltech0% (1)

- KLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFDocument10 pagesKLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFLenaldy Nuari GarnokoNo ratings yet

- PE Design OnDocument13 pagesPE Design OnMASITAH MUHAMMADNo ratings yet

- Check List - RULE 13Document4 pagesCheck List - RULE 13rajeshNo ratings yet

- 1231 de 00 DC PCJ 001 01Document33 pages1231 de 00 DC PCJ 001 01Hamid MansouriNo ratings yet

- Analisa Srtuktur Dengan Staad-Pro V8iDocument4 pagesAnalisa Srtuktur Dengan Staad-Pro V8ianggarNo ratings yet

- DPR Format SipbDocument6 pagesDPR Format SipbNet PlaZaNo ratings yet

- Bar Cutting Machine HSE ChecklistDocument2 pagesBar Cutting Machine HSE ChecklistMD Abdullah100% (1)

- Maintenance Order FormDocument2 pagesMaintenance Order FormErBikasKumarPathakNo ratings yet

- Apron FeederDocument8 pagesApron FeederBruce QuareNo ratings yet

- Design Report PDFDocument439 pagesDesign Report PDFKhaled Abdel SalamNo ratings yet

- Sample MRB Index For ENIDocument1 pageSample MRB Index For ENIAnanthu Krishnan100% (1)

- CRS - MSJSA For Lube Oil Flushing 43Document3 pagesCRS - MSJSA For Lube Oil Flushing 43Riaz Ali Khan BangashNo ratings yet

- DPR Itp CPCC 14.03.2024Document2 pagesDPR Itp CPCC 14.03.2024lahiru sudeeshaNo ratings yet

- Atc.200.p500a.00000.Spc.01.a General SpecificationDocument16 pagesAtc.200.p500a.00000.Spc.01.a General SpecificationSuraya MirandaNo ratings yet

- QA-05 (A), (B) & (C) Insp Reps 2Document1 pageQA-05 (A), (B) & (C) Insp Reps 2dominicNo ratings yet

- Design IMCS SpecificationDocument12 pagesDesign IMCS SpecificationMASITAH MUHAMMADNo ratings yet

- Manual For Shop Drawing (MN-06) Rev. 2Document51 pagesManual For Shop Drawing (MN-06) Rev. 2Sirapat PornthuengNo ratings yet

- Datasheet For RTD and ThermowellDocument1 pageDatasheet For RTD and ThermowellJeshinNo ratings yet

- JHA - 3D Laser Scan Piperack U-150 - Rev 0Document7 pagesJHA - 3D Laser Scan Piperack U-150 - Rev 0limah yahyaNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- MS Grout Rev ADocument38 pagesMS Grout Rev AAhmed GomaaNo ratings yet

- Electrical CabnetDocument19 pagesElectrical Cabnetranjith_007100% (1)

- Blue Print PPDocument52 pagesBlue Print PPKaran KadamNo ratings yet

- Job Information: Engineer Checked Approved Name: Gunjal Aniket DateDocument7 pagesJob Information: Engineer Checked Approved Name: Gunjal Aniket Date31 Gunjal AniketNo ratings yet

- QP 9.21 Form A: Work Completion Form (WCF) : Description of Job (See Overleaf For Sketches)Document3 pagesQP 9.21 Form A: Work Completion Form (WCF) : Description of Job (See Overleaf For Sketches)sivaNo ratings yet

- Job Information: Engineer Checked ApprovedDocument47 pagesJob Information: Engineer Checked ApprovedAdvent ManurungNo ratings yet

- HPCL-TBMF 5x5x5 Toolbox Meeting FormDocument1 pageHPCL-TBMF 5x5x5 Toolbox Meeting FormKemo FrederickNo ratings yet

- ST04-2nd Sty Flat SlabDocument11 pagesST04-2nd Sty Flat SlabThaung Myint OoNo ratings yet

- Slab Design ResulltsDocument5 pagesSlab Design ResulltssereneNo ratings yet

- Case Study F BatchDocument2 pagesCase Study F BatchBalujagadishNo ratings yet

- ITR-MRE (Rotating Equip.)Document25 pagesITR-MRE (Rotating Equip.)mahmoudNo ratings yet

- Form A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Document2 pagesForm A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Emma DNo ratings yet

- Datasheet For Side Entry MixerDocument4 pagesDatasheet For Side Entry Mixervinoj chandranNo ratings yet

- Commented VDRL From OxyDocument2 pagesCommented VDRL From OxySUBRAMANIAN JAMBUNATHA DEEKSHIDHARNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument3 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- FORM 08 - Intervention Report - Cold SHEAR ClutchDocument2 pagesFORM 08 - Intervention Report - Cold SHEAR ClutchRamy Hassan EmaraNo ratings yet

- Part-1 (Vol - III) - Bidding DocumentDocument23 pagesPart-1 (Vol - III) - Bidding DocumentjeevanNo ratings yet

- IPP FormDocument1 pageIPP FormbrijeshNo ratings yet

- Services Rig Survey ReportDocument3 pagesServices Rig Survey ReportKuOneMohdAzrulNo ratings yet

- Job Information: Job No Sheet No RevDocument15 pagesJob Information: Job No Sheet No RevRommel AzoresNo ratings yet

- Prosedur HDD S. PeluhDocument21 pagesProsedur HDD S. PeluhHandri PuriNo ratings yet

- Indian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Document15 pagesIndian Railways: FOR BOGIE OPEN WAGON (91.6 Tonnes)Pratap Singh GangwarNo ratings yet

- TP-CGDF-80280-SPC-A4 - A2 - Specification For Platforms, Stairs, Ladders and HandrailsDocument11 pagesTP-CGDF-80280-SPC-A4 - A2 - Specification For Platforms, Stairs, Ladders and HandrailsPrasad BaleNo ratings yet

- Technical Particulars Cum Data Sheet For LV Sq. Cage Induction MotorDocument13 pagesTechnical Particulars Cum Data Sheet For LV Sq. Cage Induction Motorasex4uNo ratings yet

- Initial Concrete Batch Plant QC Surv (2002)Document6 pagesInitial Concrete Batch Plant QC Surv (2002)aslam.ambNo ratings yet

- Structure 1Document5 pagesStructure 1Krizsel ContrerasNo ratings yet

- Session Presentation 02 - (IPES-QS-T01 Estimating and Tendering)Document21 pagesSession Presentation 02 - (IPES-QS-T01 Estimating and Tendering)musthaqhassanNo ratings yet

- Revised Resource Plan (R6)Document2 pagesRevised Resource Plan (R6)Vashav PandeyNo ratings yet

- Bechtel Rigging Handbook 2nd Edition Part 1Document26 pagesBechtel Rigging Handbook 2nd Edition Part 1Yl Wong100% (1)

- Process Industry Practices Vessels: Pip Vedbi003 Vessels For Bulk Solids Data SheetDocument7 pagesProcess Industry Practices Vessels: Pip Vedbi003 Vessels For Bulk Solids Data Sheetmsaldivar177No ratings yet

- 055A-Jash-JEC-PA 2020 C 009 G-CP823-3-Sewage PS at Doha North STW - Pkg3-Penstocks-R1Document314 pages055A-Jash-JEC-PA 2020 C 009 G-CP823-3-Sewage PS at Doha North STW - Pkg3-Penstocks-R1721917114 47No ratings yet

- Engneering WorkshopDocument29 pagesEngneering Workshopsanjeevani rawatNo ratings yet

- Work Method Statement For Fire Rated and Non-Fire Rated WallDocument14 pagesWork Method Statement For Fire Rated and Non-Fire Rated WallMohd Hafizi Azlan100% (1)

- WMS of Plasterboard Ceiling Installation 1Document11 pagesWMS of Plasterboard Ceiling Installation 1Mohd Hafizi AzlanNo ratings yet

- Read MeDocument6 pagesRead MeLuciana FaccinNo ratings yet

- ArrowDocument1 pageArrowMohd Hafizi AzlanNo ratings yet

- XeroxWC 5020DN Service Manual 03.02.2012 PDFDocument432 pagesXeroxWC 5020DN Service Manual 03.02.2012 PDFSergey100% (1)

- Transfer Request 2022 - CBOA CHENNAIDocument5 pagesTransfer Request 2022 - CBOA CHENNAIVignesh NarayananNo ratings yet

- Tender Document For EOI of NIFT BhopalDocument19 pagesTender Document For EOI of NIFT Bhopalkethhes waranNo ratings yet

- Assignment-3: Marketing Management (MGT201)Document6 pagesAssignment-3: Marketing Management (MGT201)Rizza L. MacarandanNo ratings yet

- VW 60330 2009 12 eDocument29 pagesVW 60330 2009 12 eAmir Borhanipour100% (1)

- NS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710Document27 pagesNS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710PHAM PHI HUNGNo ratings yet

- BC Caribou Recovery Program Stakeholders Teleconference MinutesDocument5 pagesBC Caribou Recovery Program Stakeholders Teleconference MinutesRevelstoke MountaineerNo ratings yet

- Guru Stotram-1Document5 pagesGuru Stotram-1Green WattNo ratings yet

- Visibility of NursesDocument17 pagesVisibility of NursesLuke ShantiNo ratings yet

- Air Quality StandardsDocument2 pagesAir Quality StandardsJanmejaya BarikNo ratings yet

- Initial 2Document6 pagesInitial 2Asad HoseinyNo ratings yet

- Functional Plant Manager 2. Geographical Vice PresidentDocument5 pagesFunctional Plant Manager 2. Geographical Vice PresidentVic FranciscoNo ratings yet

- Ictracker Summary of Stocks With Outlook 'Strong Buy' in United StatesDocument12 pagesIctracker Summary of Stocks With Outlook 'Strong Buy' in United StatesBosZ AndersonNo ratings yet

- M7Ge-Iiib-1: Renante Tillo JosolDocument3 pagesM7Ge-Iiib-1: Renante Tillo JosolRenante T. JosolNo ratings yet

- SPC Company BrochureDocument22 pagesSPC Company BrochureDaivasigamaniNo ratings yet

- Language - Introduction To The Integrated Language Arts CompetenciesDocument7 pagesLanguage - Introduction To The Integrated Language Arts CompetenciesHari Ng Sablay100% (1)

- BarDocument1 pageBarJoannalyn Libo-onNo ratings yet

- ECN 331 Fall 2018 SyllabusDocument6 pagesECN 331 Fall 2018 SyllabusDat BoiNo ratings yet

- Proposal For Research Work at Iit Indore: ProjectsDocument2 pagesProposal For Research Work at Iit Indore: ProjectsAman GargNo ratings yet

- 6 Best Chainsaw Under 300: A Complete Buying Guide: What We LikeDocument5 pages6 Best Chainsaw Under 300: A Complete Buying Guide: What We LikeFahim WatsonNo ratings yet

- Case Analysis: A Simple Strategy at Costco: Informative Background InformationDocument15 pagesCase Analysis: A Simple Strategy at Costco: Informative Background InformationFred Nazareno CerezoNo ratings yet

- REACH ArticlesDocument12 pagesREACH ArticlesChristian SugasttiNo ratings yet

- Brand Loyalty & Competitive Analysis of Pankaj NamkeenDocument59 pagesBrand Loyalty & Competitive Analysis of Pankaj NamkeenBipin Bansal Agarwal100% (1)

- Tea Board of India PDFDocument18 pagesTea Board of India PDFDebasish RazNo ratings yet

- ECON 211: Principles of Macroeconomics-901: Smhussain@vcu - EduDocument6 pagesECON 211: Principles of Macroeconomics-901: Smhussain@vcu - EdusshinnNo ratings yet

- RTI SpicesDocument226 pagesRTI SpicesvivebajajNo ratings yet

- Assignment No 5Document10 pagesAssignment No 5darshan KeskarNo ratings yet

- Final Year Project Edi IrawanDocument75 pagesFinal Year Project Edi IrawanEdi IrawanNo ratings yet

- Alien Bestiary PDFDocument450 pagesAlien Bestiary PDFDũng Lê100% (13)

- Asme B30.26 (2004)Document38 pagesAsme B30.26 (2004)Omar RamirezNo ratings yet