Professional Documents

Culture Documents

Work Method Statement For Painting Existing Truss

Uploaded by

Mohd Hafizi AzlanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Method Statement For Painting Existing Truss

Uploaded by

Mohd Hafizi AzlanCopyright:

Available Formats

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 1 of 11

Method Statement Title:

Work Method Statement for Painting Existing Trusses

Reviewed by Kinetics Approved by

KSM Project

Submitted by Manager

Contractor Project Engineer Construction

QA/QC EHS

Manager

Signature

:

Name:

Date:

Time:

Table of Content

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 2 of 11

Section Description

1.0 Introduction

2.0 Resources

2.1 Material

2.2 Machinery & Equipment

2.3 Manpower Involved/Plan

2.4 Contractor Involved

2.5 Qualification

3.0 Primary Requirement

3.1 Coordination Requirement

3.2 Others Operation Requirement

3.3 Receiving

3.4 Handling

3.5 Storage

4.0 Work Activity Methodology/ Arrangement

4.1 Site Preparation

4.2 Mobilization & Installation

5.0 Inspection, Testing, and Commissioning Proposal

6.0 List of Attachment / Appendices / References / Drawing

7.0 Hirarc Assessment

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 3 of 11

1.0 Introduction

This document shall address the typical works for cleaning and grinding works. The existing wall at

the said area are required to be cleaned and grinded for receiving the skim coat finishing.

1.1 The construction standard above is shown as following: -

IMCS Specification: -

IMCS SECTION DESCRIPTION

Section 09_91_13_00 (09915) Painting- Building

2.0 Resources

2.1 Materials

All materials used on site must be approved type and they are as follows: -

No Type / Brand Name Description of Materials

1 Nippon Paint Primer Coat/ 4.0 MDFT/ 101.6

Nippon 8048 zinc phosphate primer QD micron

x 1 coat primer

Color: Pearl Grey

2 Nippon Micaceous Iron Oxide MIO x 2 Finish Coat/ 2.0-5.0 MDFTPC

finishing coat /152.4 micron

Color: Silver Matt finish

2.2 Machinery and Equipment

No Type / Model Quantity

1 Rubber tray Various

2 Brush Various

4 Roller Brush Various

5 Plastic Sheet Various

6 Roller Bin Various

7 Roller Pole Various

8 Scraper Various

9 Sand Paper Various

10 Scissor Lift 2 Nos

11 Exhaust Fan 2 Nos

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 4 of 11

12 DFT Gauge 1 Nos

13 Wet Film Thickness Gauge 1 Nos

2.3 Manpower Involved / Plan

Designation / Name (Kinetics) Key Person Quantity

Manager: / 1

Engineer: / 1

Supervisor: / 1

EHS: / 1

QA/QC: / 1

Designation / Name (DPV) Key Person Quantity

Manager: / 1

Engineer: / 1

Supervisor: / 1

EHS: / 1

QA/QC / 1

QA/QC: / 1

2.4 Contractor Involved

Company Type / Model Quantity

Painting 4

2.5 Qualification

- Original Equipment Manufacturer (OEM) Approval installer & accordance to IMCS

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 5 of 11

3.0 Primary Requirement

3.1 Coordination Requirement

Identification of existing services and structure around the working area.

3.2 Other Operation Requirement

- Work access to the construction area need to confirmed and approved by Kinetics.

- Location for storage and the type of material to store must be approved by Kinetics.

3.3 Receiving

- Upon arrival of the material, the consignment shall be verified by the supervisor to match

the packing list and inspected by Kinetics QAQC & Client.

- All material received at site shall be visually inspected for any damages in order to avoid of

work.

- Deliver each container with labeling intact which identifies manufacturer, type of paint,

brand name, brand code, coverage, surface preparation, drying time, cleanup, color

designation, and instructions for mixing and reducing.

3.4 Handling

- Proper methods & equipment, i.e., trolley or pallet jack to be used for transferring of the

materials or tools.

- Supervisor shall monitor the work and ensure the work is complied with all safety

requirement.

3.5 Storage

- Proper barricade & barrier ownership tag to be used for materials storage.

- Proper containment tray to be used for materials storage.

- Store paint materials at minimum ambient temperature of 50 degrees F and a maximum of

90 degrees F, in well ventilated area, unless required otherwise by manufacturer’s

specifications.

- Provide storage facilities outside of buildings being constructed. Limit quantities in

buildings to daily use.

- Take precautionary measures to prevent fire hazards and spontaneous combustion.

- Daily housekeeping shall be carried out to ensure the cleanness of the area.

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 6 of 11

4.0 Work Activity Methodology / Arrangement

4.1 Site Preparation

- Planning the best route for the access to get in and out

- Investigate & coordinate of existing buildings, structure, M&E which may affected the

progress of the works.

- Identify the storage location for materials, tool and equipment.

- The working areas must be barricade using barricade cone and safety tape to avoid people

to enter the working areas.

4.2 Mobilization & Installation

No Activity Sequence

1 a) To inform related Project Manager, System Owner and KINETICS EHS management

before start work for the day.

b) To obtain the entire relevant valid EHS document, SIPP and PTP before start work.

c) To assign all the workers, stuff to attend safety induction before start work.

d) Get the valid permit for the workers and machinery to enter the site.

2 a) Inform the Project Manager or person in charge before start work

b) Detail of the activity to be performed shall be informed/briefed and explained before

starting work

c) Precautions must be taken before and during activity in accordance to DOSH standard

and Intel Safety standard.

d) During the progress of activity, the work shall be under the continuous supervision of an

experienced foreman.

e) Provide safeguards, including related signages, barricades, temporary fences, warning

lights and other similar items that are required for protection of all personnel during all

activity involved.

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 7 of 11

3 Mobilization of tools and workers

a) To inform related Project Manager, System Owner and EHS Management before start

work for the day.

b) Obtained the entire relevant valid EHS document before start work.

c) All Vehicles to comply the wheel stopper when loading material.

d) Shall be use manpower to mobilize the materials into the work location and storage

area.

f) Get advised from KINETICS project management team for the location for material

storage.

g) Shall be used forklift to mobilize the materials into the work area if necessary.

h) Pallet Jack shall be used during work where necessary for mobilize the material to work

location needed.

4 To brief the workers on the job sequence and streamline their job for hazard avoidance

prior work starts.

5 Hard barricade all working area by using tubular scaffolding.

6 To prepare the power supply to the working area by using extension wire for temporary

lighting at night.

7 Sequence of Paint

a) Clean to substrate loose, abraded, or damaged coatings by hand or power tool.

b) Apply one spot coat of the specified primer to bare areas overlapping the prepared

existing coating.

c)Apply one full coat of the specified primer or finish coat(s) overall.

d)Surface to be painted must be cleaned thoroughly and dry, it must be free from dirt,

grease and other foreign matters. Dry brushing/cleaning by using brush/fabric/cloth to wipe

and remove the dust/dirt will be sufficient.

e) Working platform to reach the height level of wall by using scissor lift

f) Barricade the perimeter of working area.

g) (IMCS 09915 division 9, Paint System P-38) for Fast Dry Alkyd Top Coat: metal and

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 8 of 11

steel

Painting Work Sequence

a) Primer coat application

1) Nippon 8048 zinc phosphate primer QD. Primer Coat/ 4.0 MDFT/ 101.6 micron.

b) Intermediate and Top Coat Application

1) Allow minimum 16 hour for curing before apply finish coat.

2) Total 2 layers of finish coat shall be at least 152.4 micron. Shall carry out

inspection together with Kinetics QAQC for the primer coat thickness test.

3) Each coat shall be checked for correct average DFT by the QC prior to

application of subsequent coat.

4) Surfaces shall not be re coated until the preceding coat has properly dried or

cured. The surface may be considered ready for re-coating when the next coat

can be applied without the development of paint film irregularities such as lifting

or loss of adhesion of the undercoat. However, the minimum or maximum drying

or curing time specified by the paint manufacturer shall be the acceptable.

5) Re-coat period paint shall not be force dried so as to cause checking, wrinkling,

blistering, pores formation or any condition detrimental to its appearance. Newly

painted surface shall be protected to the fullest extent feasible from rain

condensation, contamination snow and freezing until the coating has dried.

6) Invite Kinetics and Intel/ Rep for Mockup inspection. Proceed the rest truss

painting work upon approved.

8 Brush Application

Brush application may be used under the following circumstance:

a. When spraying for any reasons cannot properly coat areas.

b. For the application of self-etching primers

c. For "touch-up" or repair to localized damaged paint areas or areas of

incorrectly applied paint.

d. For application of initial stripe coat of paint to corners, edges, crevices,

holes, welds or other irregular surfaces.

Paint brushes used shall be of a style and quality that will permit proper and

appropriate application of paint. Good quality hog bristle is preferred and nylon or

other synthetic bristle types are prohibited. Round or oval brushes are considered

most suitable for rivets, bolts, irregular surfaces etc. Wide flat brushes are suitable

for large flat areas but not to exceed width of 120mm. Brushes shall be kept in

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 9 of 11

good condition at all times and discarded if damaged or excessively worn.

Roller Application:

Roller application shall be discouraged and shall be subject to the specific approval

of customer. If allowed, it will only be used on relatively large surface areas provide

the first primer coat of paint is applied by brush and its use in accordance to Paint

Manufacturer instructions. Rollers shall be manufactured from good quality.

9 COVID 19 Safety Measures to be follow strictly throughout the setup.

10 Housekeeping at end of each working day is a must for any scaffolding job.

Scaffolders on the site must ensure that:

All equipment has been cleaned and stored correctly away from access areas

Never leave equipment in walkways or doors

All fire exits and emergency access points are kept clear at all times and is never

blocked by equipment or rubbish

Report any hazards you might find to a supervisor promptly

Dispose of rubbish quickly and safely

The gear is consolidated and is all out of harm’s way when handing over scaffold

Before leaving the site each day, make sure that clean-up has been finalized and

no hazards are visible.

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 10 of 11

Inspection And Testing

Individual coat and completed coating shall be visually inspected for appearance. Coating shall be

smooth and free from run, cracking, blistering, pinholes, crater and sagging.

During coating, the wet firm thickness shall be spot-checked. Specified total minimum DFT shall be

spot-checked by thickness gauge. Dry film thickness shall also be measured on individual coats.

WFT and DFT measurements shall comply with ASTM D 4414 and SSPC-PA2 respectively.

Coating shall be removed and repainted if the specification reveals the following:

a. coating not adhering to surface to which it is applied

b. Surface has not been properly blasted and /or clean.

c. Loose or scaling paints remains.

d. foreign matter (contamination) embedded into coated surface.

e. Freshly coating surface is wet from rain, high humidity or low dew points.

f. Previously applied coating has not cured.

g. For other reason that will impair the coating performance.

5.0 Inspection, Testing and Commissioning Proposal

Inspection and test plan (ITP) shall include at the following stage.

a) Receiving of materials/ machinery

b) In-process inspection during installation

c) Final stage before handover

d) Mock-up inspection

e) Pre-Post inspection

ITP shall also address the “Hold Point”, where approval on the work activity is required.

Refer to Attachment 1: Inspection and Test Plan (DPV/ITP/DPPB/WP11d/CSA/002)

Rev. 5 Rev. date: 20210810

Work Method Statement for Painting Existing

Trusses

Ref. no:

Prepared by:

(Signature)

Revision:

Name:

Date:

Contact no.:

Company: Page 11 of 11

6.0 List of Attachments / Appendices / References/ Drawing

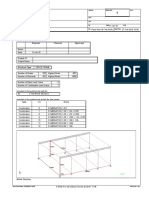

Attachment layout of the location of trusses re-painting.

6.1 List of &Catalogue

(Refer to KSM13108-DPV-WP11d-SUB-0010_R1)

Steel Trusses Paint (Nippon 8048 zinc phosphate primer QD

Nippon Micaceous Iron Oxide MIO

6.2 List of Drawing

6.2.1. Figure show the Trusses Painting construction area.

Document Reference No.

IFC Drawing

ITP

WMS

Rev. 5 Rev. date: 20210810

You might also like

- Robust Design Methodology for Reliability: Exploring the Effects of Variation and UncertaintyFrom EverandRobust Design Methodology for Reliability: Exploring the Effects of Variation and UncertaintyBo BergmanNo ratings yet

- Work Method Statement For Painting Existing WallDocument11 pagesWork Method Statement For Painting Existing WallMohd Hafizi AzlanNo ratings yet

- Work Method Statement For DemolitionDocument9 pagesWork Method Statement For DemolitionMohd Hafizi AzlanNo ratings yet

- WMS of Plasterboard Ceiling Installation 1Document11 pagesWMS of Plasterboard Ceiling Installation 1Mohd Hafizi AzlanNo ratings yet

- Work Method Statement For Constructing New RC Plinth & Top Up SlabDocument9 pagesWork Method Statement For Constructing New RC Plinth & Top Up SlabMohd Hafizi Azlan100% (1)

- Work Method Statement For Site Cabin Mobilization, Temporary Storage & Fabrication AreaDocument10 pagesWork Method Statement For Site Cabin Mobilization, Temporary Storage & Fabrication AreaMohd Hafizi AzlanNo ratings yet

- Work Method Statement For Constructing RC FoundationDocument16 pagesWork Method Statement For Constructing RC FoundationMohd Hafizi AzlanNo ratings yet

- Work Method Statement For Fire Rated and Non-Fire Rated WallDocument14 pagesWork Method Statement For Fire Rated and Non-Fire Rated WallMohd Hafizi Azlan100% (1)

- 1231 de 00 DC PCJ 001 01Document33 pages1231 de 00 DC PCJ 001 01Hamid MansouriNo ratings yet

- Construction Meeting Minutes TemplateDocument4 pagesConstruction Meeting Minutes TemplateNicholas Leone67% (3)

- WMS of Plasterboard Ceiling Installation 1Document11 pagesWMS of Plasterboard Ceiling Installation 1Mohd Hafizi AzlanNo ratings yet

- Manual For Shop Drawing (MN-06) Rev. 2Document51 pagesManual For Shop Drawing (MN-06) Rev. 2Sirapat PornthuengNo ratings yet

- Gunmetal BushesDocument19 pagesGunmetal Bushesa royNo ratings yet

- Check List - RULE 13Document4 pagesCheck List - RULE 13rajeshNo ratings yet

- Job Information: Verification For Roller BlindDocument9 pagesJob Information: Verification For Roller BlindAhsan KhanNo ratings yet

- Pipe MaterialDocument29 pagesPipe MaterialPankaj SahuNo ratings yet

- Method Statement of PaintingDocument19 pagesMethod Statement of PaintingPo RaksmeyNo ratings yet

- Job Information: Job No Sheet No RevDocument4 pagesJob Information: Job No Sheet No RevSuryakant MangajNo ratings yet

- Boundary Wall Design Staad File PDFDocument6 pagesBoundary Wall Design Staad File PDFParwan Exceltech0% (1)

- PE Design OnDocument13 pagesPE Design OnMASITAH MUHAMMADNo ratings yet

- Job Information: Engineer Checked ApprovedDocument6 pagesJob Information: Engineer Checked ApprovedkkklllyyyNo ratings yet

- Quality Checklist For Site Works: Fabrication WorkDocument1 pageQuality Checklist For Site Works: Fabrication WorkLordgie AgtucaNo ratings yet

- F-510-S04-0004 Specification For Tank Foundation and Earthen Bund WallsDocument12 pagesF-510-S04-0004 Specification For Tank Foundation and Earthen Bund WallssurNo ratings yet

- Galvanised Iron Roofing Sheet: Project Report ofDocument24 pagesGalvanised Iron Roofing Sheet: Project Report ofpushpak26No ratings yet

- WI PST 12 01 Template Shop Drawing SubmittalDocument2 pagesWI PST 12 01 Template Shop Drawing Submittalvirat_daveNo ratings yet

- Datasheet For Wax Mix Surge Tank (TK-1304) : ProjectDocument9 pagesDatasheet For Wax Mix Surge Tank (TK-1304) : ProjecthamedpdmsNo ratings yet

- Job Information: Engineer Checked Approved Name: Gunjal Aniket DateDocument7 pagesJob Information: Engineer Checked Approved Name: Gunjal Aniket Date31 Gunjal AniketNo ratings yet

- CM Form ViewDocument3 pagesCM Form ViewGyan Ka Data PackNo ratings yet

- GHD 11th FLR-PCS 73 (Revised)Document4 pagesGHD 11th FLR-PCS 73 (Revised)vincentnNo ratings yet

- Aa 11Document7 pagesAa 11Aamir SaifiNo ratings yet

- Job Information: Job No Sheet No RevDocument8 pagesJob Information: Job No Sheet No RevOng George SammyNo ratings yet

- M04 Read and Interpret PlansDocument113 pagesM04 Read and Interpret Plansmustied mohammed100% (1)

- DMS 001 Part 4 2020 Paving Blocks Rev 5Document18 pagesDMS 001 Part 4 2020 Paving Blocks Rev 5zaheerahmed77No ratings yet

- Method Statement & Risk Assessment - R0Document31 pagesMethod Statement & Risk Assessment - R0Arshad Kp100% (1)

- OpenAMIP Protocol DescriptionDocument27 pagesOpenAMIP Protocol DescriptionFernando Rodriguez0% (1)

- TMSF GDP 019Document69 pagesTMSF GDP 019Ar Rovicn LaquiannNo ratings yet

- Method Statement For Block Works - Rev01Document19 pagesMethod Statement For Block Works - Rev01rayNo ratings yet

- Order 15 DP Process 21.12.2020Document13 pagesOrder 15 DP Process 21.12.2020Varunn VelNo ratings yet

- Unops Meru-Site Status ReportDocument5 pagesUnops Meru-Site Status ReportBright MuzaNo ratings yet

- BS 1244 Part 2 (Metal Sinks For Domestic Purposes)Document12 pagesBS 1244 Part 2 (Metal Sinks For Domestic Purposes)Arun NagrathNo ratings yet

- DS 26-103-ISO 13706 Air-Cooled Heat Exchangers (API 661)Document7 pagesDS 26-103-ISO 13706 Air-Cooled Heat Exchangers (API 661)andhucaosNo ratings yet

- 3D Frame Report - MergedDocument13 pages3D Frame Report - Mergedrx135boyNo ratings yet

- Material Submittal For WPCDocument92 pagesMaterial Submittal For WPCdocument PlasmaNo ratings yet

- Job Information: Engineer Checked ApprovedDocument3 pagesJob Information: Engineer Checked ApprovedkkklllyyyNo ratings yet

- SR AO Building PDFDocument11 pagesSR AO Building PDFAmit Kumar PandeyNo ratings yet

- Desain ScaffoldingDocument10 pagesDesain ScaffoldingBoaZa HiteNo ratings yet

- Business Requirement DocumentDocument19 pagesBusiness Requirement DocumentYateen MehtaNo ratings yet

- Technical Specification Form For Aggregate For ACGDocument2 pagesTechnical Specification Form For Aggregate For ACGGelila TadesseNo ratings yet

- Paint Application Record: Condition of Surface PreperationDocument2 pagesPaint Application Record: Condition of Surface PreperationNguyen Anh TuanNo ratings yet

- Qms Form Arch & Civil ChecklistDocument32 pagesQms Form Arch & Civil ChecklistMatt CerosNo ratings yet

- Design IMCS SpecificationDocument12 pagesDesign IMCS SpecificationMASITAH MUHAMMADNo ratings yet

- Method Statement For Marble Granite Flooring BlogDocument8 pagesMethod Statement For Marble Granite Flooring BlogMohasin Khan100% (1)

- Numbering ProcedureDocument31 pagesNumbering ProcedureMOHAMMADNo ratings yet

- Analisa Srtuktur Dengan Staad-Pro V8iDocument4 pagesAnalisa Srtuktur Dengan Staad-Pro V8ianggarNo ratings yet

- Daily Report FormDocument7 pagesDaily Report FormFranklin0% (1)

- Page - of - : (A Copy of This Report Is To Remain at Job-Site. Use Additional Sheets If Necessary.)Document7 pagesPage - of - : (A Copy of This Report Is To Remain at Job-Site. Use Additional Sheets If Necessary.)Mr. Sambath LimNo ratings yet

- Department: Piping Document No: 00/L.02A/0011Document4 pagesDepartment: Piping Document No: 00/L.02A/0011Tiger HongNo ratings yet

- Handbook On Comprehensive Guide On Painting For BuildingsDocument41 pagesHandbook On Comprehensive Guide On Painting For BuildingsRohan GoyalNo ratings yet

- MDTS 262rev 02 04.11.2020Document6 pagesMDTS 262rev 02 04.11.2020Abhey DograNo ratings yet

- Automotive Air FilterDocument18 pagesAutomotive Air FilterMohamed Abderrahim FellaouineNo ratings yet