Professional Documents

Culture Documents

IE-Topic-19 - Photoelectric Devices

Uploaded by

Captain AmericaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IE-Topic-19 - Photoelectric Devices

Uploaded by

Captain AmericaCopyright:

Available Formats

Industrial Electronics

Topic 19 – Photoelectric Devices

A Introduction

1 When light strikes certain light-sensitive materials, it may cause them to

give off electrons, it may change their ability to conduct electricity, or it may

cause them to develop an electrical potential, or voltage, across two

surfaces. Devices that rely on these effects for their operation are called

photoelectric devices.

In this topic, we will discuss the principle operation of photoelectric devices

and its application.

B LIGHT EMITTING DIODES

1 1) A Light Emitting Diode, or in short, LED is a pn junction semi-

conductor device designed to emit light when forward biased.

2) The light can be red, amber, yellow or green, or it may be infrared

and thus invisible.

3) The symbol for an LED is shown in Fig 19.1.

Fig. 19.1 LED symbol

4) LEDs are frequently used as visual indicators, moving-light

displays, and also as transmitting elements in remote-control

circuits (e.g. TV remote control).

5) The LED brightness is proportional to the LED current; most

LEDs will operate safely up to absolute maximum currents of 30

to 40 mA.

6) However, it can handle a considerable amount of pulsed current,

as large as 10A.

7) The forward voltage drop VF across the diode may vary from 0.6

V to around 2.2 V depending on the type of semiconductors

used.

8) To protect a diode from excessive current, a resistor is place in

series with the LED.

9) Fig 19.2 shows how to work out the resistance value R needed to

give a particular current IF from a particular supply voltage Vs.

Nitec in Electrical Technology Page 1

Industrial Electronics

Topic 19 – Photoelectric Devices

Fig. 19.2 Method of finding the R value for a given Vs and If

10) The reverse breakdown voltage for LEDs is relatively small,

typically around 5 V.

11) To provide reverse polarity protection to a LED, a diode can be

placed in parallel and in the reverse direction with respect to the

LED, as shown in Fig 19.3.

Rs

+

Fig. 19.3 Reverse-voltage protection

12) The LED is extremely fast in its light output response, about 0.1

S, after the application of current.

13) The LEDs, because of their low drive requirements of current and

voltage, consume very little power. Consequently, LEDs generate

little heat.

14) They can be thus easily driven by low power transistor stages.

15) Fig 19.4 shows a LED brightness control circuit. A 1 k variable

resistor is used to control the amount of current that passes

through the LED and in turn acts to control the brightness.

Nitec in Electrical Technology Page 2

Industrial Electronics

Topic 19 – Photoelectric Devices

Fig. 19.4 LED brightness control

16) Fig. 19.5 shows a voltage level indicator circuit. Whenever the

voltage V+ exceeds the breakdown voltage of the zener diode,

the zener diode conducts and allows current to pass through the

LED.

Fig. 19.5 Voltage-level indicator

17) Fig 19.6 shows a ‘what not to do’ circuit. This design will not work

correctly because inevitable differences in the forward voltage

characteristics of the LEDs will usually cause one LED to ‘hog’

most of the available current, leaving little or none for the

remaining LEDs.

Fig. 19.6 This LED-driving circuit will not work

Nitec in Electrical Technology Page 3

Industrial Electronics

Topic 19 – Photoelectric Devices

2 7-Segment Display

The 7 segment display is found in many displays such as microwaves or

fancy toaster ovens and occasionally in non cooking devices. It is just 7

LEDs that have been combined into one case to make a convenient device

for displaying numbers and some letters.

Fig 19.6a LED segment and Typical device

Types of 7-segment display

(1) Common-anode

The common anode will be connected to +5 V. Therefore, when an

input to a cathode is low, the corresponding segment will light. Refer

to Fig 19.b.

(2) Common-cathode

The common cathode will be connected to 0 V. Therefore, when an

input to a anode is high, the corresponding segment will light. Refer

to Fig 19.c

E E

G G

D D

F F

Anodes Cathodes

Anodes Cathodes

C C

A A

Decimal

Decimal B B

Fig 19.6b Common-anode display Fig 19.6c Common-cathode display

To operate the 7-segment display, a resistor of 330 ohm is usually

connected in series with each segment. This is to prevent the segments

from being burned out.

Nitec in Electrical Technology Page 4

Industrial Electronics

Topic 19 – Photoelectric Devices

C PHOTOCONDUCTIVE CELLS

1) Photoconductive cell is also known as photo-resistor or light

dependent resistor (LDR). The symbol and physical appearance

is as shown in Fig 19.7.

Fig. 19.7 Symbol and basic construction of photoconductive cell

2) Photoconductive cells are light-controlled variable resistors.

3) The resistance is very high (in the mega-ohms) under dark

conditions and low (a few hundred ohms) under bright conditions.

4) Useful practical applications include light- and dark-activated

switching circuits and light-beam alarms.

5) Photocells are sensitive, inexpensive, and readily available

devices. They have good power and voltage handling

capabilities, similar to those of a resistor.

6) Their only significant defect is that they require a few milliseconds

or more to fully respond to changes in light intensity and may

require a few seconds to return to their normal dark resistance

once light is removed.

7) Cadmium sulfide photocells respond best to light, whereas lead

sulfide photocells respond best to infrared.

Nitec in Electrical Technology Page 5

Industrial Electronics

Topic 19 – Photoelectric Devices

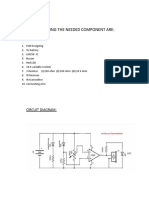

2 Circuit with LDR

Fig. 19.8 Control circuit using photoconductive cell

(a) LDR is a light dependent resistor whose resistance decreases when

light falls on it.

(b) The transistor will not switch on until the voltage at its base rises to

about 0.6 V.

(c) If the light level on the LDR falls, its resistance will increase and the

voltage at the transistor base will rise. As it reaches 0.6 V, the

transistor will turn on.

(d) Current will flow through the relay coil and energise the coil.

(e) The relay contact will be closed to activate the external circuit.

Nitec in Electrical Technology Page 6

Industrial Electronics

Topic 19 – Photoelectric Devices

D PHOTODIODES

Fig. 19.9 Symbol and physical appearance of a photodiode

1) Fig 19.9 shows the physical appearance and symbol of a

photodiode. The two arrows indicate the direction of light coming

towards the photodiode.

2) The photodiode has a small transparent window that allows light

to strike the pn junction.

3) Photodiode is usually operated in reverse bias condition and the

output is taken from across a series-connected load resistor.

4) This resistor may be connected between the diode and ground,

or between the diode and the positive supply line, as in Fig 19.10

V+ V+

ID

R1

1K

D1

ID

R1 Vout Vout

1K

Fig. 19.10 Reverse-biased diode circuit

5) When there is no incident light, the reverse current is almost

negligible and is called the dark current.

6) An increase in the amount of light intensity produces an increase

in the reverse current.

7) The current and thus the output voltage is directly proportional to

light intensity.

8) Photodiodes give a far quicker response to changes in light level

than photoconductive cells.

9) It is ideal for use in infrared remote control circuits.

Nitec in Electrical Technology Page 7

Industrial Electronics

Topic 19 – Photoelectric Devices

E SOLAR CELLS

Fig. 19.11 Symbol of solar cell

1) A solar, or photovoltaic cell is a device that directly converts

sunlight into electricity when light energy strikes the cell's surface.

The symbol is as shown in Fig 19.11.

2) Solar cells take advantage of the fact that light dislodges

electrons from atoms when it strikes the cell surface.

3) These are used to generate a potential difference between two

semi-conductor materials.

4) Closing the circuit establishes an electric current as shown in Fig

19.12.

Fig. 19.12 Photovoltaic effect

Nitec in Electrical Technology Page 8

Industrial Electronics

Topic 19 – Photoelectric Devices

5) Single crystal silicon solar cells cannot currently convert more

than 25% of the solar energy into electricity.

6) An average sized solar cell with sufficient light produces around

0.3V.

7) Solar cells are generally stacked up together in series or parallel,

and sold as solar panels. A solar panel may consist of 300 or

more solar cells.

8) If these cells are arranged in series combination as in Fig 19.13,

they yield a larger voltage (sum of cell voltages).

9) If they are arranged in parallel combination as in Fig 19.14, they

yield a larger current (sum of cell currents).

Fig. 19.13 Increased voltage

Fig. 19.14 Increased current

10) Several panels constitute a solar cell array, which can be thought

of as a solar-powered electrical generator. It makes no noise,

releases no emissions and requires no fuel, lubricant or tune-ups.

11) An array can power lights whenever the sun is shining - not a

particularly useful service. Instead, solar electricity is stored in 12

volt deep-discharge batteries similar to those used in golf carts

and forklifts.

12) Unlike a car battery, a solar cell battery is designed to be drained

and recharged many hundreds of times. A charge controller

prevents the batteries from being overcharged.

Nitec in Electrical Technology Page 9

Industrial Electronics

Topic 19 – Photoelectric Devices

13) Fig 19.15 shows how nine solar cells placed in series can be

used to recharge two 1.5 V NiCd cells. The diode is added to the

circuit to prevent the NiCd cells from discharging through the

solar cell during times of darkness.

Fig. 19.15 Battery recharger

14) The current generated is direct current (DC), and therefore

cannot be used directly in the same way as mains power, except

to charge batteries and to run light bulbs.

15) In order to be used by the mains system, it needs to be converted

to alternating current (AC).

Nitec in Electrical Technology Page 10

Industrial Electronics

Topic 19 – Photoelectric Devices

F PHOTOTRANSISTOR

1) The phototransistor has a light-sensitive, collector-base pn

junction.

2) It is exposed to incident light through a lens opening in the

transistor package. Fig 19.16 shows the physical appearance

and symbol of a phototransistor.

Fig. 19.16 Physical appearance and symbol of a phototransistor

3) When there is no incident light, there is a small thermally

generated collector-to-emitter leakage current called the dark

current and is typically in the nA range.

4) When light strikes the collector-base pn junction, a base current

is produced that is directly proportional to the light intensity.

5) Fig 19.17 shows a phototransistor with a biasing circuit and

typical collector characteristic curves.

Fig. 19.17 Phototransistor bias circuit and collector characteristic curves

Nitec in Electrical Technology Page 11

Industrial Electronics

Topic 19 – Photoelectric Devices

6) Each individual curve on the graph corresponds to a certain value

of light intensity. The collector current increases with light

intensity.

7) A phototransistor can be either a two-lead or a three-lead device.

8) In a three-lead configuration, the base lead is brought out so that

the device can be used as a conventional bipolar transistor with

or without the additional light-sensitivity feature.

9) In the two-lead configuration, the base is not electrically

available, and the device can be used only with light as the input.

10) The device is normally used with its base open circuit, in either of

the configurations shown in Fig 19.18.

V+ V+

R1

Q1 1K

R1 Vout Q1 Vout

1K

Fig. 19.18 Phototransistor configurations

11) Phototransistors are not sensitive to all light but only to light

within a certain range of wavelengths.

Nitec in Electrical Technology Page 12

Industrial Electronics

Topic 19 – Photoelectric Devices

G OPTO-ISOLATORS

1 1) The opto-isolator, also known as opto-coupler, is a device that

uses light to couple a signal from its input (a photo-emitter) to its

output (a photo-detector).

2) The photo-emitter and photo-detector are mounted close together

in a single light-excluding package.

3) The photon-emitting device is usually an infrared LED.

4) The photo-detector may be a photodiode, a phototransistor etc.

a) LED-Photodiode Opto-isolator

i) Fig 19.19 shows the symbol of a photodiode

output opto-isolator.

Fig. 19.19 Symbol of photodiode opto-coupler

ii) Fig 14.19 shows an opto-isolator IC that

consists of a LED that illuminates two

photodiodes in an 8-pin DIP package.

1 NC 8

LED

2 NC 7

3 6

4 5

PD1 PD2

Fig. 19.20 Photodiode opto-isolator IC

iii) As long as the infrared LED is on, the

photodiodes will conduct.

iv) Photodiodes can react very fast to change in

light intensity.

Nitec in Electrical Technology Page 13

Industrial Electronics

Topic 19 – Photoelectric Devices

b) LED-Phototransistor Opto-isolator

i) Fig 19.21 shows the symbol of a

phototransistor output opto-isolator.

ii) Fig 19.22 shows a 6-pin DIP transistor

output opto-isolator.

Fig. 19.21 Symbol of phototransistor opto-coupler

Anode 1 6 Gate

Cathode 2 5 Anode

NC 3 4 Cathode

Fig. 19.22 Phototransistor opto-coupler IC

iii) They are more convenient than photodiodes

because they have built in gain.

iv) The absorbed light creates a current in the

base region of the phototransistor, resulting

in current gains from 100 to several

thousands.

v) It is unsuitable for high-speed application.

5) Isolation Voltage

a) This is the maximum permissible dc potential that can

be allowed to exist between the input and output

circuits.

6) Opto-isolators are used frequently to provide electrical isolation

between two separate circuits.

Nitec in Electrical Technology Page 14

Industrial Electronics

Topic 19 – Photoelectric Devices

2 SLOTTED/REFLECTIVE OPTO-COUPLER

2.1 IRED-Phototransistor Slotted Opto-coupler

a) The slotted opto-coupler is an IC that is designed to

allow an outside object to block the light path between

the photo-emitter and the photo-detector.

b) Fig 19.23 shows the schematic diagram and physical

appearance of a slotted opto-coupler.

c) It has a slot moulded into the package between the

LED light source and the phototransistor light sensor.

d) It generates a pulse whenever an opaque object,

passing across the gap of the sensor, interrupts the

light beam.

e) The slotted opto-coupler can be used for engine-shaft

revolution counting or speed measurements, as shown

in Fig 19.24

Fig. 19.23 Schematic diagram and physical appearance of slotted opto-coupler

Slotted opto-coupler

Fig. 19.24 Using a slotted opto-coupler to measure motor speed

Nitec in Electrical Technology Page 15

Industrial Electronics

Topic 19 – Photoelectric Devices

2.2 IRED-Phototransistor Reflective Opto-coupler

(a) A reflective opto-coupler uses a light source to emit light

and a sensor to detect that light once it has reflected off an

object.

(b) Fig 19.25 shows the schematic diagram and physical

appearance of a reflective opto-coupler.

(c) It generates a pulse whenever the sensor receives

reflected light.

(d) The reflective opto-coupler can be used for end-of-tape

detection.

Fig. 19.25 Schematic diagram and physical appearance of slotted opto-coupler

Nitec in Electrical Technology Page 16

Industrial Electronics

Topic 19 – Photoelectric Devices

H PHOTOELECTRIC SENSORS

1 Through Beam Type

(a) Emitter and receiver are contained in separate housings.

(b) When properly aligned, the light beam travels from the emitter to

the receiver.

(c) An object breaking the light beam causes the receiver to change

the state of the output contacts.

(d) This type of photoelectric sensor has the advantage of a longer

sensing distance when compared to other types of sensors.

Fig. 19.26 Through beam photoelectric sensor

2 Retro-Reflective Type

(a) Emitter and receiver are contained in the same housing.

(b) This type of sensor uses a reflector to reflect the light beam

back to the sensor.

(c) When an object passes through the light beam, the receiver

changes the state of the output contacts.

Nitec in Electrical Technology Page 17

Industrial Electronics

Topic 19 – Photoelectric Devices

Fig. 19.27 Retro-reflective photoelectric sensor

3 Diffuse Type

(a) Emitter and receiver are contained in the same housing.

(b) This type of sensor emits a beam of light, which is not returned to

the sensor.

(c) When the target is placed in the light beam the beam is "diffused" in

many different directions. One of the directions is back to the

sensor.

(d) If the intensity of the return beam is sufficient, the receiver "senses"

the light and changes the state of the output contacts.

Fig. 19.28 Diffuse photoelectric sensor

Nitec in Electrical Technology Page 18

You might also like

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- ET1006 - Chapter 20 - Part 2 (Optical Diodes)Document30 pagesET1006 - Chapter 20 - Part 2 (Optical Diodes)fastNo ratings yet

- Passive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2From EverandPassive and Discrete Circuits: Newnes Electronics Circuits Pocket Book, Volume 2No ratings yet

- Special Purpose DiodesDocument4 pagesSpecial Purpose DiodesArvinALNo ratings yet

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- ECE 027 - Simulation Activity 2.1 The Zener and Light Emitting DiodeDocument8 pagesECE 027 - Simulation Activity 2.1 The Zener and Light Emitting DiodeGong BoNo ratings yet

- Wa0005.Document11 pagesWa0005.Outfit BSNo ratings yet

- ECE 027 - Simulation Activity 2.1 The Zener and Light Emitting DiodeDocument8 pagesECE 027 - Simulation Activity 2.1 The Zener and Light Emitting DiodeEmerson EspelaNo ratings yet

- Automatic Street LightDocument3 pagesAutomatic Street LightShilpa MohanNo ratings yet

- 8.slayt ElectrotechnicDocument34 pages8.slayt Electrotechnicserkan1234No ratings yet

- Lecture-7,8 Special Purpose DiodesDocument131 pagesLecture-7,8 Special Purpose DiodesDhananjayLekshmiNarayanNo ratings yet

- Circuit / Project / Electronics: Electronics Project and Circuit For Students and Hobbyist. Learn by Circuit DiagramDocument4 pagesCircuit / Project / Electronics: Electronics Project and Circuit For Students and Hobbyist. Learn by Circuit DiagramSyed Raheel AdeelNo ratings yet

- Photodiode and LIGHT Emitting DiodeDocument38 pagesPhotodiode and LIGHT Emitting DiodekaneeshaNo ratings yet

- Module 4Document72 pagesModule 4Kshitiz RastogiNo ratings yet

- A Breadboard Is A Reusable Platform For Temporarily Built Electronic CircuitsDocument17 pagesA Breadboard Is A Reusable Platform For Temporarily Built Electronic CircuitsMisliSlaluAdaNo ratings yet

- Unit-V Short Answer Questions 1. Sketch The Characteristics of An SCR and List Out Its Applications. AnsDocument19 pagesUnit-V Short Answer Questions 1. Sketch The Characteristics of An SCR and List Out Its Applications. AnsnagarajudbpNo ratings yet

- Led Interfacing With 8051 (Μc) : SynopsisDocument3 pagesLed Interfacing With 8051 (Μc) : SynopsishariNo ratings yet

- Digital Electronics ProjectDocument13 pagesDigital Electronics ProjectET201040 Mohin UddinNo ratings yet

- Module 1 - AdeDocument62 pagesModule 1 - AdeCharita NNo ratings yet

- Adaptive Lighting System For Automobiles: A Project Report OnDocument13 pagesAdaptive Lighting System For Automobiles: A Project Report Onashishgusain1991No ratings yet

- 947 SampleDocument6 pages947 SamplesarveshkdahiyaNo ratings yet

- Mini Project On Dark Sensor Using IC555 TimerDocument16 pagesMini Project On Dark Sensor Using IC555 TimerPSNo ratings yet

- Comparison of Simple LED Circuits For Low Power LEDsDocument13 pagesComparison of Simple LED Circuits For Low Power LEDsdurrani shaheerNo ratings yet

- 22223.BEE Tutorial Sheet 1 (Semiconductor Diodes and Applications)Document2 pages22223.BEE Tutorial Sheet 1 (Semiconductor Diodes and Applications)Rajiv SatijaNo ratings yet

- Basic Electronics (18ELN14/18ELN24) - Special-Purpose Diodes and 7805 Voltage Regulator (Module 1)Document6 pagesBasic Electronics (18ELN14/18ELN24) - Special-Purpose Diodes and 7805 Voltage Regulator (Module 1)Shrishail Bhat100% (2)

- Reverse Bias Characteristic of PIN DiodeDocument3 pagesReverse Bias Characteristic of PIN Diodesandeep bhukyaNo ratings yet

- Irpse 3: Iniţiere in Realizarea Practică A Schemelor Electronice (Irpse)Document36 pagesIrpse 3: Iniţiere in Realizarea Practică A Schemelor Electronice (Irpse)Maria NegruNo ratings yet

- Lect 2-1Document23 pagesLect 2-1THE BBEASTNo ratings yet

- Silo - Tips Analog Electronics Module 1 Semiconductor DiodesDocument26 pagesSilo - Tips Analog Electronics Module 1 Semiconductor DiodesKB LouisaNo ratings yet

- Detectors and Storage DevicesDocument32 pagesDetectors and Storage Devices7t854s6wd2No ratings yet

- 4 Hardware Require For Lifi ProjectDocument5 pages4 Hardware Require For Lifi ProjectmacNo ratings yet

- Chapter Eight Special Diodes and There ApplicationDocument16 pagesChapter Eight Special Diodes and There ApplicationSamuel AbaynehNo ratings yet

- Semiconductors Module 02Document40 pagesSemiconductors Module 02derejeNo ratings yet

- Semiconductors - Module - 02 (2.5 LED 2.6 LASER DIODA)Document40 pagesSemiconductors - Module - 02 (2.5 LED 2.6 LASER DIODA)Niken Arina PratiwiNo ratings yet

- Semiconductors Module 02 PDFDocument40 pagesSemiconductors Module 02 PDFRDWELN RDWELNNo ratings yet

- Bee 2Document5 pagesBee 2zeneelNo ratings yet

- EE 211 CHAPTER 2 Part2Document22 pagesEE 211 CHAPTER 2 Part2RickNo ratings yet

- LED and LDDocument22 pagesLED and LDKamalesh KolandasamyNo ratings yet

- Case Study Class 12 Physics ImportantDocument5 pagesCase Study Class 12 Physics Importantdivanshu2006yadavNo ratings yet

- Electus Distribution Reference Data Sheet ... - Jaycar ElectronicsDocument3 pagesElectus Distribution Reference Data Sheet ... - Jaycar ElectronicsSinésio GomesNo ratings yet

- Lect 2-1 (Compatibility Mode)Document23 pagesLect 2-1 (Compatibility Mode)Bawaseer KhanNo ratings yet

- CHAPTER 3 at 11 - Spec - Pur.diode and ThyristorsDocument9 pagesCHAPTER 3 at 11 - Spec - Pur.diode and ThyristorsJulius Romeo Trinidad, Jr.No ratings yet

- Case StudyDocument4 pagesCase Studyananthamoorthy666No ratings yet

- Door Sensor ProjectDocument6 pagesDoor Sensor ProjectMehmood ul Hassan100% (1)

- Petra University Digital - Design - A - Comprehensive - Guide - To - Digital - Electronics - and - Computer - System - Architecture-Part158Document2 pagesPetra University Digital - Design - A - Comprehensive - Guide - To - Digital - Electronics - and - Computer - System - Architecture-Part158Mg Thein Than HtayNo ratings yet

- Opto-Electronics Devices: Opto-Electronic Devices Light Emitting Diode (LED) (A) TheoryDocument7 pagesOpto-Electronics Devices: Opto-Electronic Devices Light Emitting Diode (LED) (A) Theoryves vegasNo ratings yet

- Exp 5 Diodes 05Document5 pagesExp 5 Diodes 05api-3717843No ratings yet

- Chapter 3 Diode Circuits and ApplicationsDocument3 pagesChapter 3 Diode Circuits and ApplicationsBRIGHT TZZZY CHINGWENANo ratings yet

- Characterisation of Electromagnetic Interference From LEDDocument2 pagesCharacterisation of Electromagnetic Interference From LEDAndres GarzonNo ratings yet

- Bel Bec Ch01 Print OutDocument38 pagesBel Bec Ch01 Print Outkenemep346No ratings yet

- Photoresistor, Transistor, and LED's: Prelab QuestionsDocument14 pagesPhotoresistor, Transistor, and LED's: Prelab QuestionsSubin UmarNo ratings yet

- 11.chapter 3Document16 pages11.chapter 3hsushweyi tint28No ratings yet

- A Photo Diode Is A Type of Photo Detector Capable of Converting Light Into Either Current or Voltage Repaired)Document14 pagesA Photo Diode Is A Type of Photo Detector Capable of Converting Light Into Either Current or Voltage Repaired)vikassist1024No ratings yet

- Application Note: Behaviour of Ingan Leds in Parallel CircuitsDocument4 pagesApplication Note: Behaviour of Ingan Leds in Parallel CircuitsMartinNo ratings yet

- Impatt DiodeDocument15 pagesImpatt DiodeTeferi LemmaNo ratings yet

- EEC111 PracticalsDocument21 pagesEEC111 PracticalsOreoluwa OmiyaleNo ratings yet

- Photo DiodeDocument10 pagesPhoto DiodeAnees AhmadNo ratings yet

- Mymensingh Engineering College: An Assignment On Optoelectronics EEE - 809Document8 pagesMymensingh Engineering College: An Assignment On Optoelectronics EEE - 809rafiNo ratings yet

- Automatic Street Light ControllerDocument4 pagesAutomatic Street Light ControllerMaha BuNo ratings yet

- Booklet 8 Projects Starter KitDocument13 pagesBooklet 8 Projects Starter KitDuarte Sousa100% (1)

- Haloalkanes Q BankDocument7 pagesHaloalkanes Q BankVishnuNo ratings yet

- الاستجابة الزلزالية للابنية الفولاذية العالية متضمنا تاثيرات تحليل الدرجة-الثانيةDocument11 pagesالاستجابة الزلزالية للابنية الفولاذية العالية متضمنا تاثيرات تحليل الدرجة-الثانيةmichelNo ratings yet

- ALSTOM Relay CatalogueDocument20 pagesALSTOM Relay CatalogueINZAMAM MUSHTAQNo ratings yet

- Lecture 10 - HydrodynamicsDocument10 pagesLecture 10 - HydrodynamicsPercival ArcherNo ratings yet

- Standard Datasheets Portfolio enDocument543 pagesStandard Datasheets Portfolio enTuna TaşkıntunaNo ratings yet

- Attach # 2. Routine Test Reports (Internal) - ReviewedDocument3 pagesAttach # 2. Routine Test Reports (Internal) - ReviewedAvinash PatilNo ratings yet

- High Voltage Skywrap: Fiber Optic CableDocument1 pageHigh Voltage Skywrap: Fiber Optic CableburvanovNo ratings yet

- Aft-Catalog - s10 - Sec CHECK AND METERINGDocument29 pagesAft-Catalog - s10 - Sec CHECK AND METERINGAmcaNo ratings yet

- Chapter 2 - First Law of TMD - EngDocument8 pagesChapter 2 - First Law of TMD - EngPHƯƠNG ĐẶNG YẾNNo ratings yet

- Chem1777 1815Document4 pagesChem1777 1815Maki DonatoNo ratings yet

- Sturm-Liouville EquationsDocument16 pagesSturm-Liouville Equationsvanaj123No ratings yet

- Electric Circuits: Lab ManualDocument78 pagesElectric Circuits: Lab Manualصدام حسینNo ratings yet

- Densit® Wear Protection ProductsDocument9 pagesDensit® Wear Protection ProductsMuhammad IqbalNo ratings yet

- Esas REVIEWER 1Document11 pagesEsas REVIEWER 1Stephen JP De Leon0% (2)

- TFX02 Torque ChartDocument1 pageTFX02 Torque ChartArnulfo SánchezNo ratings yet

- P S A A T D S R U P: Reparatory Urvey ON Ddis Baba Ransmission and Istribution Ystem Ehabilitation and Pgrading RojectDocument150 pagesP S A A T D S R U P: Reparatory Urvey ON Ddis Baba Ransmission and Istribution Ystem Ehabilitation and Pgrading RojectFiraa'ol GizaachooNo ratings yet

- Improvement of Productivity Using Tromp Curve MeasDocument11 pagesImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099No ratings yet

- FourierDocument22 pagesFourierBochiNo ratings yet

- Liners For Shaped Charges by Manfred Held (2001) PDFDocument1 pageLiners For Shaped Charges by Manfred Held (2001) PDFMalikHodzicNo ratings yet

- PSD Random Vibration Strength and Fatigue Analysis of A CNG Tube TrailerDocument10 pagesPSD Random Vibration Strength and Fatigue Analysis of A CNG Tube TrailerhaceneNo ratings yet

- International Standard: Coated Abrasives - Grain Size AnalysisDocument6 pagesInternational Standard: Coated Abrasives - Grain Size AnalysisAfzal ImamNo ratings yet

- Genphysics q2 Mod5Document28 pagesGenphysics q2 Mod5Mhasie Joy PondevidaNo ratings yet

- A Review On Design and Flow Simulation in An Axial Flow Hydro TurbineDocument3 pagesA Review On Design and Flow Simulation in An Axial Flow Hydro TurbineAron H OcampoNo ratings yet

- BME373 Electronics 2 CW 1Document53 pagesBME373 Electronics 2 CW 1azuma moses chijiokeNo ratings yet

- Total Air Solution Provider: LG Electronics VietnamDocument8 pagesTotal Air Solution Provider: LG Electronics VietnamCong VietNo ratings yet

- DC School Text Book: Interpretation of Injection WaveDocument32 pagesDC School Text Book: Interpretation of Injection WavemikeNo ratings yet

- 7300 ManualDocument12 pages7300 ManualDesmond Prince OmorogiuwaNo ratings yet

- Ch. 09 - Rotational DynamicsDocument23 pagesCh. 09 - Rotational Dynamicssthembisosthera992No ratings yet

- Name: Prasida Prabhu REGISTER NUMBER: 183003042 Experiment 3 - Emg Acquisition With Ad620 AimDocument7 pagesName: Prasida Prabhu REGISTER NUMBER: 183003042 Experiment 3 - Emg Acquisition With Ad620 AimPrasidha PrabhuNo ratings yet

- Intera Standard Neuro: Changing How The World Looks at MRDocument46 pagesIntera Standard Neuro: Changing How The World Looks at MRJuan EspinozaNo ratings yet